冷绕成形螺旋弹簧回弹理论及数值模拟

王时龙,雷松,周杰,萧红,杨勇,冯治恒

(重庆大学 机械传动国家重点实验室,重庆,400030)

摘要:针对现有研究未考虑张力对螺旋弹簧成形及回弹影响的问题,建立受张力影响的螺旋弹簧成形及回弹理论;讨论当簧丝受弯矩和张力共同作用时,弯矩与簧丝横截面应力、张力与簧丝横截面应力、回弹比与张力的关系;通过大型非线性有限元分析软件ABAQUS 6.8实现不同张力下螺旋弹簧冷绕成形过程的数值模拟。理论计算与模拟结果均表明:张力不同会导致弹簧最终回弹量的不同;张力越大,簧丝在卸载时越容易保持成形时的形状,回弹量越小;实际生产弹簧时,在除张力外的其他参数不易改变的情况下,可通过增大或减小张力的方法来减小或增大回弹量。

关键词:螺旋弹簧;簧丝;成形;回弹理论;张力;数值模拟

中图分类号:TH135 文献标志码:A 文章编号:1672-7207(2011)02-0373-06

Theory of springback and numerical simulation of

helical springs after cold coiling

WANG Shi-long, LEI Song, ZHOU Jie, XIAO Hong, YANG Yong, FENG Zhi-heng

(State Key Laboratory of Mechanical Transmission, Chongqing University, Chongqing 400030, China)

Abstract: Since there is no research about the forming and springback of helical springs considering the influence of the tensile force, the theory of it was established. The relationships between the bending moment, tensile force and the stress within the cross-section of spring wire respectively along with the relationship between the ratio of springback and the tensile force were discussed by applying the bending moment and tensile force together. The forming process numerical simulations of helical springs at different tensile forces were carried out by employing the large non-linear finite element analytical software ABAQUS 6.8. The results show that the springback is different when applying different tensile forces during the winding process. The larger the tensile force is, the smaller the springback is. Under the condition, it is easier for the spring wire to keep the shape being formed. For the helical springs in the course of being cold-coiled, when the other parameters are not easy to be altered except the tensile force, it is capable of increasing or decreasing it to decrease or increase the springback, respectively.

Key words: helical springs; spring wire; forming; theory of springback; tensile force; numerical simulation

螺旋弹簧冷绕绕制成形时,簧丝要承受较大的弹塑性弯曲,卸载后其弹性部分要恢复,因此,缠绕后存在着回弹问题[1]。回弹一直是制约弹簧生产质量、成本,并限制生产效率的关键因素之一,是工程界未能有效解决的技术难题。殷仁龙等[1-3]从圆截面梁的弹塑性纯弯曲理论出发,研究了弯曲时簧丝横截面内的应力与应变、弯矩与簧圈曲率的关系[4]。但是,弹簧冷绕成形是一种蕴含簧丝拉伸、弯曲和扭转的复合变形过程,是一个包含几何非线性、材料非线性、接触非线性的强非线性问题;因此,仅仅把弹簧冷绕成形考虑成弹塑性纯弯曲过程存在局限性。Bibel等[5]认为张力使回弹的减小是因为张力会使簧丝横截面中性轴发生偏移,但张力只作用于中性轴以内簧丝横截面区域,弯矩只作用于中性轴以外簧丝横截面区域,显然这不符合实际簧丝横截面应力分布情况。在此,本文作者建立了考虑张力影响的螺旋弹簧成形及回弹理论,进一步分析了张力对弹簧回弹的影响。目前关于板材冲压回弹及管材弯曲回弹的数值模拟较多见[6-9],而对于螺旋弹簧冷绕成形及回弹的数值模拟还未见文献报道。因此,本文作者还进行了不同张力下螺旋弹簧冷绕成形过程的有限元数值模拟。

1 受张力影响的螺旋弹簧回弹理论

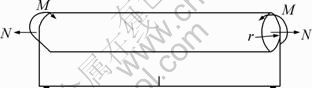

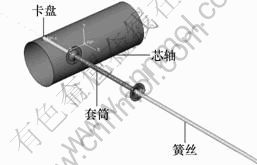

螺旋弹簧冷绕成形过程如图1所示,簧丝由卡盘固定,在主轴旋转的同时,簧丝进给装置在床身轴向左、右移动,将簧丝绕在芯轴上卷制成弹簧。该过程可等效为长为l、半径为r的簧丝受到1对弯矩M和1对张力N的共同作用,见图2。当簧丝承受的弯矩M和张力N较小时,簧丝完全为弹性变形,横截面上应力按直线分布,边缘(r=d/2,d为簧丝直径)上的应 力为:

(1)

(1)

式中:σM为因弯矩产生的应力;σN为因张力产生的应力;σ为合应力。

当弯矩M=Ms,张力N=Ns时,簧丝边缘处的应力刚好达到初始屈服应力σs,于是,有:

(2)

(2)

式中:Ms和Ns分别为簧丝边缘处的应力刚好达到初始屈服应力时的弯矩和张力。

冷绕弹簧时,簧丝受到的弯矩远大于Ms,在簧丝横截面上沿弹簧圈半径方向的内外表层纤维将产生塑性变形,并且随着力矩的增大,塑性变形还要向簧丝内层延伸。与圆截面梁的纯弯曲理论相比,弯矩和张力共同作用时簧丝的中性轴会偏离截面几何中心,见图3。在图3中:c为初始屈服纤维到中性轴的距离;b为中性轴到截面几何中心的距离。本文考虑簧丝材料为弹-线性强化材料,设z为簧丝横截面上任意一点到截面几何中心的距离,则弯矩和张力共同作用时簧丝横截面的应力为:

(3)

(3)

式中: ;E为簧丝弹性模量;E1为簧丝线性强化模量。

;E为簧丝弹性模量;E1为簧丝线性强化模量。

图1 螺旋弹簧冷绕成形过程

Fig.1 Cold-coiling process of helical springs

图2 簧丝受1对弯矩M和1对张力N的共同作用

Fig.2 Applying bending moment and tensile force to spring wire together

图3 簧丝圆形横截面上沿厚度方向的应力分布

Fig.3 Stress distributions within cross-section of spring wires along thickness

因此,弯矩M与应力σ之间对应关系为:

(4)

(4)

张力N与应力σ之间对应关系为:

(5)

(5)

式中:A为簧丝横截面的面积。

为了使公式简洁,引入弯矩无量纲量m与张力无量纲量n[10-12]:

(6)

(6)

及

(7)

(7)

式中:p和q表示应力分布特征。

把式(4), (5)和(7)代入式(6),则得:

(8)

(8)

(9)

(9)

为了说明张力对弹簧回弹的影响,需求得弹簧回弹后的曲率或回弹比。由于圆截面梁在弹塑性弯曲后卸载不会引起纤维的反向屈服,因此,卸除M和N相当于叠加-M和-N引起的纯弹性效应。轴力的纯弹性效应将不改变曲率,因而回弹后簧丝的曲率为:

(10)

(10)

式中: 为回弹后的无量纲曲率;

为回弹后的无量纲曲率; 为回弹前的无量纲曲率[6]。

为回弹前的无量纲曲率[6]。

同理,无量纲回弹比为:

(11)

(11)

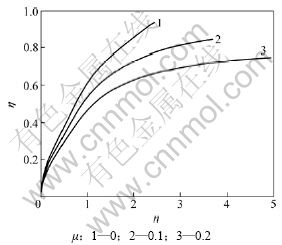

因此,只要得到了无量纲回弹比η和张力无量纲量n的关系,就能说明张力对弹簧最终回弹的影响。考虑到b<r且c+b<r,即q<1且p+q<1,由式(9)和(11)可得到η和n的关系,结果如图4所示。

由图4可见:随着张力的增大,回弹比η增大;在初始张力增大不多的情况下,回弹比急剧增大,即η/n较大;随着张力的继续增大,回弹比增大不多,η/n增大趋势逐渐趋于平缓;回弹比越大,使簧丝在卸载的过程中能够较好地保持成形时的形状,即回弹量减小。

通过进一步分析可以得到:在弹簧成形过程中,除张力变化而其余参数一定的情况下,张力不同会导致弹簧最终回弹量不同,即弹簧回弹后的尺寸、精度和质量不同。由于文献[1-3]中在没有考虑张力的情况下研究弹簧成形后的回弹,因此,其结果是有局限的。同时,冷拉碳素簧丝绕制弹簧时,在其他参数不变的情况下,可通过增大或减小张力来减小或增大最终弹簧的回弹量,以提高弹簧回弹后的精度和质量。

图4 μ不同时无量纲回弹比η与张力无量纲量n的关系

Fig.4 Relationships between dimensional springback ratio And tensile force under different μ

2 数值模拟计算

2.1 计算模型

为了进一步说明弹簧成形过程中张力的影响,本文作者采用ABAQUS 6.8中的ABAQUS/ Explicit模块,并用准静态分析的方法模拟弹簧冷绕成形过程。根据图1所示的弹簧冷绕成形原理,采用三维模型建立簧丝、芯轴、套筒和卡盘等部件。由于芯轴、套筒和卡盘的刚度远远大于簧丝的刚度,并且其本身的应力和变形不是所关心的对象,因此,采用三维离散刚体部件对芯轴和卡盘建模(芯轴与卡盘合并在一起后呈不规则形状,因此,应采用三维离散刚体部件建模);采用三维解析刚体部件对套筒建模。在分析过程中,刚体部件不参与所有基于单元的计算,因而可以节约大量的时间。另外,在接触分析中,如果接触对的主面是刚体部件的面,分析时结果就更容易收敛。

当弹簧成形时,簧丝外侧受拉伸,内侧受压缩,并且簧丝中性轴会向下偏移。应力沿簧丝横截面的分布如图3所示。为了真实地反映弹簧绕制过程中簧丝横截面应力的分布,本文作者采用三维实体单元对簧丝建模。螺旋弹簧冷绕成形的有限元计算模型如图5所示。

图5 螺旋弹簧冷绕成形有限元计算模型

Fig.5 FEM computing model of cold-coiling process of helical springs

套筒为解析刚体部件,不需要划分网格;芯轴和卡盘为离散刚体部件,选用R3D4单元进行简单网格划分即可。弹簧冷绕成形是一个大变形的复杂接触问题,因此,应使用C3D8R线性减缩积分单元对簧丝进行网格划分。该单元的优点是:可用于任何包含接触的问题中;对位移的求解结果较精确;在弯曲载荷下不容易发生剪切自锁问题;当网格存在扭曲变形时,分析精度不会受到大的影响[13-15]。模型中簧丝的节点数为81 969,单元数为68 080。

模型中簧丝材料为碳素弹簧钢丝T9A,密度为7.8 g/cm3,弹性模量为205 GPa,泊松比为0.3;成形过程中簧丝直径为2.1 mm,芯轴直径为17 mm,螺距为10 mm,张力分别为50,100,150和500 N。

簧丝成形过程分2步进行:预加张力和绕制成形。假设簧丝在成形过程中长度不变,首先在簧丝末端施加张力,该张力与自主研发的高精度多股螺旋弹簧数控加工机床的CZ系列磁粉制动器控制绕簧过程中的张力一致。由于绕簧过程中存在几何非线性、材料非线性及接触非线性,故簧丝以位移方式分段逐步加载。位移增量由簧丝的空间几何模型控制为:

(12)

(12)

式中:D为弹簧中径;ω为芯轴转速;P为弹簧节距;t为绕制时间。

2.2 计算结果与分析

比较当芯轴直径D=17 mm,簧丝直径d=2.1 mm,绕簧节距P=10 mm,成形圈数n=3条件下,张力分别为50,100,150和500 N时张力对回弹量的影响。图6所示为张力为100 N时弹簧成形后的变形与Mises应力分布。在其余张力下弹簧成形后的变形与Mises应力分布与其类似。

图6 张力为100 N时弹簧变形与Mises应力的分布

Fig.6 Deformation and Mises stresses distribution of helical spring when tensile force is 100 N

从图6可以看出:成形过程中的最大应力出现在簧丝与卡盘的连接处。这是因为簧丝与卡盘是采用RBE2的连接方式,成形过程中该处出现了应力集中。但是,该连接处的数值并不是所关注的主要对象,在实际加工中与卡盘夹紧处的簧丝也会在弹簧绕完后切掉,因此,更应该关注成形过程中连接处外簧丝的应力。

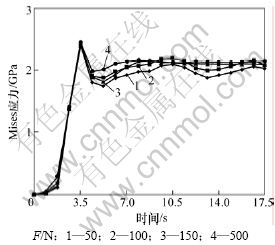

由于成形过程中,簧丝外层单元主要受拉应力作用,内层单元主要受压应力作用,并且应力呈同心圆分布。因此,取不同张力时簧丝某同一截面最外层相同的1个单元,并作出应力随着时间的变化曲线,如图7所示。

图7 不同张力下簧丝某同一横截面最外层相同的1个单元在成形过程中应力与时间的关系

Fig.7 Relationships between the Mises stresses and time of the same element within the same layer of cross-section

in cold-coiling process of helical springs under different tensile forces

由图7可以看出:张力越大,成形过程中簧丝的内应力越稳定且内应力也越大,簧丝截面内塑性区域所占比例越大,回弹量越小。这与本文理论计算结果一致。因此,在实际绕制弹簧的过程中,可在不改变其他参数的条件下,通过增大或减小张力的办法来控制弹簧回弹量。

3 结论

(1) 建立了受张力影响的螺旋弹簧成形及回弹理论。通过理论计算发现:张力对弹簧回弹影响很大;在成形过程中,张力越大,簧丝回弹后的曲率与回弹前的曲率的比值越大,即回弹比越大,簧丝在卸载的过程中越能够较好地保持成形时的形状,回弹量越小。

(2) 张力越大,在成形过程中簧丝的内应力越稳定,且内应力也越大,簧丝截面内塑性区域所占比例越大,回弹量越小。

(3) 数值模拟结论与理论计算结论一致。因此,在实际生产弹簧时,需考虑张力以控制弹簧的回弹量;在改变张力而其余参数一定或不易改变的情况下,可通过增大或减小张力来减小或增大最终弹簧的回弹量,从而可有效指导弹簧生产,降低生产成本,提高弹簧生产质量和效率。

参考文献:

[1] 殷仁龙. 弹塑性弯曲理论与冷绕螺旋弹簧的回弹[J]. 华东工学院学报, 1992(5): 73-76, 87.

YIN Ren-long. The theory of elastic-plastic bending and springback of helical springs being cold-coiled[J]. Journal of East China Institute of Technology, 1992(5): 73-76, 87.

[2] 刘金武, 高为国, 倪小丹. 冷绕螺旋弹簧回弹曲率的研究及试验[J]. 现代制造工程, 2002(3): 12-13.

LIU Jin-wu, GAO Wei-guo, NI Xiao-dan. Research and experiment of springback curvature of helical springs being cold-coiled[J]. Modern Manufacturing Engineering, 2002(3): 12-13.

[3] 张英会, 刘辉航, 王德成. 弹簧手册[M]. 北京: 机械工业出版社, 2008: 112-116.

ZHANG Ying-hui, LIU Hui-hang, WANG De-cheng. Spring handbook[M]. Beijing: Mechanical Industry Press, 2008: 112-116.

[4] Chakrabarty J. Theory of plasticity[M]. New York: McGraw-Hill Book Company, 1987: 99.

[5] Bibel G D, Kicher T P. Reduction of springback and residual stresses during winding of a helical spring[J]. Journal of Engineering for Industry, 1991, 113(2): 214-217.

[6] 林高用, 周佳, 郑小燕, 等. X5214 铝合金型材挤压过程的数值模拟[J]. 中南大学学报: 自然科学版, 2008, 39(4): 748-754.

LIN Gao-yong, ZHOU Jia, ZHENG Xiao-yan, et al. Numerical simulation of extrusion process of X5214 aluminum alloy profile[J]. Journal of Central South University: Science and Technology, 2008, 39(4): 748-754.

[7] 詹梅, 杨合, 栗振斌. 管材数控弯曲回弹规律的有限元分析[J]. 材料科学与工艺, 2004, 12(4): 349-352.

ZHAN Mei, YANG He, LI Zhen-bin. FEM numerical analysis of springback law of NC tube bending[J]. Materials Science and Technology, 2004, 12(4): 349-352.

[8] 陈磊, 杨继昌, 张立文. 板料弯曲回弹影响因素的有限元模拟研究[J]. 材料科学与工艺, 2007, 15(2): 269-272.

CHEN Lei, YANG Ji-chang, ZHANG Li-wen. Research on the factors influencing bending springback of sheetmetal by FEM[J]. Materials Science and Technology, 2007, 15(2): 269-272.

[9] 徐丙坤, 施法中. 板料冲压成形回弹的数值模拟[J]. 北京航空航天大学学报, 2001, 27(2): 194-197.

XU Bing-kun, SHI Fa-zhong. Numerical simulation of springback in sheet metal forming[J]. Journal of Beijing University of Aeronautics and Astronautics, 2001, 27(2): 194-197.

[10] 余同希, 章亮炽. 塑性弯曲理论及其应用[M]. 北京: 科学出版社, 1992: 45-55.

YU Tong-xi, ZHANG Liang-chi. Theory and application of plasticity[M]. Beijing: Science Press, 1992: 45-55.

[11] Yu T X, Johnson W. Influence of axial force on the elastic-plastic bending and springback of a beam[J]. Journal of Mechanical Working Technology, 1982, 6(1): 5-21.

[12] El-Domiaty A, Shabaik A H. Bending of work-hardening metals under the influence of axial load[J]. Journal of Mechanical Working Technology, 1984, 10(1): 57-66.

[13] 曹金凤, 石亦平. ABAQUS有限元分析常见问题解答[M]. 北京: 机械工业出版社, 2009: 130-136.

CAO Jin-feng, SHI Yi-ping. ABAQUS FEM numerical analysis and frequently asked questions[M]. Beijing: Mechanical Industry Press, 2009: 130-136.

[14] 庄茁, 张帆, 岑松, 等. ABAQUS非线性有限元软件与实例[M]. 北京: 科学出版社, 2005: 52-61.

ZHUANG Zhuo, ZHANG Fan, CEN Song, et al. ABAQUS non-linear FEM software and application example[M]. Beijing: Science Press, 2005: 52-61.

[15] 石亦平, 周玉蓉. ABAQUS有限元分析实例详解[M]. 北京: 机械工业出版社, 2008: 51-58.

SHI Yi-ping, ZHOU Yu-rong. ABAQUS FEM numerical analysis and application example explanation[M]. Beijing: Mechanical Industry Press, 2008: 51-58.

(编辑 陈爱华)

收稿日期:2009-12-22;修回日期:2010-03-05

基金项目:国家自然科学基金资助项目(50775226);教育部科学技术研究重点项目(109129);国家杰出青年科学基金资助项目(50925518);重庆大学研究生科技创新基金资助项目(200911A1A0020318);重庆大学“211工程”三期创新人才培养计划建设项目(S-90106)

通信作者:王时龙(1966-),男,湖南祁阳人,博士,教授,从事制造自动化及集成制造技术研究;电话:023-65103567;E-mail:slwang@cqu.edu.cn