热处理温度对炭/炭复合材料性能的影响

来源期刊:中南大学学报(自然科学版)2003年第5期

论文作者:于澍 刘根山 李溪滨 浦继强 浦保健

文章页码:476 - 479

关键词:炭/炭复合材料;热解炭;热处理;石墨化度

Key words:C/C composites; pyrocarbon; heat treatment; graphitization degree

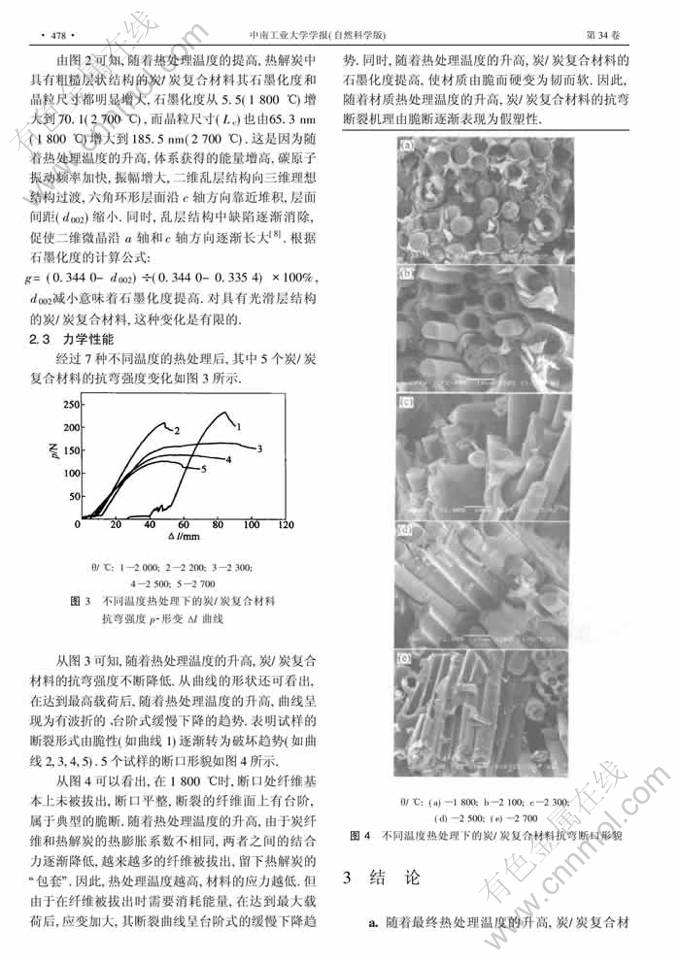

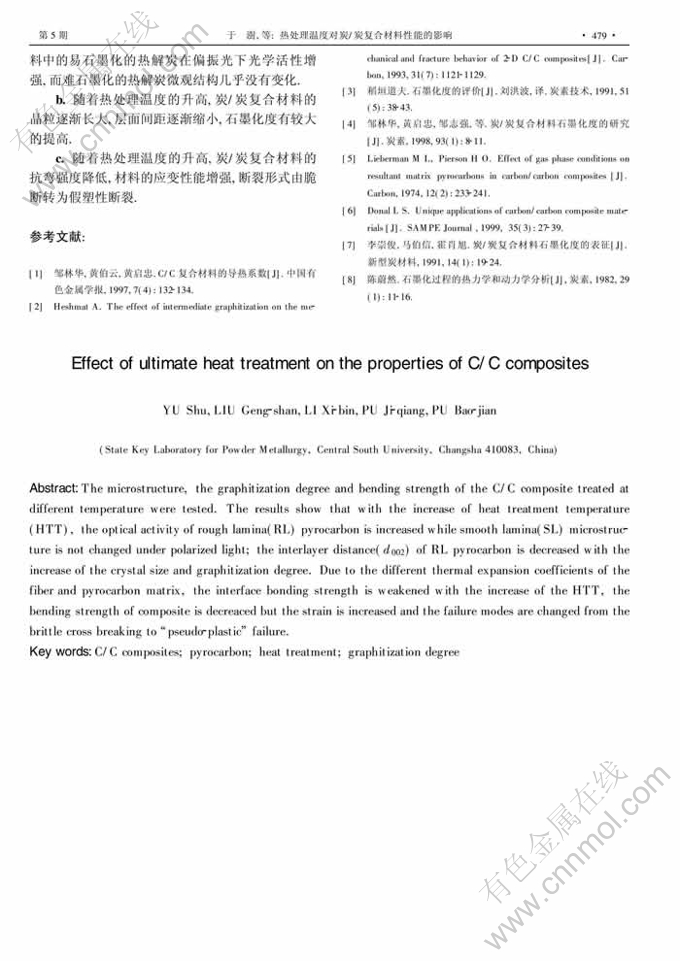

摘 要:对同一种炭/炭复合材料,经过不同温度的最终热处理后的微观结构、石墨化度和抗弯强度进行了对比研究.研究结果表明:随着最终热处理温度的升高,在偏振光下,易石墨化的热解炭光学活性增强,而难石墨化的热解炭微观结构几乎没有变化;炭/炭复合材料的晶粒逐渐长大,层面间距逐渐缩小,石墨化度有较大幅度的提高;同时,由于基体炭与炭纤维的热膨胀系数存在差别,随着热处理温度的升高,基体与增强纤维的的结合强度降低,使炭/炭复合材料的抗弯强度降低,但材料的应变性增强,材料的断裂形式由脆断转为假塑性断裂.

Abstract: The microstructure, the graphitization degree and bending strength of the C/C composite treated at different temperature were tested. The results show that with the increase of heat treatment temperature (HTT), the optical activity of rough lamina(RL) pyrocarbon is increased while smooth lamina(SL) microstructure is not changed under polarized light; the interlayer distance(d002) of RL pyrocarbon is decreased with the increase of the crystal size and graphitization degree. Due to the different thermal expansion coefficients of the fiber and pyrocarbon matrix, the interface bonding strength is weakened with the increase of the HTT, the bending strength of composite is decreaced but the strain is increased and the failure modes are changed from the brittle cross breaking to“pseudo-plastic”failure.