文章编号:1004-0609(2010)S1-s0315-05

包套锻造对Ti-45Al-5.4V-3.6Nb-0.3Y

合金组织和性能的影响

杨 非1, 2,陈玉勇1,孔凡涛1,肖树龙1,徐丽娟1

(1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001

2. 广州有色金属研究院 粉末冶金研究所,广州 510651)

摘 要:采用水冷铜坩埚真空感应熔炼技术制备名义成分为Ti-45Al-5.4V-3.6Nb-0.3Y(摩尔分数,%)的高质量合金铸锭,采用XRD、OM、SEM及TEM等分析手段分析研究该合金的组织演变过程,同时进行力学性能测试。结果表明:Ti-45Al-5.4V-3.6Nb-0.3Y合金具有近层片组织结构,由γ、α2和β三相组成;经包套锻造处理后,合金的晶粒尺寸显著减小,由100 μm下降至7 μm左右;合金的室温屈服强度提高220 MPa左右,达到620 MPa,室温伸长率提高到1.08%;经700 ℃处理后,该合金的屈服强度从562 MPa升高到708 MPa,伸长率从7.6%提高到35.55%。

关键词:TiAl合金;包套锻造;组织;性能

中图分类号:TF 804.3 文献标志码:A

Effect of canned-forging on microstructure and properties of Ti-45Al-5.4V-3.6Nb-0.3Y alloy

YANG Fei1, 2, CHEN Yu-yong1, KONG Fan-tao1, XIAO Shu-long1, XU Li-juan1

(1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. Department of Powder Metallurgy, Guangzhou Research Institute of Non-ferrous Metals,

Guangzhou 510651, China)

Abstract: A high quality TiAl alloy ingot with nominal composition of Ti-45Al-5.4V-3.6Nb-0.3Y (mole fraction, %) with nearly lamellar structure was prepared by introduction skull melting (ISM) in a water-cooled copper crucible. The microstructure evolution were detected by X-ray diffractometry (XRD), optical microscopy (OM), scan electron microscopy (SEM) and transmission electron microscopy (TEM). In addition, the mechanical properties were also tested. The result show that the Ti-45Al-5.4V-3.6Nb-0.3Y alloy prepared is composed of γ, α and β phases, the grain size of as-forged alloy decreases from 100 μm to 7 μm, the room temperature yield strength increases by about 220 MPa and reaches 620 MPa, and the ductility increases to 1.08% after canned forging. After treated at 700 ℃, the yield strength and ductility of this alloy exhibit the similar increasing trend as that at room temperature after forging, with yield strength of 708 MPa and elongation of 35.55%.

Key words: TiAl alloy; canned forging; microstructure; properties

TiAl基合金由于具有密度低、弹性模量、比强度和高温强度高、良好的抗蠕变能力以及优异的防腐蚀性能,被认为是非常具有应用前景的轻质耐高温结构材料,可应用于航空航天、海洋船舶和医疗卫生等领域[1-2],引起研究者们的广泛关注。然而,TiAl合金的室温塑性低、高温变形能力差、热加工困难等缺点限制其广泛应用[3]。近来,美国学者SHIH和KIM[4]提出制备β型γ-TiAl合金的概念,该合金的成分范围为Ti-(40~45)Al-(2~7)Nb-(1~9)(Cr, Mn, V, Mo)-(0~0.5)(B, C)(摩尔分数,%),其在1 100 ℃以上具有良好的高温变形能力。本文作者采用水冷铜坩埚真空感应熔炼设备制备了名义成分为Ti-45Al-5.4V-3.6Nb-0.3Y合金,研究包套锻造对该合金组织和性能的影响。

1 实验

实验用原材料为海绵钛(>99.7%),高纯铝 (>99.99%)以及铝钒、铝铌和铝钇中间合金。采用水冷铜坩埚真空感应熔炼炉制备名义成分为Ti-45Al- 5.4V-3.6Nb-0.3Y(摩尔分数,%)合金铸锭,随后,合金铸锭分别进行均匀化处理(900 ℃,60 h)和热等静压处理(1 200 ℃,140 MPa,4 h)。经热等静压处理后的合金铸锭进行包套锻造,锻造工艺参数如下:锻造起始温度1 200 ℃,应变速率小于0.5 s-1,总体变形率75%。

分别采用X射线衍射分析(XRD)、光学显微分析(OM)、扫描电子显微分析(SEM)和透射电子显微分析(TEM)等对Ti-45Al-5.4V-3.6Nb-0.3Y合金铸锭和锻饼进行相分析和显微组织观察。合金的拉伸性能测试在Instron万能试验机上进行,应变速率为5×10-4 s-1。

2 结果与讨论

2.1 铸态显微组织和相分析

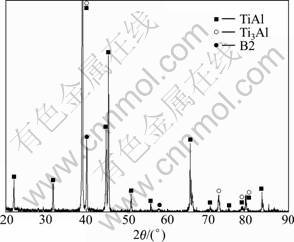

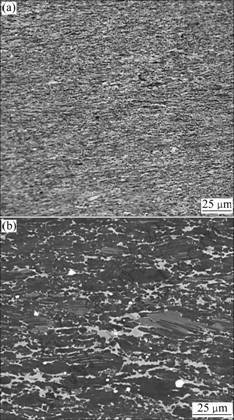

图1所示为Ti-45Al-5.4V-3.6Nb-0.3Y合金铸锭的显微组织。从图1(a)中可以看出, Ti-45Al-5.4V-3.6Nb- 0.3Y合金为近层片组织结构,其层片团簇尺寸约为100 μm。与传统的TiAl合金相比,Ti-45Al-5.4V- 3.6Nb-0.3Y合金的显微组织没有显著的柱状晶特征,而是体现等轴特征。为了研究各相的分布,对合金组织进行了背散射电子分析(见图1(b))可知,层片结构组织周围分布着一定数量的灰色和黑色块状组织,除此之外,层片结构边界和层片结构中含有少量亮白色颗粒。对不同颜色相进行能谱分析发现(见表1),灰色块状相富含大量的Nb和V元素,其含量分别为4.22%和12.31%(摩尔分数),高于Ti-45Al-5.4V-3.6Nb-0.3Y合金中Nb和V的名义含量,黑色块体的大致成分为43.79%Ti、49.09%Al、3.59%V、3.54%Nb(摩尔分数)。亮白色颗粒(见图1(b))中D和E处)主要富含Y和Al元素,结合先前的研究结果[5],认为亮白色颗粒是YAl2相。对Ti-45Al-5.4V-3.6Nb-0.3Y合金进行XRD分析(见图2)可知,该合金主要由γ-TiAl、α2-Ti3Al和β(B2)相组成,结合成分分析认为位于层片结构周围的灰色块状组织为β(B2)相,而黑色组织为γ-TiAl相。由于合金中YAl2相的含量非常少,故在XRD分析结果中没有发现YAl2相的存在。

图1 水冷铜坩埚真空感应熔炼Ti-45Al-5.4V-3.6Nb-0.3Y合金铸态显微组织

Fig.1 Microstructures of as-cast Ti-45Al-5.4V-3.6Nb-0.3Y alloy prepared by water cooled ISM: (a) Optical microstructure; (b) BS microstructure

表1 图1(b)中各位置的化学成分

Table 1 Chemical composition of different positions shown in Fig.1(b)

图2 水冷铜坩埚真空感应熔炼Ti-45Al-5.4V-3.6Nb-0.3Y合金的XRD谱

Fig.2 XRD pattern of Ti-45Al-5.4V-3.6Nb-0.3Y alloy prepared by water cooled induction skull melting

研究认为V和Nb元素均为β相稳定元素,在TiAl合金中添加该类元素促进合金的凝固过程由α凝固方式向β凝固方式的转变[6-7]。由于β相中优先生长方向á100?晶向具有等价的3个方向,即á100?、á010?和á001?,而不像α中只有一个á001]晶向为晶体优先生长方向,因此,经β凝固方式的凝固的合金具有等轴状特征,而柱状晶特征并不显著。

根据相图分析[8],可知Ti-45Al-xV合金的平衡凝固路线为L→β→α→α+γ→α+β+γ→β+γ。其中β相有序化形成B2相,其有序化温度约为1 100 ℃[8]。可以看出,平衡凝固组织应该为β+γ双相组织,而不是α+β+γ三相组织。但是由于合金熔体受到金属型壁的激冷作用而产生较大的过冷度以及与外界强烈的热交换作用,合金的实际凝固过程往往偏离平衡凝固方式,最终获得的合金组织不同于合金平衡凝固的组织。结合Ti-45Al-5.4V-3.6Nb-0.3Y合金的铸态组织特征,可以推测该合金凝固方式和相转变过程遵从如下路线:L→L+β→β→β+α→α→α+γ→α+γ+β→α+α2+γ+β→lamellar(α2/γ)+γ+β。其中β相有两种来源,一种是由于V和Nb元素的稳定作用导致β相直接从液相析出并保留至室温;另一种是由α相分解得到的。层片结构由高温α相转变而来,同时β+γ结构是由γ相从高温α相或β相的析出而形成的。最终Ti-45Al- 5.4V-3.6Nb-0.3Y合金形成层片团簇被β和γ相包围的近层片组织结构。

2.2 锻态显微组织分析

图3所示为Ti-45Al-5.4V-3.6Nb-0.3Y合金锻饼中心区域的显微组织。从图3中可以看出,与铸态组织相比,锻态组织晶粒尺寸非常细小,约为7 μm,且组织主要由大量的动态再结晶晶粒、破碎层片以及少量的残余层片构成。在残余层片周围存在细小的动态再结晶晶粒,说明锻造组织变形时存在微观不均匀性。这是由于层片晶界处具有强烈的应力集中,存在大量缺陷,原子扩散能力比晶粒内的大,再结晶驱动力高,再结晶晶粒优先在晶界处形核并长大。另外,β(B2)相和YAl2相在晶界的分布使该合金的晶界能增加,进一步提高晶界处动态再结晶的能力。晶界处动态再结晶一旦形成,将导致该区域软化,通过晶界滑移为进一步大量变形和再结晶行为提供便利条件,最终导致组织发生不均匀变形。由此可以看出,Ti-45Al-5.4V- 3.6Nb-0.3Y合金的变形在微观上也是不均匀的。

图3 锻态Ti-45Al-5.4V-3.6Nb-0.3Y合金的显微组织

Fig.3 Microstructures of as-forged Ti-45Al-5.4V-3.6Nb-0.3Y alloy: (a) Optical microstructures; (b) BS microstructure

图4所示为锻态Ti-45Al-5.4V-3.6Nb-0.3Y合金的TEM像。从图4中可看出,等轴状的动态再结晶(DRX)晶粒尺寸很小,可达3~5 μm,与其紧邻的残余层片内存在大量的位错,且缠结在一起,形成位错胞(见图4(a))。这些现象的出现是合金经历了大量变形的结果,同时也反映出动态再结晶是不充分的。除此之外,在锻态Ti-45Al-5.4V-3.6Nb-0.3Y合金的TEM像中还观察到破碎的层片组织(见图4(b)),在破碎的层片结构中出现许多亚结构。这是由于热变形过程中,α2或γ层片发生旋转运动,导致α2和γ层片偏离原先的位向关系,使合金层片结构中发生应力集中,内应力增加,随之畸变能增大,促使位于层片中较易发生开动的滑移系中的位错趋向于发生重新排布,形成垂直于滑移面的较为稳定的位错墙,进一步的变形导致层片中形成亚晶粒[9]。亚晶粒的形成为动态再结晶行为也提供了形核场所。

图4 锻态Ti-45Al-5.4V-3.6Nb-0.3Y合金的TEM像

Fig.4 TEM images of as-forged Ti-45Al-5.4V-3.6Nb-0.3Y alloy: (a) DRX grains and twin structure; (b) Residual lamellar

2.3 力学性能

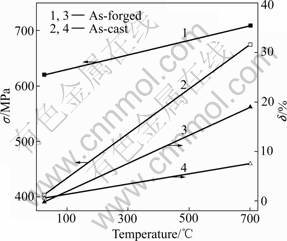

图5所示为铸态和锻态Ti-45Al-5.4V-3.6Nb-0.3Y合金的拉伸性能。从图5中可以看出,与铸态合金相比,不同测试温度条件下锻态Ti-45Al-5.4V-3.6Nb- 0.3Y合金的力学性能明显提高,在室温条件下,锻合金的屈服强度从400 MPa左右增加到620 MPa,增加了220 MPa,而伸长率从0.55%增加到1.08%;700 ℃下,锻态合金的屈服强度为708 MPa,而铸态合金的屈服强度只有562 MPa,伸长率从铸态的7.60%增加到了31.55%,体现显著的增加趋势。锻态合金的力学性能明显高于铸态合金的,其主要原因是经锻造变形后Ti-45Al-5.4V-3.6Nb-0.3Y合金的晶粒尺寸显著细化。根据Hell-Petch公式可知,晶粒细化不仅可以提高合金的强度,而且还可以提高合金的塑性。另外,锻造后合金组织在垂直于锻造方向存在明显的流线结构,产生了明显的加工硬化现象,故合金的力学性能得到提高。对于Ti-45Al-5.4V-3.6Nb-0.3Y合金的屈服强度随着测试温度的升高而增大的原因,本文作者认为这主要是由TiAl合金中位错的滑移、缠结以及位错锁的形成造成的[10]。

图5 不同状态Ti-45Al-5.4V-3.6Nb-0.3Y合金的拉伸性能

Fig.5 Tensile properties of Ti-45Al-5.4V-3.6Nb-0.3Y alloy at different states

3 结论

1) 采用水冷铜坩埚真空感应熔炼制备了Ti-45Al- 5.4V-3.6Nb-0.3Y合金,该合金具有近层片组织结构,其晶粒尺寸为100 μm,主要由γ-TiAl、α2-Ti3Al和β(B2)相组成。

2) 经包套锻造后,合金的力学性能得到显著的提高,在室温条件下,铸态合金的屈服强度为400 MPa左右,伸长率为0.55%,锻态合金的屈服强度为620 MPa,塑性为1.08%;700 ℃下,铸态合金的屈服强度为562 MPa,伸长率为7.6%,锻态合金的屈服强度为708 MPa,塑性为35.55%。

REFERENCES

[1] KIM Y W, DIMIDIK D M. Progress in the understanding of Gamma titanium aluminides [J]. JOM, 1991, 8: 40-47.

[2] TETSUI T, SHINDO K, KOBAYASHI S, TAKEYAMA M. Strengthening a high-strength TiAl alloy by hot-forging [J]. Intermetallics, 2003, 11: 299-306.

[3] HU D. Effect of boron addition on tensile ductility in lamellar TiAl alloys [J]. Intermetallics, 2002, 10: 851-858.

[4] SHIH D S, KIM Y W. Sheet rolling performance evolution of beta-gamma alloys [C]// Ti-2007 Science and Engineering. Kyoto, Japan: The Japan Institute of Metals.2007: 1021-1024.

[5] CHEN Y Y, LI B H, KONG F T. Microstructural refinement and mechanical properties of Y-bearing TiAl alloys [J]. J Alloys Compd, 2008, 457: 265-269.

[6] JIN Y G, WANG J N, WANG Y. Microstructure refinement of cast TiAl alloys by β solidification [J]. Scripta Mater, 2004, 51: 113-117.

[7] XU X J, LIN J P, WANG Y, GUO J F, LIN Z, CHEN G L. Microstructure and tensile properties of as-cast Ti-45Al- (8-9)Nb-(W, B, Y) alloy [J]. J Alloys Compd, 2006, 414: 131- 136.

[8] TAKEYAMA M, KOBAYASHI S. Physical metallugy for wroght Gamma titanium aluminides microstructure control through phase transformation [J]. Intermetallics, 2005, 13: 993- 999.

[9] ZHANG L C, CHEN G L, WANG J G, YE H Q. TEM study on lamellar microstructure and α2/γ interfacial structure in a hot-deformed two-phase γ-TiAl-based alloy [J]. Materials Science and Engineering A, 1998, 247: 1-7.

[10] YANG Fei. Research on preparation and high temperature deformation behavior of Ti-45Al-9(V, Nb, Y) alloy [D]. Harbin: Harbin Institute of Technology, 2010.

(编辑 李艳红)

通信作者:杨 非; 电话: 0451-86418802; E-mail: fyang0204@hotmail.com