V-Si-CO32--H2O体系浸出液中硅和钒的回收及浸出剂的再生

龙思思,冯其明,张国范,欧乐明,卢毅屏

(中南大学 资源加工与生物工程学院,湖南 长沙,410083)

摘要:对从石煤碱法提钒过程产生的高硅钒浸出液中回收硅和钒资源及浸出剂的再生进行研究。首先通入CO2气体调节浸出液pH至8.5,使浸出过程中所积累的大量硅杂质以水合二氧化硅沉淀的形式脱除,并经进一步处理后制备成白炭黑副产品;然后,采用溶剂萃取的方法从净化后的浸出液中回收钒;提钒后留下的余液再通过苛化反应实现浸出剂的再生。研究结果表明:浸出液按上述工艺进行净化—提钒—苛化处理后,脱硅率达到99.43%,钒回收率大于95.00%;制备的无定形白炭黑产品SiO2纯度大于98%,比表面积高达450 m2/g;再生浸出液返回浸矿时,钒的浸出率为81.7%。对于整个工艺,每生产1 t V2O5可以获得白炭黑副产品10 t,并可实现总量75%浸出剂的再生。

关键词:石煤;沉淀;白炭黑;浸出剂再生

中图分类号:TD925 文献标志码:A 文章编号:1672-7207(2014)03-0663-08

Recovery of silicon, vanadium and regeneration of lixiviant from V-Si-CO32--H2O system

LONG Sisi, FENG Qiming, ZHANG Guofan, OU Leming, LU Yiping

(School of Resources Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: A novel procedure of extracting vanadium and silicon from stone coal alkali leaching liquor was investigated. The procedures mainly consisted of three steps. Firstly, the silicon impurities were precipitated in the form of hydrated silica from the leaching liquor through introducing CO2 gas to maintain its pH 8.5. From the precipitates, carbon-white was made through further processes. Then, vanadium was extracted from the leaching liquor after precipitation by solvent extraction. Lastly, the lixiviant was recycled from the leaching liquor after two steps above through causticizing reaction. The results show that through the procedures of purification-extraction of vanadium-causticization, the desilication rate and recovery of vanadium of the leaching liquor reach 99.43% and 95.00%, respectively.And the purity and specific surface area of the amorphous carbon-white produced are up to 98% and 450 m2/g, respectively. The leaching rate of the recycled lixiviant solution is 81.7%. It is estimated that through this procedure 10 t of carbon-white are produced and 75% of lixiviant is recycled in the production of 1 t V2O5.

Key words: stone coal; precipitation; carbon-white; lixiviant reclamation

石煤型钒矿的湿法提钒处理方法主要包括酸浸、碱浸和水浸工艺。水浸工艺通常需要进行钠化焙烧的预处理,环境污染严重,钒浸出率低,因此,在处理石煤矿石时优势没有酸浸和碱浸明显[1]。氧化焙烧—酸浸工艺[2]在焙烧过程中直接利用空气中的氧气氧化石煤中的低价钒,不产生污染气体, 且钒浸出率高,是目前广泛应用的工艺。但是,酸浸工艺同时具有设备腐蚀大、浸出液中杂质种类多等缺点。采用石煤氧化焙烧—碱浸出—中和除杂—溶剂萃取—铵盐沉钒—煅烧制精钒的工艺提钒,具有钒浸出率高、设备腐蚀小、浸出液中杂质种类少、环境友好的特点[3]。然而,石煤矿石中含有大量硅矿物,部分硅矿物会在碱浸过程中和钒一起进入浸出液形成高硅钒浸出液,浸出液在进行萃取提钒前必须净化脱硅。传统的净化工艺[4-6]是采用添加硫酸的方式。该工艺需要消耗大量硫酸且碱性浸出剂无法再生,由于碱性浸出剂价格较硫酸昂贵许多,导致碱浸较酸浸提钒工艺相比成本偏高,利用碱浸提钒的工艺目前还没有得到广泛应用,因此,浸出液脱硅及浸出剂的再生问题能否得到解决将是碱浸提钒工艺处理石煤型钒矿能否得到推广应用的关键。本文作者针对石煤碱法提钒过程中产生的高硅钒浸出液,首先以CO2为pH调整剂从高浓度含硅浸出液中直接沉硅,使硅以副产品白炭黑的形式加以回收;回收硅后的溶液采用溶剂萃取工艺提钒;提钒后的余液采用苛化工艺提高溶液碱性,从而使浸出剂得以再生,取得了很好的效果。浸出剂的再生、回用以及浸出液脱硅净化渣的利用有效降低了碱浸提钒工艺的生产成本,同时增加了工艺的副产值。

1 试验

1.1 浸出液的制备及其性质

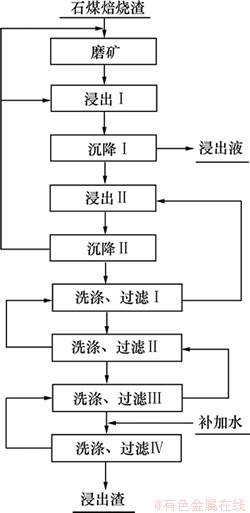

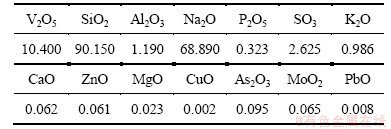

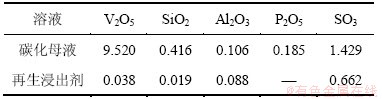

石煤矿样来自湖南某石煤型钒矿,矿样经磨矿、造球、烘干、氧化焙烧后获得焙烧渣,焙烧渣再进行NaOH浸出得到浸出液。浸出试验流程如图1所示,主要作业有磨矿、两段逆流循环浸出、固液分离和4次逆流洗涤。需要说明的是:为了降低浸出碱耗,提高浸出液中V2O5的含量,在一段浸出过程中,虽然浸出液固比为3:1,但在获取浸出液时,每次抽取量仅为0.9 L/kg焙烧渣。浸出液中的主要化学成分分析如表1所示。从表1可以看出:浸出液中硅质量浓度极高,是提钒过程中最主要的杂质成分。

1.2 工艺流程

图2所示为石煤碱浸液中硅、钒的回收及浸出剂的再生新工艺原则流程图。该流程主要包括以下工序:浸出液的净化(脱硅)、钒的提取、浸出剂的再生。其显著特点是脱硅过程中产生的滤渣可制备成高比表面积白炭黑产品,再生后的浸出剂可直接用于浸矿,苛化过程中产生的苛化渣(主要成分为CaCO3)煅烧后可循环利用。

图1 浸出工艺流程图

Fig. 1 Flow sheet of leaching process

表1 浸出液中的主要化学成分(质量浓度)

Table 1 Main chemical compositions of leaching solution g/L

图2 新工艺原则流程图

Fig. 2 Flow sheet in principle of novel process

1.3 试验原理及方法

1.3.1 脱硅试验

碳化法脱硅过程即浸出液的净化和白炭黑生成过程。一方面,需要脱除浸出过程中积累的大量硅杂质,以利于净化液进行萃取回收V2O5;另一方面,需要保证产生的滤渣具有杂质成分少、粒径小、比表面积大的特点,便于洗涤后制备成白炭黑产品。因此,脱硅过程应尽可能提高硅的沉淀率,减少钒的损失,增大滤渣的比表面积。

碳化法脱硅过程是一个包含气-液-固多相反应的复杂过程,且由于硅酸钠水溶液同时具有溶液和胶体的性质,硅酸钠溶液的组成成分和结构性质随环境温度、存放时间、溶液pH等多种因素影响,因此,碳化反应机理是极其复杂的[7-9]。实际上,由Si(OH)4沉淀生成SiO2的过程是固体二氧化硅溶解的逆过程,二氧化硅在水中的溶解度受结构、颗粒粒度、温度、溶剂性质等多个因素的影响,其中溶剂pH是影响最大的因素[10]。无定形SiO2溶解度最大,石英则很难溶解,其他形式的SiO2溶解度则介于无定形SiO2与石英的溶解度之间。图3所示为25 ℃下无定形SiO2与石英在水中的溶解度随pH的变化。由图3可知:在酸性和中性条件下,无定形SiO2和石英在水中的溶解度都很小且几乎不随溶液pH的变化而变化;而当pH>9时,无定形SiO2和石英在水中的溶解度随pH的增加急剧上升。因此,随着硅酸盐水溶液pH降至9以下时,溶液中绝大部分二氧化硅因溶解度剧降而从溶液中沉淀析出。

将制备的浸出液在一定温度的恒温水浴中通入CO2气体,固定搅拌速度和CO2充气量,调节体系pH至规定值后固液分离,分析滤液中硅含量,计算硅沉淀率。滤渣用去离子水洗涤2次,再在无水乙醇中陈化3 h,最后于120 ℃真空干燥6 h后测定比表面积,分析滤渣中的钒含量,计算钒损失率,洗水与滤液合并计量。无水乙醇陈化的目的是利用醇类洗去胶粒表面配位水分子,并以烷基取代颗粒表面的OH基,使其在干燥时保留部分内部孔结构而得到较小团聚的粉体。试验中还采用了相对分子质量为6 000的聚乙二醇(PEG6000)作为表面活性剂,其用量为7 g/L浸出液。

图3 25 ℃时无定形SiO2和石英的溶解度与pH的关系

Fig. 3 Effect of pH on solubility of amorphous silica and quartz at 25 ℃

1.3.2 白炭黑的制备及表征

碳化法脱硅产生的滤渣主要成分为SiO2,中间还夹带了少量钒、铝等杂质需要脱除以达到白炭黑的质量要求。酸洗对硅渣中许多无机元素脱除效果好[11],采用稀硫酸对滤渣进行洗涤可以有效地净化滤渣并回收脱硅过程中损失的V2O5。滤渣用一定浓度的稀硫酸洗涤2次,无水乙醇陈化3 h,于120 ℃真空干燥6 h后测定比表面积,分析滤渣中的钒含量,计算经滤渣净化回收了部分V2O5后脱硅过程的钒损失率。

滤渣经稀硫酸洗涤后获得的产物是否为白炭黑需要进一步表征。首先根据HG/T 3061—2009(《橡胶配合剂 沉淀水合二氧化硅》)技术要求,对产物进行多元素分析、热重分析、比表面积测定和白度测定,然后,对产物物相和形貌通过X线衍射、红外光谱和SEM扫描电镜分析进行表征。

1.3.3 提钒试验

由于采用萃取—铵盐沉钒—煅烧制精钒的工艺技术比较成熟,因此,这里只对弱碱性条件下的萃取提钒过程进行简要说明。

1.3.4 苛化试验

苛化过程即浸出剂的再生过程需要将体系pH调至最优浸出条件,以便于再生后的浸出剂返回浸矿。提钒后余液在一定温度的恒温水浴中,加入一定量的CaO搅拌一段时间后,固液分离,滤渣用去离子水洗涤,洗水与滤液合并计量。由于洗水的加入,滤液需要进一步浓缩提高pH,待体系pH升至指定值时,浸出剂得以再生[12-13]。苛化过程涉及的主要化学反应如下。

Na2CO3+Ca(OH)2(s)→CaCO3(s)+2NaOH

苛化率(即碳酸钠的转化率, )按下式计算:

)按下式计算:

式中:c0和c1分别为原液和苛化完成液中的Na2CO3浓度。

1.4 分析方法

溶液体系中高浓度的钒和硅用化学滴定法分析;低浓度的钒、硅和溶液中的杂质用ICP-AES分析;固体样中的多元素分析采用X线荧光(XRF)分析;白炭黑比表面积用氮吸附法测定;溶液中CO32-由滴定法测定。

2 试验结果及讨论

2.1 高硅钒浸出液碳化法脱硅条件试验

采用单因素试验法考察脱硅温度、反应终点pH及CO2流速和搅拌速度对硅沉淀率、钒损失率和滤渣比表面积的影响。由于试验是在敞开体系中进行的,因此,没有考虑CO2分压的影响。脱硅条件试验规模为200 mL浸出液/次,按前面方法进行试验。

2.1.1 温度对脱硅效果的影响

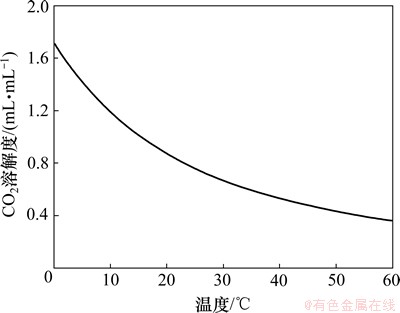

控制反应终点pH为9左右,在CO2流速为0.6 L/min,搅拌速度为600 r/min的条件下,研究脱硅温度对钒损失率、硅沉淀率和渣样比表面积的影响,结果如图4(a)所示。由图4(a)可见:钒损失率和滤渣比表面积均随反应温度的升高而减少;从硅酸的聚合作用上讲,当反应温度在60 ℃以下时,生成的不是多孔的胶体颗粒而是半透明的凝胶,夹带了大量V2O5,造成V2O5大量损失,因此,反应温度不宜过低;同时,温度对硅沉淀生成的反应速度和产物的粒径影响显著,在沉淀形成过程中,颗粒粒度主要由成核速度和核增长速度决定,而后者比前者更容易受温度影响;随体系温度升高,核增长速度增大,形成的一次粒子粒径越大,比表面积越小。从试验结果还发现:高温时碳化反应速度极慢,95 ℃时甚至很难将体系pH降低至9以下,其原因是温度对CO2溶解度有很大的影响。图5所示为1×105 Pa时,二氧化碳的溶解度(体积比)和温度的关系。由图5可以看出:二氧化碳的溶解度随温度的升高而降低;此外,随着反应温度的升高,硅的溶解度增大,不利于过饱和硅溶液的形成,反应时间将大大延长,一次粒子粒径增大,比表面积减小,因此,反应温度也不宜过高。经综合考虑,脱硅温度以60 ℃左右为宜。

图4 脱硅温度、终点pH、CO2流速、搅拌速度对钒损失率、硅沉淀率和滤渣比表面积的影响

Fig. 4 Effect of temperature, pH, gas flow rate of CO2 and stirring rate on loss rate of vanadium, precipitation rate of silicon and specific surface area of precipitated silica powder

图5 在105 Pa时二氧化碳的溶解度(体积比)与温度的关系

Fig. 5 Relationship between solubility of CO2 gas and temperature at 105 Pa

2.1.2 终点pH对脱硅效果的影响

在脱硅温度为60 ℃,搅拌速度为600 r/min,CO2流速为0.4 L/min的条件下,研究反应终点pH对钒损失率、硅沉淀率和渣样比表面积的影响,结果如图4(b)所示。由图4(b)可见:反应终点pH对滤渣比表面积的影响较大随着终点pH的降低,滤渣比表面积也逐渐增大。这是因为滤渣的比表面积取决于粒子粒度,而粒子粒度与硅酸的聚合度相关。根据戴安邦等提出的硅酸聚合机制,在碱性或微酸性溶液中,硅酸的聚合作用主要是硅酸分子和硅酸负离子四配位之间的氧联反应。硅在pH大于11时,大部分以硅酸根离子的形式存在;在pH为8~10的碱性溶液中,硅溶胶迅速发生聚合反应并聚集在一起形成沉淀或者硅凝胶,产物比表面积随体系pH降低而增大。当pH降至8.5以下时,CO2对于体系pH的调节效率很低,且由于碳化母液将进一步用于浸出剂的回用,碳化反应终点pH越低,后续的苛化反应消耗的石灰量越大。因此,为了避免造成不必要的浪费,确定本次试验反应终点pH为8.5。

2.1.3 CO2流速对脱硅效果的影响

在脱硅温度为60 ℃,搅拌速度为600 r/min,终点pH为8.5的条件下,研究CO2流速对硅沉淀率、钒损失率和滤渣比表面积的影响,结果如图4(c)所示。由图4(c)可知:钒的损失率随CO2流速的增大而减小,硅渣比表面积随CO2流速的增大而增大。这可能是由于CO2流速对反应速率有显著的影响,CO2流速越小,反应速率越慢,硅沉淀在溶液中生长的时间增长,产物的粒径也越大。一般地,滤渣比表面积越大,吸附的V2O5量应该越多。而图4(c)中的试验结果表明滤渣比表面积越大,V2O5的损失量反而越少,说明V2O5除了以吸附形式损失外,还有可能以被层间水或结晶水夹带的形式损失。当CO2流速达到0.4 L/min时,钒损失率减小和滤渣比表面积增大的幅度都不大,因此,选定CO2流速为0.4 L/min。

2.1.4 搅拌速度对脱硅效果的影响

在脱硅温度为60 ℃,CO2流速为0.4 L/min,终点pH为8.5的条件下,研究搅拌速度对硅沉淀率、钒损失率和滤渣比表面积的影响,结果如图4(d)所示。由图4(d)可知:滤渣比表面积随搅拌速度增大而增大。这是因为搅拌速度越大,CO2传质越均匀,有利于沉淀在瞬间生成。考虑到强搅拌时的能源消耗及反应液不至于向外溅射,选定搅拌速度为600 r/min。

2.2 白炭黑的制备及表征

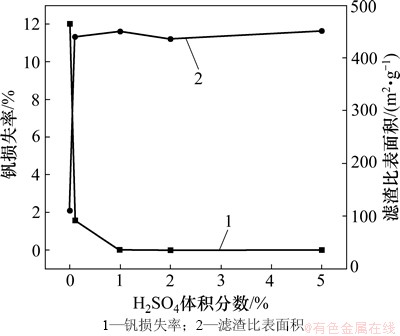

2.2.1 洗涤试验

试验原料为碳化法脱硅工艺获得的滤渣,碳化条件如下:反应温度为60 ℃,PEG6000用量为1.5 g,CO2流速为0.4 L/min,搅拌速度为600r/min。考察稀硫酸浓度对V2O5回收效果和产物比表面积的影响,试验规模为30 g滤渣/次,试验结果如图6所示。由图6可知:用稀硫酸洗涤滤渣可以使碳化脱硅过程中V2O5的损失率从水洗的12%降至1%以下,滤渣的比表面积也大幅度增加。这可能是钒的化合物在硫酸中的溶解度很大,用稀硫酸冲洗过后的氧化硅渣中残留的钒含量极小,且硫酸的加入会与滤渣中残留的碳酸钠和碳化过程中生成的碳酸氢钠结晶体发生剧烈的化学反应,生成二氧化碳气体,二氧化碳气体溢出产生强烈的气泡,使产物结构更加松散,比表面积增大。当硫酸体积分数大于1%时,滤渣中钒回收效果和比表面积都没有明显变化,因此,选择体积分数为1%的稀硫酸对滤渣进行洗涤以获得白炭黑产品。

图6 硫酸体积分数对V2O5回收效果和滤渣比表面积的影响

Fig. 6 Effect of H2SO4 concentration on loss rate of vanadium and specific surface area of precipitated silica powder

2.2.2 产物物相和形貌分析

对于制备白炭黑的最佳工艺参数进行试验验证。试验规模为200 mL浸出液/次。脱硅条件如下: 反应温度为60 ℃,PEG6000用量为1.5 g,CO2流速为0.4 L/min,搅拌速度为600 r/min。白炭黑制备条件为:滤渣用体积分数为1%稀硫酸洗涤2次,无水乙醇陈化3 h,于120 ℃真空干燥6 h后作为最终产物进行化学成分分析、白度测试和比表面积测定。由于滤液需要进一步实现浸出剂的再生,这一部分的洗水与滤液分别计量。产物化学成分分析、白度测试和比表面积测定结果表明:样品中SiO2质量分数为98.56%,白度为96.35%,比表面积为450 m2/g。

图7所示为对产物物相和形貌分析的粉末X线衍射(XRD)分析图谱、红外光谱(FT-IR)分析图谱和扫描电镜(SEM)分析图像。

图7(a)中未出现尖锐的晶体衍射峰,只在2θ=25°左右出现1个非晶衍射峰,说明制备的二氧化硅样品为为非晶体结构。

从图7(b)可见:802.3 cm-1峰和469.2 cm-1处的峰为Si—O键对称伸缩振动峰,说明颗粒中含有部分Si—O四面体结构;1 095.6 cm-1处的峰为Si—O—Si反对称伸缩振动峰;3 412.2 cm-1和1 624.5 cm-1处的峰为水的吸收峰;950.5 cm-1处的峰主要为表面Si—OH的弯曲振动峰,其易于与水结合,煅烧后该峰消失。产物的FT-IR图谱与白炭黑的标准图谱基本一致,由此可确定所制备的样品确为白炭黑。

从图7(c)可以看出:样品颗粒呈近似球形,颗粒之间团聚现象严重,平均粒径为50 nm左右。

综上所述,碳化法脱硅反应得到的滤渣经简单酸洗后可制备成为高比表面积无定形白炭黑产品,产品呈球形簇团状。

2.3 提钒试验

结合Clark等绘制的V-H2O系浓度对数图、德尔汤比等绘制的φ-pH图以及钒在不同pH的水溶液中存在的主要平衡反应可以预测:钒在碳化反应终点pH范围内(8<pH<9)主要以偏钒酸根V4O124-的形式存在于溶液中。寻找到一种能与偏钒酸根V4O124-作用而使其从水相转入有机相的有效萃取剂是萃取试验成功的关键。结合文献[14-15],作者选用萃取剂N235和N263分别对pH为8.5左右的弱碱性溶液中钒的萃取效果进行了对比研究,并对试验条件进行了优化,最终确定选用N263作为萃取剂、仲辛醇作为协萃剂、磺化煤油作为有机溶剂进行萃取提钒试验。

图7 滤渣的XRD图、FT-IR图和SEM图

Fig. 7 XRD pattern, FT-IR spectrum and SEM image of precipitated silica powder

按图2中工艺流程进行试验,萃取剂由N263、仲辛醇和磺化煤油3种物质组成。萃取工艺条件如下:萃取剂中,N263、仲辛醇、煤油体积比为1:2:7,相比为1:4,平衡时间为5 min,室温。反萃工艺条件如下:反萃剂是质量分数为6%的氢氧化钠,反萃相比为2:1,混合时间为15 min,分相时间为10 min,室温。铵盐沉钒条件如下:沉钒温度为30 ℃,pH为6~8,硝酸铵用量为80 g/L,搅拌时间为2 h。通过偏钒酸铵沉淀法获得的偏钒酸铵通过煅烧得到最终的五氧化二钒产品,在煅烧温度为540 ℃、煅烧时间为1 h的条件下可以获得纯度为99.58%的五氧化二钒产品。整个提钒过程钒的回收率大于95%。

2.4 苛化试验

苛化条件试验规模为250 mL提钒余液/次。苛化反应原料为提钒余液,pH为8.5左右。提钒余液组成:CO32-浓度为0.25~0.30 mol/L,HCO32-浓度为0.40~ 0.60 mol/L。图8所示为CaO用量、苛化反应时间和温度对碳酸钠转化率的影响。由图8可知:碳酸钠转化率随CaO用量的增加、苛化反应时间的延长和苛化温度的升高而增加。苛化反应的最佳条件如下:CaO用量为60 g/L,苛化反应时间为1 h,苛化反应温度为95 ℃,搅拌速度为400 r/min。在最佳条件下进行苛化反应,浸出液pH由苛化前的8.50增大到13.84。再生浸出剂中主要化学成分的ICP分析结果见表2。由表2可看出:再生浸出剂成分较单纯,杂质含量低,可作为合格浸出剂返回浸出工艺使用。

图8 CaO用量、苛化时间和苛化温度对碳酸钠转化率的影响

Fig. 8 Effect of CaO content in surpernatant, causticizing time and temperature on Na2CO3 conversion

表2 碳化母液与再生浸出剂中的几种主要化学成分(质量浓度)

Table 2 Mass concentrationof main chemical compositions of purified solution and recycled caustic soda solution g/L

2.5 再生浸出剂浸矿

为了验证再生浸出剂的浸出效率,按图1中浸出试验流程进行2组浸出试验:试验一选用再生浸出液作为浸出剂;试验二为对比试验组,选用质量浓度为80 g/L的NaOH溶液作为浸出剂。试验结果表明:利用质量浓度为80 g/L的NaOH溶液和再生浸出剂浸矿时,V2O5的浸出率分别为85.15%和81.70%。

流程数质量计算结果表明:每加入80 kg NaOH,通过苛化反应可回收60 kg左右,即75%左右的浸出剂可以实现再生。浸出剂不可能实现100%回收,浸出剂会在浸出和碳化反应过程中损失。一方面,浸出过程中20%左右的碱会被浸出渣带走或在洗水中循环;另一方面,碳化反应体系中存在大量NaHCO3,由于NaHCO3的溶解度低而易于从碱性环境中沉淀析出,这就导致部分碱在碳化反应滤渣中损失。

3 结论

(1) 浸出液中有价元素Si可在脱硅过程中加以回收;脱硅温度、终点pH、CO2流速、洗涤酸浓度对产物性质均有较大影响,在最优脱硅条件下,硅沉淀率为99.43%,钒回收率为99%;获得的含硅滤渣可制备比表面积达450 m2/g的白炭黑产品。

(2) CaO用量和反应温度对苛化反应效果影响较大,在最优苛化条件下,体系碳酸钠转化率为90.91%。

(3) 再生浸出剂浸矿效果良好,钒浸出率为81.7%。

参考文献:

[1] ZHANG Yimin, BAO Shenxu, LIU Tao, et al. The technology of extracting vanadium from stone coal in China: History, current status and future prospects[J]. Hydrometallurgy, 2011, 109: 116-124.

[2] 汪平, 冯雅丽, 李浩然, 等. 采用氧化焙烧-酸浸法从高碳石煤中提钒试验研究[J]. 中南大学学报(自然科学版), 2011, 42(10): 2917-2921.

WANG Ping, FENG Yali, LI Haoran, et al. Extracting vanadium from high-carbon stone coal by oxidizing roasting-acid leaching method[J]. Journal of Central South University (Science and Technology), 2011, 42(10): 2917-2921.

[3] HE Dongsheng, FENG Qiming, ZHANG Guofan, et al. An environmentally-friendly technology of vanadium extraction from stone coal[J]. Minerals Engineering, 2007, 20: 1184-1186.

[4] 谭爱华. 某石煤钒矿空白焙烧-碱浸提钒工艺研究[J]. 湖南有色金属, 2008, 24(1): 24-26.

TAN Aihua. Study on extraction V2O5 by the roasting-alkaline leaching from vanadium-containing stone coal[J]. Hunan Nonferrous Metals, 2008, 24(1): 24-26.

[5] 李婕, 姚金江, 王智友, 等. 石煤钒矿碱法提钒浸出液净化过程中回收白炭黑的工艺研究[J]. 湖南有色金属, 2011, 27(6): 26-29.

LI Jie, YAO Jinjiang, WANG Zhiyou, et al. Purification process study on recovery white carbon from the acid leaching solution of stone coal vanadium ore with alkali[J]. Hunan Nonferrous Metals, 2011, 27(6): 26-29.

[6] 肖超, 肖连生, 李青刚. 石煤提钒碱浸液的除硅试验研究[J]. 稀有金属与硬质合金, 2010, 38(1): 8-10.

XIAO Chao, XIAO Liansheng, LI Qinggang. Silicon removal from the alkali leach liquor of carbonaceous shale containing vanadium[J]. Rare Metals and Cemented Carbides, 2010, 38(1): 8-10.

[7] 赵仁保. CO2对硅酸钠-丙烯酰胺溶液聚合行为及产物性质的影响[J]. 高等学校化学学报, 2009, 30(3): 596-600.

ZHAO Renbao. Influence of carbon dioxide on the polymerization behavior of sodium silicate-acrylamide solution and products properties[J]. Chemical Journal of Chinese Universities, 2009, 30(3): 596-600.

[8] 涂华, 周永华, 余嘉耕, 等. 碳化法生产白炭黑工艺研究及反应动力学分析[J]. 无机盐工业, 2001, 33(6): 8-11.

TU Hua, ZHOU Yonghua, YU Jiageng, et al. Study on the technology and reaction kinetics in preparing silica pigment by carbonization[J]. Inorganic Chemicals Industry, 2001, 33(6): 8-11.

[9] 李歌, 马鸿文, 刘浩, 等. 粉煤灰碱溶脱硅液碳化法制备白炭黑的试验与硅酸聚合机理研究[J]. 化工学报, 2011, 62(12): 3581-3587.

LI Ge, MA Hongwen, LIU Hao, et al. Preparation of precipitated silica from desilicated solution of high-alumina fly ash by dissolution with alkali: experiment and principle of polymerization of silicic acid[J]. CIESC Journal, 2011, 62(12): 3581-3587.

[10] Nangia S, Garrison B J. Reaction rates and dissolution mechanisms of quartz as a function of pH[J]. J Phys Chem A, 2008, 112: 2027-2033.

[11] 李成义, 赵立新, 王志, 等. 酸洗去除冶金硅中的典型杂质[J]. 中国有色金属学报, 2011, 21(8): 1989-1995.

LI Chengyi, ZHAO Lixin, WANG Zhi, et al. Removal of representative impurities from metallurgical grade silicon by acid leaching[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(8): 1989-1995.

[12] 余政哲, 孙德智, 杜龙弟, 等. 苛化法再生乙烯生产中的废碱液[J]. 石油化工, 2003, 32(6): 517-520.

YU Zhengzhe, SUN Dezhi, DU Longdi, et al. Regeneration of spent caustic from ethylene plant by cauticization[J]. Petrochemical Technology, 2003, 32(6): 517-520.

[13] 李莉, 曲景奎, 齐涛, 等. 熔盐法活化处理含铬红土镍矿浸出液的铬铝分离及碱液循环[J]. 过程工程学报, 2010, 10(4): 668-672.

LI Li, QU Jingkui, QI Tao, et al. Separation of chromium and aluminum and alkali recirculation in treatment of laterite nickel ore containing chromium with NaOH solution[J]. The Chinese Journal of Process Engineering, 2010, 10(4): 668-672.

[14] Einadi Y A, Awwad N S, Nayl A A. A comparative study of vanadium extraction by Aliquat-336 from acidic and alkaline media with application to spent catalyst[J]. Int J Miner Process, 2009, 90: 115-120.

[15] Bal Y, Bal K E, Cote G. Kinetics of the alkaline stripping of vanadium(Ⅴ) previously extracted by Aliquat 336[J]. Minerals Engineering, 2002, 15: 377-379.

(编辑 陈灿华)

收稿日期:2013-03-21;修回日期:2013-05-24

基金项目:国家自然科学基金资助项目(50974133);国家科技支撑计划项目(2012BAB07B02)

通信作者:张国范(1971-),男,湖南常德人,博士,副教授,从事矿产资源综合利用和有色金属矿选矿技术研究;电话:0731-88830913;E-mail: Zhangguofan2002@163.com