选择性还原-磁选回收镍渣中的有价金属

来源期刊:中国有色金属学报(英文版)2013年第11期

论文作者:潘 建 郑国林 朱德庆 周仙霖

文章页码:3421 - 3427

Key words:nickel slag; selective reduction; magnetic separation

摘 要:采用选择性还原-磁选工艺富集某镍渣中的镍、铜,通过控制还原过程参数实现选择性还原。结果表明:添加熔剂并适当提高渣料的碱度(CaO与SiO2质量比)有助于镍、铜的富集;对碱度0.15、还原温度1200 °C、还原时间20 min、内配煤量5%(质量分数)的优化条件下得到的还原样品,通过磨矿-磁选获得镍、铜、铁品位分别为3.25%、1.20%、75.26%的精矿,镍、铜、铁的回收率分别为82.20%、80.00%、42.17%,实现了镍、铜相对于铁的选择性富集;选择性还原-磁选没有显著降低S、P的含量,两者在工艺过程中的行为需要进一步研究。

Abstract: In order to utilize slag discarded by nickel plants, the selective recovery of nickel and copper versus iron was investigated by selective reduction, which was achieved by controlling the reduction parameters and magnetic separation process on bench scale. The results show that increasing the basicity (mass ratio of CaO to SiO2) of nickel slag facilitates the enrichment of nickel and copper. The process parameters for selective reduction were optimized as follows: basicity of 0.15, reducing at 1200 °C for 20 min, 5% coal on a dried slag mass base. The grinding-magnetic separation results of reduced briquettes show that concentrate containing 3.25%Ni, 1.20%Cu and 75.26%Fe is obtained and selective enrichment is achieved with a recovery of 82.20%, 80.00% for nickel and copper respectively, while the recovery of iron is only 42.17%. The S and P contents are not reduced obviously and further research may be needed to examine the behaviors of S and P in the process.

Trans. Nonferrous Met. Soc. China 23(2013) 3421-3427

Jian PAN, Guo-lin ZHENG, De-qing ZHU, Xian-lin ZHOU

School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China

Received 8 October 2012; accepted 30 January 2013

Abstract: In order to utilize slag discarded by nickel plants, the selective recovery of nickel and copper versus iron was investigated by selective reduction, which was achieved by controlling the reduction parameters and magnetic separation process on bench scale. The results show that increasing the basicity (mass ratio of CaO to SiO2) of nickel slag facilitates the enrichment of nickel and copper. The process parameters for selective reduction were optimized as follows: basicity of 0.15, reducing at 1200 °C for 20 min, 5% coal on a dried slag mass base. The grinding-magnetic separation results of reduced briquettes show that concentrate containing 3.25%Ni, 1.20%Cu and 75.26%Fe is obtained and selective enrichment is achieved with a recovery of 82.20%, 80.00% for nickel and copper respectively, while the recovery of iron is only 42.17%. The S and P contents are not reduced obviously and further research may be needed to examine the behaviors of S and P in the process.

Key words: nickel slag; selective reduction; magnetic separation

1 Introduction

Nickel can be produced from laterite ores by reduction-smelting process [1] or from sulfide ores by roasting-smelting process [2], and both of these processes generate slags, which will not only take up a lot of land, bring pollution to the environment, but will also cause waste of resources [3]. Similar to other non-ferrous metal slag, nickel slag without sufficient amount of valuable metals can be used to produce ceramics [4], cement [5], etc. Hydrometallurgical, pyrometallurgical or even physical processes can be applied when non-ferrous slag contains valuable metals. These processes include acid leaching to recover non-ferrous metals (nickel, cobalt, copper and zinc) [6,7], smelting reduction process to recover iron [8], roasting followed by electrowinning [9] or leaching with water [10], direct reduction-magnetic separation process to recover iron and copper [11] and flocculation-magnetic separation to recover iron as magnetite [12]. Since the content of non-ferrous metals is low compared with iron in the slag, the enrichment of these non-ferrous metal may be enhanced by controlling the reduction of iron, which can be realized by slag modifier [13] or selective reduction, but the latter does not appear to receive much attention in the utilization of nickel slag.

This study involves the selective recovery of non-ferrous metals (nickel and copper) versus iron, from nickel slag by selective reduction-magnetic separation process, with an aim to make high-grade nickel and copper concentrate for producing special steel, i.e. stainless steel or weathering steel [14,15].

2 Experimental

2.1 Raw materials

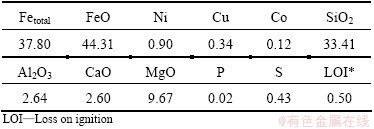

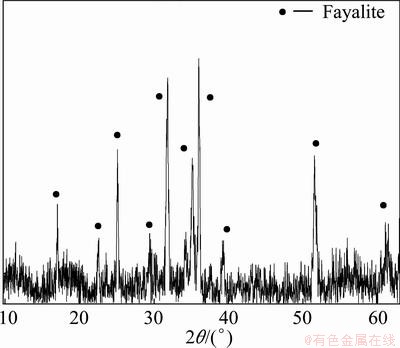

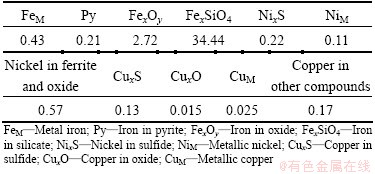

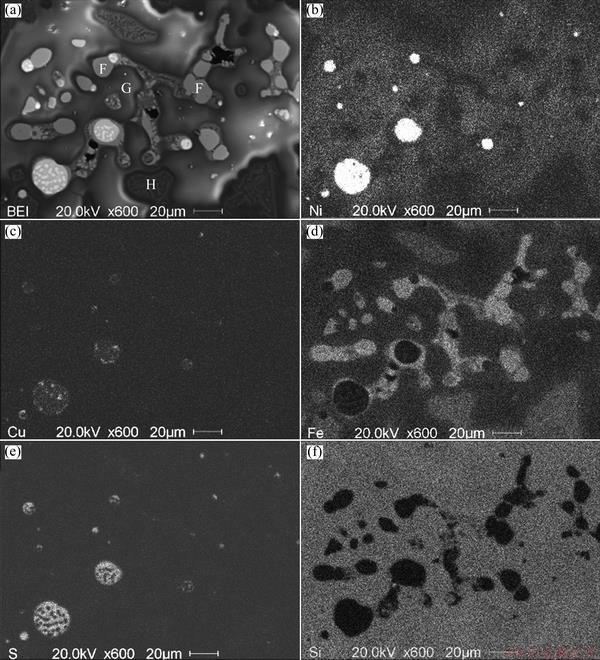

The nickel slag, which was generated from a flash smelter furnace, appears to be round, black granules. The chemical composition of the slag, which was determined by chemical titration, is listed in Table 1. It is easy to find from Table 1 that FeO and SiO2, are the main components which exist mainly as fayalite (FexSiO4) in the slag. Nickel and copper constitute 0.90% and 0.34% of the slag mass, respectively. The X-ray diffraction pattern shown in Fig. 1 confirms that the major mineral in the nickel slag is crystallized fayalite, which is consistent with previous research [6]. By analysis of the chemical phase composition for this slag, as listed in Table 2, it can be found that iron mainly exists as iron silicate or fayalite, and a large part of copper and nickel are in the compounds of oxides or sulfides. The backscatter electron (BSE) image for a block-section slag sample and elemental surface scanning result in Fig. 2 show that nickel and copper are finely disseminated in the iron silicate matrix, which makes the enrichment of nickel and copper difficult. The slag was ground to 88.16% (mass fraction) passing 0.075 mm by wet screen sizing test for making briquettes.

Table 1 Chemical composition of nickel slag (mass fraction, %)

Fig. 1 XRD pattern of nickel slag

Table 2 Chemical phase analysis of nickel slag (mass fraction, %)

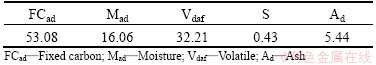

Soft coal was used as reductant in this study and its proximate analysis results are listed in Table 3, from which it can be concluded that the coal is a good reducing agent for its high fixed carbon, high volatile and low ash content [16]. Calcium carbonate and an additive which has a role in the promotion of grain growth, are analytically pure reagents (AR).

Table 3 Proximate analysis of soft coal (mass fraction, %)

2.2 Relevant thermodynamics principles

The main reactions of blending coal with nickel, copper and iron oxides, and fayalite within the nickel slag which may occur during reduction are as follows [17,18]:

CuO(s)+C(s)=Cu(s)+CO(g),

ΔGm=37860-171.02T (1)

NiO(s)+C(s)=Ni(s)+CO(g),

ΔGm=120218-171.37T (2)

Fe3O4(s)+4C(s)=3Fe(s)+4CO(g),

ΔGm=645520-650.46T (3)

Fe2SiO4(s)+2C(s)=2Fe(s)+SiO2(s)+2CO(g),

ΔGm=335400-321.81T (4)

The main reactions of nickel, copper, iron sulfides and fayalite in the slag with reducing agent and calcium carbonate which may occur during reduction are as follows [17,18]:

FeS(s)+2C(s)+CaCO3(s)=Fe(s)+CaS(s)+3CO(g),

ΔGm=469677-462.54T (5)

NiS(s)+2C(s)+CaCO3(s)=Ni(s)+CaS(s)+3CO(g),

ΔGm=433160-499.61T (6)

CuS(s)+2C(s)+CaCO3(s)=Cu(s)+CaS(s)+3CO(g),

ΔGm=430602-487.49T (7)

Fe2SiO4(s)+4C(s)+2CaCO3(s)=2Fe(s)+Ca2SiO4(s)+6CO(g),

ΔGm=909601-941.09T (8)

Ni2SiO4(s)+4C(s)+2CaCO3(s)=2Ni(s)+Ca2SiO4(s)+6CO(g),

ΔGm=642777-850.15T (9)

Under the standard state, it can be calculated from formulas (1)-(4) that the reduction temperatures of CuO(s), NiO(s), Fe3O4(s), Fe2SiO4(s), which are 221.25 K (-51.90 °C), 701.51 K (428.36 °C), 992.41 K (719.26 °C),1042.23 K (769.08 °C) respectively, vary a lot. And from formulas (5) to (9) it can be found that the reduction temperatures of FeS(s), NiS(s), CuS(s), Fe2SiO4(s), Ni2SiO4(s) also have difference, which are 1015.53 K (742.38 °C), 867.00 K (593.85 °C), 883.30 K (610.15 °C), 966.54 K (693.39 °C), 732.55 K (459.40 °C) respectively. Therefore, the reduction of nickel and copper is prior to the reduction of iron oxides and fayalite to metallic iron by controlling the reduction parameters, such as the reduction temperature and reduction duration.

2.3 Experimental procedure and equipment

The nickel slag, reductant, water and additive, whose amount was fixed at 3% on the basis of nickel slag mass according to the preliminary test, were homogeneously mixed at a given ratio and prepared for briquettes. 3 g of the mixture was loaded into a cylinder with d10 mm×50 mm to form a briquette, followed by being dried at 120 °C for at least 4 h in a drying oven to ensure complete drying of the briquettes. Dried briquettes with a total mass around 45 g were loaded into a graphite crucible and reduced in a muffle furnace, then were slowly cooled in a container to about 100 °C under nitrogen atmosphere. The cooled briquettes were broken and ground in a wet ball mill, and then were separated in a Davis tube: the grinding fineness of the reduced calcine is 100% passing 0.075 mm and the magnetic field intensity is maintained at 131.34 kA/m. After grinding- magnetic separation, the concentrate and tailing were dried, weighed, sampled and analyzed by chemical titration following the Chinese standard to determine the iron, nickel and copper grade. The iron recovery was calculated according to the following formula:

RFe=[mcβFe/(mcβFe+mtγFe)]×100%

where mc is the mass of concentrate; mt is the mass of tailing; βFe is the iron grade in concentrate; γFe is the iron grade in tailing.

Fig. 2 BSE image (a) for slag sample and corresponding elemental surface scanning images of Ni (b), Cu (c), Fe (d), S (e) and Si (f)

The calculation of nickel and copper recovery is similar.

Respectively, SX-12-16Q type resistance furnace (muffle furnace) was used for selective reduction, and the RK/ZQM (BM) series ball mill was applied to finely grinding; XCGS-73 Davis tube was used for weak magnetic separation.

3 Results and discussion

3.1 Effect of basicity on selective reduction-magnetic separation

The effects of basicity (mass ratio of CaO to SiO2 in the mixture of nickel slag, additive and calcite) on the metal grade and the metal recovery from the nickel slag were examined under the conditions of the amount of blending soft coal being 3% based on the dried slag mass, reduction at a temperature of 1200 °C for 60 min.

As shown in Fig. 3(a), with a rise in basicity, the grades of nickel, copper and iron in concentrate were elevated at first, and then declined. The result indicates that adding a certain amount of CaCO3 could promote the reduction of minerals containing these metals. However, higher basicity will result in the increase of melting point of slag phase [11], retarding the aggregation of metal grains and decreasing the metal grade in concentrate.

From Fig. 3(b), it can be seen that the metal recoveries do not change significantly and the iron recovery is much lower than that of nickel or copper, reflecting that the selective reduction is achieved. The suitable basicity is recommended at 0.15 to obtain relatively high nickel and copper grades in the concentrate with a satisfactory recovery.

Fig. 3 Effect of basicity on metal grade (a) and recovery (b)

3.2 Effect of reduction temperature on selective reduction-magnetic separation

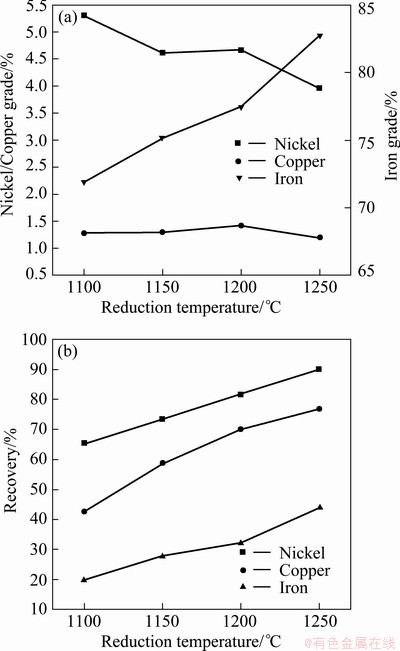

Under the conditions that the basicity, the reduction time, and the dosage of coal are 0.15, 60 min and 3%, respectively. The effects of reduction temperature on the enrichment of nickel, copper and iron were examined and the results are shown in Fig. 4.

Fig. 4 Effect of temperature on metal grade (a) and metal recovery (b)

It can be found from Fig. 4(a) that with the temperature increasing, the nickel grade shows a downward trend in the whole process; however, the copper grade is less affected by temperature; and the iron grade is raised continuously. This may be explained by that the starting reduction temperature of nickel oxide is lower than that of the iron oxide, the reduction of nickel will be prior to iron at low temperatures, but with the temperature increasing, more iron oxide is reduced, leading to a drop in the nickel grade. The change in the copper grade is not so significant as it is quite lower compared with the nickel grade.

Figure 4(b) shows that the recoveries of nickel, copper and iron go up as the temperature increases in the range of temperature examined, which clearly demonstrates that the raising of temperature contributes to the reduction of nickel, copper and iron. But higher temperatures mean higher energy consumption and lower nickel grade, so the suitable reduction temperature is selected at 1200 °C. The temperature used in this study is much higher than the aforementioned commence reduction temperature for the metal-containing minerals. This indicates that the reduction rate and the aggregation of reduced metals are essential to provide a satisfactory recovery during grinding-magnetic separation as high temperature is beneficial to reduction and the growth of metallic particles [19].

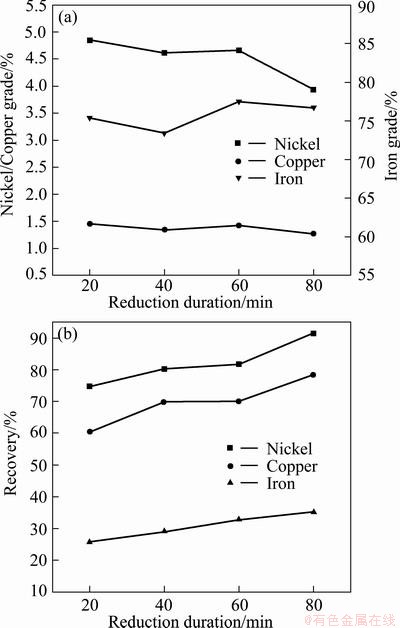

3.3 Effect of reduction duration on selective reduction-magnetic separation

Under the conditions of basicity 0.15, the reduction temperature 1200 °C and the amount of coal 3%, a series of reduction tests were performed for various time to determine the effect of reduction duration on the metal concentration as shown in Fig. 5.

Fig. 5 Effect of reduction duration on metal grade (a) and metal recovery (b)

As can be seen from Fig. 5(a), with the reduction time prolonging, both the grades of nickel and copper in the concentrate show a downward trend, while the grade of iron is ascending. Meanwhile, the recoveries of nickel, iron and copper are elevated, as shown in Fig. 5(b). It can be concluded that with the reduction time prolonging, nickel, copper and iron can be reduced more fully but the increase in iron reduction will result in lower grades of nickel and copper. Comprehensively considering the energy consumption and the grade of nickel and copper, the reduction duration is selected as 20 min.

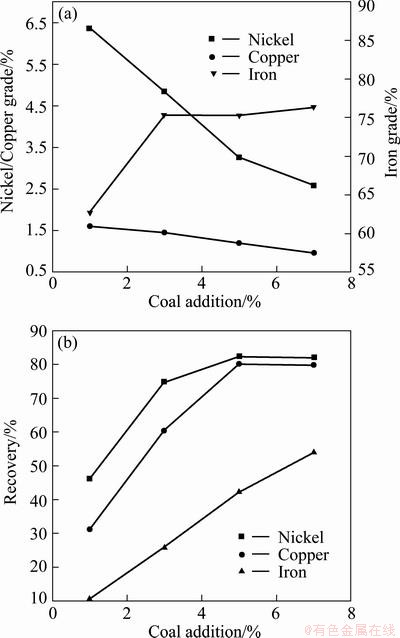

3.4 Effect of dosage of coal on selective reduction- magnetic separation

Under the conditions of the reduction temperature 1200 °C, reduction time 20 min and basicity 0.15, the effect of the amount of blending soft coal on the enrichment of metals from the nickel slag is shown in Fig. 6.

Fig. 6 Effect of dosage of coal on metal grade (a) and metal recovery (b)

From Fig. 6(a) it can be found that the grades of nickel and copper in the concentrate decline as the ratio of reducing agent increases, while the iron grade increases. This indicates that sufficient reductant can promote the reduction of iron oxide to metallic iron, which is similar to the effect of long reduction duration.

The impact of the blending soft coal on the metal recovery is shown in Fig. 6(b), from which it can be seen that the recovery is elevated at first, but further increase in coal addition (higher than 5%) gives no obvious improvement in the recovery of nickel and copper but iron. This indicates that the reduction of iron can be effectively controlled via the addition of reductant. The recovery of nickel is 82.20% with the amount of coal up to 5%, at which the yield of concentrate is 20.00%, the grades of nickel, copper and iron in the concentrate are 3.25%, 1.20%, 75.26%, and the recoveries of copper and iron are 80.00%, 42.17% respectively. By analysis, the S and P contents in the concentrate are 0.24% and 0.032%, which indicates that the S content is reduced but P is enriched in the concentrate in the process as the S and P contents in the slag are 0.43% and 0.02%, respectively.

4 Conclusions

1) Increasing the basicity of nickel slag to some extent is beneficial to the enrichment of nickel and copper during the selective reduction—magnetic separation process. High reduction temperature is required to promote the reduction of metal and provide a good recovery. The selective reduction of nickel and copper relative to iron is enhanced by the control of reduction duration and coal amount.

2) The optimal parameters for selective reduction are basicity of 0.15, the reduction temperature of 1200 °C with a retention time of 20 min, the amount of 5% coal. Through grinding-magnetic separation of the briquettes reduced under these conditions, selective recovery of nickel and copper versus iron is achieved. The grades of nickel, copper in the concentrate are 3.25% and 1.20%, and their recoveries are 82.20% and 80.00%, respectively, while the iron recovery is only 42.17%.

3) The S and P contents are not reduced obviously during selective reduction—magnetic separation and further research may be needed to examine the behaviors of S and P in the process.

References

[1] WANG Cheng-yan, YIN Fei, CHEN Yong-qiang, WANG Zhong, WANG Jun. Worldwide processing technologies and progress of nickel laterites [J]. The Chinese Journal of Nonferrous Metals, 2008, 18(S1): s1-s8. (in Chinese)

[2] ZHANG Chuan-fu, LIU Hai-xia, ZHONG Da-long, ZENG De-wen. Thermodynamical analysis of smelting process of nickel sulfide concentrate [J]. The Chinese Journal of Nonferrous Metals, 1999, 9(4): 805-810. (in Chinese)

[3] CHEN Jin-li, WU Yong-sheng. The current comprehensive utilization and developing tendency of nonferrous metallurgical waste [J]. China Resources Comprehensive Utilization, 2008, 26(10): 22-25. (in Chinese)

[4] WANG Zhong-jie, NI Wen, LI Ke-qing, HUANG Xiao-yan, ZHU Li-ping. Crystallization characteristics of iron-rich glass ceramics prepared from nickel slag and blast furnace slag [J]. International Journal of Minerals, Metallurgy and Materials, 2011, 11(4): 455-459.

[5] SHAN Chang-feng, WANG Jian, ZHENG Jin-fu, YU Yan. Study on application of nickel slag in cement concrete [J]. Bulletin of the Chinese Ceramic Society, 2012, 31(5): 1263-1268. (in Chinese)

[6] LI Yun-jiao, PAPANGELAKIS V G, PEREDERIY I. High pressure oxidative acid leaching of nickel smelter slag: Characterization of feed and residue [J]. Hydrometallurgy, 2009, 97: 185-193.

[7] ZHANG Yang, MAN Rui-lin, NI Wang-dong, WANG Hui. Selective leaching of base metals from copper smelter slag [J]. Hydrometallurgy, 2010, 103: 25-29.

[8] NI Wen, MA Ming-sheng, WANG Ya-li, WANG Zhong-jie, LIU Feng-mei. Thermodynamic and kinetic in recovery of iron from nickel residue [J]. Journal of University of Science and Technology Beijing, 2009, 31(2): 163-168. (in Chinese)

[9] RUDNIK E, BURZYNSKA L, GUMOWSKA W. Hydrometallurgical recovery of copper and cobalt from reduction- roasted copper converter slag [J]. Minerals Engineering, 2009, 22: 88-95.

[10] ALTUNDOGAN H S,  F. Metal recovery from copper converter roasting with ferric sulphate [J]. Hydrometallurgy, 1997, 44: 261-267.

F. Metal recovery from copper converter roasting with ferric sulphate [J]. Hydrometallurgy, 1997, 44: 261-267.

[11] YANG Hui-fen, JING Li-li, DANG Chun-ge. Iron recovery from copper-slag with lignite-based direct reduction followed by magnetic separation [J]. The Chinese Journal of Nonferrous Metals, 2011, 21(5): 1165-1170. (in Chinese)

[12] DONG Hai-gang, GUO Yu-feng, JIANG Tao, LI Guang-hui, YANG Yong-bin. Study on recovering magnetite from nickel metallurgical residue with iron [J]. Ming and Metallurgical Engineering, 2008, 28(1): 37-39. (in Chinese)

[13] BANDA W, MORGAN N, EKSTEEN J J. The role of slag modifiers on the selective recovery of cobalt and copper from waste smelter slag [J]. Minerals Engineering, 2002, 15: 899-907.

[14] YAN Wang-sheng. The developing prospect for the stainless steel of type 200 (Mn-serials) [J]. China’s Manganese Industry, 2004, 22(2): 8-12. (in Chinese)

[15] YU Qian. Review and prospect of weathering steel [J]. Journal of Iron and Steel Research, 2007, 19(11): 1-4. (in Chinese)

[16] ZHU De-qing, LI Jian, QIU Guan-zhou, PAN Jian, OU Ying-qin, ZHOU Wei. One-step process for direct reduction of Xinjiang magnetite concentrate [J]. Journal of Central South University: Science and Technology, 2007, 38(3): 421-427. (in Chinese)

[17] LIU Chun-peng. Copper metallurgy physical chemistry [M]. Shanghai: Shanghai Science and Technology Press, 1990: 48-51, 254. (in Chinese)

[18] HUANG Xi-hu. Principle of iron and steel metallurgy [M]. Beijing: Metallurgical Industry Press, 2002: 304, 436-438. (in Chinese)

[19] LI Yan-jun, LI Shu-fei, HAN Yue-xin. Deep reduction/magnetic separation of laterite for concentration of Ni and Fe [J]. Journal of Northeastern University: Natural Science, 2011, 32(5): 740-744. (in Chinese).

潘 建,郑国林,朱德庆,周仙霖

中南大学 资源加工与生物工程学院,长沙 410083

摘 要:采用选择性还原-磁选工艺富集某镍渣中的镍、铜,通过控制还原过程参数实现选择性还原。结果表明:添加熔剂并适当提高渣料的碱度(CaO与SiO2质量比)有助于镍、铜的富集;对碱度0.15、还原温度1200 °C、还原时间20 min、内配煤量5%(质量分数)的优化条件下得到的还原样品,通过磨矿-磁选获得镍、铜、铁品位分别为3.25%、1.20%、75.26%的精矿,镍、铜、铁的回收率分别为82.20%、80.00%、42.17%,实现了镍、铜相对于铁的选择性富集;选择性还原-磁选没有显著降低S、P的含量,两者在工艺过程中的行为需要进一步研究。

关键词:镍渣;选择性还原;磁选

(Edited by Xiang-qun LI)

Foundation item: Project ([2009]606) supported by the National Development and Reform Commission of China; Project (50974135) supported by the National Natural Science Foundation of China

Corresponding author: Guo-lin ZHENG; Tel: +86-13467506186; E-mail: zgreen@csu.edu.cn

DOI: 10.1016/S1003-6326(13)62883-6