Trans. Nonferrous Met. Soc. China 22(2012) 1896-1901

Influence of secondary extrusion on microstructures and mechanical properties of ZK60 Mg alloy processed by extrusion and ECAP

YING Tao, HUANG Jian-ping, ZHENG Ming-yi, WU Kun

School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 10 November 2011; accepted 11 June 2012

Abstract: The microstructures and properties of ZK60 alloy were evaluated under four different conditions: extrusion; extrusion and 4 passes of equal channel angular pressing (ECAP); extrusion, 4 passes of ECAP and secondary extrusion; and extrusion, 4 passes of ECAP, annealing and secondary extrusion. Secondary extrusion at ambient temperature was successfully processed to produce ultrafine-grained ZK60 alloy. The results show that ECAP introduces significant grain refinement and there is additional refinement in secondary extrusion. High yield strength of 342 MPa is achieved after secondary extrusion at room temperature, but the elongation to failure is only 0.8%. However, by applying annealing before secondary extrusion, the ductility of ZK60 could be greatly improved to 4.5%, meanwhile the yield strength almost remains the same, and the ultimate strength of up to 388 MPa is obtained.

Key words: ZK60 magnesium alloy; extrusion; equal channel angular pressing; secondary extrusion

1 Introduction

Magnesium alloys are currently the lightest alloys used as structural metals [1,2]. Mg products have been used for structural applications, such as automobile parts. Although the demand for Mg alloys used by the industries is increasing, their applications are still quite limited due to the poor workability at room temperature. In order to improve the workability of Mg alloys, it is necessary to refine their grain size [3]. As one of the most effective ways to produce ultrafine-grained materials, equal channel angular pressing (ECAP) has attracted considerable attention in recent years [4-6]. During ECAP, the sample is pressed through a die containing two intersecting channels of equal cross-section, which indicates the work piece can be deformed repeatedly, so very high strain can be accumulated [7,8].

A few works have been reported on the texture evolution in Cu alloys heavily deformed by ECAP and then rolled [9,10]. Such studies are quite demanding because some applications, such as sputtering targets [11], require additional processing steps after ECAP. However, little information is available about the additional processes after ECAP of Mg alloys. In this study, a three-step processing route involving an initial extrusion step, subsequent processing by ECAP and finally secondary extrusion was used to produce ultrafine grain (UFG) Mg alloys. The effect of secondary extrusion on the microstructures and mechanical properties was mainly investigated.

2 Experimental

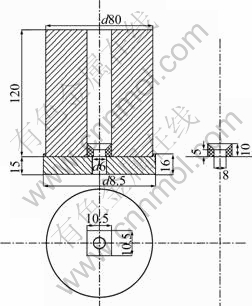

The experiments were conducted using a Mg-6.0Zn-0.5Zr alloy (mass fraction, %). Cylinder as-cast ZK60 alloy was extruded at 623 K with extrusion ratio of 20:1, and then cut into bars. ECAP processing was performed using a solid die having an angle of Φ=90° between two channels and an additional angle of ψ=20° at the outer arc of curvature where the two channels intersect. Route Bc [12], which rotates the work piece 90° clockwise along its longitudinal axis between adjacent passes, was used to process the ZK60 billets. During ECAP, molybdenum disulphide (MoS2) was used as a lubricant and up to 4-pass of ECAP was carried out at 523 K. After ECAP, the samples were secondary extruded with an extrusion ratio of 3.9 at room temperature and 373 K through a die, respectively, as shown in Fig. 1. To get better ductility, the samples were annealed at 523 K for 30 min after ECAP and then secondary extruded under the same condition.

Fig. 1 Schematic diagram of secondary extrusion die

The tensile specimens were machined from billets prepared under four different conditions. First, for the as-cast ZK60 alloy after extrusion, henceforth the “extruded” condition was designated; second, for the 4 pass-ECAPed samples after extrusion, henceforth the “ex+ECAPed” condition was designated; third, for the secondary extruded materials directly following ECAP, henceforth the “ex+ECAP+extruded” condition was designated; finally, for the secondary extruded samples with annealing after ECAP, henceforth the “ex+ECAP+ anneal+extruded” condition was designated. The dimensions of tensile specimens after secondary extrusion are shown in Fig. 2, while other tensile specimens had gauge lengths of 50 mm and cross-sectional areas of 2 mm×10 mm. Tensile test was carried out on an Instron Series 5569 test machine at room temperature at a tensile rate of 0.5 mm/min.

Fig. 2 Dimensions of tensile specimens after secondary extrusion

Microstructure observation was carried out by an Olympus DP11 optical microscope (OM) and FEI- TECNAI G2 F30 transmission electron microscope (TEM). The specimens for OM were ground, polished and then etched in acetic picral (5 mL acetic acid + 6 g picric acid + 10 mL H2O + 100 mL ethanol (95%)). Specimens for TEM were prepared by grinding-polishing to produce a foil with 50 μm thickness and then ion-thinned. The orientations of the basal plane were qualitatively analyzed by a Philips X’Pert X-ray diffractometer (XRD).

3 Results and discussion

3.1 Microstructures

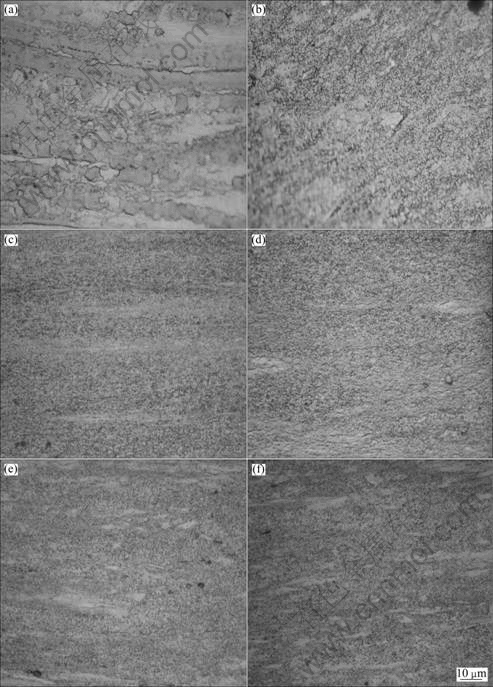

Figure 3 shows the optical microstructures for the samples under four conditions. Figure 3(a) shows the microstructure under the extruded condition, where the sample was extruded at 623 K. Figure 3(b) shows the microstructure under the ex+ECAPed condition, where the sample was extruded at 623 K and then processed by ECAP for four passes. Figures 3(c) and (d) show the microstructure under the ex+ECAP+extruded condition, where the samples were first extruded and ECAPed and then secondary extruded at room temperature and 373 K, respectively. Figures 3(e) and (f) show the microstructure under the ex+ECAP+anneal+extruded condition, where the samples were first extruded and ECAPed and then annealed at 523 K for 30 min, finally secondary extruded at room temperature and 373 K, respectively. The extrusion and ECAP pressing directions are horizontal. In Fig. 3(a), the grains of ZK60 after extrusion are elongated along the extrusion direction, and compared with the ex+ECAPed condition shown in Fig. 3(b), the grain size is much larger. After 4 passes of ECAP at 523 K, no obvious shear band occurs and the grains are too small to be visible. As for the ex+ECAP+extruded condition, secondary extruded samples at room temperature and 373 K shown in Figs. 3(c) and (d) show a similar structure with grains aligned along the extrusion direction as shown in Fig. 3(a), but the grains are further refined. The grain size of samples under ex+ECAP+anneal+extruded condition, which means annealing between the process of ECAP and secondary extrusion, is a little larger than that of the ex+ECAP+extruded ones, this is due to the recrystallization and grain growth during annealing.

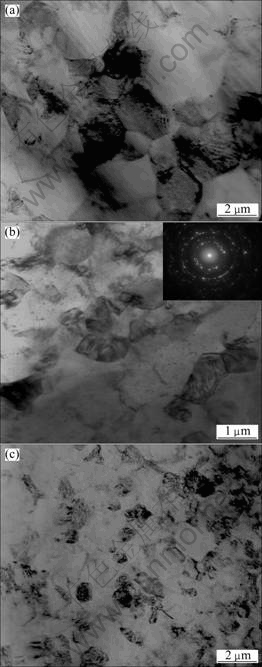

To obtain more detailed information on the microstructural development associated with the ECAP and secondary extrusion processes, the TEM micrographs of the alloy are shown in Fig. 4. In Fig. 4(a), the grains of the sample after extrusion and ECAP are refined to about 2 μm, and most of them are equiaxed due to the dynamic recrystallization during ECAP. In contrast, the grains of sample after secondary extrusion at 373 K (Fig. 4(b)) exhibit irregular shapes, which are attributed to the low processing temperature of secondary extrusion. The SAED pattern taken from the ex+ECAP+ extruded sample exhibits the rings of diffracted spots, indicating the presence of boundaries have high angles of misorientation. The grains of the sample after secondary extrusion are further refined to about 1 μm. Compared with Fig. 4(b), more large grains are found in the sample with annealing between processes of ECAP and secondary extrusion (Fig. 4(c)), which is due to the grain growth during annealing.

Fig. 3 Optical micrographs of ZK60 alloys under different conditions: (a) Extruded; (b) Ex+ECAPed; (c) Ex+ECAP+extruded at room temperature: (d) Ex+ECAP+extruded at 373 K; (e) Ex+ECAP+anneal+extruded at room temperature; (f) Ex+ECAP+anneal+ extruded at 373 K

3.2 Texture evolution

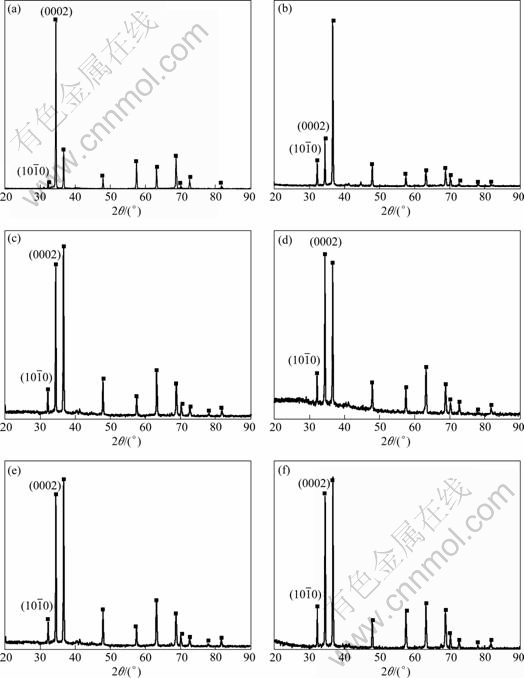

Figure 5 shows the X-ray diffraction spectra of ZK60 alloys under four different conditions. Compared with the X-ray diffraction spectra of the as-extruded ZK60 alloy, the peak of basal plane is much lower after ECAP, which means that the strong basal plane texture formed during extrusion [13-15] is weakened after ECAP processing. This may be due to the dynamic recrystallization during ECAP.

Fig. 4 TEM images and SAED pattern of ZK60 alloys: (a) Ex+ECAPed; (b) Ex+ECAP+extruded; (c) Ex+ECAP+anneal+ extruded

In order to study the effect of secondary extrusion on the change of the basal plane texture, I(0002) and  were chosen to denote the intensity of basal plane peak and pyramidal plane peak, respectively. So the relative intensity of basal plane peak could be got by

were chosen to denote the intensity of basal plane peak and pyramidal plane peak, respectively. So the relative intensity of basal plane peak could be got by  [16]. Table 1 lists the

[16]. Table 1 lists the  of ZK60 alloy under four conditions. The

of ZK60 alloy under four conditions. The  value of basal plane after secondary extrusion is much higher than that under the ex+ECAPed condition, which indicates the restoration of strong basal plane texture, but the intensity of basal plane is much lower than that under the extruded condition. The

value of basal plane after secondary extrusion is much higher than that under the ex+ECAPed condition, which indicates the restoration of strong basal plane texture, but the intensity of basal plane is much lower than that under the extruded condition. The  values of basal plane in ZK60 alloy with or without annealing before secondary extrusion are almost the same. Though the annealing process may weaken the basal plane texture through static crystallization, this can be ignored because of the low temperature of secondary extrusion.

values of basal plane in ZK60 alloy with or without annealing before secondary extrusion are almost the same. Though the annealing process may weaken the basal plane texture through static crystallization, this can be ignored because of the low temperature of secondary extrusion.

Table 1  value of ZK60 alloys

value of ZK60 alloys

3.3 Mechanical properties

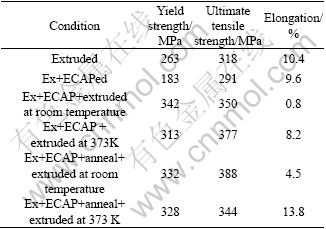

The tensile properties of ZK60 alloy under four conditions are listed in Table 2. Though the grain size is significantly refined after 4 passes of ECAP, the yield strength of the sample does not increase according to the Hall-Petch relationship because of the texture evolution of ZK60 alloy after 4 passes of ECAP mentioned above, the non basal slip systems are activated and the basal texture intensity is lowered. As for the sample under ex + ECAP + extrusion condition, the yield strength increases dramatically after secondary extrusion. This is due to the further grain refinement and restore of strong basal texture [3]. But the elongation to failure of the sample is rather low when secondary extruded at room temperature due to the high dislocation density. By applying annealing before secondary extrusion, the ductility can be greatly improved to about 4.5%, and high ultimate tensile strength of 388 MPa and yield strength of 332 MPa are obtained. Compared with the sample extruded at room temperature, the sample secondary extruded at 373 K shows a good combination of high strength and good ductility.

Table 2 Tensile properties of ZK60 alloys

Fig. 5 XRD patterns of ZK60 alloy: (a) Extruded; (b) Ex+ECAPed; (c) Ex+ECAP+extruded at room temperature; (d) Ex+ECAP+ extruded at 373 K; (e) Ex+ECAP+anneal+extruded at room temperature; (f) Ex+ECAP+anneal+extruded at 373 K

4 Conclusions

1) The grain size of ZK60 alloy decreases significantly after ECAP, and the grains are further refined to 1 μm after subsequent secondary extrusion. With annealing between ECAP and secondary extrusion, the grain size is a little larger. Irregular shape of grains and high angle grain boundaries occur after secondary extrusion.

2) The strong basal plane texture formed in the extruded ZK60 alloy is weakened by ECAP, and restored after secondary extrusion, but the intensity of basal plane peak after secondary extrusion is not as high as that of the extruded ones.

3) The yield strength of ZK60 decreases after ECAP due to the texture evolution after ECAP, and then increases dramatically to 342 MPa after secondary extrusion at room temperature. The increase of yield strength is attributed to the grain refinement and strong basal plane texture restoration. By applying annealing before secondary extrusion, a good combination of high strength and good ductility can be achieved.

References

[1] KIM W J, SA Y K. Micro-extrusion of ECAP processed magnesium alloy for production of high strength magnesium micro-gears [J]. Scripta Mater, 2006, 54: 1391-1395.

[2] CHINO Y, HOSHIKA T, LEE J S, MABUCHI M. Mechanical properties of AZ31 Mg alloy recycled by severe deformation [J]. J Mater Res, 2006, 21(3): 754-760.

[3] SUWAS S, GOTTSTEIN G, KUMAR R. Evolution of crystallographic texture during equal channel angular extrusion (ECAP) and its effects on secondary processing of magnesium [J]. Materials Science and Engineering A, 2007, 471: 1-14.

[4] YING Tao, ZHENG Ming-yi, HU Xiao-shi, WU Kun. Recycling of AZ91 Mg alloy through consolidation of machined chips by extrusion and ECAP [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(s2): s604-s607.

[5] ZHENG Ming-yi, FAN Guo-dong, TONG Li-bo, HU Xiao-shi, WU Kun. Damping behavior and mechanical properties of Mg-Cu-Mn alloy processed by equal channel angular pressing [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(s1): s33-s38.

[6] TONG L B, ZHENG M Y, HU X S, WU K, XU S W, KAMADO S, KOJIMA Y. Influence of ECAP routes on microstructure and mechanical properties of Mg–Zn–Ca alloy [J]. Materials Science and Engineering A, 2010, 527(16–17): 4250-4256.

[7] SEGAL V M. Materials processing by simple shear [J]. Materials Science and Engineering A, 1995, 197(2): 64-157.

[8] VALIEV R Z, LANGDON T G. Principles of equal-channel angular pressing as a processing tool for grain refinement [J]. Prog Mater Sci, 2006, 51: 881-981.

[9] FERRASSE S, SEGAL V M, ALFORD F. Effect of additional processing on texture evolution of Al0.5Cu alloy processed by equal channel angular extrusion (ECAE) [J]. Materials Science and Engineering A, 2004, 372(1-2): 44-55.

[10] MISHIN O V, GERTSMAN V Y, VALIEV R Z, GOTTSTEIN G. Grain boundary distribution and texture in ultrafine-grained copper produced by severe plastic deformation [J]. Scripta Mater, 1996, 35(7): 873-878.

[11] FERRASSE S, SEGAL V M, ALFORD F, KARDOKUS J, STROTHERS S. Scale up and application of equal-channel angular extrusion for electronics and aerospace industries [J]. Materials Science and Engineering A, 2008, 493(1-2): 130-140.

[12] FERRASSE S, SEGAL V M, KALIDINDI S R, ALFORD F. Texture evolution during equal channel angular extrusion: Part 1. Effect of route, number of passes and initial texture [J]. Materials Science and Engineering A, 2004, 368(1-2): 28-40.

[13] UEMATSU Y, TOKAJI K, KAMAKURA M, UCHIDA K, SHIBATA H, BEKKU N. Effect of extrusion conditions on grain refinement and fatigue behaviour in magnesium alloys [J]. Materials Science and Engineering A, 2006, 434(1-2): 131-140.

[14] DING H L, LIU L F, KAMADO S, DING W J, KOJIMA Y. Study of the microstructure, texture and tensile properties of as-extruded AZ91 magnesium alloy [J]. J Alloys Compd, 2008, 456: 400-406.

[15] SASAKI T T, YAMAMOTO K., HONMA T, KAMADO S, HONO K. A high-strength Mg-Sn-Zn-Al alloy extruded at low temperature [J]. Scripta Mater, 2008, 59(10): 1111-1114.

[16] DENG K K, WU K, WU Y W, NIE K B, ZHENG M Y. Effect of submicron size SiC particulates on microstructure and mechanical properties of AZ91 magnesium matrix composites [J]. J Alloys Compd, 2010, 504(2): 542-547.

二次挤压对挤压和ECAP变形后ZK60镁合金显微组织和力学性能的影响

应 韬,黄建平,郑明毅,吴 昆

哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001

摘 要:测试四种状态下ZK60合金的显微组织和力学性能,四种状态分别为:挤压;挤压+4道次ECAP;挤压+4道次ECAP+二次挤压;挤压+4道次ECAP+退火+二次挤压。在室温下成功地进行ZK60的二次挤压,得到超细晶组织。结果表明:ECAP和二次挤压可以显著细化晶粒。挤压+4道次ECAP+二次挤压后的ZK60合金的屈服强度为342 MPa,但是其伸长率只有0.8%。在二次挤压之前进行退火,ZK60合金的伸长率可以提高到4.5%,而屈服强度基本不变,抗拉强度达到388 MPa。

关键词:ZK60镁合金;挤压;等通道角挤压;二次挤压

(Edited by FANG Jing-hua)

Foundation item: Projects (50201005, 50571031) supported by the National Natural Science Foundation of China; Project (2009DFA51830) supported by the Program for International Science and Technology Cooperation Projects of China

Corresponding author: ZHENG Ming-yi; Tel: +86-451-86402291; E-mail: zhenghe@hit.edu.cn

DOI: 10.1016/S1003-6326(11)61404-0