Tensile and fracture behavior of DZ951 Ni-base superalloy

CHU Zhao-kuang(储昭贶)1,2, YU Jin-jiang(于金江)1 , SUN Xiao-feng(孙晓峰)1,

ZHAO Nai-ren(赵乃仁)1, GUAN Heng-rong(管恒荣)1, HU Zhuang-qi(胡壮麒)1

1. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China;

2. Graduate School of Chinese Academy of Sciences, Beijing 100039, China

Received 28 July 2006; accepted 15 September 2006

Abstract: The tensile and fracture behavior of DZ951 directionally solidified Ni-base superalloy was studied in the temperature range of 20-1 100 ℃. The fracture mode was examined by scanning electron microscopy. The results show the experimental temperature has no significant effect on the tensile strengths, which are greater than 1 000 MPa from room temperature to 800 ℃. The yield strength reaches its maximum (970 MPa) at 800 ℃. When the experimental temperature is higher than 800 ℃, the tensile and yield strengths decrease evidently and the ductility increases remarkably. The fractograph of fracture surface for the tensile specimen at room temperature shows a dimple-ductile fracture mode. The fractograph from 600 to 800 ℃ shows a slide fracture mode. The fractograph from 900 to 1 100 ℃ exhibits a creep rupture mode with uneven deformation.

Key words: Ni-base superalloy; tensile strength; yield strength; fractograph

1 Introduction

Nickel-base superalloys are widely used in manufacturing the gas turbine components which are required to possess high temperature strength, better oxidation and corrosion resistance, excellent fatigue and creep resistance, optimal stability of microstructure and service reliability [1-2]. DZ951 alloy is considered a candidate material for the vane of advanced turbine engine with high ratio of thrust-mass. As the alloy spends all of its lifetime at high temperatures, it is worth studying the mechanical properties of this alloy at high temperatures. The temperature dependence of tensile properties of many Ni-base superalloys have been studied[3-6]. BETTGE et al[5] concluded that the yield strength of IN738LC alloy decreases with increasing temperature up to 450 ℃, then increases up to 750 ℃ and finally decreases sharply. They attributed the variation to different deformation mechanisms operating at different temperatures. The temperature dependence of tensile properties and fracture behavior of DZ951 alloy was researched in this study.

2 Experimental

The nominal composition of DZ951 alloy used in this study is listed in Table 1. The alloy was melted in VZM-25F vacuum induction furnace. The directionally solidified specimens were made by the method of high rate solidification in ZGD2 vacuum furnace. The temperature gradient was 60-80 ℃/cm and the with- drawal rate was 6 mm/min. The procedure of heat treatment was follows: 1 220 ℃, 4 h AC+ 1 050 ℃, 4 h AC +870 ℃, 24 h AC(AC: air cooling). The tensile tests were carried out in a DCX-25T type universal test machine.

Table 1 Nominal composition of DZ951 alloy (mass fraction, %)

Optical microscope (OM) and scanning electron microscope (SEM) were used to observe the microstructure of DZ951 alloy. The specimens which were investigated by OM were cleaned by alcohol after polishing. Then they were etched with a solution of 20 g CuSO4+100 mL HCl+5 mL H2SO4+100 mL H2O. The specimens used for SEM were electrolyzed in a solution of 5 mL HNO3+10 mL CH3COOH+85 mL H2O with a voltage of 7 V. JSM-E001F cold field emission SEM was used to observe the fractural surface.

3 Results and discussion

3.1 As-cast microstructure of DZ951 alloy

The as-cast microstructures of DZ951 alloy are shown in Fig.1, which indicates that as-cast alloy has obvious dendritic structure (Fig.1(a)) and a little γ+γ′ eutectic at grain boundary and interdendrite (arrow indicated in Fig.1(a)). There are blocky or script-like carbides near grain boundary and interdendrite (Fig.1(b)). The size of γ′ phase is large and the shape is roughly cubic. Most γ′ phase particles have a shape of cube, but some reveal exaggerated octagonal form(arrowed in Fig.1(c)).

Fig.1 OM and SEM images of as-cast DZ951 alloy: (a) Dendritic structure; (b) Carbides; (c) γ shape

3.2 Tensile properties

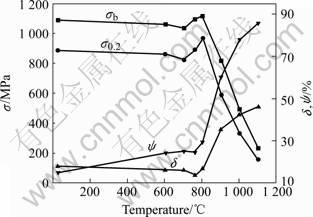

The tensile properties of DZ951 alloy are shown in Fig.2. It indicates that the tensile strength and yield strength change only a little from room temperature to 800 ℃; those reach their maxima at 800 ℃. When the test temperature exceeds 900 ℃, the strength decreases sharply with increasing the test temperature. The ductility is also without significant change from room temperature to 800 ℃. As the experimental temperature is higher than 800 ℃, the ductility increases remarkably with temperature.

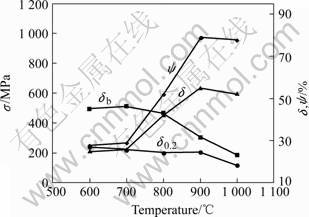

Tensile properties of DZ40M alloy[7] are shown in Fig.3 for comparison. The tensile strength of DZ40M alloy reaches its maximum at 700 ℃. When the test temperature exceeds 700 ℃, the tensile strength of DZ40M alloy decreases, but not sharply as DZ951 alloy, with increasing the test temperature; The yield strength of DZ40M alloy reaches its maximum at 600 ℃. When the test temperature exceeds 600 ℃, the yield strength of DZ40M alloy decreases tardily with increasing test temperature. Compared with DZ40M alloy, the tensile and yield strength of DZ951 alloy are two times more than those of DZ40M alloy in the same condition. The ductility of DZ951 alloy is nearly the same as that of DZ40M alloy in the same condition.

Fig.2 Tensile properties of DZ951 alloy

Fig.3 Tensile properties of DZ40M alloy

It is a particular strengthening mechanism for γ′ phase that its strength increases with increasing the temperature[8], which can offset the decrease of the strength of matrix γ phase with increasing the temperature. A dynamic model founded by COPLRY et al[9] was used to explain the relation between the yield strength and the experimental temperature of Mar-M200 alloy. KEEP et al[10] considered the invigoration effect of γ′ phase could be explained by the slipping of dislocation from {111} to {110} made by thermal activation. The process of slipping was easier with increasing the temperature. As the experimental temperature is higher than 900 ℃, γ′ phase dissolves rapidly, which induces the strength decrease of alloy. In this test, it is observed that the experimental temperature has no significant effect on the strength from room temperature to 800 ℃. As the experimental temperature is higher than 900 ℃, the strength drops evidently.

3.3 Fracture behavior

The fractographs of a tensile-fractured specimen of DZ951 alloy at room temperature are shown in Fig.4. The fracture is planar macroscopically, the separation angle of fracture surface with tensile axis equals 90?. There are large numbers of dimples in the fracture, which are in the similar dimension. The fractograph of fracture surface for the tensile specimen at room temperature shows a dimple-ductile fracturing mode. According to the dimple initiation and expansion model proposed by BROEK[11], the dislocation ring was accumulated surrounding γ′ phase in the primary alloy. On the one hand, the dislocation ring got the repulsive interaction of γ′ particle; on the other hand, the dislocation ring was forced to γ′ particle on account of the effect of dislocation accumulating stress. The dislocation ring and γ′ particle were in the equilibrium state without accessional stress. When the specimen was exposed to the tensile stress, the equilibrium was broken, and the dislocation ring was forced to γ′ particle. After the dislocation ring reached the interface of γ′ particle and matrix, the interface would split and come into being micropore. New dislocation ring would be formed followed micropore and be forced ceaselessly to the micropore. The micropore extended rapidly. Finally the alloy formed the dimple-ductile fracture.

Fig.4 Fractographs of tensile-fractured specimen of DZ951 alloy at room temperature

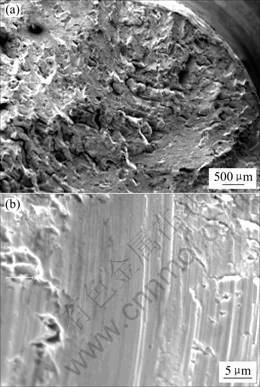

The fractographs from 600 to 800 ℃ are similar. The fractographs at 600 ℃ are shown in Fig.5. Fracture is ‘V’ font style macroscopically, the separation angle of each fracture surface with tensile axis is nearly 45?. Though no big dimple is formed, intracrystalline breakage of the characteristic of ductility fracture occurs in the fracture. Sliding surface can be observed in some region of fracture, which forms some angle with stress orientation. The fractograph from 600 to 800 ℃ shows a slide fracturing mode. First some parallel dislocation lines are formed on the orientation of {111}〈110〉slip system of matrix alloy. With the increase of strain capacity, parallel slip steps appear, and are developed into slip lines. When the slip line encounters γ′ phase, it is ceased at γ/γ′ phase boundary and engenders new dislocation. Large numbers of dislocations formed surrounding the slip line can release local strain partly. When the strain capacity goes up to a certain value, the slip line cracks through γ′ phase along sliding surface.

Fig.5 Fractographs of tensile-fractured specimen of DZ951 alloy at 600 ℃

The fractographs from 900 to 1 100 ℃ are similar. The fractographs at 900 ℃ are shown in Fig.6. It is observed that the fracture shows plastic deformation obviously, many polygonal cracks occur on the fracture surface. There are many dimples on the surface, the shapes of which are dissimilar. Some dimples are equiaxed and others are oblong. The sizes of the dimples are non-uniform and greatly discrepant, which indicates that the process of distortion is uneven. The fracture displays typical ductility fracture characteristic, in which no slip deformation is found. The fractograph from 900 to 1 100 ℃ shows a creep rupture mode with uneven deformation.

Fig.6 Fractographs of tensile-fractured specimen of DZ951 alloy at 900 ℃

4 Conclusions

1) The experimental temperature has no significant effect on the tensile strength from room temperature to 800 ℃. The yield strength reaches its maximum at 800 ℃. As the experimental temperature is higher than 800 ℃, the tensile and yield strengths decrease evidently and the ductility increases remarkably with increasing the temperature.

2) Compared with DZ40M alloy, the tensile and yield strengths of DZ951 alloy are twice more than those of DZ40M alloy in the same condition. The ductility of DZ951 alloy is nearly the same as that of DZ40M alloy in the same condition.

3) The fractograph of fracture surface for the tensile specimen at room temperature has a dimple-ductile fracture mode. The fractograph from 600 to 800 ℃ shows a slide fracture mode. The fractograph from 900 to 1 100 ℃ exhibits a creep rupture mode with uneven deformation.

References

[1] SIMS C T, STOLOFF N S, HAGREL W C. Superalloy Ⅱ[M]. New York: Boston Rougeclaitor Publishing Company, 1987: 3-26.

[2] MATTHEW J, DONACHIE J. Superalloy [M]. Ohio: American Society for Metals, Metal Park, 1984: 3-14.

[3] SCHEUNEMANN FRERKER G, GABRISCH H, FELLER KNIEPMEIER M. Dislocation microstructure in a single crystal Ni-base superalloy after tensile testing at 823 K in the [001] direction [J]. Phil Mag A, 1992, 65(6): 1353-1368.

[4] SENGUPTA A, PUTATUNDA S K, BARTOSIEWICZ L, et al. Tensile behavior of a new single crystal Ni-base superalloy (CMSX-4) at room and elevated temperatures [J]. J Mater Eng Perform, 1994, 3(5): 664-672.

[5] BETTGE D, OSTERLE W, ZIEBS J. Temperature dependence of yield strength and elongation of the Nickel-base superalloy IN738LC and the corresponding microstructural [J]. Z Metallkd, 1995, 86(3): 190-197.

[6] FELLER-KNIEPMEIER M, LINK T, POSCHMANN L, et al. Temperature dependence of deformation mechanisms in a single crystal Ni-base alloy with high volume fraction of γ′ phase [J]. Acta Mater, 1996, 44(6): 2397-2407.

[7] Institute of Metal Research, Chinese Academy of Sciences. Report of research and development of a directionally solidified Co-base superalloy DZ40M[R]. 1998.

[8] NABARRO F R N, DUESERY M S. Dislocations in Solids [M]. Amsterdam: North-Holland Publishing Company, 1996: 113-119.

[9] COPLRY S M, KEAR B H. A dynamic theory of coherent precipitation hardening with application to nickel-base superalloys [J]. Trans AIME, 1967, 239: 984-992.

[10] KEEP B H, WILSDORF H G F. Dislocation configurations in plastically deformed polycrystalline Cu3Au alloys [J]. Trans AIME, 1962, 224: 382-386.

[11] BROEK D. The role of inclusions in ductile fracture and fracture toughness[J]. Engineering Fracture Mechanics, 1973, 5: 55-56.

(Edited by CHEN Wei-ping)

Corresponding author: CHU Zhao-kuang; Tel: +86-24-23971767; E-mail: zkchu@imr.ac.cn