搅拌摩擦焊清洁制造工艺过程中的缺陷分析

来源期刊:中国有色金属学报(英文版)2017年第7期

论文作者:Noor Zaman KHAN Zahid A. KHAN Arshad Noor SIDDIQUEE Abdulrahman M. AL-AHMARI Mustufa H. ABIDI

文章页码:1507 - 1516

关键词:清洁焊件工艺;搅拌摩擦焊;工艺参数

Key words:clean welding process; friction stir welding; defect; process parameter

摘 要:清洁生产是制造工艺过程中追求的目标。搅拌摩擦焊是一种比目前最好的传统焊接工艺更好、对环境损害更低的连接技术。搅拌摩擦焊工艺的能量效率高、无耗材、无损耗、无辐射。因此,它是一种能获得优质焊接接头的清洁焊接工艺。但它在焊接过程中会产生缺陷,为使其成为一种可靠的生产工艺,需要对其进行进一步优化。本文作者对搅拌摩擦焊接头的缺陷进行表征。结果表明,缺陷的产生是由于焊件过程的产生的热量不够、搅拌针附近的物质移动不充分、搅拌针后部的材料致密化不够。焊接过程中产生的热量和物料的搅拌程度取决于搅拌摩擦焊的焊接参数。焊接参数选择不当,可导致缺陷的产生。本文所得结果来源于文献和实验。根据各种缺陷的特征,如其可能产生的位置、减少缺陷产生的主要参数等,提出了减少缺陷产生的一些措施。

Abstract: Striving for cleaner production is a sought-after manufacturing philosophy. Friction stir welding (FSW) is a joining technique with par excellence and far less invasive to the environment than even best conventional welding processes. It is energy efficient and free from consumables, affluent and radiations. It is, thus, accepted as a clean welding process that can produce acceptable quality joints. It suffers from some major challenges of defects of its own kind that subject the process open to improvements so as to prove itself a reliable production process. This study presents a holistic characterization of defects commonly found in FSW joints. The finding of the present study reveals that most defects are caused by inadequate heat generation, improper material movement around the pin and inadequate material consolidation behind the pin. The amount of heat generation and material stirring depends on several FSW parameters which may lead to the defect formation, if not selected properly. The results reported in this work are derived from sound literature support and experimentation. Prescriptions are made in the form of characteristics of defects such as likelihood of their location, main responsible parameters along with the recommendations for minimizing them.

Trans. Nonferrous Met. Soc. China 27(2017) 1507-1516

Noor Zaman KHAN1, Zahid A. KHAN1, Arshad Noor SIDDIQUEE1, Abdulrahman M. AL-AHMARI2, Mustufa H. ABIDI2

1. Department of Mechanical Engineering, Jamia Millia Islamia (A Central University), New Delhi, PIN-110025, India;

2. Princess Fatima Alnijris Research Chair for Advanced Manufacturing Technology, Advanced Manufacturing Institute, King Saud University, Riyadh-11421, Saudi Arabia

Received 2 May 2016; accepted 15 December 2016

Abstract: Striving for cleaner production is a sought-after manufacturing philosophy. Friction stir welding (FSW) is a joining technique with par excellence and far less invasive to the environment than even best conventional welding processes. It is energy efficient and free from consumables, affluent and radiations. It is, thus, accepted as a clean welding process that can produce acceptable quality joints. It suffers from some major challenges of defects of its own kind that subject the process open to improvements so as to prove itself a reliable production process. This study presents a holistic characterization of defects commonly found in FSW joints. The finding of the present study reveals that most defects are caused by inadequate heat generation, improper material movement around the pin and inadequate material consolidation behind the pin. The amount of heat generation and material stirring depends on several FSW parameters which may lead to the defect formation, if not selected properly. The results reported in this work are derived from sound literature support and experimentation. Prescriptions are made in the form of characteristics of defects such as likelihood of their location, main responsible parameters along with the recommendations for minimizing them.

Key words: clean welding process; friction stir welding; defect; process parameter

1 Introduction

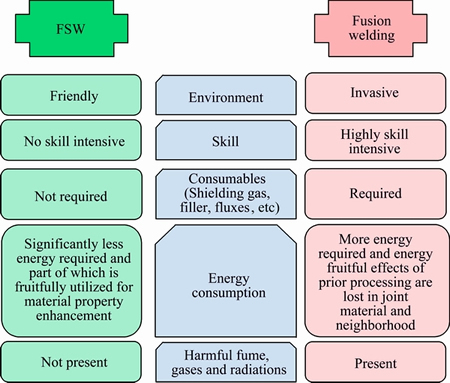

Welding plays a vital role in producing complex products that are difficult to manufacture as a single component. Various welding processes are used on a large scale for different applications. Generally, fusion welding processes enjoy the status of most preferred joining processes in the industries. Fusion welding processes require several consumables including filler metal and fluxes during welding and also release fumes, harmful gases and radiations which adversely affect the environment. Additionally, the fusion welded zone and material in its neighborhood suffer deterioration of the advantageous effects of the previous processing on the base materials. Evidently, fusion welding processes are invasive to the environment. A fabrication activity such as fusion welding, which is being industrially utilized on a mass scale, yet remains highly invasive to the environment, must be checked with a clean alternative process. An autogenous solid state welding process like friction stir welding (FSW) has recognized as an effective alternative process which minimizes negative environmental impacts, conserves natural resources and energy, and is safe for workers and consumers and economically sounds. FSW, being a solid state welding process, does not require use of consumables (filler material, fluxes and shielding gas, etc.) for joining, produces no harmful emissions, is safe to the human (its features are represented in Fig. 1) and is, therefore, considered to be an energy efficient, environment friendly and clean material joining process.

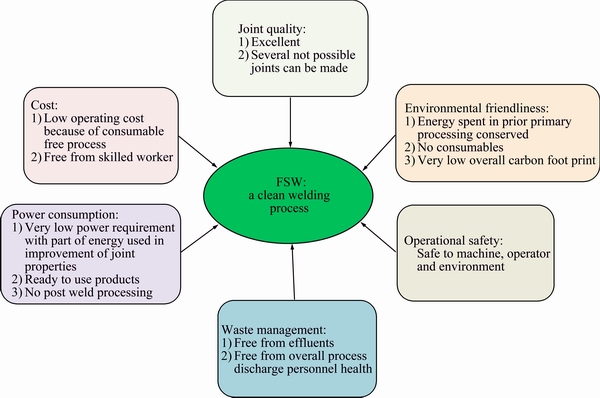

Owing to such qualities, FSW has been regarded as a clean welding process for joining similar and dissimilar materials as shown in Fig. 2. FSW is distinguished for its ability to join dissimilar alloys which are otherwise unweldable by conventional technique. It has been emerged as a process of choice for joining aerospace grade aluminium alloys (2xxx and 7xxx series) that are difficult to weld by fusion welding. Moreover, fusion welding processes have their own limitations with regard to welding defects such as, hydrogen embrittlement, porosity, undesirable metallurgical changes and micro- structural discontinuities. Such defects do not exist in FSW which in turn produces joints free from these fusion related defects. However, FSW also poses concerns of some characteristic defects that are different from fusion welding processes and significantly affect the quality of the welded joint.

Fig. 1 Advantages of friction stir welding over fusion welding

Fig. 2 Friction stir welding as clean welding process

Defect formation is more prominent in FSW of dissimilar alloys mainly due to difference in their softening temperature, metallurgy, chemistry, thermal conductivity and flow stress which hinders the material movement and improper heat distribution. Weld defects lead to failures and question the suitability of the FSW as a sound, reliable and dependable alternative. Producing defect-free joint continues to remain one of the major challenges for FSW. Thus, for the FSW as a clean welding process, it is essential to eliminate defects, and equally importantly, is a clear understanding of the occurrence of defects.

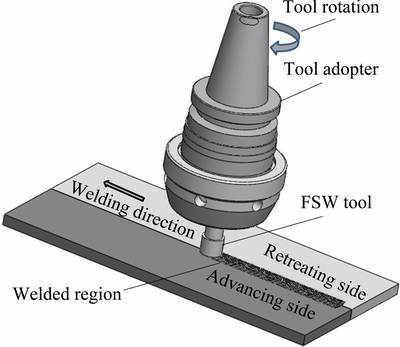

FSW first came into being in 1991 when THOMAS et al [1] invented a new family of solid-state joining techniques to weld aluminium sheets. The FSW process uses a combination of frictional heating coupled with heat of plastic deformation affected by a rotating cylindrical shouldered pin [1]. FSW has now established itself to be a remarkable solid state welding technique to effectively join similar and dissimilar aluminum alloys [2]. In FSW, a rotating non-consumable tool consisting of a probe (also known as pin) and shoulder plunges into the joint line of the base material, generating heat through both friction and plastic deformation, and traverses along the joint line to perform welding, as shown in Fig. 3.

Fig. 3 Schematic diagram of friction stir welding process

Frictional heat generated by tool rotation softens the material under the shoulder and the advancement of the tool severely plastically deforms the material, pushing it simultaneously from front to the back and forging it to complete the joint. FSW has emerged as one of the most significant achievements in the field of joining of aluminum alloys [3]. The use of FSW is extended for welding high melting temperature materials such as steel [4]. FSW technique has already been applied to successfully joining train panels, air frames, cryogenic tanks, marine structures, and automotives.

In recent years, many industrial sectors such as marine, automobile and aerospace have been extensively using FSW with a persistent interest in the understanding of factors that result in defect formation during FSW [5]. Flaws such as tunneling, kissing-bonds (KB), joint line remnant (JLR), incomplete root penetration, voids and hooking defects in FSW are quite different from defects of conventional fusion welding. These defects are generally caused by inadequate heat generation, improper material movement around the pin and inadequate material consolidation behind the pin. The amount of heat generation and material stirring depend on several parameters such as tool design, tool rotation and traverse speed, depth of tool plunge, tool tilt angle, tool pin offset and workpiece position, and these factors may, consequently, lead to the defect formation, if not selected properly. Heat generation is primarily affected by tool rotational and traverse speed. Tool rotation balances the material movement from advancing side (AS) to retreating side (RS). It also affects the heat generation during welding that has significant effects on the mechanical properties and the quality of welded joints. The generated heat increases by increasing the tool rotational speed and vice versa. Tool traverse speed affects the heat input per unit time and the material consolidation behind the tool pin. Higher tool traverse speed delivers lower heat input per unit time, reducing welding temperature and consequently resulting in higher flow stress. High flows stress is one of the main causes of deficient material movement which hampers material consolidation. Similarly, tool design, depth of tool plunge, tool tilt angle, tool pin offset etc. also play vital role during plastic deformation at the time of stirring and consequently their values should be chosen carefully to obtain desired results.

Some researchers investigated the effect of FSW parameters on defect formation. DEHGHANI et al [6] investigated the effects of FSW parameters on the formation of intermetallic compounds (IMCs) and tunnel formation during dissimilar joining of Al5186 and mild steel. KHODIR and SHIBAYANAGI [7] studied the effect of FSW parameters on the formation of kissing bond (KB) during dissimilar joining of aluminium alloys and found that an increase in traverse speed results in the formation of KB. NAKATA et al [8] studied the effect of FSW parameters on defect formation and reported that defects were formed at high traverse speeds coupled with slow tool rotation and inadequate tool plunge depth. KADLEC et al [9] investigated the effect of size of KB defect on fatigue strength of AA7475 alloy. They found that a KB size of 315 μm is insignificant to hamper fatigue and static behavior.

The foregoing literature reveals that various defects are formed during FSW whereas the researchers have focused on specific flaws in part meal. It is imperative that a holistic understanding of various FSW defects is needed for the inclusive development of FSW to emerge as a proven and reliable clean joining process. Keeping this important aspect in view, in the present work, a detailed analysis was performed on most prevalent FSW defects (mentioned above), and meticulous efforts were made to characterize these defects along with recommendations to minimize their occurrence. The findings are substantiated by performing some experiments alongside intensive literature.

2 Formation of defects

Low heat generation is one of the most prominent causes of defect formation in FSW. The heat produced softens the material directly under the shoulder. It, however, does not mean that excessive heat input can improve the joint quality. Heat input is observed to increase by increasing the tool rotation and plunge depth, and decreasing the traverse speed. Higher heat input condition is favorable to the formation of IMC [10] which are hard and brittle and can reduce the ductility and strength of the joint. Higher heat input also results in grain growth and may cause the strength to suffer. At lower heat input, on the other hand, insufficient softening of the material welded occurs and flow stress increases, which in turn leads to inefficient consolidation and inadequate mixing. So, appropriate heat input is important to form good quality joints during FSW. Specific defect, however, occurs due to very specific relevant causes.

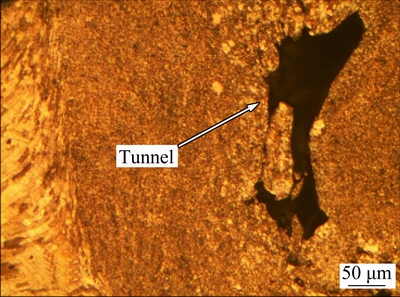

2.1 Tunneling defect

Tunneling defect is a common defect in FSW which significantly affects mechanical properties of the welded joints. BALOS and SIDJANIN [11] investigated the effect of tunneling on mechanical properties and reported that the presence of tunneling defect resulted in the reduction of mechanical properties by 25%-82%. Also,  et al [12] investigated the effect of welding parameters on tunneling and found that the welding parameters (welding and rotation speed) have significant effect on tunnel formation. It is not normally visible on the surface as it is formed inside, below the surface. Tunneling defect generally appears on the AS between the thermo-mechanically affected zone (TMAZ) and the weld nugget. FSW of AA7475 was performed as part of this study at 710 r/min and 50 mm/min using cylindrical pin profile and tunneling defect was obtained as shown in Fig. 4. Like most FSW defects, tunneling also occurs due to improper selection of welding process parameters that include tool rotation and traverse speed, applied pressure, tool offset and improper design of tool [13-16]. Improper selection of these parameters results in insufficient plasticization of the material welded and imbalance in material movement around the tool pin. Under such situation, the tool traverses more depositing less material in the space vacated behind it, consequently forming the tunnel. It has been reported that the tunneling defects are also formed due to low heat input [16]. Lower heat input results in higher flow stress, causing deficient material movement which hampers material consolidation.

et al [12] investigated the effect of welding parameters on tunneling and found that the welding parameters (welding and rotation speed) have significant effect on tunnel formation. It is not normally visible on the surface as it is formed inside, below the surface. Tunneling defect generally appears on the AS between the thermo-mechanically affected zone (TMAZ) and the weld nugget. FSW of AA7475 was performed as part of this study at 710 r/min and 50 mm/min using cylindrical pin profile and tunneling defect was obtained as shown in Fig. 4. Like most FSW defects, tunneling also occurs due to improper selection of welding process parameters that include tool rotation and traverse speed, applied pressure, tool offset and improper design of tool [13-16]. Improper selection of these parameters results in insufficient plasticization of the material welded and imbalance in material movement around the tool pin. Under such situation, the tool traverses more depositing less material in the space vacated behind it, consequently forming the tunnel. It has been reported that the tunneling defects are also formed due to low heat input [16]. Lower heat input results in higher flow stress, causing deficient material movement which hampers material consolidation.

Fig. 4 Tunneling defect of welded joints

Tunnel acts as a site for stress concentration and also reduces the load carrying cross-sectional area, thus, adversely affects the mechanical properties. To avoid tunneling defect, some researchers focused on increasing heat input and improving the material flow by supplying additional secondary energy. The additional energy was, however, supplied with an aim to increase traverse speed (consequently productivity as well) yet avoiding defects. KOHN et al [17] used a laser beam for preheating the workpieces ahead of the FSW tool and found that the maximum welding speed obtaining defect-free joint was increased apparently. SUN et al [18] studied laser- assisted FSW of S45C steel plates and found that the maximum welding speed can be expanded from 400 to 800 mm/min. LIU et al [19] employed micro-plasma arc for preheating AA2219 during FSW and reported that the welding speed could be increased without compromising mechanical properties.

KHAN et al [20] investigated the tunnel formation during FSW of dissimilar aluminium alloys and concluded that 1) improper pin offset caused insufficient mixing due to unequal flow stress for the two alloys, and 2) insufficient forging action because inadequate plunge depth would have caused the tunneling defect. An insufficient forging pressure also decreases the highest temperature of the weld, causing flow stress of base materials to increase, consequently resulting in insufficient plastic deformation and a slugging material movement. Tunneling defects thus appear mainly due to improper mixing and inadequate consolidation of material at joint. Under inappropriate welding conditions, the tool may move before depositing enough material behind it, creating a tunnel. LIU and WU [21] reported that the insufficient material flow from RS to AS side in the pin affected zone and the shortage of downward material transfer in the shoulder affected zone are the primary and secondary reasons for tunnel defect occurrence, respectively. The tunneling defect can be minimized or eliminated by appropriate generation and distribution of heat on respective sides of the joint and proper consolidation of material behind the tool pin.

2.2 Kissing bond

KB is a solid state bonding defect, which is formed as a result of inefficient material deformation due to inadequate pressure and insufficient stirring of the material. If such conditions prevail, the oxide layer present on the BM, if not properly removed before welding, will lead to improper bonding [22], manifesting itself as KB. This discontinuity is usually formed at the interface of the joint.

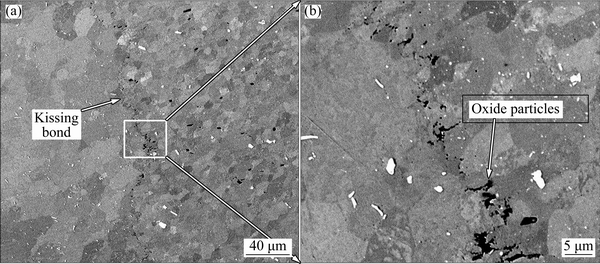

In KB, there is little or no metallic bond present between the two previously separated regions of the BM [20]. Insufficient flow of materials on the lower side of the probe or abnormal stirring action of the probe may result in KB [23]. Figure 5 shows the SEM images of KB defect in friction stir welded joint of dissimilar aluminium alloys (AA6063-AA5083) [20]. During the formation of the friction stir weld, it is vital that the oxide interface (specifically for aluminum alloy as it has high affinity to oxygen) between the abutting plates must be carefully removed in order to form an intimate bond. Apart from this, a lack of deposition of material, which may be associated with inadequate heat and higher flow stresses, may also lead to the formation of KB [24]. The lack of intimate mixing of material on faying surface is also manifested in the form of KB. The presence of KB hinders the strong bonding between the faying surfaces of base materials, thereby resulting in poor mechanical properties. To eliminate this defect, thoroughly mixing during welding is required by providing material movement around the pin that should break and distribute the oxide layer on the abutting surface of the base material.

2.3 Joint line remnant

Joint line remnant (JLR) is one of the defects in FSW which significantly degrades the mechanical properties of the joints. During FSW, the stirring at the bottom of the pin or below it is less. It happens that less stirring at the bottom of pin may not offer enough whisking and the traces of faying interface may remain there, forming JLR. Due to the same reason, a semi-continuous layer of oxide through the weld nugget causes JLR defect, as shown in Fig. 6 [25]. This is because the oxide film around the initial butt surface could not be adequately broken up during severe plastic deformation induced by FSW. The JLR is, thus, formed at the root of the weld or it can even extend into the stir zone.

JLRs may form due to inappropriate cleaning of workpieces prior to welding or insufficient deformation at the abutting surface interface due to incorrect tool location relative to the joint line, inappropriate tool geometry, too fast welding speed or insufficient plunge depth [26]. Sometimes, the distribution of oxide particles through the weld thickness results in the formation of JLR [27]. The presence of zigzag line in the form of JLR as shown in Fig. 6 significantly affects the mechanical properties of the welded joint [28]. Zigzag line may form due to inadequate heat generation and improper material movement during FSW [29,30]. JOLU et al [31] investigated the effect of JLR on the mechanical properties of AA2198 alloy and concluded that the JRL significantly affects the tensile strength and slightly affects the fatigue strength of the welded joint compared with the base material. JLR can be minimized or eliminated by generating appropriate heat during welding and providing proper mixing in stir zone that leads to the sound joint of the base materials.

2.4 Incomplete root penetration

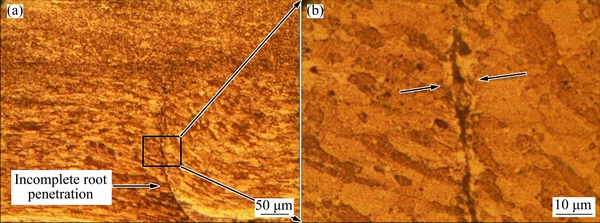

An inadequate tool plunge or a deficient pin length or both may cause a small portion of the joint root to remain unstirred or unconsolidated, which is manifested as a prominent incomplete root penetration. Incomplete root penetration in welded joint may also form due to improper tool pin offset, local variations in the plate thickness, uneven face of abutting plates and inappropriate tool design. It may be resulted from too short pin length compared with the plate thickness, low heat input or incorrect tool orientation [32].

Fig. 5 SEM images showing KB defect in dissimilar aluminium joint [20]

Fig. 6 Macrostructure of JLR defect [25]

Sometimes plunge depth may be the cause of incomplete root penetration. Plunge depth plays an important role in the generation of heat during welding and forging action of the tool which, consequently, affects the consolidation of the material to form joint [20]. Accordingly, lower plunge depth causes inadequate material flow and lack of bonding between the base materials which, in turn, results in incomplete root penetration, leading to reduced joint strength. An excessively high plunge depth, however, causes over heating which leads to the generation of inter-metallic compound which may cause reduction in strength. So, optimal value of plunge depth is required for a defect-free FSW joint. Incomplete root penetration of FS welded joints of AA7475 as shown in Fig. 7 was observed after welding was performed as a part of the present study at 710 r/min and 50 mm/min.

Also, incomplete root penetration occurs when the FSW pin is too distant from the support anvil. Thus, an undeformed region exists between the bottom of the tool pin and the bottom surface of the plate as shown in Fig. 7. Inappropriate material stirring throughout the faying surface leads to the improper bonding between the base materials at the joint line. When subjected to a load, the friction stir welds fail along the lack of penetration line. To eliminate this defect, thorough mixing during welding throughout the weld root is required by providing appropriate tool pin length and plunge depth so that tool pin reaches the bottom of the base material, while ensuring that the pin will not touch the backing anvil.

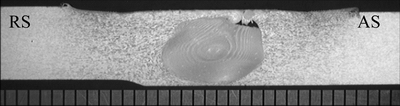

2.5 Void

Voids are generally found on the AS of the welded joint and they may or may not break thoroughly to the surface of the weld as shown in Fig. 8 [27]. Too low rotational speed in relation to the speed of welding may result in the formation of void. The presence of void strongly reduces the ductility and slightly reduces the strength [33]. PARK et al [34] observed groove-type defect on AS of the weld at lower rotational speed. They also reported that the chance of void formation increases by increasing welding speed at a constant rotation speed of 500 r/min and by decreasing rotational speed from 500 to 250 r/min. LIU and ZHANG [35] reported that the degradation of mechanical properties of the joints is observed due to the formation of continuous grove defect and this may be attributed to inappropriate filling of plasticized material from RS to AS near the back surface of tool pin. Lower rotational speed and higher welding speed result in inappropriate generation of heat. The proper softening of material due to lower heat input leads to the formation of cracks (voids) [36]. DAWOOD et al [37] found that higher heat input also resulted in the formation of voids due to increased fluidity of metal and turbulent flow in welded zone.

Fig. 7 Microstructures showing incomplete root penetration in friction stir weld along with high magnification

Fig. 8 Macrograph showing void imperfection in friction stir weld [27]

For a given tool design, insufficient workpiece clamping (too large joint gap), insufficient forging pressure and too high welding speed [27] may lead to the formation of void. The stirred material cools before completely filling the region directly behind the tool, consequently, creating the void. This happens when the tool design is improper or too fast travel speed is used. Adequate heat generation is required to allow the material to flow around the tool pin and completely fill the void produced by traversing pin. In case of insufficient heat input (through insufficient forging pressure or incorrect shoulder diameter), the material will undergo deficient movement, leading to void formation.

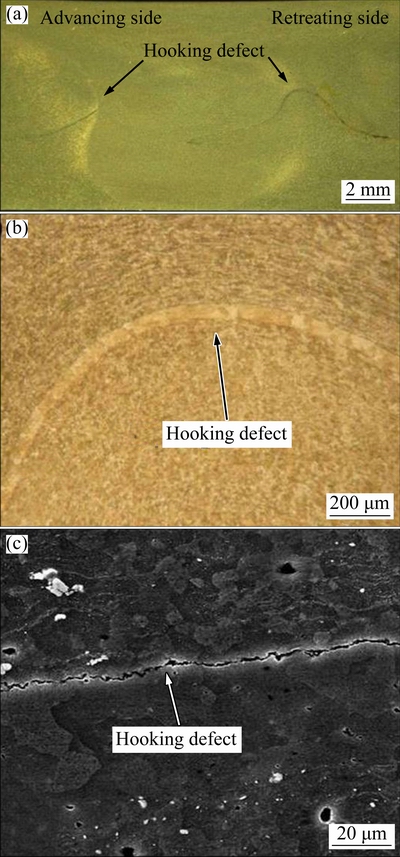

2.6 Hooking defect

The hooking defect is one of the most probable defects in FSW lap joints during FSW. It is generally observed in the TMAZ on the AS when the sheet interface is pulled up into the top sheet, but sometimes it may be seen on both AS and RS. The mechanism of joining during FSW is such that material is picked by the tool pin on the AS and during its movement from AS to RS, on the AS, it undergoes a simultaneous upwards extrusion and rotation around the pin layer-by-layer [38,39]. The material dragged on the AS when moving to the RS undergoes downwards forging action while simultaneously rotating layer-by-layer under the pressure of tool shoulder. This combination of extrusion and forging is mainly affected by the tool tilt and plunge depth. Improper forging of the lifted material due to inadequate tool tilt and plunge depth leads to the hooking defect as shown in Fig. 9 [40]. The macrograph of the lap welded joint with hooking defect, optical micrograph of hooking defect on RS and SEM image of the hooking defect are respectively presented in Figs. 9(a)-(c).

As illustrated in Fig. 9(a), upward flow on AS of stir zone behind the tool drives the material upwards and thus a portion of the unwelded lap curves up, forming a hook. The size of hooking defect is proportional to the heat transfer to the weld area. High heat input to the weld softens the material more greatly, resulting in enlarging the hooking defect mainly due to more frenzied flow in the weld area. Hook height is increased by increasing rotational speed of the tool as vertical movement of material increases (specially in case of threaded pin) and at constant rotational speed, hooking height decreases by increasing welding speed due to less vertical movement of material. Hooking defect might not appear in heat- affected zone (HAZ) as this zone does not experience plastic deformation and is only affected by heating by conduction [41]. The size and shape of hooking differ from AS to RS. This difference may be due to the tool geometry and material flow because AS experiences higher strain and temperature by undergoing severe plastic deformation compared to the RS [42]. The presence of hooking defect results in the low mechanical strength of dissimilar FS welded joints [43].

Fig. 9 Macrostructure of lap welded specimen (a), optical microscopy image showing hooking defects on RS (b), and SEM image of hooking defect (c) [40]

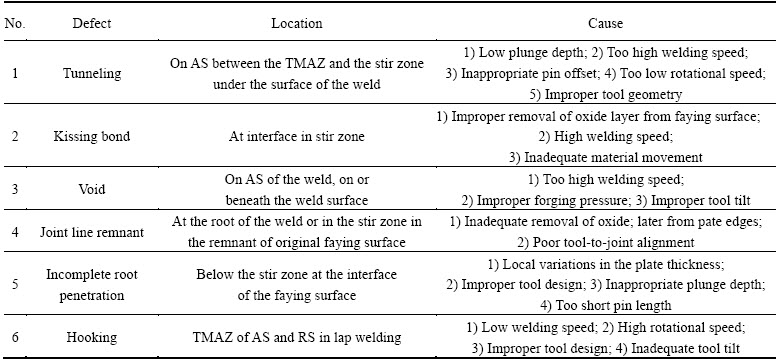

Table 1 summarizes the defects that generally form in FSW of aluminum alloys. Summary includes the location where defects are formed and causes of their formation. Defects are clearly addressed in the present study and recommendations for their minimizing or elimination are made. Though FSW is a clean welding process for joining materials difficult to weld, the formation of defects may hinder the effectiveness of this process. With the knowledge domain on various defects being expanded the FSW process may become a stronger and more reliable clean fabrication process.

Table 1 Defects along with their location and causes during FSW

3 Conclusions

1) The FSW is regarded as a clean fabrication technology. Since it is new, it has to go a long way to establish itself as an unquestionable process of high degree of reliability in terms of joint quality. Although, it has been adequately accepted by the industry and has been aptly commercialized, yet sporadic failure of the FSW joint is the cause of great concern. This study presents a comprehensive characterization of defect formation in FSW which occurs due to inappropriate combinations of welding parameters (mainly rotational speed, welding speed and plunge depth) and welding conditions. Improper selection of welding parameters leads to insufficient or excessive heat input, inappropriate material movement and consolidation that deteriorate the mechanical properties of the joints.

2) Tunneling defect generally appears on the AS between TMAZ and the weld nugget. It is mainly caused by low heat input that has resulted from too high welding speed. Low heat input, in turn, leads to higher flow stress causing deficient material movement which hampers material consolidation behind the tool pin.

3) Kissing bond is an extremely thin bond line visible in the stir zone at a high magnification. It forms due inadequate pressure and insufficient stirring of the material and the chance of its occurrence increases when the oxide layer from the faying surface is not effectively removed.

4) Joint line remnant usually seen extending from the bottom of the joint appears in the form of inadequately dispersed oxide particles that may be produced either due to inadequate cleaning of abutting edges of base materials prior to welding or inadequate heat generation.

5) Incomplete root penetration forms at the bottom of the stir zone due to local variations in the plate thickness, improper tool design and inappropriate plunge depth. It may be eliminated by adequate plunging and thorough mixing during welding throughout the weld root, allowing the tool pin to reach the bottom of the base material.

6) Voids generally form on the surface or just beneath the surface of the weld due to insufficient forging pressure or too high welding speed. Improper consolidation of the plastically deformed material behind the tool leads to the void formation.

7) Hooking defect is generally found in lap joints of FSW. It forms on both sides of the joint line, but the direction of material hooking on the AS and RS is different and determined by the pin length and direction of the tool’s rotational movement.

Acknowledgments

The authors thank the University Grants Commission (UGC) for its financial assistance (vide sanction order No. F.3-40/2012(SAP-II)) under its SAP (DRS-I) sanctioned to the Department of Mechanical Engineering for the project entitled Friction Stir Welding and Ultrasonic Machining. This project was also financially supported by the King Saud University, Vice Deanship of Research Chairs.

References

[1] THOMAS W M, NICHOLAS E D, NEEDHAM J C, NURCH M G, TEMPLESMITH P, DAWES C. Friction stir butt welding: GB patent, 9125978.8 [P]. 1991-12-20.

[2] MISHRA R S, MA Z Y. Friction stir welding and processing [J]. Materials Science and Engineering R, 2005, 50(1-2): 1-78.

[3] ENOMOTO M. Application of friction stir welding for aluminium alloys [J]. Journal of Light Metal Welding and Construction, 1998, 36(2): 75-79.

[4] SIDDIQUEE A N, PANDEY S. Experimental investigation on deformation and wear of WC tool during friction stir welding (FSW) of stainless steel [J]. International Journal of Advanced Manufacturing Technology, 2014, 73: 479-486.

[5] FRATINI L, BUFFA G. CDRX modelling in friction stir welding of aluminium alloys [J]. International Journal of Machine Tool and Manufacturing, 2005, 45(10): 1188-1194.

[6] DEHGHANI M, AMADEH A, AKBARI MOUSAVI S A A. Investigations on the effects of friction stir welding parameters on intermetallic and defect formation in joining aluminum alloy to mild steel [J]. Materials & Design, 2013, 49: 433-441.

[7] KHODIR S A, SHIBAYANAGI T. Friction stir welding of dissimilar AA2024 and AA7075 aluminum alloys [J]. Material Science and Engineering B, 2008, 148: 82-87.

[8] NAKATA K, KIM Y G, USHIO M, HASHIMOTO T, JYOGAN S. Weldability of high strength aluminium alloys by friction stir welding [J]. ISIJ International, 2000, 40: 515-519.

[9] KADLEC M, RUZEK R, NOVAKOVA L. Mechanical behaviour of AA7475 friction stir welds with the kissing bond defect [J]. International Journal of Fatigue, 2015, 74: 7-19.

[10] DICKERSON T L, SHERCLIFF H R, SCHMIDT H. A weld marker technique for flow visualization in friction stir welding [C]//Proceedings of the Fourth International Conference on Friction Stir Welding, Park City: TWI Ltd., 2003.

[11] BALOS S, SIDJANIN L. Effect of tunneling defects on the joint strength efficiency obtained with FSW [J]. Materials and Technology, 2014, 48(4): 491-496.

[12]  I, ZIVKOVIC A, RADOVIC N. Avoidance of tunnel type defect in FSW welded Al 5052-H32 plates [J]. Welding & Welded Structures, 2012, 1(1): 5-11.

I, ZIVKOVIC A, RADOVIC N. Avoidance of tunnel type defect in FSW welded Al 5052-H32 plates [J]. Welding & Welded Structures, 2012, 1(1): 5-11.

[13] ZETTLER R, VUGRIN T, SCHMUCKER M. Friction stir welding from basics to applications [M]. Cambridge: Woodhead Publishing Limited, 2010: 245-265.

[14] ZHAO Y, ZHOU L, WANG Q, YAN K, ZOU J. Defects and tensile properties of 6013 aluminum alloy T-joints by friction stir welding [J]. Materials & Design, 2014, 57: 146-155.

[15] KUMAR K, KAILAS S V. The role of friction stir welding tool on material flow and weld formation [J]. Materials Science and Engineering A, 2008, 485(1): 367-374.

[16] KIM Y G, FUJII H, TSUMUR T, KOMAZAKI T, NAKATA K. Three defect types in friction stir welding of aluminum die casting alloy [J]. Materials Science and Engineering A, 2006, 415: 250-254.

[17] KOHN G, GREENBERG Y, MAKOVER I, MUNITZ A. Laser- assisted friction stir welding [J]. Welding Journal, 2002, 81(2): 46-48.

[18] SUN Y F, KONISHI Y, KAMAI M, FUJII H. Microstructure and mechanical properties of S45C steel prepared by laser-assisted friction stir welding [J]. Materials & Design, 2013, 47: 842-849.

[19] LIU H J, GUO N, FENG J C. Friction stir welding assisted by micro-plasma arc [C]//Proceedings of the 6th International Symposium on Friction Stir Welding. Cambridge: TWI Ltd., 2006.

[20] KHAN N Z, SIDDIQUEE A N, KHAN Z A, SHIHAB S K. Investigations on tunneling and kissing bond defects in FSW joints for dissimilar aluminum alloys [J]. Journal of Alloys and Compounds, 2015, 648: 360-367.

[21] LIU X C, WU C S. Elimination of tunnel defect in ultrasonic vibration enhanced friction stir welding [J]. Materials & Design, 2016, 90: 350-358.

[22] CHEN H B, YAN K, LIN T, CHEN S B, JIANG C Y, ZHAO Y. The investigation of typical welding defects for 5456 aluminum alloy friction stir welds [J]. Materials Science and Engineering A, 2006, 433: 64-69.

[23] KHODIR S A, SHIBAYANAGI T. Microstructure and mechanical properties of friction stir welded dissimilar aluminum joints of AA2024-T3 and AA7075-T6 [J]. Materials Transactions, 2007, 48(7): 1928-1937.

[24] OOSTERKAMP A, OOSTERKAMP L D, NORDEIDE A. ‘KB’ phenomena in solid-state welds of aluminum alloys [J]. Welding Journal, 2004, 83(8): 225-231.

[25] MISHRA R S, MAHONEY M W. Friction stir welding and processing [M]. Ohio: ASM International, 2007.

[26] CHEN H B, WANG J F, ZHEN G D, CHEN S B, LIN T. Effects of initial oxide on microstructural and mechanical properties of friction stir welded AA2219 alloy [J]. Materials & Design, 2015, 86: 49-54.

[27] LEONARD A J, LOCKYER S A. Flaws in friction stir welds [C]// Proceedings of the Fourth International Conference on Friction Stir Welding. Park City: TWI Ltd., 2003.

[28] LIU H J, CHEN Y C, FENG J C. Effect of zigzag line on the mechanical properties of friction stir welded joints of an Al-Cu alloy [J]. Scripta Materialia, 2006, 55: 231-234.

[29] SATO Y S, TAKAUCHI H, PARK S H C, KOKAWA H. Characteristics of the kissing-bond in friction stir welded al alloy 1050 [J]. Materials Science and Engineering A, 2005, 405: 333-338.

[30] SATO Y S, YAMASHITA F, SUGIURA Y, PARK S H C, KOKAWA H. FIB-assisted TEM study of an oxide array in the root of a friction stir welded aluminium alloy [J]. Scripta Materialia, 2004, 50: 365-369.

[31] JOLU T L, THILO F, MORGENEYER, DENQUIN A, SENNOUR M, LAURENT A, BESSON J, GOURGUES-LORENZON A. Microstructural characterization of internal welding defects and their effect on the tensile behavior of FSW joints of AA2198 Al-Cu-Li alloy [J]. Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science, 2014, 45: 5531-5544.

[32] ZHOU C, YANG X, LUAN G. Effect of root flaws on the fatigue property of friction stir welds in 2024-T3 aluminum alloys [J]. Materials Science and Engineering A, 2006, 418: 155-160.

[33] KAHL S. The influence of small voids on the fatigue strength of friction stir welds in the aluminium alloy AA6061-T6 [J]. HERON, 2010, 55(3-4): 223-234.

[34] PARK H S, KIMURA T, MURAKAMI T, NAGANO Y, NAKATA K, MASAO U. Microstructures and mechanical properties of friction stir welds of 60%Cu-40%Zn copper alloy [J]. Materials Science and Engineering A, 2004, 371:160-169.

[35] LIU Hui-jie, ZHANG Hui-jie. Repair welding process of friction stir welding groove defect [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: 563-567.

[36] CHEN Yu-hua, NI Quan, KE Li-ming. Interface characteristic of friction stir welding lap joints of Ti/Al dissimilar alloys [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 299-304.

[37] DAWOOD H I, MOHAMMED K S, RAHMAT A, UDAY M B. Effect of small tool pin profiles on microstructures and mechanical properties of 6061 aluminum alloy by friction stir welding [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 2856-2865.

[38] CHEN Z W, PASANG T, QI Y. Shear flow and formation of nugget zone during friction stir welding of aluminium alloy 5083-O [J]. Materials Science and Engineering A, 2008, 474: 312-316.

[39] MUTHUKUMARAN S, MUKHERJEE S K. Multi-layered metal flow and formation of onion rings in friction stir welds [J]. International Journal of Advanced Manufacturing Technology, 2008, 38: 68-73.

[40] SHIRAZI H, KHEIRANDISH S H, SAFARKHANIAN M A. Effect of process parameters on the macrostructure and defect formation in friction stir lap welding of AA5456 aluminium alloy [J]. Measurement, 2015, 76: 62-69.

[41] CAO X, JAHAZI M. Effect of tool rotational speed and probe length on lap joint quality of friction stir welded magnesium alloy [J]. Materials & Design, 2011, 32(1): 1-11.

[42] FONDA R W, PAO P S, JONES H N, FENG C R, CONNOLLY B J, DAVENPORT A J. Microstructure, mechanical properties, and corrosion of friction stir welded Al5456 [J]. Material Science and Engineering A, 2009, 519: 1-8.

[43] COSTA M I, VERDERA D,  C, RODRIGUES D M. Dissimilar friction stir lap welding of AA5754-H22/AA6082-T6 aluminium alloys: Influence of material properties and tool geometry on weld strength [J]. Materials & Design, 2015, 87: 721-731.

C, RODRIGUES D M. Dissimilar friction stir lap welding of AA5754-H22/AA6082-T6 aluminium alloys: Influence of material properties and tool geometry on weld strength [J]. Materials & Design, 2015, 87: 721-731.

Noor Zaman KHAN1, Zahid A. KHAN1, Arshad Noor SIDDIQUEE1, Abdulrahman M. AL-AHMARI2, Mustufa H. ABIDI2

1. Department of Mechanical Engineering, Jamia Millia Islamia (A Central University), New Delhi, PIN-110025, India;

2. Princess Fatima Alnijris Research Chair for Advanced Manufacturing Technology, Advanced Manufacturing Institute, King Saud University, Riyadh-11421, Saudi Arabia

摘 要:清洁生产是制造工艺过程中追求的目标。搅拌摩擦焊是一种比目前最好的传统焊接工艺更好、对环境损害更低的连接技术。搅拌摩擦焊工艺的能量效率高、无耗材、无损耗、无辐射。因此,它是一种能获得优质焊接接头的清洁焊接工艺。但它在焊接过程中会产生缺陷,为使其成为一种可靠的生产工艺,需要对其进行进一步优化。本文作者对搅拌摩擦焊接头的缺陷进行表征。结果表明,缺陷的产生是由于焊件过程的产生的热量不够、搅拌针附近的物质移动不充分、搅拌针后部的材料致密化不够。焊接过程中产生的热量和物料的搅拌程度取决于搅拌摩擦焊的焊接参数。焊接参数选择不当,可导致缺陷的产生。本文所得结果来源于文献和实验。根据各种缺陷的特征,如其可能产生的位置、减少缺陷产生的主要参数等,提出了减少缺陷产生的一些措施。

关键词:清洁焊件工艺;搅拌摩擦焊;工艺参数

(Edited by Wei-ping CHEN)

Corresponding author: Arshad Noor SIDDIQUEE; Tel: +91-11-26985176; Fax: +91-11-26981261; E-mail: arshadnsiddiqui@gmail.com

DOI: 10.1016/S1003-6326(17)60171-7