Structural evolution of Si-50%C powder during mechanical alloying and heat treatment

TANG Wen-ming(汤文明), ZHENG Zhi-xiang(郑治祥), WU Yu-cheng(吴玉程),

XU Guang-qing(徐光青), L? Jun(吕 珺), LIU Jun-wu(刘君武), WANG Jian-min(王建民)

School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China

Received 22 December 2007; accepted 23 April 2008

Abstract: The nanocrystalline β-SiC powder was successfully synthesized by ball milling the Si-50%C elemental powder. During ball milling, a solid solution of C in Si, Si(C), firstly forms, followed by SiC. The formation of SiC is controlled by the mixing mechanism of the gradual diffusion reaction(GDR) and the mechanically induced self-propagating reaction(MSR). The amount of β-SiC increases with milling time increasing. After 40 h milling, there exists only β-SiC in the milled powder. The grain size of β-SiC is about 6.4 nm after the powder is milled for 60 h. After the 60 h-milled Si-50%C elemental powder is heat treated at 1 100 ℃ for 1 h, the grain size of β-SiC does not change, but the lattice ordering degree of β-SiC increases.

Key words: SiC; mechanical alloying; structural evolution; nanocrystalline

1 Introduction

Silicon carbide (SiC) is an important material for engineering applications due to its excellent properties, such as high hardness, high wearability and chemical compatibility. Most of SiC powders are manufactured in the process by carbothermic reduction of SiO2 with carbon powders at temperatures of 2 000-2 300 ℃. SiC is also synthesized though some physical and chemical processes, such as laser induced synthesis, plasma induced synthesis, gas-phase reaction, pyrolysis of tetramethylsilane (Si(CH3)4), trimethylchlorosilane ((CH3)3SiCl) or trimethylsilane ((CH3)3SiH), sol-gel [1-3]. Most of the aforementioned approaches for producing SiC require temperatures higher than 1 500 ℃. However, SiC can also be synthesized without heating, for example, mechanical alloying (MA) process by high-energy ball milling of the Si and C elemental powders at ambient temperature[4-9].

Although SiC synthesized by ball milling the elemental powder has been reported, some fundamental topics in the MA process, such as the structural evolution and the alloying mechanism are not clarified precisely. For example, in EL-ESKANDARANY et al’s trial[4], ball milling of the Si-50%C (mole fraction) powder firstly results in the formation of the twin and nanotwin boundaries on Si and C. A solid state reaction takes place at the interface of these couples to form the β-SiC phase that has longitudinal lathlike morphology. YANG et al[6] observed that during ball milling the Si-50%C powder, the amorphous C and Si are firstly formed, and then the amorphous α-Si(C) is generated through the diffusion of C atoms into Si. Finally, the C atoms gradually replace the Si atoms to form SiC. Moreover, the effect of heat treatment on the structure of the milled powder is not concerned so far. In the present study, MA is employed to synthesize ultrafine SiC powder by ball milling the Si-50%C elemental powder. Some analyzing techniques were used to study in detail the structural evolution of the Si-50%C elemental powder during ball milling and the effect of heat treatment on the structure of the milled Si-50%C powder. And the reaction mechanism of the formation of SiC via MA technique is also discussed.

2 Experimental

Elemental Si (<45 μm, 99.9% purity, mass fraction) and graphite (CGr) (<30 μm, 99.9% purity) were firstly blended in a molar ratio of Si-50%C. The MA of the Si-50%C powder was carried out using a GN-2 type ball mill operating at 700 r/min. The vial was cooled with forced air during milling to prevent excessive temperature rise. Hardened steel balls of 12 mm in diameter were employed. The mass ratio of ball to powder was maintained at 10?1. To minimize the oxidizing and nitriding of the powder mixtures, the steel vial was first evacuated with a vacuum pump, and then filled with argon with a purity of 99.99%.

The structural evolution of the milled Si-50%C powder in different ball milling durations was characterized using X-ray diffraction(XRD) on a D/max-γ B type X-ray diffractometer with Cu Kα radiation (λ=0.154 nm) and a H800 type transmission electron microscope with selected area electronic diffractometer (TEM+SAED). The average grain sizes of phases were determined by Scherrer formula eliminating the strain and instrumental broadening contribution using standard method[10]. The thermal analysis of the 60 h milled powder was performed by using a NETZSCH STA 449C type differential scanning calorimeter(DSC) in the temperature region of 25-1 200 ℃. During the DSC testing, the powder was heated at a rate of 20 ℃/min and protected by pure argon flowing. The 60 h milled Si-50%C powder was annealed at 900 ℃ and 1 100 ℃ for 1 h, respectively, in a GSL1600X type tube-like vacuum/atmosphere furnace by pure argon flowing. The heat treated powder was then investigated by XRD and TEM+SAED to study the effect of heat treatment on the structure of the milled Si-50%C powder.

3 Results and discussion

3.1 Structural evolution

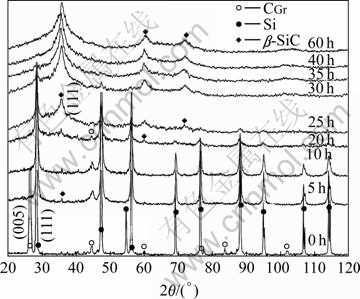

The XRD patterns taken as a function of milling time for the Si-50%C powder are illustrated in Fig.1. No Fe impurity is detected by XRD in the milled Si-50%C powder, suggesting that the Fe impurity content of the milled powder is limited. The crystallographic data (the Bragg angle, 2θ, and the spacing, D) of the main lattice planes of the phases present in the Si-50%C powder are listed in Table 1. After milling for 5 h or above, the diffraction peaks of Si slightly shift into larger angles, and D of Si (111) decreases due to the dissolution of C atoms in the Si lattice, which has not been reported in other studies[3]. Under the equilibrium condition at room temperature, the solid solubility of C in Si is about zero, but it can be extended during MA, because the large volume fraction of grain boundaries present in the nanocrystalline state is expected to enhance the solid solubility. Because the radius of C atom (0.091 4 nm) is less than that of Si atom (0.117 2 nm), when the C atoms occupy the Si locations in the Si lattice to form the solid solution Si(C), the D value of Si(C) (111) decreases.

Fig.1 XRD patterns of Si-50%C powder after milling for different time

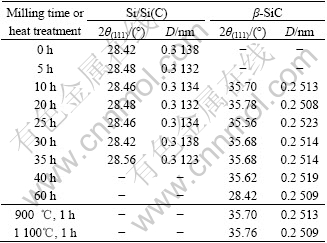

Table 1 Crystallographic data of phases present in ball milled and subsequently heat treated Si-50%C powder

Till milling to 5 h, the peak of CGr (005) disappears completely, which can be explained as follows:

1) During ball milling, the formation of the crystal defects, including basal plane stacking disorder, cleavage, low-angle twist boundaries and half Frank loops, and etc, leads to the breakage of the hexagonal network in a very fine scale until an amorphous-like structure of CGr forms[11].

2) The X-ray diffraction intensity of CGr is less than that of Si due to the smaller atomic number of the C element. During ball milling, the peaks of CGr gradually disappear, which is the same as those of CGr during ball milling the Ti50C50 powder[12].

3) The diffusion of C into Si leads to form Si(C).

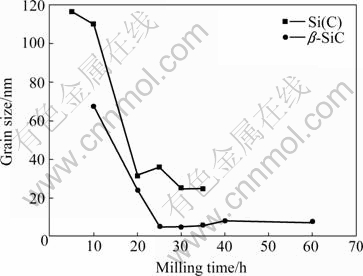

The initial sharp diffraction peaks of Si are considerably broadened during MA as a result of the refinement of the Si grains and the introduction of internal strain. In Fig.2, the grain size of Si(C) during ball milling is described as a function of milling time. In the initial stage (<20 h), the decrease of grain size is very fast. In the next stage (>20 h), the grain size decreases very slowly, which is about 24.9 nm when the powder is milled for 35 h.

Fig.2 Grain size of phases of milled Si-50%C powder vs milling time

In the XRD patterns of Si-50%C powder milled from 5 to 25 h, a new phase corresponding to SiC appears, as shown in Fig.1. Both the intensity and width of the diffraction peaks of SiC increase with milling time, indicating an increase of the amount of SiC, and a reduction in the grain size of SiC (Fig.2). After 25 h milling, the grain size of SiC is about 4.3 nm. After 30 h milling, the Si-50%C powder is mainly composed of SiC and a small amount of remained Si(C). After 40 h milling, no peaks of Si(C) are found but those of SiC appear. During milling from 25 to 40 h, the width of the diffraction peaks of SiC decreases gradually, indicating the increase of SiC grain size (Fig.2). After 60 h milling, the grain size of SiC decreases again, which is calculated to be about 6.4 nm. Although there are many kinds of crystal structures of SiC, SiC formed by ball milling the Si-50%C powder has the 3C type cubic structure (β-SiC) by checking its XRD data with the JCPDS cards.

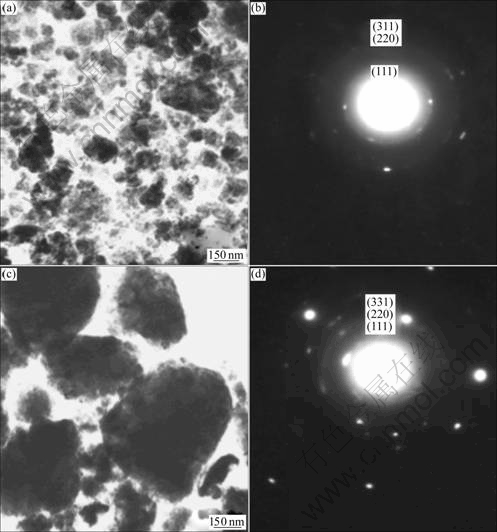

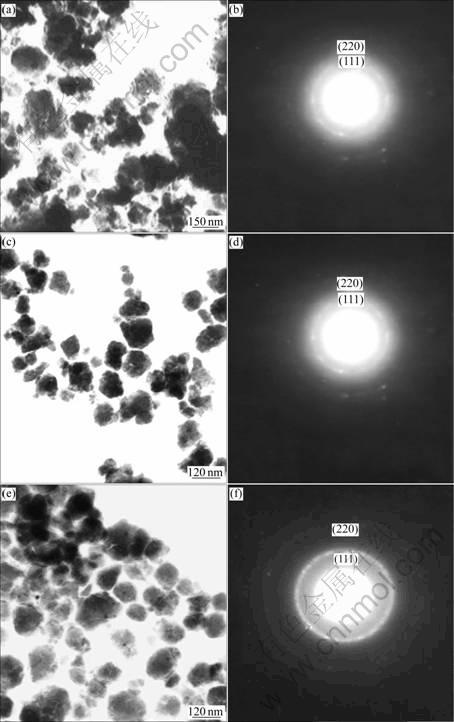

The TEM images and SAED patterns of the 10 h milled powder are shown in Fig.3. The milled powder is sphere-like with a non-homogeneous particle size distribution. Most of the small particles are below 100 nm (Fig.3(a)). The SAED pattern is composed of the big divergent center diffraction speckle and the diffraction rings of the Si polycrystal (Fig.3(b)). In the 10 h milled powder, there also exist some larger particles above 500 nm (Fig.3(c)), in which the finer CGr particles disperse in the Si particles to form the composite powder. EL-ESKANDARANY et al [4] observed that there are twin and nano-twin boundaries on Si and CGr in the composite particles, which is favorable to the formation of β-SiC at the interface. The SAED pattern is composed of the diffraction speckle of the Si single crystal, besides the diffraction rings of polycrystal Si (Fig.3(d)). This shows that the refinement of the Si particles during ball milling results in the formation of the Si single crystal. The TEM images and SAED patterns of the powder milled from 20 to 60 h are shown in Fig.4.

Fig.3 TEM images and SAED patterns of Si-50%C powder milled for 10 h: (a) Image of small particles; (b) SAED pattern of Fig.3(a); (c) Image of large particles, (d) SAED pattern of Fig.3 (c)

Fig.4 TEM images and SAED patterns of Si-50%C powder milled from 20 to 60 h: (a) Image of powder milled for 20 h, (b) SAED pattern of Fig.4(a); (c) Image of powder milled for 30 h; (d) SAED pattern of Fig.4(c); (e) Image of powder milled for 60 h; (f) SAED pattern of Fig.4(e)

Compared with those of the 10 h milled powder, the morphology and size of the 20 h milled powder are similar, but the intensity of the Si diffraction rings are lower. After 30 h milling, the powder particles are fine and have a homogeneous distribution, and the average particle size is about 120 nm (Fig.4(c)). The SAED pattern is composed of the β-SiC polycrystal rings (Fig.4(d)). After 60 h milling, the morphology and particle size of the powder are not apparently changed (Fig.4(e)), but the intensity of the β-SiC diffraction rings (Fig.4(f)) is weaker because after a long time milling, the defect density in the β-SiC crystal increases, resulting in the decrease of the degree of order of β-SiC lattice.

3.2 Reaction mechanism

Up to date, two kinds of reaction mechanisms have been accepted in MA[13-14]. 1) The powders around the colliding balls undergo severe plastic deformation, causing that the flattened particles contact with clean surface, and alloys form through gradual diffusion of thin layers, which is called the gradual diffusion reaction (GDR). 2) The alloys form through a reaction taking place within a short time with release of large heat after certain milling time, which is self-propagating high-temperature synthesis or self-sustained reaction during mechanical alloying, and it is suggested that mechanical impact plays an important role in igniting the reaction. Therefore, the reaction mechanism is usually named mechanically induced self-propagating reaction (MSR)[15]. The MSR was often observed in highly exothermic system, such as Ni-Al, Mo-Si and Nb-C. In their studies, the XRD diffraction peaks of the products by the MSR are always sharper and higher. It is suggested that the products are completely formed within a short time after ball milling for certain duration. The grain sizes of the products are generally large, which is attributed to the high temperature resulted from the large formation heat release of the products.

In the present study, the intensity of the β-SiC peaks increases with the milling time as shown in Fig.1. This suggests that the amount of β-SiC gradually increases during ball milling. Therefore, the MA synthesis of SiC may be controlled by the GDR mechanism. From XRD patterns in Fig.1, the width of the β-SiC peaks decreases, suggesting that the grain size increases form 5 to 8.5 nm during milling the Si-50%C powder form 25 to 40 h (Fig.2). The result does not conform to the GDR mechanism, but conforms to the MSR mechanism. So,it can be concluded that the MA synthesis of SiC is controlled by a mixing mechanism of the GDR mechanism and the MSR mechanism, in which the GDR mechanism may be the main mechanism. Although it was reported by YANG et al in term of HREM observation[6], the MSR mechanism during ball milling the Si-50%C powder is firstly detected by the XRD investigation.

The plastic deformation of the elements may not happen during MA of the Si-50%C powder. During MA of the brittle Si-50%C powder, the Si and CGr grains are rapidly refined, resulting in the formation of nanocrystalline and amorphous phases with a high defect density. Meanwhile, ball milling results in the local temperature rise[16]. All of these provide the large clear interface areas, short diffusion paths, high diffusion rates and high driving forces for the diffusion of C into Si to form Si(C). Due to the large mismatch of the structure and atomic radius between Si and C, a severe lattice distortion is implied in Si(C). In addition, the interfacial energy increases with the refinement of the grain of Si(C) to a nanosize scale. Both of them results in a very high energy state of the Si(C) powder, which makes Si(C) transform into SiC induced by mechanical forces applied by the milling balls and vials during MA. When a large amount of SiC forms controlled by the GDR mechanism, more formation heat ( (SiC)=-74.1 kJ/mol[17]) is released and ignites reactions in the neighbor. And hence, SiC is formed by MSR mechanism, resulting in the formation of larger SiC grains.

(SiC)=-74.1 kJ/mol[17]) is released and ignites reactions in the neighbor. And hence, SiC is formed by MSR mechanism, resulting in the formation of larger SiC grains.

3.3 DSC analysis and heat treatment

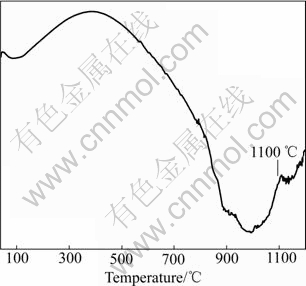

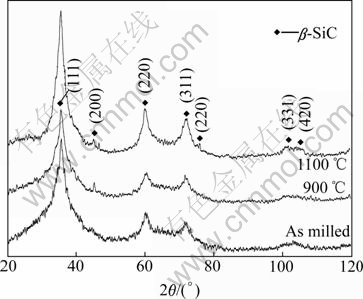

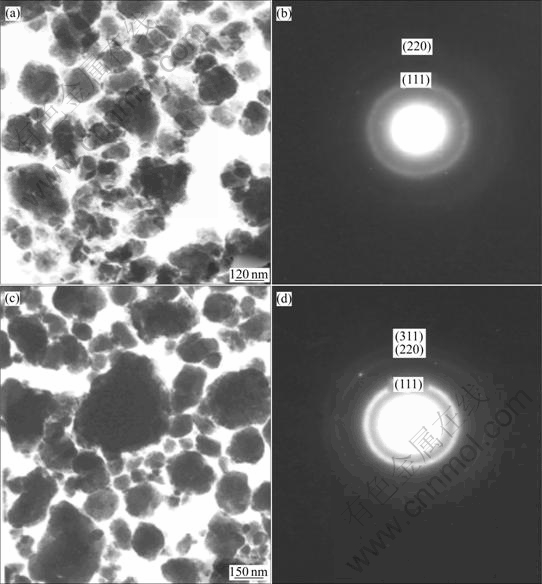

Fig.5 shows the DSC trace of the Si-50%C powder after ball milling for 60 h. In the testing temperature region, there exists no intensively endothermal or exothermal peak, but a weakly exothermal peak at 1 100 ℃. This shows that there are no apparent reactions and/or phase transformations happened. In order to verify the DSC result, the 60 h milled Si-50%C powder was subsequently heat treated at 900 and 1 000 ℃ for 1 h, respectively. After heat treatment, the intensity and shape of the β-SiC diffraction peaks are not apparently changed (Fig.6). After annealing at 900 and 1 100 ℃, the grain size of β-SiC is about 4.6 nm (900 ℃ heating) and 6.6 nm (1 100 ℃ heating), respectively. The heat treating process has no apparent effect on the grain growth of β-SiC, with regard of the Scherrer formula’s errors. This shows that the nanocrystalline β-SiC powder has a high thermal stability, possibly because of the stable structure of SiC and the low diffusion rate of Si and C[18]. More β-SiC diffraction peaks appear after the milled powder is treated at1 100 ℃, which almost possesses all of the β-SiC diffraction peaks with a higher peak intensity. It is suggested that the lattice ordering degree of β-SiC increases during the heat treatment. After being heat treated at 900 ℃, the particle morphology and size of the milled powder are not apparently changed (Fig.7(a)). The SAED pattern is also similar to that of the milled powder (Fig.7(b)). The lattice ordering degree of β-SiC of the milled powder does not increase during the heat treatment. After being heat treated at 1 100 ℃, the milled powder aggregates to form larger particles (Fig.7(c)). More diffraction rings of β-SiC appear in the SAED pattern of the heat treated powder (Fig.7(d)), indicating that the lattice ordering degree of β-SiC increases during the heat treatment. And hence, the exothermal peak at 1 100 ℃ in the DSC trace may be corresponded to the lattice ordering of β-SiC during heat treating.

Fig.5 DSC trace of Si-50%C powder milled for 60 h

Fig.6 XRD patterns of Si-50%C powder after milling for 60 h and then heat treating at 900 ℃ and 1 100 ℃, respectively

Fig.7 TEM images and SAED patterns of heat treated Si-50%C powder milled for 60 h: (a) Heat treated at 900 ℃ for 1 h; (b) SAED pattern of Fig.7 (a); (c) Heat treated at 1 100 ℃ for 1 h; (d) SAED pattern of Fig.7(c)

4 Conclusions

1) Nanocrystalline β-SiC powder was synthesized by ball milling the Si-50%C elemental powders. The formation of SiC is controlled by the mixing mechanism of the gradual diffusion reaction(GDR) and the mechanically induced self-propagating reaction(MSR).

2) During ball milling the Si-50%C elemental powders, the diffusion of C into Si occurs to form Si(C) solid solution with many defects, and then ultrafine SiC. The formation heat of SiC releases during ball milling and ignites reactions in the neighbor, resulting in the formation of SiC with a larger grain size controlled by the MSR mechanism. During ball milling the powder, the grain size of β-SiC firstly decreases (<25 h), and then increases (from 25 to 40 h), finally, decreases again (form 40 to 60 h) to about 6.4 nm after the powder is milled for 60 h.

3) The lattice ordering degree of β-SiC for the 60 h milled powder increases with the annealing temperature increasing. It apparently increases after heat treating the milled powder at 1 100 ℃ for 1 h. But the grain growth of β-SiC does not take place. The weak exothermal peak at 1 100 ℃ of the DSC trace may be corresponded to the ordering of β-SiC lattice during heat treating. References

[1] HAREL S, BRANCHU S, RENAULT P O, BAVIERA P, GROSBRA M. Elaboration and compressibility behavior of nanostructured SiC [J]. Nanostruct Mater, 1998, 10: 25-34.

[2] XIAN Q G, LIANG Y, YANG K, WANG S L. Synthesis of nano SiC powder by laser induced gas phase reaction [J]. J Shenyang Uni Technol, 2003, 25(2): 170-172. (in Chinese)

[3] YANG Z G, SHAW L L. Synthesis of nanocrystalline SiC at ambient temperature through high energy reaction milling [J]. Nanostruct Mater, 1996, 79: 873-886.

[4] EL-ESKANDARANY M S, KONNO T J, SUMIYAMA K, SUZUKI K. Formation of titanium and silicon carbides by mechanical alloying [J]. J Jpn Soc Powder & Powder Metall, 1996, 43: 579-583.

[5] KIM I, BLOMGREN G E, KUMTA P N. Si-SiC nanocomposite anodes synthesized using high-energy mechanical milling [J]. J Power Sources, 2004, 130: 275-280.

[6] YANG X Y, HUANG Z W, WU Y K, YE H Q. HREM observations of the synthesized process of nano-sized SiC by ball milling of Si and C mixed powders [J]. Mater Sci Eng A, 2001, 300: 278-283.

[7] MATTEAZZI P, CARE G L. Room-temperature mechano-synthesis of carbides by grinding of elemental powders [J]. J Am Ceram Soc, 1991, 74: 1378-1390.

[8] RADLINSKI A P, CALKA A. Mechanical alloying of high melting point intermetallics [J]. Mater Sci Eng A, 1991, 134: 1376-1379.

[9] JIE X H, CHENG X, CAI L S, XIE G R. Effect of rare earths on the synthesis of nano-sized SiC powder by ball milling method [J]. J Mater Sci Eng, 2004, 22: 55-58. (in Chinese)

[10] WILLIAMSON G K, HALL W H. X-ray line broadening from filed aluminium and wolfram [J]. Acta Metall, 1953, 1: 22-31.

[11] HUANG J Y. HRTEM and EELS studies of defects structure and amorphous-like graphite induced by ball milling [J]. Acta Metall, 1999, 47: 1801-1808.

[12] TANG W M, ZHENG Z X, WU Y C. Structural evolutions of mechanically alloyed and heat treated Ti50C50 and Ti33B67 powders [J]. Mater Chem Phys, 2006, 99: 144-149.

[13] SURGANARAYANA C. Mechanical alloying and milling [J]. Prog Mater Sci, 2001, 46: 1-184.

[14] YE L L, LIU Z G., QUAN M X, HU Z Q. Different reaction mechanisms during mechanical alloying Ti50C50 and Ti33B67 [J]. J Appl Phys, 1996, 80:1910-1912.

[15] TAKACS L. Self-sustaining reaction induced by ball milling [J]. Prog Mater Sci, 2002, 47: 355-414.

[16] MURTY B S, RANGANATHAN S. Novel materials synthesis by mechanical alloying/milling [J]. Inter Mater Rev, 1998, 43:101-141.

[17] TANG W M, ZHENG Z X, DING H F, JIN Z H. A model of the solid state reaction of SiC/Fe [J]. J Inorganic Mater, 2003, 18: 885-891. (in Chinese)

[18] CHOU T C, JOSHI A, WADSWORTH J. Solid state reactions of SiC with Co, Ni, and Pt [J]. J Mater Res, 1991, 4: 796-809.

Foundation item: Project(050440704) supported by the Natural Science Foundation of Anhui Province, China; Project(103-037016) supported by the Innovation Foundation of Science and Technology, Hefei University of Technology, China

Corresponding author: TANG Wen-ming; Tel: +86-551-2901372; Fax: +86-551-2901362; E-mail: wmtang69@126.com

(Edited by YUAN Sai-qian)