文章编号:1004-0609(2010)08-1520-07

Al-Si-Mg-Y合金消失模铸造振动压力凝固的组织与性能

赵 忠,樊自田,成 平,蒋文明,董选普

(华中科技大学 材料成形与模具技术国家重点实验室,武汉 430074)

摘 要: 应用消失模铸造振动压力凝固成形技术制备了Al-7Si-0.8Mg-0.3Y(ASMY)合金。通过SEM、XRD、DSC和TEM等测试方法对其铸态和T6组织进行分析,研究其对力学性能的影响。结果表明:在ASMY合金铸态组织的晶界处生成有少量Al3Y短棒状颗粒相;在T6热处理过程中,稀土Y或Al3Y阻碍Mg2Si相的析出和扩散聚集,使析出相Mg2Si呈弥散分布;Mg2Si相与晶界稳定相Al3Y对合金同时起到钉扎强化作用;采用消失模铸造振动压力凝固技术后,铝合金的孔隙率显著降低,从1.1%降低0.18%;ASMY合金消失模铸造振动压力凝固试样T6态的抗拉强度达到308 MPa,比A356普通消失模试样T6态的抗拉强度提高29%。

关键词:Al-Si-Mg-Y合金;消失模铸造;振动压力;组织;性能

中图分类号:TG292 文献标志码:A

Microstructures and properties of Al-Si-Mg-Y alloy with vibration-pressure solidification in lost form casting

ZHAO Zhong, FAN Zi-tian, CHENG Ping, JIANG Wen-ming, TONG Xuan-pu

(State Key Laboratory of Material Processing and Die and Mould Technology,

Huazhong University of Science and Technology, Wuhan 430074, China)

Abstract: Al-7Si-0.8Mg-0.3Y (ASMY) alloy was produced with vibration-pressure solidification in lost foam casting (LFC). The microstructure and mechanical properties of the as-cast and T6 heat treatment ASMY alloys were investigated by SEM, XRD, DSC and TEM. The results indicate that a small amount of short rod-like Al3Y particle generates at the grain boundary of the as-cast ASMY alloy. In the T6 heat treatment process, the rare-earth Y or Al3Y has a certain inhibition for the precipitation and aggregation of Mg2Si phase, which leads to the dispersive distribution of precipitated Mg2Si phase. Both Mg2Si phase and Al3Y stable phase in the grain boundary play an important role in pinning dislocations. The porosities of aluminium alloy by vibration-pressure solidification in LFC are reduced obviously from 1.1% to 0.18%. After T6 heat treatment, the ultimate tensile strength of ASMY alloy by vibration-pressure solidification in LFC reaches 308 MPa, and it is increased by 29% compared with that of A356 alloy by conventional LFC.

Key words: Al-Si-Mg-Y alloy; lost foam casting (LFC); vibration-pressure; microstructure; mechanical property

A356铝合金具有良好的铸造流动性、抗热裂性、较小的收缩性以及良好的抗腐蚀性等优点,成为应用最多的消失模铸造铝合金[1-2]。然而,限制A356铝合金消失模铸造技术广泛应用的最主要的问题是其力学性能较低、针孔较多等。

为了提高A356铝合金消失模铸件的力学性能,现在主要采用的方法有变质共晶硅、细化α晶粒、增加强化相和热处理等[3-4]。较成熟的工艺有加Na、Sr等变质细化共晶硅,加Ti、B等细化α(Al)晶粒。另外,采用振动等物理改性方法也能减少α(Al)枝晶数量,细化晶粒[5]。研究表明[6],将振动技术应用到消失模铸造中对枝晶有明显的细化效果。为了降低A356铝合金消失模铸造中的针孔、缩孔,提高铸件致密性,采用的方法主要有精炼除气、冒口补缩和采用压力凝固[2, 7]等。目前,在消失模铸造工艺中,叠加振动场和压力场,能够在细化晶粒的同时显著降低针孔,该技术在一定程度上提高了铝合金消失模铸件的性能。

对A356铝合金进行T6热处理时,其强化机理主要是时效析出强化相Mg2Si。另外,通过加入稀土等元素对A356铝合金进行变质强化,也是提高性能的有效手段[8]。研究认为[9-12],铝合金中加入少量稀土元素Y,可生成Al-Y稀土化合物,起强化作用。因此,本文作者在A356合金的基础上,适当增加Mg元素含量,同时添加少量稀土元素Y,并改进消失模铸造工艺,在合金凝固过程中叠加振动场和压力场,旨在提高铝合金消失模铸件的力学性能。

1 实验

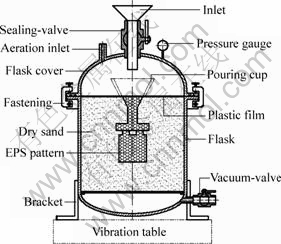

实验采用消失模铸造振动压力凝固技术,装置示意图如图1所示。可发性聚苯乙烯(EPS)模件的密度为20 mg/cm3上涂料烘干后放入砂箱中,填入干燥石英砂紧实、覆盖塑料薄膜、开真空阀抽真空(真空压力为-30 kPa)、合砂箱盖后进行振动(振动频率50Hz,振幅0.23 mm)。铝合金按规范方法熔化并采用Sr变质,氩气精炼除气,750 ℃时从导入杯浇注,浇注结束后,迅速关闭密封阀及真空阀,以5 kPa/s的加压速率从加压口加入空气,待箱内压力达0.8 MPa后开始保压,10 min后开真空阀泄压并停止振动,之后取出铸件。

图1 消失模铸造振动压力凝固试验装置示意图

Fig.1 Schematic diagram of vibration-pressure solidification in LFC

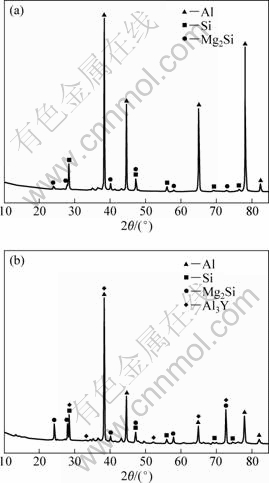

实验用A356合金与制备的Al-7Si-0.8Mg- 0.3Y(ASMY)合金的化学成分如表1所列。

表1 实验合金的化学成分

Table 1 Chemical compositions of alloys in experiment (mass fraction, %)

将成形的直径为10 mm的标准铸造试棒,在Instron-810万能试验机上测试室温力学性能,拉伸速率为3 mm/min,每组测试3根试棒,取平均值。金相试样用0.5%HF水溶液腐蚀,显微组织观察采用MDS型光学显微镜和FEI-Quanta 200环境扫描电子显微镜 (SEM)。合金组成相分析采用X’Pert Pro X射线衍射仪 (XRD)和微区成分分析(EDS)相结合的方法。相变温度采用PERKIN ELMER DSC7型差示扫描量热仪(DSC)分析。将薄膜样品电解双喷减薄,在Tecnai-G2-20透射电镜(TEM)上进行时效析出相微观组织的分析。

2 结果与分析

2.1 铸态的显微组织

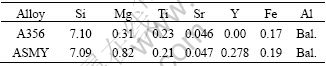

图2所示为A356和ASMY合金消失模振动压力凝固的金相组织。由图2可知,两种合金的组织特征相似,基体主要由等轴晶或枝晶α(Al)组成,且ASMY的α(Al)晶粒比A356的细小。

图2 A356和ASMY合金消失模铸造振动压力凝固的显微组织

Fig.2 Microstructures of A356 (a) and ASMY (b) alloys with vibration-pressure solidification in LFC

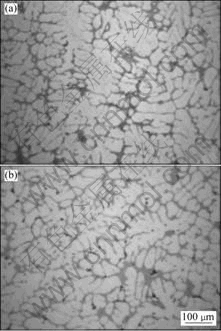

A356和ASMY铸态组织的XRD谱如图3所示。从图3(a)可以看出,A356合金主要由Al、Si以及Mg2Si相组成;从图3(b)可以看出,ASMY合金中除含Al、Si以及Mg2Si相以外,还出现了少量新相Al3Y。另外,ASMY合金中Mg2Si相的衍射峰强度明显比A356合金中Mg2Si相的强,表明合金中Mg2Si相的量较多。从图2中也可观察到ASMY合金中晶间的黑色针状Mg2Si相明显比A356合金中的多。

图3 铸态A356与ASMY合金的XRD谱

Fig.3 XRD patterns of as-cast A356 and ASMY alloys: (a) A356 alloy; (b) ASMY alloy

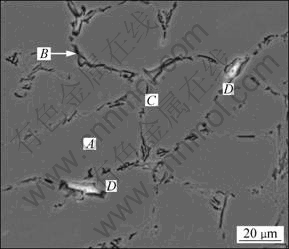

ASMY合金铸态组织的SEM像如图4所示。图4中A区是α(Al)基体。对图4中B、C和D相进行标点测试,对物相的成分进行EDS能谱分析,结果如图5、6和7所示。

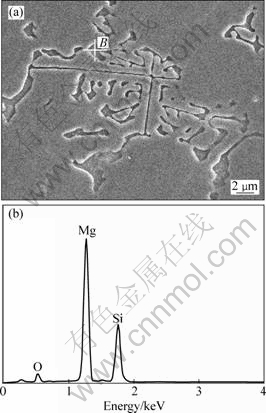

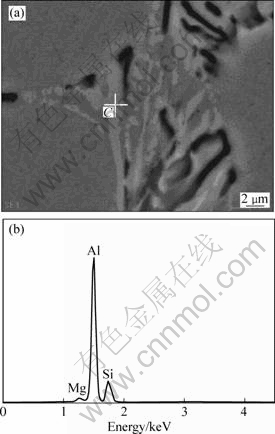

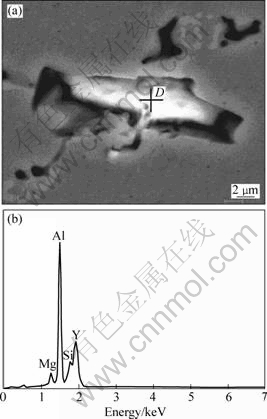

通过对能谱峰值和各元素含量分析可知,图5中B相是Mg2Si,在铸态组织中,呈骨骼汉字形状,割裂基体,降低合金性能。图6中的C相是Al-Si共晶相,由于Sr变质,该相呈片层状或颗粒状。图7中的D相是Al3Y相,呈圆柱状或短棒状颗粒,分布在晶界处。从Y和Al相图分析[13],在富Y区域,Y很容易和Al形成金属间化合物Al3Y,这种化合物常常存在于晶界,起钉扎作用,阻碍位错通过[9,11],合金的抗变形能力增强。

图4 ASMY合金铸态组织的SEM像

Fig.4 SEM image of as-cast ASMY alloy

图5 ASMY合金中B点的SEM像及EDS谱

Fig.5 SEM image (a) and EDS spectrum (b) of point B in ASMY alloy

图6 ASMY合金中C点的SEM像及EDS谱

Fig.6 SEM image (a) and EDS spectrum (b) of point C in ASMY alloy

图7 ASMY 合金中D点的SEM像及EDS谱

Fig.7 SEM image (a) and EDS spectrum (b) of point D in ASMY alloy

2.2 合金的力学性能

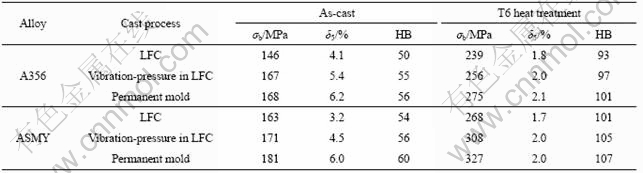

在不同铸造工艺下A356和ASMY两种合金的力学性能如表2所列。其中T6热处理工艺采用538 ℃保温12 h,80 ℃温水淬火的固溶处理后,再进行200 ℃保温6 h的时效处理。

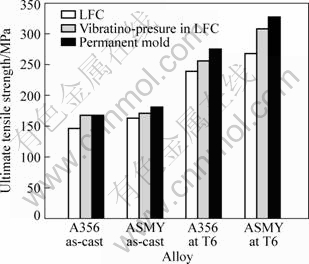

由表2可知,在相同的工艺下,ASMY合金铸态下的抗拉强度比A356合金的略有提高,而伸长率的变化不大。经过T6热处理后, ASMY合金的抗拉强度比A356合金的显著提高。对比表2中3种不同铸造工艺,发现消失模铸造振动压力凝固工艺成形合金的力学性能明显优于普通消失模铸造的,其性能接近金属型铸造性能。其中,消失模铸造振动压力凝固工艺下的ASMY合金试样,T6热处理后的抗拉强度达到308MPa,比普通消失模铸造下A356合金的强度(239 MPa)提高了29%。ASMY和A356合金的硬度变化趋势与抗拉强度的基本一致。A356和ASMY合金抗拉强度的变化趋势如图8所示。

图8 不同铸造方法下A356和ASMY合金的抗拉强度

Fig.8 Ultimate tensile strength of A356 and ASMY alloys in different casting processes

3 讨论

3.1 工艺分析

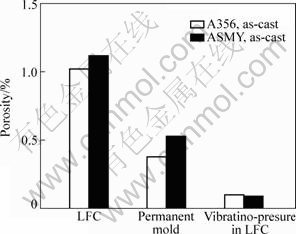

消失模铸造振动压力凝固技术是利用振动细化晶粒,利用压力降低针孔,增加补缩的原理,将振动场和压力场叠加至普通消失模铸造工艺中的一种成形方法。从图9中显示的不同铸造工艺条件下ASMY合金和A356合金的断面孔隙率分析,消失模铸造振动压力凝固成形试样的孔隙率明显低于普通消失模铸造试样的,平均孔隙率从普通消失模铸造试样的1.1%,下降到0.18%,显著提高铸件致密性,减小因为孔洞造成的应力集中,有效提高合金的抗拉强度。

表2 不同铸造工艺下A356和ASMY合金的力学性能

Table 2 Mechanical properties of A356 and ASMY alloys in different cast processes

图9 不同铸造方法处理的铸造态合金的孔隙率

Fig.9 Porosities of A356 and ASMY alloys cast by different processes

3.2 铸态组织分析

从图2中两种合金的铸态显微组织观察到,ASMY合金组织中的α(Al)晶粒比A356合金中的细小。由于Y的原子半径(0.177 nm)比Al的原子半径(0.143 nm)大,且Y在α(Al)中固溶度小于0.03%,Y主要富集在晶界,凝固过程中阻碍α(Al)晶体的长大。此外,稀土Y是表面活性元素物质,降低固液界面张力,使晶粒的形核能下降,从而有效增加了形核[9]。Hall-Petch关系表明,减少晶粒尺寸可使合金强度提高。另外,ASMY合金晶界少量棒状颗粒的Al3Y相起到钉扎晶界的作用,阻碍了合金的变形,提高了ASMY合金的强度。

3.3 合金的时效分析

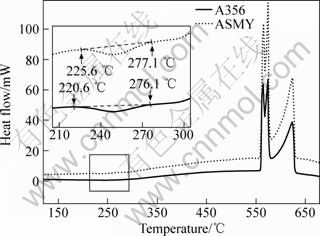

通过T6热处理后,Al-Si-Mg系合金时效析出Mg2Si强化相。图10所示为A356合金和ASMY合金的DSC差示扫描量热分析曲线,加热速率为10 K/min。由图10可知,在220~270 ℃间有一个放热峰,为时效析出相变峰,ASMY合金的析出相变开始温度比A356合金的略高,说明ASMY合金中的Y对β相的析出有一定阻碍作用。Al-Si-Mg系合金的时效转变过程为[14]:

α(Al)supersaturation→GP zone(rod-like)→

β″→β′→β(Mg2Si)

图10 A356和ASMY合金的DSC曲线

Fig.10 DSC curves of A356 and ASMY alloys

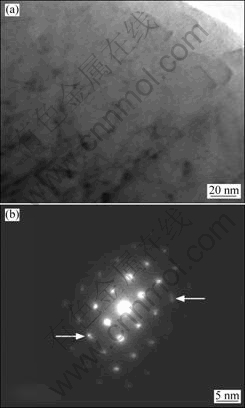

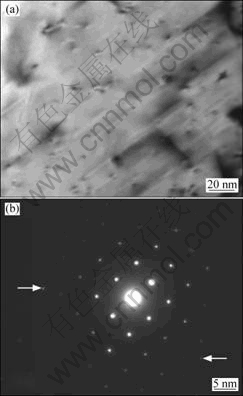

Al-Si-Mg系合金经固溶处理后,Mg和Si溶入α(Al)中形成过饱和固溶体,在200℃时效过程中,Mg和Si聚集开始形成GP区,并迅速沿基体[100]方向伸长,演变成针状β″相[4]。随着时效时间的延长,β″相逐步转变为β′相和β相,所以在A356和ASMY合金的TEM像中(见图11和12),观察不到GP区和β″相。β′相为立方晶系,a=0.642 nm,与基体的位相关系如下[4]:

而文献[15]认为,β相与基体的位相关系如下:

因此,从衍射花样[001]晶带(见图11(b))分析可知,合金中存在与基体半共格关系的β′相和稳定相β。

图11 T6态A356合金的TEM像和[001]晶带的选区衍射花样

Fig.11 TEM image of A356 alloy and diffraction pattern of [001] at T6 heat treatment

图12 T6态ASMY合金的TEM像和[001]晶带的选区衍射花样

Fig.12 TEM image of ASMY alloy and diffraction pattern of [001] at T6 heat treatment

Al3Y金属间化合物具有六方结构,晶格常数为a=0.629 nm,b=0.458 nm,熔点为980 ℃[13],形状为细小的柱状或短棒状,主要分布在ASMY合金晶界,在热处理过程中几乎不能固溶,所以稀土Y含量超过一定阈值时,对合金力学性能反而不利。从TEM图中显示,ASMY合金中析出相(β)的体积分数明显大于A356合金中析出相的,这是由于ASMY合金中Mg元素含量较多。而ASMY合金中析出相(β)多为弥散颗粒状,这是由于稀土Y或Al3Y对Mg2Si的析出与聚集长大有一定的抑制作用,从而使析出β相的分布弥散均匀,减弱其对基体的割裂作用。弥散β相与晶界的细小棒状Al3Y相阻碍了变形过程中位错的运动,从而提高了合金的强度。

4 结论

1) ASMY合金的铸态组织主要由α(Al)基体、共晶Si、Mg2Si相和分布在晶界稀土金属间化合物Al3Y组成。稀土元素Y富集在晶界上,凝固过程中阻碍α(Al)晶体的长大,有细化晶粒的作用。

2) ASMY合金经过T6热处理后,弥散析出的强化相Mg2Si的量明显大于A356合金中的;Mg2Si与晶界少量Al3Y颗粒相对基体起钉扎作用,阻碍变形时位错的通过,起强化作用。稀土Y使ASMY合金的析出相变温度提高,并对Mg2Si的析出具有一定的阻碍作用,从而使Mg2Si相析出更细小、分布更均匀。

3) 采用消失模铸造振动压力凝固技术制备的ASMY铸件的孔隙率明显低于普通消失模铸造的A356铝合金的,试样的孔隙率从1.1%下降到0.18%。消失模铸造振动压力凝固工艺下试样的性能接近金属型铸造试样的性能,而明显高于普通消失模铸造试样的性能。

REFERENCES

[1] BROWN J R. The lost foam casting process[J]. Metals Mater, 1992(8): 550-555.

[2] WANG Q G, JONES P, OSBORNE M. The effects of applied pressure during solidification on the microstructure and mechanical properties of lost foam A356 castings[J]. Advances in Aluminum Casting Technology Ⅱ, 2002(10): 75-84.

[3] MONDOLFO L F. Structures and properties of aluminum alloys[M]. London: Butterworths, 1979.

[4] 耿浩然, 滕新营, 王 艳, 王桂青. 铸造铝合金和镁合金[M]. 北京: 化学工业出版社, 2007.

GENG Hao-ran, TENG Xin-ying, WANG Yan, WANG Gui-qing. Cast aluminum alloy and magnesium alloy[M]. Beijing: Chemical Industry Press, 2007.

[5] CAMPBELL J. Effects of vibration during solidification[J]. Int Met Rev, 1981(2): 71-108.

[6] 李继强, 樊自田, 王元庆, 董选普. 振动和合金化对消失模铸造AZ91D组织与性能的影响[J]. 中国有色金属学报, 2007, 17(7): 1047-1053.

LI Ji-qiang, FAN Zi-tian, WANG Yuan-qing, DONG Xuan-pu. Effects of vibration and alloying on microstructure and properties of AZ91D magnesium alloy via lost foam casting[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1047-1053.

[7] 夏振佳, 李 峰. 加压对铝合金消失模铸造的影响[J]. 特种铸造及有色合金, 2000(4): 43-46.

XIA Zhen-jia, LI Feng. Influence of applied pressure on lost foam casting for aluminum alloy[J]. Special Casting & Nonferrous Alloys, 2000(4): 43-46.

[8] 孙成伟, 张淑荣, 侯爱芹. 稀土在铝合金中的行为[M]. 北京:兵器工业出版社, 1992.

SUN Cheng-wei, ZHANG Shu-rong, HOU Ai-qin. Behavior of rare earth in aluminum alloy[M]. Beijing: Ordnance Industry Press, 1992.

[9] 李慧中, 张新明, 陈明安, 周卓平. 钇对2519铝合金铸态组织的影响[J]. 中南大学学报: 自然科学版, 2005, 36(4): 544-548.

LI Hui-zhong, ZHANG Xin-ming, CHEN Ming-an, ZHOU Zhuo-ping. Effect of yttrium on as-cast microstructure of 2519 aluminum alloy[J]. Journal of Central South University: Science and Technology, 2005, 36(4): 544-548.

[10] 金松哲, 冉 旭, 陈 华. 稀土钇对含Zn和Mg铸态铝合金相组成的影响[J]. 吉林工学院学报, 1999, 20(2): 1-4.

JIN Song-zhe, RAN Xu, CHEN Hua. Effect of yttrium on the phase constituents in Zn and Mg containing aluminium alloys[J]. Journal of Jilin Institute of Technology, 1999, 20(2): 1-4.

[11] 王建华, 易丹青, 卢 斌, 刘 沙, 曹 昱. 钇对2618合金组织及性能的影响[J]. 中国稀土学报, 2002, 20(2): 150-153.

WANG Jian-hua, YI Dan-qing, LU Bin, LIU Sha, CAO Yu. Effect of Y on microstructure and properties of 2618 aluminum alloy[J]. Journal of the Chinese Rare Earth Society, 2002, 20(2): 150-153.

[12] 周守则, 潘复生, 丁培道. 钇对2024铝合金铸态组织的影响[J]. 中国稀土学报, 1993, 11(3): 277-279.

ZHOU Shou-ze, PAN Fu-sheng, DING Pei-dao. Effect of Y on as-cast microstructure of 2024 aluminum alloy[J]. Journal of the Chinese Rare Earth Society, 1993, 11(3): 277-279.

[13] RAN Q S, LUKAS H L, EFFENBERG G, PETZOW J. A thermodynamic optimization of the Al-Y system [J]. J Less-Common Met, 1989, 146: 213-222.

[14] 祝汉良, 郭景杰, 贾 均, 赵九洲, 李沛勇. 铸造Al-Si-Mg合金的时效特性及形变机制[J]. 中国有色金属学报, 1997, 7(1): 143-146.

ZHU Han-liang, GUO Jing-jie, JIA Jun, ZHAO Jiu-zhou, LI Pei-yong. Aging characteristics and deformation mechanisms of a cast Al-Si-Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 1997, 7(1): 143-146.

[15] 李普超, 汪明朴, 孙孝华, 徐国富. Al-Mg-Si合金的时效研究[J]. 中南工业大学学报: 自然科学版, 1998, 29(3): 262-265.

LI Pu-chao, WANG Ming-pu, SUN Xiao-hua, XU Guo-fu. Study of ageing of Al-Mg-Si alloys[J]. Journal of Central South University of Technology: Science and Technology, 1998, 29(3): 262-265.

(编辑 龙怀中)

基金项目:国家高技术研究发展计划资助项目(2007AA03Z113)

收稿日期:2009-09-29;修订日期:2010-01-25

通信作者:樊自田,教授,博士;电话:027-87540094;E-mail:fanzt@mail.hust.edu.cn