文章编号:1004-0609(2015)-05-1270-07

Co添加对17Ni-(10NiO-NiFe2O4)金属陶瓷的致密化及力学性能的影响

林启权,赵 爽,姜 滔,董文正

(湘潭大学 机械工程学院,湘潭 411105)

摘 要:为了改善17Ni-(10NiO-NiFe2O4)金属陶瓷惰性阳极中金属相的分布,在原料中添加不同含量的Co,以Co-Ni取代纯Ni作为金属相,采用真空烧结方法制备17(xCo-Ni)-(10NiO-NiFe2O4)金属陶瓷,并研究Co添加量对金属陶瓷物相组成、显微组织、致密度及力学性能的影响。结果表明:烧结样品主要由Co-Ni、NiFe2O4、NiO组成,部分Co与陶瓷基体反应生成CoO与Fe2O3。添加适量Co可以改善金属相在陶瓷相的分布和形貌,使团聚孤立的金属相分布均匀,且部分球状金属相变为长条状金属相;同时,添加适量Co还可以促进烧结,提高试样的致密度。适量Co的添加还能降低晶粒尺寸,大幅提高金属陶瓷材料强度与韧性。当Co质量分数为金属相的20%时,金属陶瓷的综合性能最好,致密度、抗弯强度、断裂韧性及硬度分别达到96.87%、163.65 MPa、8.38 MPa/m1/2和820.81HV。

关键词:10NiO-NiFe2O4基金属陶瓷;Co添加;致密度;力学性能

中图分类号:TF821 文献标志码:A

Effect of Co addition on densification and mechanical properties of 17Ni-(10NiO-NiFe2O4) cermet

LIN Qi-quan, ZHAO Shuang, JIANG Tao, DONG Wen-zheng

(School of Mechanical Engineering, Xiangtan University, Xiangtan 411105, China)

Abstract: In order to improve the distribution of metal phase in the 17Ni-(10NiO-NiFe2O4) cermet, 17(xCo-Ni)-(10NiO-NiFe2O4) cermet were prepared by vacuum sintering method using Co-Ni instead of Ni as the metal phase. And the effects of Co content on the phase composition, microstructure, relative density and mechanical properties of the cermet were investigated. The results show that the cermet is composed of Co-Ni, NiFe2O4 and NiO, a part of Co reacts with ceramic matrix to form CoO and Fe2O3. The proper addition of Co can significantly improve the distribution and morphology of the metal phase, the agglomerate isolated metal phases can distribute uniformly and a part of spherical metal phases can change to elongated metal phases. Moreover, the proper addition of Co can promote sintering and increase the density of sample. Co addition can refine the grain size and greatly increase the strength and the toughness of cermet. When the mass fraction of Co in metal phase is 20%, the combination properties of sample are the best. The density, bending strength, fracture toughness and hardness are 96.87%, 163.65 MPa, 8.38 MPa/m1/2 and 820.81 HV, respectively.

Key words: 10NiO-NiFe2O4 based cermet; Co addition; relative density; mechanical property

传统铝电解采用碳素材料作阳极,不仅污染重、能耗高,而且成本高,并难以实现自动化。开发基于惰性阳极的铝电解新技术是实现节能减污的重要途径之一。采用惰性阳极后,铝电解工业中阳极的产物是与环境友好的O2,而不再是CO2,反应方程式如式(1)所示:

Al2O3=2Al+3/2O2 (1)

惰性阳极材质的研究一直是惰性阳极技术开发的重点和难点。作为惰性阳极材料,要求能够耐受电解质熔体的腐蚀,在熔体中的溶解度小,耐受新生态氧的渗蚀,具有良好导电性,抗热震性强,不易脆裂,易加工成型,易与金属导杆连接,原料易得且价格低廉。经过多年研究,金属陶瓷特别是NiFe2O4基金属陶瓷由于兼具陶瓷相的热化学稳定性、耐腐蚀性、抗氧化性以及金属相的良好导电性和抗热冲击性等优点,被认为是最具应用前景的铝电解惰性阳极材料之一[1]。从前人的研究来看,虽然对NiFe2O4基金属陶瓷惰性阳极研究取得了很大的成绩,但是仍存在一些问题,如金属Ni、Cu对陶瓷相NiFe2O4的润湿不好,金属陶瓷阳极材料在高温烧结过程中存在金属溢出、金属相分布不均匀、团聚等现象[2-3],且呈孤立的不规则球状分布在陶瓷基体中。同时,金属陶瓷惰性阳极过低的致密度会使电解过程中阳极由于电解质的渗蚀而产生肿胀或开裂,并且也将降低其导电性能和力学性能。而且由于较差的韧性使阳极与导电杆的连接加工中会出现碎裂现象。国内外学者通过改善烧结工艺与添加氧化物烧结助剂或纤维等方法来加强金属陶瓷的烧结以提高材料各方面性能。CHEN等[4]研究了烧结气氛对5Ni-(10NiO-NiFe2O4)金属陶瓷物相组成及力学性能的影响,结果表明合理控制氧体积分数可以促进烧结,提高材料力学性能。陶玉强等[5]研究了添加Yb2O3对10NiO-NiFe2O4基金属陶瓷性能的影响,结果表明:适量Yb2O3能提高材料的导电性与抗腐蚀性。王昊等[6]研究了Nb2O5添加NiFe2O4陶瓷的显微组织以及电导率,结果表明:适量添加可以消除晶界空隙,提高致密度和导电率。华中胜等[7]研究了NiFe2O4基惰性阳极材料纤维增强体的选择,结果表明:添加3% ZrO2(质量分数)阳极试样的力学性能得到明显改善。

目前,研究较多的主要集中在Cu、Ni、Ag、Fe及其合金作为金属陶瓷的金属相,而本研究旨在选用一种相对更合适的金属相,从而促使10NiO-NiFe2O4基金属陶瓷应用于铝电解生产。Co的热膨胀系数(12×10-6 ℃-1)较Ni(15×10-6 ℃-1)的更接近于NiFe2O4 (10.8×10-6 ℃-1)陶瓷,这对于金属陶瓷烧结过程中减少界面孔隙及冷却时降低界面内应力起一定作用。通过热力学计算与相图反应,Co与Ni可以无限固溶,同时,Co由于自身优良的物理性能(熔点高、韧性高、强度大等)常被用于超细晶粒金属陶瓷材料中硬质合金的主要原料。LEIDERMAN等[8]发现当以W、Co、C为原料,制备的WC-Co系金属陶瓷晶粒细小、抗弯强度高。MA等[9]利用Co-Ni合金高温耐蚀等特点研制出具有优良耐腐蚀性能的Ni-Co-Fe2O3镀层。同时,CoO作为添加剂能完全固溶于陶瓷基体,提高金属陶瓷致密度以及导电性能[10]。由于CoFe2O4与NiFe2O4同属于尖晶石结构,性质有许多共同之处。钱旭坤[11]以Co-Ni合金金属作为基体相, NiFe2O4陶瓷作为第二相,研究了Co-Ni-xNiFe2O4惰性阳极的制备及其导电性与抗高温氧化性等性能,结果表明:在高温氧化后,氧化膜在生长上产生明显择优取向,该氧化膜主要由CoNiO2组成,但研究并没有涉及惰性阳极显微组织及力学性能。基于以上原因,本文作者根据前期研究确定17Ni/(10NiO-NiFe2O4)金属陶瓷具有良好的耐腐蚀性与抗氧化性能,引入Co元素,并选用Co-Ni取代纯Ni作为金属相,通过改变金属相的方法来改善金属陶瓷金属相与陶瓷相的形貌与性能。着重研究了不同添加量的Co-Ni取代纯Ni后对17Ni-(10NiO-NiFe2O4)金属陶瓷的物相组成、显微组织、致密度以及力学性能的影响。

1 实验

1.1 试样制备

按质量分数为38.68%和61.32%分别称Fe2O3粉末和NiO粉末,经球磨混合均匀并真空干燥后,装入刚玉坩锅置于电阻炉中于1200 ℃煅烧6 h,得到10NiO-NiFe2O4陶瓷粉体。将分析纯Co、Ni粉末和预先制备的10NiO-NiFe2O4粉末按照一定比例进行混合,金属粉末总质量分数为17%,其中Co质量分数分别为0、10%、20%、30%、40%、50%、70%,其余为l0NiO-NiFe2O4。混合料加入酒精(分散剂)和PVA(粘接剂)于不锈钢球磨罐中二次球磨,干燥后采用模压成型,得到d 20 mm×10 mm和6 mm×6 mm×36 mm的生坯。坯体在氧分压为102 Pa数量级下的真空气氛中,按一定升温工艺在1300 ℃烧结6 h,得到最终烧结样品。

1.2 性能检测

采用日本理学D/MAX2500型X射线衍射仪(XRD)对所制备的金属陶瓷试样进行物相成分分析。采用JSM-6360LV型扫描电镜(SEM)对复合陶瓷试样进行显微组织分析。采用阿基米德排水法原理测定复合陶瓷的相对密度和孔隙率。在CSS-44100型电子万能试验机上采用三点弯曲法测试试样的抗弯强度,测试试样为5 mm×5 mm×32 mm的试样条,跨距为20 mm,加载速率0.5 mm/min;每个数据点至少测试5根试条,然后取平均值。采用压痕法在AKASHI(AVK-A)显微硬度仪上测试材料的断裂韧性,所用压头载荷为98 N,保压时间为10 s。

2 结果与讨论

2.1 17(xCo-Ni)-(10NiO-NiFe2O4)金属陶瓷的物相组成与显微组织

图1所示为17(xCo-Ni)-(10NiO-NiFe2O4)金属陶瓷的XRD谱。从图1中可以看出,在可控气氛下烧结出未添Co的试样具有明显的Ni、NiO和NiFe2O4相,而添加Co的试样主要包含Ni-Co、NiO和NiFe2O4相,同时出现了CoO与Fe2O3相的衍射峰,并随着Co含量的增多,NiFe2O4的衍射峰向右微弱漂移,偏移量随着Co添加量的增大而增大。这可能是由于添加Co后,Co除了与Ni形成固溶体外,还与基体陶瓷发生反应生成Co2+和Fe3+。根据文献[10]报道,Co2+可以完全固溶于陶瓷基体,并嵌入到NiFe2O4和NiO晶格取代部分Ni2+形成Ni1-xCoxFe2O4和NiyCo1-yO相,从而导致晶格膨胀,晶胞参数增大。然而,由于Co2+的生成量不够大,晶格膨胀量较小,因此,NiFe2O4相的衍射峰轻微地向右偏移。在1300℃含一定氧分压的真空气氛中合成17(xCo-Ni)-(10NiO-NiFe2O4)金属陶瓷,烧结过程中可能发生如下反应:

(2)

(2)

[12] (3)

[12] (3)

(4)

(4)

图1 17(xCo-Ni)-(10NiO-NiFe2O4)金属陶瓷的XRD谱

Fig. 1 XRD patterns of 17(xCo-Ni)-(10NiO- NiFe2O4) cermet

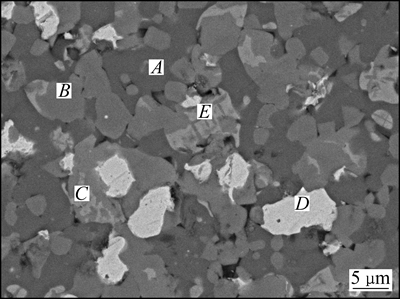

图2所示为17(20Co-Ni)-(10NiO-NiFe2O4)金属陶瓷的SEM像,深色区域A为NiFe2O4相,灰色区域B为NiO相,浅灰区域C为Fe2O3相,白色区域D为Ni-Co相,区域E中还出现长条状物。由能谱分析可知,Co元素不止存在区域D中,在区域A、B、C都能检测到,证实了Co与陶瓷基体发生了一定反应生成了Co2+固溶于陶瓷基体中。根据置换固溶体的生成条件,生成的Co2+易于取代基体中半径与之接近而稍小的Ni2+。而生成的Fe2O3相主要存在于NiO相与NiFe2O4相交界处。

图2 17(20Co-Ni)-(10NiO-NiFe2O4)金属陶瓷的SEM像

Fig. 2 SEM image of 17(20Co-Ni)-(10NiO- NiFe2O4) cermet

2.2 17(xCo-Ni)-(10NiO-NiFe2O4)金属陶瓷的致密度

表1所列为不同Co添加量的17(xCo-Ni)- (10NiO-NiFe2O4)金属陶瓷的致密度、孔隙率和径向收缩率。由表1可知,随着Co含量的增加,致密度呈现先增大后减小的趋势;未添加Co的试样密度仅为90.01%,远低于添加Co试样的致密度;当Co添加量为金属相的20%~30%时(质量分数),密度都为95%以上,其中添加量为20%时密度达到了96.87%,径向收缩率超过13%,说明添加适量的Co对于提高材料的致密度有很大作用。

图3所示为不同Co添加量的17(xCo-Ni)- (10NiO-NiFe2O4)金属陶瓷显微组织。从图3中可以看出,随着Co添加量的增大,孔隙率先减小后增大,当Co添加量为20%时,孔隙率最小。图3(a)所示的金属相颗粒粗大,分布不均,产生团聚孤立现象;图3(b)~(e)所示的金属相得到明显细化,分布也变得均匀,同时还出现了细长条状的金属相,说明金属相在陶瓷相之间很好地铺展[13];图3(f)~(g)所示的金属相中孔洞开始增多且Fe2O3相也明显增加。因此,其致密度随着Co添加量的增加先增大后减小。该结论与表(1)所列烧结致密度结果一致的。

表1 不同Co添加量的17(xCo-Ni)-(10NiO-NiFe2O4)金属陶瓷的致密度、孔隙率和径向收缩率

Table 1 Relative densities, porosity and diametrical shrinkage rate of 17(xCo-Ni)-(10NiO-NiFe2O4) cermet with different contents of Co addition

材料在整个烧结过程中处于固相。在固相烧结时, 材料的致密化主要受颗粒扩散的影响,而扩散系数与烧结温度以及固相颗粒的扩散激活能间的关系如式 (5)所示[14]:

(5)

(5)

式中:D为材料的扩散系数,m2/s;D0为频率因子,m2/s;T为烧结温度,K;R 为气体常数;Q为扩散激活能,kJ/mol。

材料在烧结时,温度T恒定,频率因子D0为常数,因此,扩散主要受扩散激活Q的影响,而影响扩散激活能Q的因素主要包括扩散机制、晶体结构、原子结合力、材料成分,对于仅存在微弱成分差别的材料,前3个因素基本相同,因此可视作仅成分差别使得材料的扩散激活能不同,从而使晶粒的扩散系数不同。由此可以推断,添加Co有利于降低材料内部颗粒的扩散激活能,使得扩散增快,从而提高了材料的致密度,使晶粒间的结合更紧密。结合XRD谱及相图热力学分析,未添加Co的试样的金属相发生团聚形成大尺寸颗粒,导致空间位阻的产生,阻碍了致密化;而添加Co后,试样的致密度提高,原因是在烧结过程中,NiFe2O4相的少量离解形成一定的氧空位,并成为烧结过程重要的传质源,由于Co与O的亲和力大于Ni,加速了陶瓷基体烧结过程中的扩散传质[15];其次,较大半径的Co2+取代部分Ni2+形成Ni1-xCoxFe2O4和NiyCo1-yO相,使其晶格发生畸变,产生一定的空位。由于空位的产生是降低晶格内应力的一个有效途径,Co2+取代Ni2+导致两相空位浓度增大,加快了陶瓷颗粒的烧结进程,使金属相分布均匀。随着Co添加,当添加量达到50%以上,试样中Fe2O3相也变得越来越多,并聚集在相晶界处,阻碍了晶界迁移,影响基体与陶瓷之间的扩散,并且造成基体结构不稳定,从而导致致密度下降。

图3 不同Co添加量的17(xCo-Ni)/(10NiO-NiFe2O4)金属陶瓷的SEM像

Fig. 3 SEM images of 17(xCo-Ni)/(10NiO- NiFe2O4) cermets with different contents of Co addition

2.3 17(xCo-Ni)-(10NiO-NiFe2O4)金属陶瓷的力学性能

图4~6所示分别为不同Co添加量对试样抗弯强度、断裂韧性以及硬度的影响。在17Ni-(10NiO- NiFe2O4)金属陶瓷添加Co后,材料的的抗弯强度、断裂韧性与硬度与未添Co的材料相比有明显改善,且整体变化趋势相同,都是随Co添加量的增加呈现先增大后减小。当Co添加量为20%时,试样的力学性能达到极大值(163.65 MPa、8.38 MPa/m1/2与820.81 HV),比未添Co试样的力学性能(84.18 MPa、3.26 MPa/m1/2与597 HV)分别提高了94.4%、157.1%和37.5%。不同的是材料硬度值变化范围较大,这可能是由压痕处金属相与陶瓷基体相质量比不同造成。

图4 不同Co添加量的17(xCo-Ni)-(10NiO-NiFe2O4)金属陶瓷的抗弯强度

Fig. 4 Bending strengths of 17(xCo-Ni)-(10NiO-NiFe2O4) cermet with different contents of Co addition

金属陶瓷复合材料的强度除决定于本身材料特性外,显微组织对强度也有显著地影响,其中孔隙率与晶粒尺寸是两个最重要的影响因素。从表1可以看到,随着Co添加量的增加,试样的致密度也不同程度的增加,因而试样内部孔隙率减小,缺陷减少,强度增加。另外,从图3可知,材料的晶粒尺寸也不同程度的变小。由DUCKWORTH[16]提出的经验公式如式(6)所示:

(6)

(6)

式中:p为材料的孔隙率,%;σ为非完全致密材料的强度,MPa;σ0为完全致密材料的强度,MPa;b为常数。

图5 不同Co添加量的17(xCo-Ni)-(10NiO-NiFe2O4)金属陶瓷的断裂韧性

Fig. 5 Fracture toughnesses of 17(xCo-Ni)-(10NiO-NiFe2O4) cermet with different contents of Co addition

根据脆性材料断裂理论,降低基体的晶粒尺寸可以减小本征缺陷的尺寸;同时材料中晶粒越细,单位体积中晶粒数目也就越多,每个晶粒上承受的压力越小,其强度值越高。断裂强度与基体晶粒尺寸的关系可用Hall-Petch方程来表示[17]:

(7)

(7)

式中:σ为材料的强度,MPa;σ0、k、m均为常数,且m≈0.5;d为材料中晶粒尺寸,mm。

由图5可知,材料的断裂韧性不高,均小于10 MPa/m1/2,主要原因可能是由于材料中脆性基体的比例大,使得材料内部裂纹的延伸扩展与脆性材料类似。陶瓷材料断裂韧性与陶瓷强度及裂纹尺寸的关系如式(8)所示:

(8)

(8)

式中:KIC为材料的断裂韧性,MPa/m1/2;σ为材料的强度,MPa;am为材料内部的最长裂纹尺寸的半长,μm。

材料内部的最大裂纹长度2am大致与材料烧结后内部的空隙尺寸相当[14], 当烧结后材料内部的空隙越少,存在的裂纹就越少,从而提高材料的断裂韧性。

因此,材料中Co的添加引起了材料孔隙率与晶粒尺寸的变化而间接对金属陶瓷的强度与韧性产生影响。

实验还发现在(NiFe2O4+10NiO)基金属陶瓷材料断裂过程中,其金属相以拔出为主,增韧机制以裂纹偏转为主[18]。因此,材料中金属-陶瓷相界面越多,裂纹偏转的可能性就越大,材料韧性越好。同时,金属与陶瓷相界面强度越高,裂纹偏转增韧效果也越好。因此,添加Co后,金属分布形态呈条、柱状甚至铺展成面状分布能增加金属-陶瓷界面,有利于断裂韧性的提高。另外,金属Ni与NiFe2O4陶瓷间的热膨胀系数差异较大,容易形成具有尖锐角的间隙,这种形状的间隙受力容易产生大应力集中,而萌发裂纹,对材料的断裂韧性十分不利。添入Co可以使金属相与陶瓷基体相热膨胀系数更匹配,从而减少间隙,降低内应力,提高其断裂韧性。

图6 不同Co添加量的17(xCo-Ni)-(10NiO-NiFe2O4)金属陶瓷的硬度

Fig. 6 Hardnesses of 17(xCo-Ni)-(10NiO-NiFe2O4) cermet with different contents of Co addition

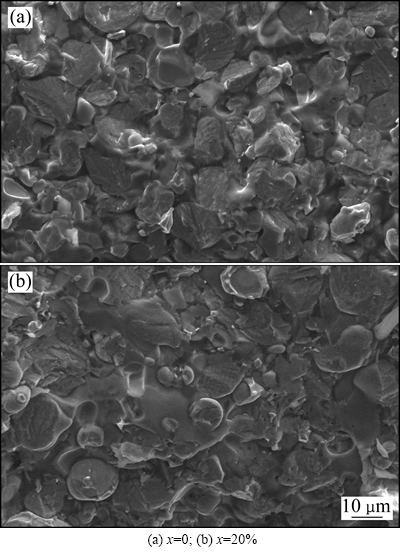

图7所示为17Ni-(10NiO-NiFe2O4)金属陶瓷与17(20Co-Ni)-(10NiO-NiFe2O4)金属陶瓷断口形貌。由图7(a)可知,未添加Co的试样显微组织有明显的疏松,晶粒之间结合不紧密,平整断裂面很少,断裂方式以沿晶断裂为主。由图7(b)可知,17(20Co-Ni)- (10NiO-NiFe2O4)的显微组织致密,平整的断裂面比较多,断裂方式以穿晶断裂为主。说明添加Co后,金属与陶瓷之间的界面结合紧密,界面强度变大,大大降低了弥散分布的金属颗粒在裂纹张开时因界面强度低而发生的拔出现象,从而需要吸收更多断裂功,达到增强增韧的效果。因此,综合作用下,Co添加量为20%时力学性能达到最优。

图7 17(xCo-Ni)-(10NiO-NiFe2O4)金属陶瓷的断口形貌

Fig. 7 Cross-section morphologies of 17(xCo-Ni)-(10NiO- NiFe2O4) cermets

3 结论

1) 以Co-Ni取代纯Ni作为金属相,在1300 ℃下烧结得到17(xCo-Ni)/(10NiO-NiFe2O4)金属陶瓷物相主要是NiO、NiFe2O4和Co-Ni,同时,部分Co与基体反应生成了CoO与Fe2O3,并随着Co添加量的增加而增多。Fe2O3相在NiO与NiFe2O4交界处,CoO相则完全固溶于陶瓷基体。

2) 添加Co降低了材料内部颗粒的扩散激活能,且Co2+取代部分Ni2+所产生的空位,使得扩散增快,提高了材料致密度。Co添加量为金属相20%试样的致密度比未添加Co的试样的致密度提高了6.86%。

3) 17(xCo-Ni)/(10NiO-NiFe2O4)金属陶瓷的抗弯强度、断裂韧性、硬度都是随Co添加量的增加先增大后减小,在Co添加量为金属相20%时,达到极大值。添加Co可以提高试样的致密度、细化晶粒、减小内应力、增大金属与陶瓷界面强度,从而使金属陶瓷的力学性能得到显著提高。

REFERENCES

[1] 周科朝, 陶玉强, 刘宝刚, 李志友. 铁酸镍基金属陶瓷的强化烧结与熔盐腐蚀行为[J]. 中国有色金属学报, 2011, 21(6): 1348-1358.

ZHOU Ke-chao, TAO Yu-qiang, LIU Bao-gang, LI Zhi-you. Enhanced sintering and molten salt corrosion behavior of nickel ferrite based cermets[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(6): 1348-1358.

[2] 张 刚, 赖延清, 田忠良, 秦庆伟, 李 劼, 黎文献. 铝电解用NiFe2O4基金属陶瓷的制备[J]. 材料科学与工程学报, 2003, 21(4): 510-513.

ZHANG Gang, LAI Yan-qing, TIAN Zhong-liang, QIN Qing-wei, LI Jie, LI Wen-xian. Preparation of nickel ferrite based cermets for aluminum electrolysis[J]. Journal of Materials Science and Engineering, 2003, 21(4): 510-513.

[3] ZHANG Gang, LI Jie, LAI Yan-qing, TIAN Zhong-liang. Effect of metallic phase content on mechanical properties of (85Cu-15Ni)/(10NiO-NiFe2O4) cermet inert anode for aluminum electrolysis[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(5): 1063-1068.

[4] CHEN Duan, ZOU Zhong, TIAN Zhong-liang, XIN Peng-fei, LIU Kai, LAI Yan-qing, LI Jie. Effect of sintering atmosphere on phase composition and mechanical properties of 5Ni/(10NiO-NiFe2O4)[J]. Transactions of Nonferrous Metals Society of China, 2012, 12(1): 124-128.

[5] 陶玉强, 刘建元, 李志友, 周科朝, 谭占秋. Yb2O3或Y2O3掺杂Cu-(NiFe2O4-10NiO)惰性阳极的导电性和耐蚀性[J]. 中国有色金属学报, 2011, 21(5): 1137-1144.

TAO Yu-qiang, LIU Jian-yuan, LI Zhi-you, ZHOU Ke-chao, TAN Zhan-qiu. Conductivity and corrosion resistance of 10Cu-(NiFe2O4-10NiO) inert anode doped Yb2O3 or Y2O3[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(5): 1137-1144.

[6] 王 昊, 周科朝, 李志友. Nb2O5掺杂NiFe2O4陶瓷材料的显微结构和导电性能[J]. 中国有色金属学报, 2013, 23(2): 410-416.

WANG Hao, ZHOU Ke-chao, LI Zhi-you. Microstructure and electrical properties of Nb2O5-doping NiFe2O4 ceramic[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(2): 410-416.

[7] 华中胜, 姚广春, 龙秀丽, 王海川, 赵 卓. 铝电解NiFe2O4基惰性阳极材料纤维增强体的选择[J]. 中国有色金属学报, 2013, 23(1): 154-161.

HUA Zhong-sheng, YAO Guang-chun, LONG Xiu-li, WANG Hai-chuan, ZHAO Zhuo. Selection of fiber reinforcement for NiFe2O4 based inert anode materials in aluminum electrolysis[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(1): 154-161.

[8] LEIDERMAN M, BOSTEIN O, ROSEN A. Sintering microstructure and properties of submicrometre cemented carbides[J]. Powder Metallurgy, 1997, 40(3): 219-225.

[9] MA Li, ZHOU Ke-chao, LI Zhi-you. Hot corrosion of a novel (Ni,Co)O/(Ni,Co)Fe2O4 composite coating thermally converted from an electrodeposited Ni-Co-Fe2O3 composite coating[J]. Corrosion Science, 2011, 53(7): 2357-2367.

[10] 吴海明, 李志友, 甘雪萍, 周科朝. CoO掺杂对15(20Ni-Cu)/(NiO-NiFe2O4)金属陶瓷导电性能的影响[J]. 粉末冶金材料科学与工程, 2011, 16(2): 206-211.

WU Hai-ming, LI Zhi-you, GAN Xue-ping, ZHOU Ke-chao. Effect of CoO doping on electrical conductivity of 15(20Ni-Cu)/(NiO-NiFe2O4) based cermets[J]. Materials Science and Engineering of Powder Metallurgy, 2011, 16(2): 206-211.

[11] 钱旭坤. Co-Ni-xNiFe2O4惰性阳极的制备与性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2006: 30-72.

QIAN Xu-kun. Preparation and properties research on Co-Ni-xNiFe2O4 inert anodes[D]. Harbin: Harbin Institute of Technology, 2006: 30-72.

[12] 王宇栋, 王 飚, 戴永年, 周晓奎, 张自华. NiFe2O4-M金属陶瓷惰性阳极成分设计的热力学分析[J]. 化学工程2011, 39(1): 62-65.

WANG Yu-dong, WANG Biao, DAI Yong-nian, ZHOU Xiao-kui, ZHANG Zi-hua. Thermodynamic analysis for components design of NiFe2O4-M cermet inert anode[J]. Chemical Engineering, 2011, 39(1): 62-65.

[13] 席锦会, 吉 喆, 葛世荣, 强颖怀. CuO对金属陶瓷惰性阳极微观结构及性能的影响[J]. 中国矿业大学学报, 2011, 40(1): 157-161.

XI Jin-hui, JI Zhe, GE Shi-rong, QIANG Ying-huai. Effect of CuO on microstructure and properties of cermets inert anodes[J]. Journal of China University of Mining and Technology, 2011, 40(1): 157-161.

[14] SHI De-ke. Material science foundation[M]. Beijing: China Machine Press, 2003: 420-425.

[15] 周科朝, 陶玉强. 铁酸镍基金属陶瓷惰性阳极材料的研究进展[J]. 中国有色金属学报, 2011, 21(10): 2418-2429.

ZHOU Ke-chao, TAO Yu-qiang. Research development of nickel ferrite based cermet inert anode materials[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2418-2429.

[16] DUCKWORTH W. Discussion of Ryshkewitch paper by Winston Duckworth[J]. Journal of the American Ceramic Society, 1953, 36(3): 65-68.

[17] 周 玉. 陶瓷材料学[M]. 哈尔滨: 哈尔滨工业大学出版社, 1995: 343-345.

ZHOU Yu. Ceramic materials[M]. Harbin: Harbin Institute of Technology Press, 1995: 343-345.

[18] 李枝林. 金属相对(NiFe2O4-10NiO)基金金属陶瓷的影响[D]. 长沙: 中南大学, 2007: 30-50.

LI Zhi-lin. Effect of metal phase on the properties of (NiFe2O4-10NiO) based cermet[D]. Changsha: Central South University, 2007: 30-50.

(编辑 王 超)

基金项目:科技部国际合作专项(2012DFG70640,2010DFA52130)

收稿日期:2014-09-26;修订日期:2015-01-28

通信作者:林启权,教授,博士;电话:0731-58292209;E-mall:xtulqq@126.com