混杂比对AZ91D纳米复合材料油润滑摩擦磨损行为的影响

来源期刊:中国有色金属学报(英文版)2018年第3期

论文作者:周霞 李利 文冬 刘霄霞 吴承伟

文章页码:440 - 450

关键词:镁纳米复合材料;混杂比;油润滑;滑动磨损;磨损机理

Key words:magnesium nanocomposites; hybrid ratio; oil-lubricating; sliding wear; wear mechanism

摘 要:使用MRS-10P型四球摩擦试验机对AZ91D镁合金及不同混杂比碳纳米管和纳米碳化硅增强AZ91D镁合金复合材料在油润滑条件下的摩擦磨损行为进行研究。在加载载荷为200~1000 N、主轴转速为380 r/min时测试AZ91D及其复合材料的摩擦因数和磨损率,采用扫描电子显微镜(SEM)、X射线衍射仪(XRD)和能谱分析仪 (EDS)分析磨损表面形貌、相和元素组成,并讨论碳纳米管和纳米碳化硅的协同作用机制。结果表明,与AZ91D镁合金相比,由少量碳纳米管和纳米碳化硅混杂增强的AZ91D镁基纳米复合材料具有更好的耐磨性能和不同的磨损机理, 质量分数分别为0.5%的碳纳米管和纳米碳化硅增强的AZ91D镁合金基纳米复合材料具有最好的摩擦性能。镁基混杂纳米复合材料的磨损机理为微犁沟、微切削、轻微磨粒及脱粘磨损的复合形式。

Abstract: Friction and wear behavior of AZ91D and its nanocomposites reinforced by different contents of hybrid multi-walled CNTs and nano-SiC particulates under oil lubrication was investigated using a MRS-10P four-ball tribometer. Friction coefficients and wear rates were measured within a load range of 200–1000 N at a spindle rotary speed of 380 r/min. Worn surface morphologies, phase and element compositions were studied by scanning electron microscope (SEM), X-ray diffraction (XRD) and energy dispersive spectroscopy (EDS), respectively. The mechanism of synergistic effect of CNTs and SiC nanoparticles was discussed. The results indicate that the AZ91D nanocomposites show better wear resistance properties and different wear mechanisms compared with AZ91D. The AZ91D nanocomposites reinforced with 0.5% CNTs and 0.5% nano-SiC have the best tribological capacity. The wear mechanisms for the Mg-based hybrid nanocomposites appear to be a mix-up of micro-ploughing, micro-cutting, slight adhesive wear and delamination.

Trans. Nonferrous Met. Soc. China 28(2018) 440-450

Xia ZHOU, Li LI, Dong WEN, Xiao-xia LIU, Cheng-wei WU

State Key Laboratory of Structural Analysis for Industrial Equipment, Department of Engineering Mechanics, Faculty of Vehicle Engineering and Mechanics, Dalian University of Technology, Dalian 116024, China

Received 21 October 2016; accepted 8 June 2017

Abstract: Friction and wear behavior of AZ91D and its nanocomposites reinforced by different contents of hybrid multi-walled CNTs and nano-SiC particulates under oil lubrication was investigated using a MRS-10P four-ball tribometer. Friction coefficients and wear rates were measured within a load range of 200–1000 N at a spindle rotary speed of 380 r/min. Worn surface morphologies, phase and element compositions were studied by scanning electron microscope (SEM), X-ray diffraction (XRD) and energy dispersive spectroscopy (EDS), respectively. The mechanism of synergistic effect of CNTs and SiC nanoparticles was discussed. The results indicate that the AZ91D nanocomposites show better wear resistance properties and different wear mechanisms compared with AZ91D. The AZ91D nanocomposites reinforced with 0.5% CNTs and 0.5% nano-SiC have the best tribological capacity. The wear mechanisms for the Mg-based hybrid nanocomposites appear to be a mix-up of micro-ploughing, micro-cutting, slight adhesive wear and delamination.

Key words: magnesium nanocomposites; hybrid ratio; oil-lubricating; sliding wear; wear mechanism

1 Introduction

Magnesium alloys have been attractive to designers as an advanced material owing to their low density and excellent specific strength. However, low wear resistance under service conditions has been an important factor in limiting the use of magnesium alloys in high friction and wear designs [1-3]. Magnesium alloy matrix composites reinforced with short fibers and hard particles especially nanosized reinforcements display a number of useful integrated properties in comparison with the monolithic matrix metal or reinforcement, being potentially attractive for aerospace, aircraft, automotive and other important engineering applications which require suitable friction coefficient and wear [4-8]. The tribological and wear behavior study of magnesium alloy nanocomposites is therefore of practical and theoretical significance.

In recent years, the fabrication method, microstructure and mechanical behavior of magnesium matrix nanocomposites reinforced with nano-sized particle or fiber such as Al2O3, Y2O3, SiC, AlN and/or carbon nanotubes (CNTs) have been studied extensively [9-14], whereas a relatively little amount of research is conducted to investigate tribological and wear behavior of nano-sized particulate or fiber reinforced metal matrix composites. NARAYANASAMY and SELVAKUMAR [5] investigated mechanical properties and wear behaviour of self-lubricating magnesium composites reinforced with the graphite and MoS2 particles. They found that the addition of MoS2 solid lubricants at all mass fractions can improve the hardness, tensile and compressive strength and tribological properties over that of the graphite. HABIBNEJAD- KORAYEM et al [6] investigated the wear and friction behavior of pure Mg and AZ31 Mg alloy and their composites reinforced with 2.0% Al2O3 nano-particles. Results indicated that magnesium based nanocomposites had a better wear resistance than the monolithic pure Mg or AZ31 magnesium alloy under the same conditions. SHANTHI et al [15] illustrated that the wear resistance of calcium containing AZ31B/Al2O3 nanocomposites was improved due to the presence of nanosized alumina reinforcement and hard intermetallic phases because of alloying of calcium in the matrix under both low and high sliding speeds. DAS et al [16] further studied tribological properties of magnesium-nano-alumina composites under nano-graphite lubrication and found that protective self-lubricating graphite layer could improve the wear resistance and reduce friction of the Mg composites. UMEDA et al [7] prepared the CNT-Mg2Si/MgO reinforced magnesium composite by powder metallurgy process. They attributed the improvement in tribological properties to hard Mg2Si intermetallic compounds distributed in the matrix and carbon nanotubes having significant self-lubricant properties [8]. As stated above, the research on the friction and wear behavior of magnesium alloy based composites is mainly focused on the magnesium alloy based composites containing single nanosized reinforcement and micro/nano-sized hybrid reinforce- ments. Although the wear resistance of these magnesium alloy based composites is significantly improved, there are still some problems in improving wear resistance and analyzing wear mechanism due to the presence of nanosized reinforcements in magnesium alloy.

Mg-based hybrid composites reinforced by different forms of reinforcements such as particle, whisker or short fiber are attractive as structural materials because of their high thermal stiffness, good wear resistance, strength and isotropic mechanical property compared with other types of MMC and monolithic alloys [17]. Such hybrid MMCs can attain tailored properties through the appropriate combination of different forms and sizes of reinforcements [18,19]. In our previous studies, AZ91D matrix hybrid composites with uniform dispersion of CNTs and SiC nanoparticles have been fabricated by semisolid stirring assisted ultrasonic cavitation [20]. The preliminary research results indicated that small amounts of nanosized SiC and CNT reinforcement additions (1.0%) can significantly improve the mechanical properties of the hybrid composites [20,21]. However, the research on the friction and wear behavior of magnesium based hybrid nanocomposites is rarely reported [22]. The objective of this work was to study the friction and wear behavior as well as relevant wear mechanisms of the AZ91D matrix hybrid composites under oil lubricated conditions. Focus was placed to correlate the mechanical properties, friction and wear behavior with the microstructural characteristics due to the co-presence of SiC nanoparticle and CNT reinforcement. In addition, the friction and wear properties of the hybrid composites were compared with those of AZ91 alloy to justify their property improvements.

2 Experimental

2.1 Raw materials and fabrication of Mg-based hybrid composites

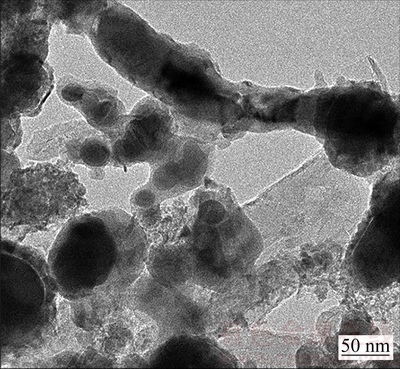

Bulk AZ91D magnesium alloy with a nominal composition of Mg-9.0Al-0.95Zn-0.2Mn (acquired from Shenyang Research Institute of Foundry, China) was used as the matrix material. The beta-SiC with a particulate size range of 30 nm (supplied with Jiuyuan Nano-materials Inc., Sichuan, China) and MWCNT with an average diameter of 50 nm and a length of 1-5 μm (procured from Nanotech Port Inc., Shenzhen, China) were used as the hybrid reinforcements. To improve the interfacial adhesion between hybrid nanosized reinforcements and AZ91D alloy matrix, the Ni-coated CNT and Ni-coated SiC nanoparticle were prepared by an electroless coating technique before fabrication of composites. The detailed electroless plating processes and the chemicals used as well as their concentrations of the plating solution for CNTs and SiC nanoparticles can be found elsewhere [23,24]. The Ni-coated CNTs and SiC nanoparticles were further dispersed in the alcohol solution containing 5% polyvinyl alcohol by continuous stirring at 99 °C for 1 h. The TEM image of the hybrid reinforcements is shown in Fig. 1 after they were pretreated by purification, surface modification, and ultrasonic dispersion.

Fig. 1 TEM image of surface-coated CNT and SiC nanoparticle hybrid composites

The AZ91D alloy based hybrid composites AZ91D/(CNT+SiC) reinforced with different hybrid mass ratios of CNTs and SiC nanoparticles were prepared by using self-designed semisolid stirring assisted ultrasonic cavitation process and subsequent hot extrusion in two steps. First, 1.0% total content of Ni-coated CNTs and Ni-coated SiC nanoparticles were ultrasonically dispersed in the AZ91D alloy melt to obtain Mg matrix nanocomposites with non- agglomerated nanosized hybrid reinforcements by using self-signed experimental setup for the semisolid stirring assisted ultrasonic processing. More details of ultrasonic activation method for preparing AZ91D matrix hybrid nanocomposite billets can be found in our previous work [20]. In the next step, all AZ91D hybrid composite billets prepared with semisolid stirring assisted ultrasonic cavitation process were machined to 30 mm in diameter and hot extruded using 18.3:1 extrusion ratio at extrusion speed of 2.5 mm/s on a 100 ton hydraulic press with colloidal graphite as a lubricant. The extrusion temperature was 380 °C. The billets were held at 200 °C for 2 h and then solution treated at 410 °C for 22 h in a furnace prior to extrusion. Rod of 16 mm in diameter was finally obtained following the above hot extrusion process and it is shown in Fig. 2.

Fig. 2 Photo of magnesium alloy matrix nanocomposites after extrusion

In the AZ91D/(CNT+SiC) hybrid composites mentioned in this work, the total mass fraction of CNTs and SiC nanoparticles was 1.0%, while the hybrid mass ratio of CNTs to SiC nanoparticles could be different. The hybrid mass ratios of CNTs to SiC nanoparticles were 7:3, 5:5 and 3:7, respectively. The corresponding AZ91D alloy based hybrid composites were respectively denoted as AZ91/(0.7%CNT+0.3%SiC), AZ91/ (0.5%CNT+0.5%SiC) and AZ91/(0.3%CNT+0.7%SiC). For comparison, 1.0% carbon nanotube reinforced AZ91 alloy based composites (AZ91D/1.0%CNT) and 1.0% SiC nanoparticle reinforced AZ91 alloy based composites (AZ91D/1.0%SiC) were also prepared with semisolid stirring assisted ultrasonic cavitation process.

2.2 Microstructural characterization and mechanical performance tests

The AZ91D alloy based hybrid nanocomposite samples were cut vertically to the extrusion direction to observe their microstructure and check their microhardness. The metallographic samples of the monolithic AZ91D Mg alloy and its hybrid composites were produced by a standard metallography method, and etched using a 4% nitric acid alcohol solution. The microstructure and fractography of these samples as well as morphology of nanosized hybrid reinforcements were observed with a XJG-05 optical microscope (OM), an environmental FEI Quanta 200 scanning electron microscope (SEM) and a TECNAI G2205-TWIN TEM, respectively. The X-ray diffraction (XRD) pattern was measured for identification of intermetallic phases and microstructure contents in the Mg matrix composites using the X-ray diffractometry with Cu Kα radiation of wavelength 1.54056  , while the morphological and elemental analysis of the Mg matrix and its composites was conducted using SEM and energy dispersive spectroscopy (EDS). The room temperature tensile properties of the monolithic AZ91D Mg alloy and its hybrid composites were measured on 3354 Instron tensile testing machine using round tension test specimens of 5 mm in diameter and 25 mm in gauge length at a nominal strain rate of 2×10-3s-1, while Brinell hardness was measured with a HB-3000 Brinell hardness tester using 29400 N indenting load and 10 mm indenter in diameter as well as 15 s dwell time.

, while the morphological and elemental analysis of the Mg matrix and its composites was conducted using SEM and energy dispersive spectroscopy (EDS). The room temperature tensile properties of the monolithic AZ91D Mg alloy and its hybrid composites were measured on 3354 Instron tensile testing machine using round tension test specimens of 5 mm in diameter and 25 mm in gauge length at a nominal strain rate of 2×10-3s-1, while Brinell hardness was measured with a HB-3000 Brinell hardness tester using 29400 N indenting load and 10 mm indenter in diameter as well as 15 s dwell time.

2.3 Wear tests under oil lubricated conditions

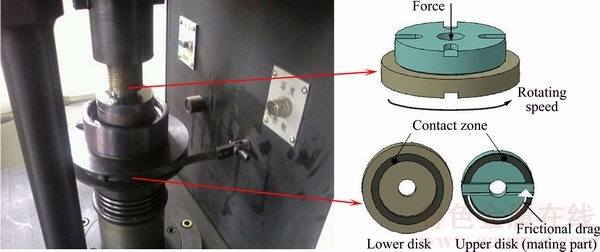

A MRS-10P four-ball tribometer (supplied by Ji’nan Yihua Tribology Testing Technology Co., Ltd., Shandong, China) was used to evaluate the sliding friction and wear characteristics of the monolithic AZ91D Mg alloy matrix and AZ91D Mg alloy matrix nanocomposites against a SUS440C stainless steel counterface under oil lubricated conditions. The upper counterpart for friction pairs was machined from the extruded AZ91D Mg alloy matrix nanocomposites and monolithic AZ91D Mg alloy. Wear tests were carried out onto surfaces that were perpendicular to the extrusion direction. The annular specimen had a dimension of 45 mm in outer diameter and 25 mm in inner diameter. The lower counterpart for friction pairs was ring-shaped SUS440C stainless steel with the hardness of HRC62 and it had a dimension of 48 mm in outer diameter and 20 mm in inner diameter. All specimens were polished, cleaned in an ultrasonic bath with acetone, dried in the oven at 60 °C and weighed prior to each test. The specimens were cleaned again with acetone cotton balls after they were mounted on the wear test machine. In addition, the specimens were also ultrasonically cleaned in acetone for 10 min after the wear test was finished. When the wear test was conducted, the upper counterpart was fixed with the rotating shaft together and the hydraulic motor drove the mainshaft to rotate, while the lower counterpart was connected with the wheel torque sensor installed on the front panel and it was subjected to a downward load applied at its upper face by the upper counterpart through the hydraulic loading system. Thus, the sliding wear tests could be carried out onto the appressed counterface of the upper and lower counterpart through the rotation of the upper counterpart driven by the rotating shaft with the fixed speed. When different loads were applied, the signals were received by the force sensor connected with the wheel torque and thus the friction force could be calculated under loading force, while the friction coefficient could be obtained by conversion. At least three samples were tested for each wear condition and the friction coefficient (μ) was given by Eq.(1):

μ=T/(p×r) (1)

where T is the friction torque (N·mm), p is the force applied vertically downward (N) and r is the radius of hard SUS440C stainless steel counterpart (mm).

A diagram of the wear test configuration with a photo of wear tester chamber is shown in Fig. 3. The wear testing conditions selected are as follows: a constant mainshaft rotating speed of 380 r/min was maintained under different loads (200, 400, 600, 800, and 1000 N) for the test. The friction time and the ambient temperature are 1-5 h and 20-25 °C, respectively. The CD40 diesel engine oil is used as the lubricating oil. The wear amount of the AZ91D Mg based nanocomposite specimens was measured by mass loss. Before and after each test, the surfaces of the specimens were cleaned ultrasonically in acetone and weighed using an electronic balance with an accuracy of 0.0001 g to measure the mass loss.

3 Results and discussion

3.1 Microstructure and mechanical properties of AZ91D based nanocomposites

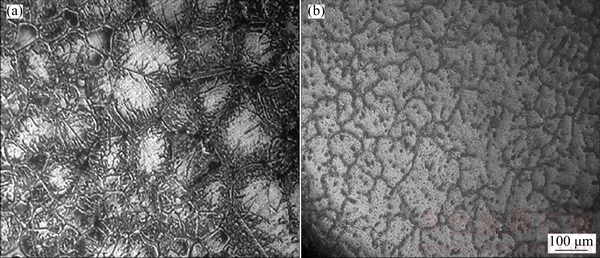

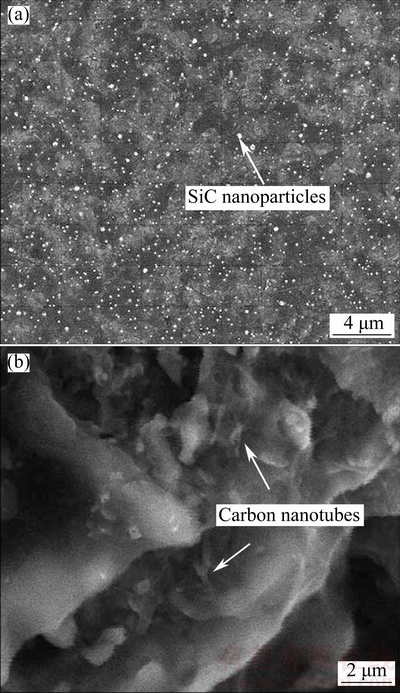

The optical micrographs of the monolithic AZ91D Mg alloy and AZ91D/(0.7%CNT+0.3%SiC) hybrid nanocomposites are shown in Figs. 4(a) and (b), respectively. Here, AZ91D/(0.7%CNT+0.3%SiC) refers to the hybrid CNT/SiC nanoparticle mass ratio of 7:3 and the hybrid content of 1.0% in this composite. The rest can be analogized. It can be seen that a significant grain refinement is achieved due to the concurrent presence of a small amount (1.0%) of CNT and nanosized SiC hybrid reinforcements in the composites. Representative SEM images of the AZ91D/(0.7%CNT+0.3%SiC), shown in Fig. 5, indicate a relatively good dispersion of SiC nanoparticles (Fig. 5(a)) and CNTs (Fig. 5(b)) in the matrix. The small bright spots in Fig. 5(a) correspond to SiC nanoparticles, while the gray strips in Fig. 5(b) denote carbon nanotubes embedded in the Mg matrix. The uniform distribution of SiC nanoparticles and carbon nanotubes in the Mg matrix can be attributed to the combined effects of surface modification of hybrid nanoreinforcements, mechanical stirring and high intensity ultrasonic dispersion.

Fig. 3 Wear-test device and schematic diagram of ring and ring with directions of rotation and force

Fig. 4 Optical micrographs of monolithic AZ91D Mg alloy (a) and AZ91D/(0.7%CNT+0.3%SiC) hybrid nanocomposite (b)

Fig. 5 SEM images of SiC nanoparticles distributed in AZ91D Mg alloy (a) and CNTs distributed in tensile fracture surface of composites (b)

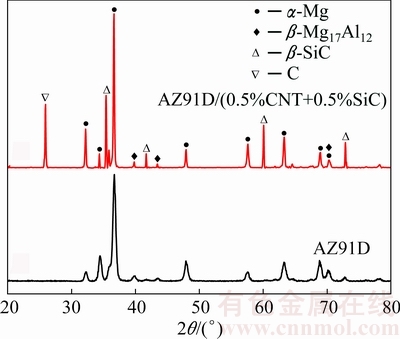

Figure 6 shows the XRD patterns of the extruded AZ91D matrix alloy and AZ91D/(0.5%CNT+0.5%SiC) hybrid nanocomposites. It can be found that the primary α-Mg and eutectic β-Mgl7Al12 phases were present in the AZ91D Mg alloy, while the peaks of α-Mg, β-Mgl7Al12, β-SiC and C phases could be observed in the case of the AZ91D matrix hybrid composites. This indicates the co-existence of the SiC and carbon nanotube phases in the Mg matrix hybrid composites. Moreover, the peaks of α-Mg and β-Mgl7Al12 phases in the hybrid composites become sharper than those in the monolithic Mg alloy. This is related to the grain refinement of the Mg matrix alloy and less connected β-Mgl7Al12 phase [25] caused by addition of nanosized hybrid reinforcements.

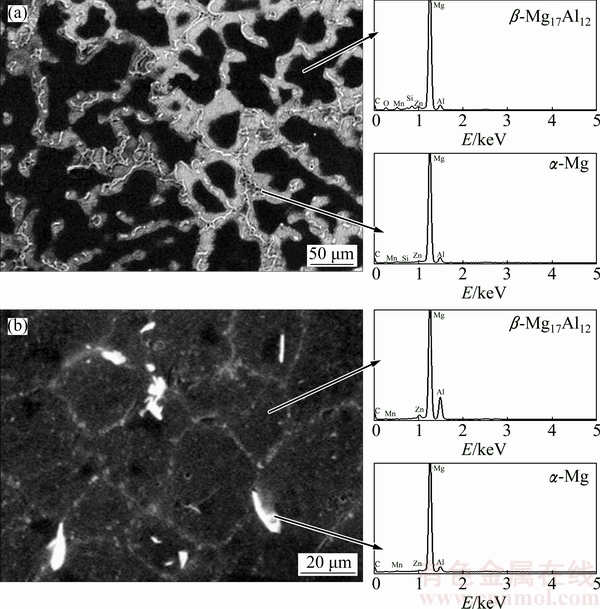

Figure 7 shows the SEM images and EDS spectra of AZ91D magnesium alloy and AZ91D/(0.5%CNT+ 0.5%SiC) hybrid nanocomposites. It is clear that the eutectic β-Mgl7Al12 phases are coarse and mainly distributed around the primary α-Mg grain boundaries in the AZ91D magnesium matrix (Fig. 7(a)). In the case of hybrid nanocomposites (Fig. 7(b)), the volume fraction of β-Mgl7Al12 phases is significantly decreased and they are discontinuously distributed in the hybrid nanocomposite. The EDS analysis results further demonstrate that the local content of element Al is higher and the possible AlMn dispersion phases appear in the hybrid nanocomposite compared with the magnesium alloy matrix.

Fig. 6 XRD patterns of AZ91D Mg alloy and AZ91D/ (0.5%CNT+0.5%SiC) hybrid nanocomposite

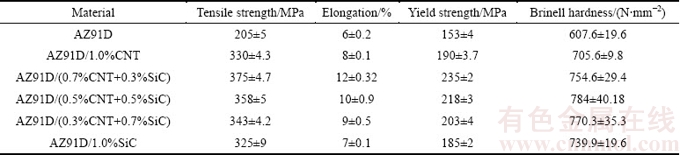

Table 1 lists the room-temperature mechanical properties of the monolithic AZ91D Mg alloy and its nanocomposites. Compared with the monolithic AZ91D Mg matrix, the significant improvements in both tensile properties and microhardness can be achieved for the hybrid carbon nanotube and SiC nanoparticle reinforced AZ91D magnesium based composites, while the smaller increase in tensile properties and microhardness can be obtained for the single carbon nanotube or single SiC nanoparticle reinforced Mg matrix composites. This is because when hybrid CNT and SiC nanoparticle fillers were incorporated in the Mg matrix, the van der Waals attractive forces between the same kind of nanosized reinforcements will be reduced. It is the synergistic effects between the CNT and nanosized SiC hybrid nanoreinforcements that can greatly enhance dispersion of nanosized reinforcements in the matrix and thus they can play an effective strengthening role [26]. In addition, the improvement of the mechanical properties of the Mg matrix composites is beneficial to enhancing their wear resistance.

3.2 Wear properties of AZ91D alloy based nanocomposites

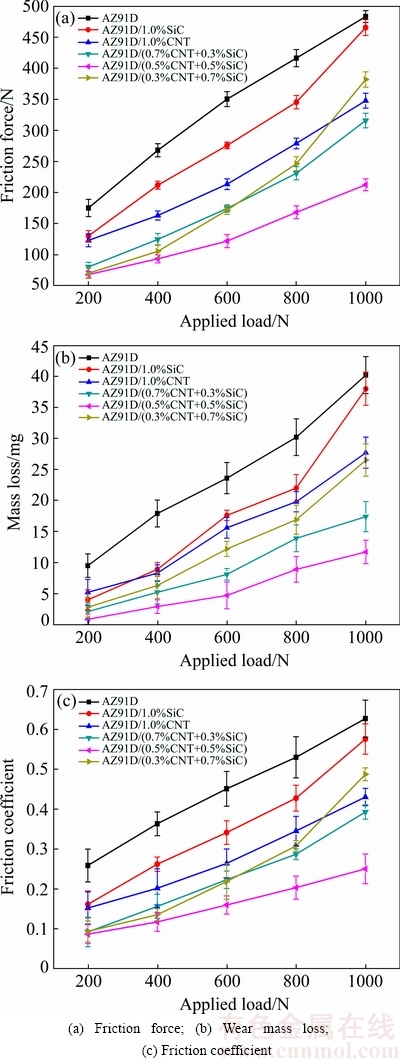

Figures 8(a)-(c) respectively show variations of friction force, wear loss and friction coefficient with applied loads for the monolithic AZ91D Mg alloy and its nanocomposites at a sliding speed of 380 r/min for 1 h of wear time. As can be seen from Fig. 8, the friction force, wear loss and friction coefficient of the AZ91D Mg based nanocomposites were all less than those of the monolithic AZ91D Mg alloy matrix under the same conditions, while the wear resistance of the AZ91D based hybrid nanocomposite reinforced with CNTs to SiC nanoparticles was superior to that of the AZ91D based composites with single reinforcement. Moreover, when the hybrid mass ratio of CNTs to SiC nanoparticles was 5:5, the AZ91D based hybrid nanocomposites displayed the best wear resistance, whereas the increment in wear resistance was smaller in the single-CNT or single-SiC nanoparticle reinforced AZ91D based nanocomposites than that in the Mg based hybrid nanocomposites. This is because the synergistic effects of the carbon nanotube and nanosized SiC hybrid reinforcements can make them evenly disperse in the Mg matrix more easily than a single reinforcement when the addition amount of carbon nanotubes and SiC nanoparticles is larger. The friction force, wear mass loss and friction coefficient of the AZ91D/(0.5%CNT+0.5%SiC) composites respectively were reduced by 57.4%, 67.9% and 57.4%, respectively at an applied load of 1000 N compared with those of the monolithic AZ91D Mg alloy matrix.

Fig. 7 SEM images and EDS spectra of AZ91D magnesium alloy (a) and AZ91D/(0.5%CNT+0.5%SiC) (b)

Table 1 Room-temperature mechanical properties of AZ91D alloy and its nanocomposites

It has to be also noted from Fig. 8 that the friction force, wear loss and friction coefficient of the monolithic AZ91D Mg alloy and its nanocomposites all increase with increasing the applied load, but these experimental data of the AZ91D matrix all increase more sharply under high applied loads (600-1000 N) than those of the AZ91D matrix hybrid nanocomposites, indicating that the Mg matrix suffers more serious wear damage than the Mg based nanocomposites. For example, in the range of the testing loads (600-1000 N), the wear rates of the AZ91D matrix and AZ91D/(0.5%CNT+0.5%SiC) composites increased by 168% and 83%, respectively. Therefore, the coupled addition of nanosized hybrid reinforcements led to an increasement in the hardness and strength properties of the Mg matrix composites (see Table 1) and further improved the wear resistance under high applied loads.

Fig. 8 Effects of applied load on wear performance of monolithic AZ91D Mg alloy and AZ91D based nanocomposites

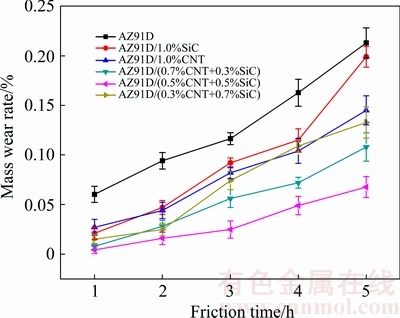

Figure 9 shows variation of mass wear rate as a function of friction time for the monolithic AZ91D Mg alloy and its nanocomposites under a high applied load of 800 N. It can be seen that the wear rate of the AZ91D matrix shows a dramatic increase with the increase of friction time although it has no significant change at the beginning of the friction test. However, the wear rate of the AZ91D hybrid nanocomposites increases from small to large and then tends to be stable with increasing the friction time, while the wear rate of the single CNT or nanosized SiC reinforced AZ91D based composites increases constantly with increasing time though there is substantial improvement in the wear rate compared with the Mg matrix. This also shows that the wear resistance of the Mg matrix hybrid composite reinforced with carbon nanotubes and SiC nanoparticles is better than that of the Mg matrix and has the best wear resistance.

Fig. 9 Variation of wear rate as function of wear time

3.3 Wear surface morphology and wear mechanism

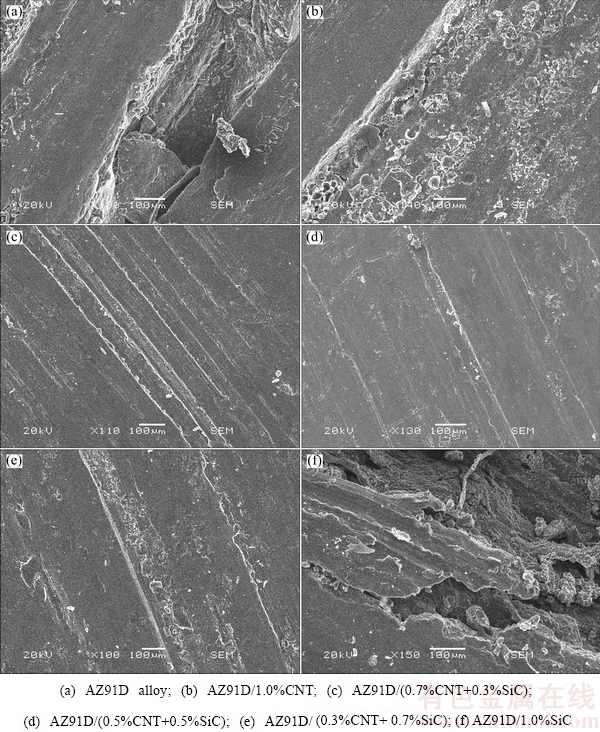

Figure 10 shows SEM images of worn surfaces of AZ91D and its nanocomposites subjected to wear for 1 h at a high applied load of 800 N with a sliding speed of 380 r/min. It can be found from Fig. 10(a) that there are wide and deep plowing grooves with adhered powders from wear debris and scratch marks parallel to the sliding direction on the worn surfaces of the AZ91D sample. The adhesive wear and abrasive wear are the dominant wear mechanisms of the AZ91D matrix. Compared with Fig. 11(a), when adding different contents of CNTs and SiC nanoparticles into the AZ91D matrix, the worn appearance of the nanocomposite samples shown in Figs. 10(b)-(f) has generally become smoother, and no deep mechanical plowing grooves and shearing tear features can be observed on their wear surface. As can be seen from Figs. 10(c)-(e), the main wear mechanism of the AZ91D matrix hybrid nanocomposites is the abrasive wear and mild adhesive wear. Different from the wear mechanism of the Mg matrix hybrid nanocomposites, when the addition of 1.0% CNTs (Fig. 10(b)) or 1.0% SiC nanoparticles (Fig. 10(f)) to the AZ91D matrix, the peeling wear features exist on the wear surface of the single CNT or SiC nanoparticle reinforced AZ91D matrix nanocomposites. Although the wear resistance of the magnesium matrix composites reinforced by single reinforcement is improved, delamination on surface is still present and this can also be observed under dry sliding friction conditions [27,28].

Fig. 10 Worn surfaces of AZ91D alloy and its nanocomposites at high applied load of 800 N with sliding speed of 380 r/min

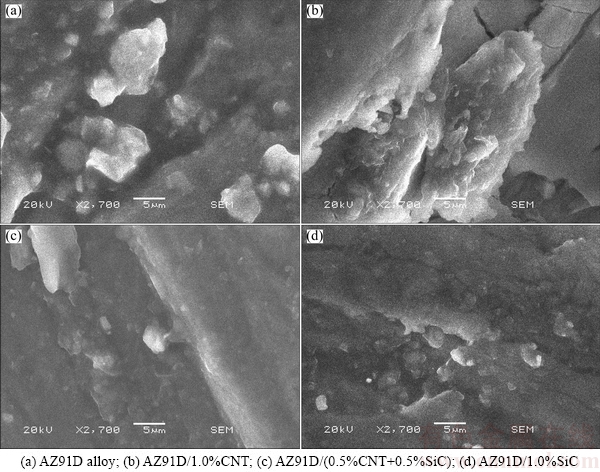

For the AZ91D/1.0%CNT and AZ91D/1.0%SiC composites with single nanoreinforcement (see Figs. 10(b) and (f)), there both existed delamination peeling phenomena occurred on their worn surface although the presence of CNTs or SiC nanoparticles improved the wear resistance of the AZ91D matrix. The main reason is that when the mass fraction of CNTs or nanosized SiC addition is up to 1%, their relatively uneven dispersion in the AZ91D matrix will result in the formation of the loose oxide film on the partial surface of the composites, and the abrasive grains resulting from the spalling of the oxide film during the sliding friction process accelerate the wear of the composites. On the other hand, the agglomerated nano-reinforcements will also lead to the decrease in the strength and hardness of the composites, thus making the composites prone to peeling off and the spalling pits formed on the wearing surface. Different from the wear situations of the AZ91D/1.0%CNT and AZ91D/1.0%SiC composites with single nano-reinforcement, the mild wear is observed to occur and the worn surface is smoother for the AZ91D hybrid nanocomposites such as AZ91D/(0.7%CNT+ 0.3%SiC), AZ91D/(0.5%CNT+0.5%SiC) and AZ91D/ (0.3%CNT+0.7%SiC) under the same wear conditions. The worn surfaces of the Mg matrix hybrid nanocomposites have shown un-conspicuous plastic deformation and micro-ploughing in the form of shallow grooves, as can be seen in Figs. 10(c)–(e). The wear resistance of the hybrid nanocomposites especially the AZ91D/(0.5%CNT+0.5%SiC) composites is significantly higher than that of the composites with single nano-reinforcement, which is consistent with the experimental results in Figs. 8 and 9. The reason for higher wear resistance of the hybrid nanocomposite is that the smaller size of hybrid nano-reinforcements can prevent the plastic flow of the AZ91D matrix as surface asperities during sliding wear [29] and meanwhile the carbon nanotubes with low friction efficient of 0.016- 0.0040 can also play a self-lubrication role [30,31]. As shown in Fig. 7(c), the decrease in the friction coefficients of the Mg matrix hybrid composites is also partly attributed to the self lubrication nature of CNTs. Another reason for higher wear resistance of the hybrid nanocomposite is that when hybrid ratio is appropriate for CNTs and SiC nanoparticles, the hybrid composites are not liable to spall off during the wearing tests and fewer spalling pits are formed on the worn surface due to the excellent compatibility of deformation between the matrix and nanohybrids. As shown in Fig. 11, micro- cracks are produced in the nanocomposite samples under yield loads during the wear process and the worn surface roughness of the nanocomposites varies with the content of carbon nanotubes and SiC nanoparticles in the composite, indicating that the AZ91D/(0.5%CNT+ 0.5%SiC) composites with 5:5 mass ratios of CNTs to SiC nanoparticles can most effectively prevent the serious wear of the AZ91D magnesium alloy.

As for the reasons of the difference in the hybrid enforcing effects between magnesium matrix composites containing different hybrid ratios of CNTs to SiC nanoparticles, CNTs and SiC nanoparticles in the Mg matrix play different roles and the proper dispersion of hybrid reinforcements is affected by hybrid ratios, resulting from different synergistic reinforcement effects in mechanical and wear properties. Carbon nanotubes have high specific strength, specific stiffness and self-lubricating behavior, and the CNTs in the hybrid reinforcements play a dominant role in the improvement of the strength and ductility of the Mg matrix composites. However, a high content of CNTs will lead to a significant deterioration in the mechanical properties of the composites due to the CNT agglomeration [32]. On the other hand, nanosized SiC particles have high hardness and high wear resistance, and the nano-SiC contents in the hybrid reinforcements have positive effects on wear resistance of the composites. What is more, the enhancement effect of hybrid nano- reinforcements is also related to their dispersion, hybrid nano-reinforcements with the appropriate hybrid ratio can be well dispersed in the Mg matrix under a given hybrid content.

Fig. 11 High-resolution SEM images of worn surfaces of AZ91D alloy and its nanocomposites at high applied load of 800 N with sliding speed of 380 r/min

4 Conclusions

1) The wear resistance of AZ91D magnesium alloy can be improved by the addition of single carbon nanotube or nanosized SiC especially their nanohybrids under oil lubricated sliding wear. Moreover, when the hybrid mass ratio of CNTs to SiC nanoparticles is 5:5, the AZ91D/(0.5%CNT+0.5%SiC) hybrid nanocomposites have the best wear resistance and good application prospect under high applied loads. This is due to the load supporting action of SiC nanoparticles, the self-lubricating property of CNTs and the synergistic effects of the hybrid nanoreinforcements on improving the strength and hardness of the composites.

2) The abrasive wear and adhesive wear are identified as the main wear mechanism of the AZ91D alloy, while the micro-ploughing and micro-cutting combined with slight adhesive wear and delamination appear to be the predominant wear mechanisms of the AZ91D matrix nanocomposites with single and hybrid nano-reinforcements under oil lubricated sliding contacts.

3) The friction force, wear loss and friction coefficient of the AZ91D Mg based nanocomposites are all less than those of the monolithic AZ91D Mg alloy matrix under the same conditions, but the wear resistance of the AZ91D based hybrid nanocomposite reinforced with CNTs and SiC nanoparticles is superior to that of the AZ91D based composites with single reinforcement. The effect of applied load on the wear rate of the hybrid composites is not obvious.

References

[1] WANG Shu-yan, SI Nai-chao, XIA Yong-ping, LIU Li. Influence of nano-SiC on microstructure and property of MAO coating formed on AZ91D magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(6): 1926-1934.

[2] AN Jian, LI Rong-guang, LU You, CHEN Chun-mei, XU Yong-chao, CHEN X, WANG Li-min. Dry sliding wear behavior of magnesium alloys [J]. Wear, 2008, 265: 97-104.

[3] AUNG N N, ZHOU Wei, LIM L E N. Wear behaviour of AZ91D alloy at low sliding speeds [J]. Wear, 2008, 265: 780-786.

[4] FALCON-FRANCO L, BEDOLLA-BECERRIL E, LEMUS-RUIZ J,  J G, GUARDIAN R, ROSALES I. Wear performance of TiC as reinforcement of a magnesium alloy matrix composite [J]. Composites (Part B): Engineering, 2011, 42: 275-279.

J G, GUARDIAN R, ROSALES I. Wear performance of TiC as reinforcement of a magnesium alloy matrix composite [J]. Composites (Part B): Engineering, 2011, 42: 275-279.

[5] NARAYANASAMY P, SELVAKUMAR N. Tensile, compressive and wear behaviour of self-lubricating sintered magnesium based composites [J]. Transactions of Nonferrous Metals Society of China, 2017, 27(2): 312-323.

[6] HABIBNEJAD-KORAYEM M, MAHMUDI R, GHASEMI H M, POOLE W J. Tribological behavior of pure Mg and AZ31 magnesium alloy strengthened by Al2O3 nano-particles [J]. Wear, 2010, 268: 405-412.

[7] UMEDA J, KONDOH K, IMAI H. Friction and wear behavior of sintered magnesium composite reinforced with CNT-Mg2Si/MgO [J]. Materials Science and Engineering A, 2009, 504:157-162.

[8] MOGHADAM A D, OMRANI E, MENEZES P L, ROHATGI P K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and grapheme—A review [J]. Composites (Part B): Engineering, 2015, 77: 402-420.

[9] LAN Jie, YANG Yong, LI Xiao-chun. Microstructure and microhardness of SiC nanoparticles reinforced magnesium composites fabricated by ultrasonic method [J]. Materials Science and Engineering A, 2004, 386: 284-290.

[10] CAO G, CHOI H, OPORTUS J, KONISHISHI H, LI X. Study on tensile properties and microstructure of cast AZ91D/AlN nanocomposites [J]. Materials Science and Engineering A, 2008, 494: 127-131.

[11] NIE Kai-bo, WANG Xiao-jun, WU Kun, HU Xiao-shi, ZHENG Ming-yi. Development of SiCp/AZ91 magnesium matrix nanocomposites using ultrasonic vibration [J]. Materials Science and Engineering A, 2012, 540: 123-129.

[12] TJONG S C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets [J]. Materials Science and Engineering R, 2013, 74: 281-350.

[13] PARAMSOTHY M, TAN X H, CHAN J, KWOK R, GUPTA M. Carbon nanotube addition to concentrated magnesium alloy AZ81: Enhanced ductility with occasional significant increase in strength [J]. Materials & Design, 2013, 45:15-23.

[14] SRIVATSAN T S, GODBOLE C, PARAMSOTHY M, GUPTA M. Influence of nano-sized carbon nanotube reinforcements on tensile deformation, cyclic fatigue, and final fracture behavior of a magnesium alloy [J]. Journal of Materials Science, 2012, 47: 3621-3638.

[15] SHANTHI M, NGUYEN Q B, GUPTA M. Sliding wear behaviour of calcium containing AZ31B/Al2O3 nanocomposites [J]. Wear, 2010, 269: 473-479.

[16] DAS L, AGGARWAL M, RAJKUMAR K, ARAVINDAN S, GUPTA M. Tribological properties of magnesium nano-alumina composites under nano-graphite lubrication [J]. Tribology Transactions, 2012, 55: 334-344.

[17] MONDAL A K, KUMAR S. Dry sliding wear behaviour of magnesium alloy based hybrid composites in the longitudinal direction [J]. Wear, 2009, 267: 458-466.

[18] PRASAD D S, SHOBA C. Hybrid composites—A better choice for high wear resistant materials [J]. Journal of Materials Science & Technology, 2014, 3(2): 172-178.

[19] ZHANG Su-qing, CHEN Ti-jun, CHENG Fa-liang, LI Lei-liang. Microstructural evolution and phase transformation during partial remelting of in-situ Mg2Sip/AM60B composite [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(6): 1564-1573.

[20] ZHOU Xia, SU De-peng, WU Cheng-wei, LIU Li-ming. Tensile mechanical properties and strengthening mechanism of hybrid carbon nanotube and silicon carbide nanoparticle-reinforced magnesium alloy composites [J]. Journal of Nanomaterials, 2012, 2012: 851862-1–851862-7.

[21] SONG Shang-yu, ZHOU Xia, LI Li, MA Wu-ming. Numerical simulation and experimental validation of SiC nanoparticle distribution in magnesium melts during ultrasonic cavitation based processing of magnesium matrix nanocomposites [J]. Ultrasonics Sonochemistry, 2015, 24: 43-54.

[22] HASSAN S F, AL-QUTUB A M, TUN K S, GUPTA M. Study of wear mechanisms of a novel magnesium based hybrid nanocomposite [J]. Journal of Tribology, 2015, 137: 011601-1– 011601-4.

[23] LIANG Jun-hao, LI He-jun, HU Xiao-jun, WEI Jian-feng, QI Le-hua. Fabrication of Ni-coated carbon nanotubes reinforced magnesium matrix composites [C]//2013 International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale (3M-NANO). Los Alamitos, CA, United States: IEEE, 2013: 299-302.

[24] ZOU Gui-zhen, CAO Mao-sheng, LIN Hai-bo, JIN Hai-bo, KANG Yu-qing, CHEN Yu-jin. Nickel layer deposition on SiC nanoparticles by simple electroless plating and its dielectric behaviors [J]. Powder Technology, 2006, 168: 84-88.

[25] BARKER E I, CHOI K S, SUN X, DEDA E, ALLISON J, LI M, FORSMARK J, ZINDER J, GODLEWSKI L. Microstructure based modeling of β phase influence on mechanical response of cast AM series Mg alloys [J]. Computational Materials Science, 2014, 92: 353-361.

[26] LU Bai, WANG Xiang, TAN Jin, LI Hong-yan, ZHENG Jun-ping. Study of distinctions in the synergistic effects between carbon nanotubes and different metal oxide nanoparticles on enhancing thermal oxidative stability of silicone rubber [J]. Journal of Materials Science, 2016, 51: 7130-7144.

[27] HU Mao-liang, WANG Qu-dong, LI Cheng, DING Wen-jiang. Dry sliding wear behavior of cast Mg-11Y-5Gd-2Zn magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 1918-1923.

[28] LIU Shi-ying, LI Wen-zhen, ZHANG Qiong-yuan, ZHU Xue, HE Guang-jin, LI Ming-yuan. Study on friction and wear behavior of SiCp/AZ91D nanocomposites [J]. Rare Metal Materials and Engineering, 2012, 41(1):110-114.

[29] STOTT F H. High-temperature sliding wear of metals [J]. Tribology International, 2002, 35: 489-495.

[30] BASTWROS M M H, ESAWI A M K, WIFI A. Friction and wear behavior of Al-CNT composites [J]. Wear, 2013, 307: 164-173.

[31] ZHANG Wei, MA Guo-jun, WU Cheng-wei. Anti-friction, wear- proof and self-lubrication application of carbon nanotubes [J]. Reviews on Advanced Materials Science, 2014, 36: 75-88.

[32] ZHANG Cong-yang, LI Wen-zhen, JIN Yu, XUE Wei-dong, GAO Wei-ming. Mechanical properties and fabrication of carbon nanotubes reinforced AZ91D magnesium matrix nanocomposites [J]. Special Casting & Nonferrous Alloys, 2013, 33: 891-894. (in Chinese).

周 霞,李 利,文 冬,刘霄霞,吴承伟

大连理工大学 运载工程与力学学部 工程力学系 工业装备结构分析国家重点实验室,大连 116024

摘 要:使用MRS-10P型四球摩擦试验机对AZ91D镁合金及不同混杂比碳纳米管和纳米碳化硅增强AZ91D镁合金复合材料在油润滑条件下的摩擦磨损行为进行研究。在加载载荷为200~1000 N、主轴转速为380 r/min时测试AZ91D及其复合材料的摩擦因数和磨损率,采用扫描电子显微镜(SEM)、X射线衍射仪(XRD)和能谱分析仪 (EDS)分析磨损表面形貌、相和元素组成,并讨论碳纳米管和纳米碳化硅的协同作用机制。结果表明,与AZ91D镁合金相比,由少量碳纳米管和纳米碳化硅混杂增强的AZ91D镁基纳米复合材料具有更好的耐磨性能和不同的磨损机理, 质量分数分别为0.5%的碳纳米管和纳米碳化硅增强的AZ91D镁合金基纳米复合材料具有最好的摩擦性能。镁基混杂纳米复合材料的磨损机理为微犁沟、微切削、轻微磨粒及脱粘磨损的复合形式。

关键词:镁纳米复合材料;混杂比;油润滑;滑动磨损;磨损机理

(Edited by Xiang-qun LI)

Foundation item: Projects (11272072, 11672055) supported by the National Natural Science Foundation of China

Corresponding author: Xia ZHOU; Tel: +86-411-84706782; Fax: +86-411-84708400; E-mail: zhouxia@dlut.edu.cn

DOI: 10.1016/S1003-6326(18)64677-1