开采环境再造人工顶板锚索支护设计

周科平1, 2,朱和玲1, 2,肖 雄1, 2,陈庆发1, 2

(1. 中南大学 资源与安全工程学院,湖南 长沙,410083;

2. 湖南省深部金属矿产开发与灾害控制重点实验室,湖南 长沙,410083)

摘 要:针对新疆喀拉通克铜镍矿高价值软破矿体的特点和试验开采环境再造连续采矿方法,并以顶板沉降量和塑性区范围为判据,运用FLAC3D软件对人工顶板预应力锚索支护进行模拟分析。设计3种锚网支护方案分别为:方案1,网度为4 m×6 m;方案2,网度为6 m×8 m;方案3,网度为8 m×10 m。通过比较各方案下顶板的沉降量、塑性区范围以及锚索最大轴力变化等参数,筛选出最佳支护方案。研究结果表明:方案1中顶板最大沉降量仅为4.24 cm,塑性破坏区延伸高度小于7 m,锚索最大轴力为16.59 MN,且变化平稳,满足金属矿山安全规程和经济合理的要求,而其他方案结果参数均超出混凝土顶板的稳定性极限,由此得出方案1为最佳设计方案。

关键词:开采环境再造;预应力锚索;数值模拟;支护设计

中图分类号:TD353+.6 文献标识码:A 文章编号:1672-7207(2008)06-1119-06

Pre-stressed anchor supporting design for artificial roof based on reconstructed mining environment

ZHOU Ke-ping1, 2, ZHU He-ling1, 2, XIAO xiong1, 2, CHEN Qing-fa1, 2

(1. School of Resources and Safety Engineering, Central South University, Changsha 410083, China;

2. Hunan Key Laboratory of Mineral Resources Exploitation and Hazard Control for Deep Metal Mines,Changsha 410083, China)

Abstract: According to characteristics of complex high-value deposit, the reconstructed environment and caving-successive were tested with backfilling delayed mining method. Using the displacement and plastic zone as the criterion, the stability of artificial roof was analyzed by FLAC3D software. The three different types of net-degree cable shoring, i.e., type Ⅰ 4 m×6 m, type Ⅱ 6 m×8 m and type Ⅲ 8 m×10 m were simulated. These subsidence, disturbance band, plastic zone and axial force were analyzed. The results show that the maximum subsidence decreases to 4.24 cm, the height of plastic zones is less than 7 m, the maximal axial force is 16.59 MN and fluctuates smoothly in type Ⅰ. All these accord with mine security rules and economical requests, so type Ⅰ is adopted.

Key words: reconstructed mining environment; pre-stressed anchor; numerical simulation; supporting design

新疆喀拉通克铜镍矿地处准噶尔盆地东北缘即世界级的有色金属成矿带上,远景储量巨大,矿石品位高,但矿岩节理裂隙发育,稳固性差,地应力高,是典型的复杂难采矿体。古德生等[1-2]提出开采环境再造连续采矿方法,打破了传统采矿方法间的界限,大大提高了采矿效率。开采环境再造连续采矿方法的本质是在回采矿段周围用胶结充填料构筑一个人工封闭结构,然后在新的采矿环境下进行回采。其中,保证人工顶板的稳定性是实施开采环境再造的一项关键技 术[3]。除受顶板自身强度影响外,其与围岩的共同作用效果也是影响其稳定性的重要因素。由于人工顶板与围岩在强度、刚度等方面差异明显,且相互之间粘结力小,造成变形不协调,易发生离层,难以形成整体共同承载。而长锚索支护则可依靠强大的托锚力,充分发挥锚索的组合梁和悬吊作用,实现支护体与围岩共同承载作用,提高人工顶板稳定性。目前,人们对锚索支护机理及支护设计研究较多,如张乐文等[4-5]对岩土锚固机理及参数进行了研究,Jarred等[6]通过室内仿真模拟试验,研究了注浆锚杆的侧限刚度、注浆长度及膨胀水泥含量对杆体与注浆体界面力学性质的影响;此外,朱维申等[7-11]将水利水电和公路等边坡的锚索支护技术应用到矿山工程岩体的支护。但是,锚索加固理论研究仍落后于工程实践,目前还没有一种比较成熟和完善的预锚加固设计计算方法,许多大型的锚固工程设计主要依靠工程类比法或半经验半理论的方法进行,给锚固工程设计造成浪费或产生潜在的危险[12]。对此,张发明等[13]应用优化与决策分析双重理论,提出了确定岩锚设计参数的优化方法;姜谙男等[14]提出了基于三维数值模拟的大型洞室锚固参数的多目标智能优化方法。但是,这些方法的研究对象均局限于浅地表或低地应力环境,而对于地下“三高”(高应力、高地温、高渗流压力)条件下锚索的应用,特别是在高阶段采场中应用锚索群对离层现象的控制研究较少。在此,本文作者运用国际上通用的岩土工程分析软件FLAC3D有限差分程序分别对3种不同的锚索网度支护方案进行比较研究,以期从中优选出更安全、合理的支护方案。

1 顶板锚索支护数值模拟

1.1 工程概况

新疆喀拉通克铜镍矿是典型的复杂难采矿体,埋藏深,地质条件复杂,采用环境再造法进行回采,其人工顶板构筑采用下向分层进路胶结充填工艺,分3层(2.0 m,3.5 m和3.5 m)构筑,按照С20混凝土配比,并在进路间布钢筋加强顶板的连续性和整体性;顶板的两端由条柱支撑,中间则设计全长注浆锚索支护,预应力为100 kN,锚固端深入围岩11 m,另一端锚固在顶板底层,依靠锚索的组合梁作用和悬吊作用来限制顶板的沉降和变形。

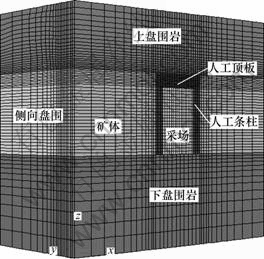

1.2 模型构建

为保证计算的准确性,模型严格按照设计图纸建立,但考虑到模型对称性,取1/2采场进行计算。其模型尺寸为:竖向(z方向)取152 m,纵向(y方向)取75 m,横向(x方向)取157 m,模型划分为46 716个单元,51 951个节点,见图1。在计算模型中,矿岩采用Mohr-Coulomb强度准则,长锚索采用Cable单元模拟,岩体的初始地应力场考虑了自重应力和构造应力,根据现场实测侧压系数取1.2。矿岩、混凝土和锚杆材料的物理力学参数分别如表1和表2所示。

图1 混凝土计算模型

Fig.1 Calculation model of concrete

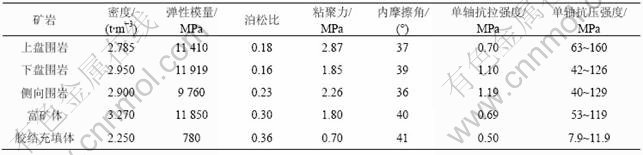

表1 主要矿岩物理力学参数

Table 1 Physical and mechanical properties of rocks and orebodies

表2 砂浆锚索单元计算参数

Table 2 Computing parameters of anchor cable element

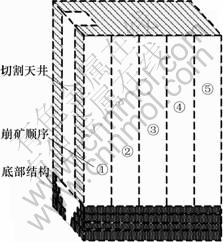

1.3 模拟过程

数值模拟结果的可靠性除受所建模型(包括计算范围、边界条件、初始应力以及计算参数选取)影响外,还与模拟步骤与实际步骤是否一致有关,因此,应尽量使两者保持基本一致,以得出较真实的试验结果。这里模拟完全按照实际步骤分别对3种不同网度的锚索支护形式和过程进行模拟,3种方案的锚索网度分别设计为:方案1,4 m×6 m;方案2,6 m×8 m;方案3,8 m×10 m。实际的开挖形式采用分步侧向崩矿,整个循环过程共计5步,如图2所示。

图2 采场开挖步骤示意图

Fig.2 Excavation steps of process

2 计算结果与分析

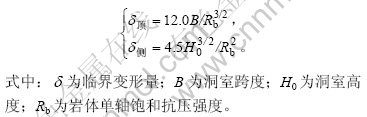

沉降量和塑性变形是顶板稳定性评价的重要指标,根据普氏理论总结出来的岩体失稳时临界变形与地下洞室跨度、高度以及岩体的抗压强度有关的经验公式,以围岩变形量为判据,来评价各区域岩体的稳定性程度[15],表达破坏区和扰动区范围,并作为本文评价锚索支护效果的主要依据。对于沉降量和扰动范围的信息监测,主要通过在顶板及围岩内布设一系列监测点来获取。以顶板中心点为基点,按一定间距分别沿纵向L1、横向L2和竖向L3各设置6个监测点,其编号和位置如图3所示。

图3 监测点布置

Fig.3 Location of monitoring points

2.1 沉降量分析

运用FLAC3D软件对顶板稳定性进行模拟运算,结果表明,在无锚索支护条件下顶板的最大沉降量达14.10 cm,塑性区范围扩展到顶板以上5 m围岩内,顶板与围岩有明显离层现象,必须对其进行支护。加锚支护后顶板稳定性加强,图4~6所示分别为3种支护方案下顶板纵向L1、横向L2和竖向L3上各监测点在开挖完毕时的最终沉降量图。可见,顶板沉降得到不同程度地抑制,且各监测点的沉降量互不相同;无论采用哪种方案,各点沉降量受网度影响较大,总的趋势是随锚网的加密而减少,且减少的幅度越来越大。以纵向L1上各监测点为例,图4中1~3号点(布置在顶板内)的沉降量远大于4~7号点(布置在围岩内)的沉降量,且突变布置在顶板与围岩交界面的4号监测点上,说明在纵向方向,采场开挖的扰动范围主要局限在顶板范围内;在横向和竖向方向的沉降虽然也以顶板所在范围为主,但曲线波动相对较缓,说明各处沉降量在顶板与围岩间平缓过渡。

1—方案1,网度为4 m×6 m;2—方案2,网度为6 m×8 m;3—方案3,网度为8 m×10 m

图4 L1监测点最终沉降量

Fig.4 Final subsidences of monitoring points in L1

1—方案1,网度为4 m×6 m;2—方案2,网度为6 m×8 m;3—方案3,网度为8 m×10 m

图5 L2监测点最终沉降量

Fig.5 Final subsidences of monitoring points in L2

1—方案1,网度为4 m×6 m;2—方案2,网度为6 m×8 m;3—方案3,网度为8 m×10 m

图6 L3监测点最终沉降量

Fig.6 Final subsidences of monitoring points in L3

统计结果表明:方案1中,1号监测点的沉降量约为10号监测点最终沉降量的2.1倍,是16号监测点最终沉降量的2.3倍,即在距顶板中心横向15 m处围岩的沉降量为2.01 cm,在距顶板中心竖向9 m处围岩的沉降量为1.91 cm。依据顶板的允许变形量,按如下经验公式进行估算[16]:

扰动范围在顶板外表面纵向5 m、横向8 m、竖向10 m范围内。从沉降量来看,采用方案1时3个方向上各监测点的沉降量均最小,方案2次之,方案3最大;方案2和3的支护效果差别不大,而采用方案1的支护效果明显,说明该网度最佳;此外,1号监测点反映的是顶板最大变形状态,3种方案下其最大沉降量分别为4.24,8.25和9.68 cm;基于混凝土顶板抗拉强度特点和矿山安全规程[17],只有方案1满足安全要求。

2.2 塑性区分析

从整体上看,加锚后顶板的塑性区比无锚索支护时明显减少,且顶板的塑性变形主要以拉应力破坏和剪切破坏为主。图7所示是支护网度分别为4 m× 6 m(方案1)、6 m×8 m(方案2)和8 m×10 m(方案3) 3种方案下顶板的塑性变形图。采用方案1时,塑性区成三角状,底端大上部小,塑性变形区域在7 m以内,主要分布在顶板下部分2层;采用方案2时,塑性区面积扩大,成梯形状,且塑性区延伸至顶板最上分层;采用方案3时,塑性区成驼峰状,也可视为2个三角形塑性区的非完全叠加,其塑性区沿横向范围进一步扩大,竖向范围也超出顶板厚度9 m,造成有厚度1~ 2 m的围岩产生塑性变形。可见,采用方案1能有效控制顶板的塑性变形,满足顶板的稳定性要求。

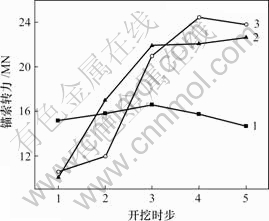

2.3 锚索最大轴力分析

图8所示为不同网度的锚索支护方案对其最大轴力的影响。可以看出,采用方案1时,锚索最大轴力随开挖变化最小,在第3步开挖后达到最大值,为16.59 MN,随后,最大轴力开始逐步下降,终值降至14.67 MN;采用方案2和方案3时,锚索最大轴力则随开挖进程变化较大且呈增大趋势,并在开挖完毕后达到峰值,分别为22.67 MN和23.88 MN。锚索的最大轴力变化可反映围岩所受拉应力和剪切应力的变化,为了使岩土介质抗拉强度和抗剪强度小,应避免其受过大的拉应力和剪应力,可见,支护方案1效果最好。

(a) 方案1;(b) 方案2;(c) 方案3

图7 3种方案下顶板塑性区分布图

Fig.7 Plastic zone of roof in three schemes

1—方案1;2—方案2;3—方案3

图8 锚索轴力变化图

Fig.8 Relationship between cable axial force and excavation steps

3 结 论

a. 锚索支护能有效改善顶板的受力状态,限制顶板的沉降和变形,但网度不同,其支护效果又有明显差异:在无锚索支护时最大沉降量达14.10 cm,采用方案1时沉降量为4.24 cm,方案2为8.25 cm,方案3为9.68 cm。

b. 不同锚网支护对顶板的塑性区范围也有显著影响:采用方案1时塑性区呈三角状,范围为顶板外表面纵向5 m,横向8 m,竖向10 m;采用方案2时,下塑性区呈梯形状,范围为顶板外表面纵向6 m,横向10 m,竖向12 m;采用方案3时,下塑性区呈驼峰状,范围为外表面顶板纵向7 m,横向13 m,竖向15 m。

c. 不同锚网支护还影响锚索的受力状态,如采用方案1时,锚索轴力变化平稳,极大值出现在第3步开挖,达16.59 MN,而在开挖完毕后则降至14.67 MN;采用方案2和3时,锚索轴力变化波动大且呈增大趋势,最终值分别为22.67 MN和23.88 MN。经综合对比分析,方案1为最佳支护方案。

参考文献:

[1] 古德生, 李夕兵. 现代金属矿床开采科学技术[M]. 北京: 冶金工业出版社, 2006.

GU De-sheng, LI Xi-bing. Modern mining science and technology for metal mineral resources[M]. Beijing: China Metallurgical Industry Press, 2006.

[2] 周科平, 朱和玲, 肖 雄, 等. 采矿环境再造连续开采地压演化过程的控制与仿真[J]. 中南大学学报: 自然科学版, 2008, 39(3): 417-422.

ZHOU Ke-ping, ZHU He-ling, XIAO Xiong, et al. Control and simulation of ground pressure evolutional process based on reconstructed mining environment and continuous caving method[J]. Journal of Central South University: Science and Technology, 2008, 39(3): 417-422.

[3] 周科平, 苏家红, 古德生, 等. 复杂充填体下矿体开采安全顶板厚度非线性预测方法[J]. 中南大学学报: 自然科学版, 2005, 36(6): 1094-1099.

ZHOU Ke-ping, SU Jia-hong, GU De-sheng, et al. The nonlinear forecasting method of the least security coping thickness when mining under complex filling body[J]. Journal of Central South University: Science and Technology, 2005, 36(6): 1094-1099.

[4] 张乐文, 汪 稔. 岩土锚固理论研究之现状[J]. 岩土力学, 2002, 23(5): 627-631.

ZHANG Le-wen, WANG Ren. Research on status quo of anchorage theory of rock and soil[J]. Rock and Soil Mechanics, 2002, 23(5): 627-631.

[5] 彭文祥, 赵明华, 袁海平, 等. 基于拉格朗日差分法的全长注浆锚杆支护参数优化[J]. 中南大学学报: 自然科学版, 2006, 37(5): 1002-1007.

PENG Wen-xiang, ZHAO Ming-hua, YUAN Hai-ping, et al. Parameters analysis of grouted bolts by Lagrangian difference method[J]. Journal of Central South University: Science and Technology, 2006, 37(5): 1002-1007.

[6] Jarred D J, Haberfield C M. Tendon/grout interface performance in grouted anchors[C]//Proceeding Ground Anchorages and Anchored Structures. London: Thomas Telford, 1997.

[7] 朱维申, 刘建华, 杨法玉. 小浪底水利枢纽地下厂房岩体支护效果数值分析研究[J]. 岩土力学, 2006, 27(7): 1087-1091.

ZHU Wei-shen, LIU Jian-hua, YANG Fa-yu. Numerical analysis of supporting effect of underground caverns surrounding rockmass of Xiaolangdi Key Water Control Project[J]. Rock and Soil Mechanics, 2006, 27(7): 1087-1091.

[8] 曾祥勇, 邓安福. 锚索与锚杆联合锚固支护岩坡的有限元分析[J]. 岩土力学, 2007, 28(4): 790-794.

ZENG Xiang-yong, DENG An-fu. Finite element analysis of rock cutting slope reinforced by combined action of prestressed anchor cable and anchor bolt[J]. Rock and Soil Mechanics, 2007, 28(4): 790-794.

[9] 孙晓明, 何满潮. 深部开采软岩巷道耦合支护数值模拟研究[J]. 中国矿业大学学报, 2005, 34(2): 166-169.

SUN Xiao-ming, HE Man-chao. Numerical simulation research on coupling support theory of roadway within soft rock at depth[J]. Journal of China University of Mining & Technology, 2005, 34(2): 166-169.

[10] 高 谦, 宋建国, 余伟健, 等. 金川深部高应力巷道锚喷支护设计与数值模拟技术[J]. 岩土工程学报, 2007, 29(2): 279-284.

GAO Qian, SONG Jian-guo, YU Wei-jian, et al. Design and numerical simulation of rock bolting and shotcrete for deep tunnels with high stress in Jinchuan Mine[J]. Chinese Journal of Geotechnical Engineering, 2007, 29(2): 279-284.

[11] 谢文兵, 笪建原, 冯光明. 综放沿空留巷围岩控制机理[J]. 中南大学学报: 自然科学版, 2004, 35(4): 657-661.

XIE Wen-bing, DA Jian-yuan, FENG Guang-ming. Mechanism of controlling surrounding rock around gob-side entry retaining in top-coal caving mining face[J]. Journal of Central South University: Science and Technology, 2004, 35(4): 657-661.

[12] 顾金才, 沈 俊, 陈安敏, 等. 锚索预应力在岩体内引起的应变状态模型试验研究[J]. 岩石力学与工程学报, 2000, 19(增): 917-921.

GU Jin-cai, SHEN Jun, CHEN An-min, et al. Model testing study of stra in distribution regularity in rockmass caused by prestressed anchorage cable[J]. Chinese Journal of Rock Mechanics and Engineering, 2000, 19(Suppl): 917-921.

[13] 张发明, 刘 宁, 赵维炳. 岩质边坡预应力锚索加固的优化设计方法[J]. 岩土力学, 2002, 23(2): 187-190.

ZHANG Fa-ming, LIU Ning, ZHAO Wei-bin. Optimizing design method of prestressed cables in reforcing rock slope[J]. Rock and Soil Mechanics, 2002, 23(2): 187-190.

[14] 姜谙男, 冯夏庭, 刘 建, 等. 基于三维数值模拟的地下大型洞室锚固参数智能优化[J]. 岩石力学与工程学报, 2004, 23(10): 1700-1705.

JIANG An-nan, FENG Xia-ting, LIU Jian, et al. Intelligent optimization of anchoring parameters for large underground houses based on three dimensional numerical simulation[J]. Chinese Journal of Rock Mechanics and Engineering, 2004, 23(10): 1700-1705.

[15] 于学馥, 郑颖人, 刘怀恒, 等. 地下工程围岩稳定分析[M]. 北京: 煤炭工业出版社, 1983.

YU Xue-fu, ZHENG Ying-ren, LIU Huai-heng, et al. Stability analysis of underground cavern[M]. Beijing: China Coal Industry Press, 1983.

[16] 李 宁, 陈蕴生, 陈方方, 等. 地下洞室围岩稳定性评判方法新探讨[J]. 岩石力学与工程学报, 2006, 25(9): 1941-1944.

LI Ning, CHEN Yun-sheng, CHEN Fang-fang, et al. Research on tunnel stability criterion[J]. Chinese Journal of Rock Mechanics and Engineering, 2006, 25(9): 1941-1944.

[17] 于骁中, 谯常忻, 周群力. 岩石与混凝土断裂力学[M]. 长沙: 中南工业大学出版社, 1991.

YU Yao-zhong, QIAO Chang-xin, ZHOU Qun-li. Fracture mechanics of rock and concrete[M]. Changsha: Central South University of Technology Press, 1991.

收稿日期:2008-01-12;修回日期:2008-04-25

基金项目:“十一五”国家科技支撑计划项目(2006BAB02A02);国家自然科学基金资助项目(50490274);国家教育部博士点基金资助项目(20050533035)

通信作者:周科平(1964-),男,湖南衡阳人,教授,博士生导师,从事采矿与矿山岩石力学教学与研究工作;电话:0731-8879965;E-mail: kpzhou@263.net