高温短时人工时效对2524合金疲劳性能的影响

刘志义1, 2,周 杰1, 2,刘延斌1, 2,李云涛1, 2,段水亮1, 2,柏 松1, 2,邓才智1, 2

( 中南大学 有色金属材料科学与工程教育部重点实验室,湖南 长沙,410083;

2. 中南大学 材料科学与工程学院,湖南 长沙,410083)

摘 要:研究高温短时时效对2524合金室温拉伸及疲劳性能的影响,采用3DAP分析、透射电镜等对合金组织进行观察。结果表明:经过高温短时时效试样的抗拉强度与自然时效试样的相当,但是塑性有很大的提高;高温短时时效后试样的疲劳裂纹扩展速率比自然时效试样低。经过高温短时人工时效的2524合金组织中Cu和Mg原子发生强烈偏聚形成圆盘状的GPB区,尺寸较大,这种人工时效组织既能提高应力循环下的裂纹张开扩展阻力,又不影响裂纹闭合,从而降低疲劳裂纹扩展速率。

关键词:2524合金;高温短时时效;疲劳裂纹扩展;GPB区;裂纹闭合

中图分类号:TG146 文献标识码:A 文章编号:1672-7207(2009)01-0112-05

Effect of artificial ageing on fatigue behaviour of

2524 aluminum alloy

LIU Zhi-yi1, 2, ZHOU Jie1, 2, LIU Yan-bin1, 2, LI Yun-tao1, 2, DUAN Shui-liang1, 2,

BAI Song1, 2, DENG Cai-zhi1, 2

The Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The effects of artificial ageing on the fatigue crack propagation and room mechanical properties of 2524 aluminum alloy were investigated. The results of tension test at room temperature show that the elongation of samples artificially aged at high temperature for short time is much higher than that of naturally aged samples, at the same time, both of the high temperature-short time artificial aged and naturally aged samples have the similar tensile strength. The fatigue crack growth rate tests indicates that the fatigue crack growth of high temperature-short time artificially aged samples decreases. 3DAP (three-dimensional atom probe) analysis suggests that a bigger size and a plate-shaped Cu-Mg clusters form when artificially aged at high temperature for short time. These GPB zones can improve the fatigue crack propagation resistance of 2524 aluminum alloy, however the crack closure does not change.

Keywords: 2524 aluminum alloy; high temperature-short time artificial ageing; fatigue crack propagation; GPB zones; crack closure

2×××系高强度铝合金具有密度低、强度高、加工性能好及焊接性能良好等综合性能,长期以来被广泛应用于航天、航空工业及民用工业等领域。尤其是在航空工业中有着十分重要的地位,是航空工业主要结构材料之一[1-5]。该系列合金的时效析出序列一般认为是:GPB区,S′相,S相[6-7];而Wang等[8]则认为是GPB区、S″、S′相和S相。

作为耐疲劳损伤构件的合金[9-11],其使用的时效状态一般为自然时效态,也就是说合金的微观组织处于时效析出的GPB区阶段。文献[12-13]研究时效对2×××系铝合金的疲劳行为的影响,结果表明弥散强化的2×××系铝合金通常使用的是欠时效状态,由于欠时效态下的析出相是可剪切的,并且有利于滞留滑移带的形成。Sadeler等[14-15]认为固溶处理后进行时效比铸态合金有更高的疲劳性能。Bray等[9]认为人工时效降低了2×××系铝合金的疲劳裂纹扩展阻力。张国君等[16]认为细小时效强化相体积分数增加,或者同一体积分数下尺寸的降低,都将导致铝合金疲劳裂纹扩展速率的增加。田秀云等[17]研究认为采用时效温度(45±5) ℃,时效时间12 h的新时效制度可以使2024合金的常规机械性能、抗疲劳性能和断裂性能以及耐腐蚀性能等达到与自然时效时的性能要求。刘志义 等[18]认为高温短时间人工时效合金中形成的GPB区尺寸大于自然时效合金中的GPB区,而在热暴露过程中尺寸较大的GPB区要比尺寸较小的GPB区较难回溶,所以高温短时人工时效获得的GPB区组织比自然时效获得的GPB区稳定性更高。

本文作者在此基础之上研究了高温短时人工时效对2524合金疲劳性能的影响,并利用3DAP分析、透射电镜分析针对高温短时人工时效获得的GPB区进行了观察,以及其对疲劳裂纹扩展速率的影响进行了研究。

1 实 验

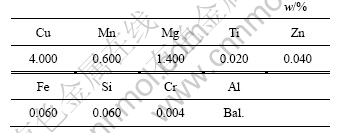

本实验所用材料为2 mm厚的2524合金板材。合金化学成分见表1。

表1 2524合金化学成分

Table 1 Chemical composition of alloy studied mass fraction

从板材上切取的拉伸试样及疲劳试样先在500 ℃下进行固溶,淬火后进行3%的冷变形后进行自然时效(即T351处理状态)以及 170 ℃的硅油里人工时效30 min的处理。固溶处理在电阻加热炉中进行,用电位差计控制炉温,误差控制在±1 ℃内,淬火介质为室温水。时效处理在硅油中进行,用水银温度计读数,油温误差控制在±1 ℃。在室温、大气环境下测定2524合金在R=0.1时的L-T向疲劳裂纹扩展速率。用CSS-4400万能电子拉伸机测试2524-T351和2524- 170 ℃/30 min处理后的试样的的力学性能(σb,σ0.2和δ5)。用Tecnai G2 20型透射电镜(TEM)以及3DAP进行微观组织分析。3DAP分析用的样品要制成针尖状,尖端的曲率半径为10~100 nm。先将样品加工成圆截面(直径为0.5 mm)或方截面的细丝(<0.5 mm×0.5 mm),再用电解抛光方法制备针尖状的样品。电解抛光时采用两步法:首先,使一薄层电解液漂浮在密度较大的惰性液体上,丝状样品垂直放入电解液中进行电解抛光,在长度的中部产生细颈直至断开,得到针状样品,但尖端的曲率半径仍不能满足要求,需要进行下一步显微电解抛光;显微电解抛光时用铂丝弯曲成小环作为负极,环中能保留一小滴电解液,将极细的丝状样品插入带有电解液的环中,在样品和Pt丝间通上脉冲电源,利用短暂时间的电解抛光来完成针尖样品的制备过程,操作在显微镜下完成[19]。

2 结果与讨论

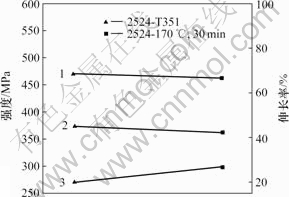

图1所示为2524合金T351态及170 ℃/30 min高温短时人工时效态的室温拉伸性能比较图。从图中可以看出,经过高温短时人工时效后的合金强度与T351态相差并不大,而合金的塑性却提高很多。

1—抗拉强度;2—屈服强度;3—伸长率

图1 2524合金T351态与170 ℃,30 min高温短时人工时效力学性能的比较

Fig.1 Comparison of mechanical properties of 2524 aluminum alloy after T351 and 170 ℃, 30 min ageing

图2所示为室温、大气环境下测定的不同热处理状态的2524合金在应力比R=0.1时L-T方向疲劳裂纹扩展速率。从图2可以看到,2524合金经过时效后的L-T向疲劳裂纹扩展速率比2524-T351态合金要低,特别是在疲劳裂纹扩展的第二阶段(10<ΔK< 25 MPa?m1/2)比较明显。这说明2524合金经过高温短时人工时效后的L-T向疲劳裂纹扩展速率降低了。

图2 室温、大气环境下测定的2524合金在应力比R=0.1时的L-T向疲劳裂纹扩展速率

Fig.2 Fatigue crack growth rate vs applied ΔK for 2524 aluminum alloy at L-T direction

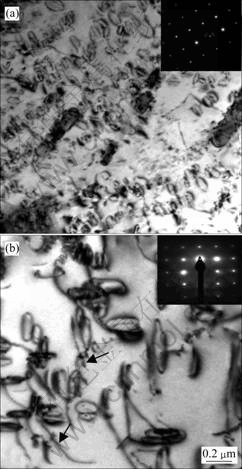

图3所示为2524合金经过T351以及 170 ℃,30 min的高温短时人工时效后的透射电镜照片。从图3(a)及对应的衍射斑可以看出通过T351处理的合金组织主要为GPB区、淬火空位崩塌而成的位错环以及在长期的自然时效过程中空位向位错中心扩散而使得位错环长大成为蜷线位错。从图3(b)及对应的衍射斑点中的微弱衍射茫可以看出通过170 ℃,30 min高温短时人工时效处理合金组织中的晶格畸变较大,从而说明高温短时人工时效获得的GPB区尺寸比T351态的GPB区尺寸大。通过170 ℃,30 min高温短时人工时效处理的合金基体中除GPB区外,还存在一定数量的位错环和蜷线位错,图中箭头标识的这种位错线位于与入射电子束平行的原子面上,而其他椭圆形的位错线位于与电子束和<100>Al方向均成45°角的晶面上。显然这些位错线均位于{110}Al晶面簇上。因此图3(b)中的螺型位错线实际上是由不同{110}Al晶面上的分个的位错环叠加重合形成的。由此可以看出,无论是经过T351还是170 ℃,30 min高温短时人工时效处理的2524合金,其显微组织都是以GPB区为主,同时也说明高温短时人工时效的合金仍处在GPB区强化阶段。经过高温短时人工时效后的合金强度与T351态相差并不大,而合金的塑性提高很多,这说明通过高温短时人工时效获得的较大尺寸的圆盘状GPB区可以更有效的阻碍位错的运动。

(a) T351; (b)170 ℃, 30 min

图3 2524合金显微组织与衍射斑点

Fig.3 TEM micrographs and corresponding selected area electron diffraction pattern of 2524 aluminum alloy

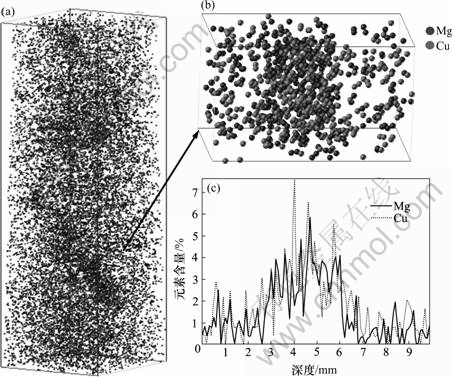

为了观察高温短时人工时效获得的GPB区的合金组织进行了3DAP分析。图4所示为3DAP照片,图4(b)所示为图4(a)中截取典型的GPB区原子偏聚团。从图中可以看出经过高温短时人工时效的2524合金组织中Cu和Mg原子发生强烈偏聚成圆盘状,这与Silcock等[20]认为的GPB区为小的圆柱体,其直径为1~2 nm、高为4~8 nm的实验结果基本一致。人工时效促进了Cu-Mg原子团的形成,并形成了较大尺寸的GPB区,这与透射电镜所观察到的结果一致。从浓度深度分布(图4(c))可以看出,Cu和Mg元素的摩尔分数为6%~7%。

(a),(b) 元素分布;(c) GPB区元素含量深度分布

图4 2524合金经过170 ℃,30 min高温短时人工时效的3DAP元素分布

Fig.4 3DAP elemental content mapping of GPB zones in artificial aged 2524 aluminum alloy

作为耐损伤构件的2524合金,其使用的时效状态一般为自然时效态,也就是说合金的微观组织处于时效析出的GPB区阶段。而GPB区强化的Al-Cu-Mg合金有着优异的疲劳性能,各种耐疲劳合金特别是2×××铝合金一般都在自然时效状态下使用而GPB区一般被认为是Al-Cu-Mg合金的主要抗疲劳微组 织[9]。据文献[7]报道,由于铝具有高的层错能,发生在纯铝合金多个滑移系中的滑移是不可回复的。而在Al-Cu-Mg合金中,自然时效或者人工时效初期形成的溶质原子偏聚团能够使滑移集中到一个平面上去,因此这一类型的滑移将有利于循环加载过程中变形的回复[21],从而减少疲劳损坏。在疲劳应力循环过程中,高温短时人工时效获得的较大尺寸的GPB区,对正应力循环周期内的裂纹扩展张开的阻力较大,使得裂纹在每个应力循环的扩展距离减小;同时,在压应力循环的负周期内,又不会影响裂纹尖端的闭合,使得裂纹尖端能够顺利有效地闭合,裂纹闭合度提高。因此,降低了裂纹扩展速率,提高了材料的抗疲劳性能。另一方面, T351 态合金中的GPB区由于尺寸较小,容易发生循环软化现象,在裂纹扩展过程中,GPB区被位错往复切割,容易发生回溶使组织发生退化,降低了材料的疲劳阻力,从而有利于疲劳裂纹的扩展。由于采用的高温短时170 ℃,30 min人工时效是欠时效状态,欠时效状态的合金基体内含有可切变的与基体共格的GPB区,这些原子偏聚团易于被位于疲劳裂纹前沿的滑移带所剪切,不易产生应力集中,不会形成新的疲劳裂纹,也有助于降低疲劳裂纹扩展速率。

3 结 论

a. 经过高温短时人工时效后的合金强度与T351态合金的强度相当,而合金的塑性却有所提高。

b. 经过高温短时人工时效的合金组织仍然是以GPB区为主。

c. 疲劳裂纹扩展速率的测定说明高温短时人工时效可以降低2524合金的L-T向疲劳裂纹扩展 速率。

d. 3DAP分析表明经过高温短时人工时效的2524合金组织中Cu和Mg原子发生强烈偏聚成圆盘状,形成的GPB区尺寸较大。

高温人工时效的2524合金组织既能提高应力循环下的裂纹张开扩展阻力,又不影响裂纹闭合,从而降低疲劳裂纹扩展速率,提高了2524合金的疲劳 性能。

参考文献:

[1] 王祝堂. 铝合金加工手册[M]. 长沙: 中南大学出版社, 2000.

WANG Zhu-tang. The handbook of aluminum alloy and process[M]. Changsha: Central South University Press, 2000.

[2] 刘志义, 李云涛, 刘延斌, 等. Al-Cu-Mg-Ag合金析出相的研究进展[J]. 中国有色金属学报, 2007, 17(12): 1905-1915.

LIU Zhi-yi, LI Yun-tao, LIU Yan-bin, et al. Development of Al-Cu-Mg-Ag alloys[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(12): 1905-1915.

[3] 李云涛, 刘志义, 夏卿坤, 等. Er在Al-Cu-Mg-Ag合金中的存在形式及其均匀化工艺[J]. 中南大学学报: 自然科学版, 2006, 37(6): 1043-1047.

LI Yun-tao, LIU Zhi-yi, XIA Qing-kun, et al. Homogenizing process and form of Er in Al-Cu-Mg-Ag alloy[J]. Journal of Central South University: Science and Technology, 2006, 37(6): 1043-1047.

[4] 王昌臻, 潘清林, 何运斌, 等. 2124铝合金热轧厚板的热处理制度[J]. 中南大学学报: 自然科学版, 2007, 38(3): 386-393.

WANG Chang-zhen, PAN Qing-lin, HE Yun-bin, et al. Heat treatment of thick hot-rolled plate of 2124 alloy[J]. Journal of Central South University: Science and Technology, 2007, 38(3): 386-393.

[5] Feng C, Liu Z Y, Ning A L, et al. Effect of low temperature aging on microstructure and mechanical properties of super-high strength aluminum alloy[J]. Journal of Central South University of Technology, 2006, 13(5): 461-467.

[6] Ringer S P, Hono K, Sakurai T, et al. Cluster hardening in an aged Al-Cu-Mg alloy[J]. Scripta Materialia, 1997, 36(5): 517-521.

[7] Ringer S P, Hono K, Polmear I J.Precipitation processes during the early stages of ageing in Al-Cu-Mg alloys [J]. Applied Surface Science, 1996, 94/95(2): 253-260.

[8] Wang S C, Starink M J. Two types of S phase precipitates in Al-Cu-Mg alloys[J]. Acta Materialia, 2007, 55: 933-941.

[9] Bray G H, Glazov M, Rioja R J, et al. Effect of artificial aging on the fatigue crack propagation resistance of 2000 series aluminum alloys[J]. International Journal of Fatigue, 2001, 23(1): 265-276.

[10] Srivatsan T S, Kolar D, Magnusen P. Influence of temperature on cyclic stress response, strain resistance, and fracture behavior of aluminum alloy 2524[J]. Materials Science and Engineering A, 2001, 314(1/2): 118-130.

[11] Srivatsan T S, Kolar D, Magnusen P. The cyclic fatigue and final fracture behavior of aluminum alloy 2524[J]. Materials and Design, 2002, 23(2): 129-139.

[12] Sure S, Vasudevan A K, Bretz P E. Mechanism of slow fatigue crack-growth in high-strength aluminium alloys-role of microstructure and environment[J]. Metall Trans A, 1984, 15A(2): 369-379.

[13] Kamp N, Gao N, Starink M J, et al. Influence of grain structure and slip planarity on fatigue crack growth in low alloying artificially aged 2××× aluminium alloys[J]. International Journal of Fatigue, 2007, 29(5): 869-878.

[14] Sadeler R, Totik Y, Gavgah M, et al. Improvements of fatigue behaviour in 2014 Al alloy by solution heat treating and age-hardening[J]. Materials & Design, 2004, 25(5): 439-445.

[15] Song M, Chen K H, Qi X W. Modeling effects of constituents and dispersoids on tensile ductivity of aluminum alloy[J]. Journal of Central South University of Technology, 2007, 14(4): 456-459.

[16] 张国君, 刘 刚, 丁向东, 等. 含有第二相的高强铝合金疲劳模型[J]. 稀有金属材料与工程, 2004, 33(1): 35-39.

ZHANG Guo-jun, LIU Gang, DIANG Xiang-dong, et al. A fatigue model of high strength Al alloys containing second phase particles of various sizes[J]. Rare Metal Materials and Engineering, 2004, 33(1): 35-39.

[17] 田秀云, 杜洪增, 王 毅, 等. 2024铝合金的一种新时效制度[J]. 材料科学与工艺, 2000, 8(3): 6-11.

TIAN Xiu-yun, DU Hong-zeng, WANG Yi, et al. New aging process for aluminum alloy 2024[J]. Material Science & Technology, 2000, 8(3): 6-11.

[18] 刘延斌, 刘志义, 邓才智, 等. 时效对Al-Cu-Mg合金热稳定性的影响[J]. 材料研究学报, 2007, 21(6): 585-588.

LIU Yan-bin, LIU Zhi-yi, DENG Cai-zhi, et al. Effect of aging process on thermal stability of an Al-Cu-Mg alloy[J]. Chinese Journal of Materials Research, 2007, 21(6): 585-588.

[19] 周邦新, 刘文庆. 三维原子探针及其在材料科学研究中的应用[J]. 材料科学与工艺, 2007, 15(3): 405-408.

ZHOU Bang-xin, LIU Wen-qing. The application of 3DAP in the study of materials science[J]. Material Science & Technology, 2007, 15(3): 405-408.

[20] Ringer S P, Sakurai T, Polmear I J. Origins of hardening in aged Al-Cu-Mg-(Ag) alloys[J]. Acta Mater, 1997, 45(9): 3731-3744.

[21] Ber L B. Accelerated artificial ageing regimes of commercial aluminum alloys (Ⅰ): Al-Cu-Mg alloys[J]. Materials Science and Engineering A, 2000, 280(1): 83-90.

收稿日期:2008-04-10;修回日期:2008-06-20

基金项目:国家“973”重点基础研究发展资助项目(2005CB623705-04)

通信作者:刘志义(1962-),男,湖南绥宁人,教授,从事铝合金强韧化的研究;电话:0731-8836011;E-mail: liuzhiyi@mail.csu.edu.cn