文章编号:1004-0609(2010)07-1339-07

Mg粉添加量对泡沫铝发泡行为的影响

王 磊1, 2,姚广春1, 2,罗洪杰1, 2,梁李斯1, 2,张志刚1, 2

(1. 东北大学 材料与冶金学院,沈阳 110819;

2. 东北大学 教育部材料先进制备技术工程研究中心,沈阳 110004)

摘 要:利用粉末冶金法制备不同Mg粉添加量的纯铝闭孔泡沫铝材料,并对Mg粉添加量对泡沫铝发泡行为及泡沫稳定性的影响进行研究。结果表明:Mg粉的添加导致前驱体膨胀率的显著增大和泡沫体泡孔结构的均匀化;添加的Mg粉同空气雾化Al粉表面的Al2O3反应,生成同铝熔体有良好润湿性的MgAl2O4相,打破原有铝粉表面的氧化物结构,生成的MgAl2O4相均匀地分布于泡孔的布拉德边界和泡壁上;润湿性MgAl2O4相的出现增加熔体的表观黏度,大大减弱重力排液、毛细作用和气泡流动带来的负面影响,从而提高泡沫的稳定性;在空气雾化工业纯Al粉含氧量(质量分数)为(0.34±0.01)%和Mg粉添加量为(0.6%~1.0)%的条件下,可以获得最佳的膨胀率和均匀的泡孔结构。

关键词:泡沫铝;粉末冶金;Mg粉;发泡行为;泡沫稳定性

中图分类号:TG 146.21 文献标志码:A

Effect of addition of Mg powders on foaming behaviors of Al foams

WANG Lei1, 2, YAO Guang-chun1, 2, LUO Hong-jie1, 2, LIANG Li-si1, 2, ZHANG Zhi-gang1, 2

(1. School of Materials and Metallurgy, Northeastern University, Shenyang 110819, China;

2. Engineering and Researching Center of Advanced Preparation Technology of Materials, Ministry of Education, Northeastern University, Shenyang 110004, China)

Abstract: Closed-cell pure aluminum (Al) foams with Mg powders were prepared by powder metallurgy route. The effects of addition of Mg powders on the foaming behaviors and foam stability were discussed. The results show that the expansion rate of the precursor increases significantly with addition of Mg powders and uniform cell structures of Al foams are obtained; MgAl2O4 phases with good wettability with Al melt are formed due to the reaction between Mg powders and Al2O3 on the surface of Al powders; original oxide structures on surfaces of Al powder are destroyed and MgAl2O4 phases locate uniformly into the plateau borders and cell walls; the apparent viscosity of melt is enhanced due to the present of MgAl2O4 phases. Negative impacts caused by gravity drainage,capillarity and bubble flow are weakened greatly and hence foam stability is improved. The optimum expansion rate and uniform cell structures are achieved as oxygen content for air-atomized Al powder is (0.34±0.01)% (mass fraction) and addition of Mg powder is (0.6%-1.0) %.

Key words: Al foams; powder metallurgy; Mg powder; foaming behaviors; foam stability

泡沫铝是一种集结构与功能为一体的新型复合材料,具有轻质、高比刚度、高能量吸收以及电磁屏蔽和阻尼减震等优点[1-3]。在众多泡沫铝制备方法(熔体直接发泡法、注气法和粉末冶金法)中,粉末冶金法由于具有近净成形[4-6]的特点,可以制备各种形状复杂的泡沫铝零部件,越来越受到泡沫铝研究者的青睐。采用该方法所制备出来的泡沫铝产品也广泛应用于汽车制造和航空航天等领域[7-8]。

在泡沫铝的制备过程中,重力排液、毛细作用和气泡流动是不可避免的。重力作用下的液态金属会沿着泡壁和布拉德边界形成的通道向重力垂直向下的方向流动,导致实铝层的出现;而毛细作用使得已经形成的液态泡壁由于布拉德边界的允吸而变得更细;气泡流动使得相互形成的气泡相互挤压,同样会增加气泡合并的概率。因此减小重力排液、毛细作用以及气泡流动是稳定气泡的关键所在。目前,金属泡沫最主要的稳定机理是由DUDKA等[9]提出的颗粒稳定机理,即通过添加陶瓷颗粒或者能与基体材料反应的颗粒物质到金属熔体或者粉末冶金法制备的前驱体中,通过陶瓷颗粒在气-固界面处的富集,增加熔体的表观黏度,减小布拉德边界与泡壁之间的压差而稳定泡沫。液态金属发泡方法是将陶瓷颗粒添加到熔融金属中,并且普遍地认为与液态金属有很好润湿性的陶瓷颗粒能够改善泡沫的稳定性[10-11]。在采用粉末冶金法制备泡沫铝的过程中,Al粉表面氧化是不可避免的,这与铝粉极易氧化的特性密切相关,而且文献[12]报道了过低氧含量的Al粉会导致泡沫的不稳定,因此使用适当氧含量的Al粉是必需的。但是由于氧化铝颗粒与铝熔体之间差的润湿性[13],导致这些铝粉表面的氧化铝颗粒并不能稳定泡沫。文献[14]报道过Mg粉在铝粉烧结实验中的关键作用,即通过添加适量的Mg粉,这些Mg粉同Al粉表面的氧化膜反应形成MgAl2O4,破坏了原来的氧化物结构,促进了铝粉的烧结。因此,通过将适量Mg粉添加到粉末冶金泡沫铝的前驱体中,必然会破坏铝粉表面的氧化物结构。目前,国内外少见相关文献报道系统研究Mg粉对粉末冶金泡沫铝泡孔结构和泡沫稳定性的影响。

本文作者通过添加不同含量Mg粉到前驱体中,分析发泡后泡沫体膨胀行为和表面形貌来确定其最佳Mg粉含量,并利用原位反应生成的润湿性颗粒稳定机理[9]探讨Mg粉的添加对泡沫稳定性的影响。

1 实验

1.1 实验原料

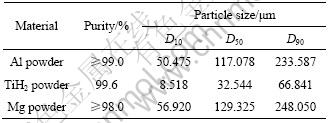

采用Malvern Mastersizer2000激光粒度分析仪分析试验中所使用的粉末,粉末原料的特性如表1所列。

采用LECO公司生产的TC-436型氧氮测定仪测得空气雾化Al粉中氧含量(质量分数)为(0.34±0.01)%。

表1 实验用粉末原料的物理特征

Table 1 Physical characteristics of powder materials used in experiment

1.2 检测方法

利用分辨率为300dpi的扫描仪对发泡后未切割样品进行外观形貌扫描。利用线切割机将泡沫体沿高度方向切开,将切开后的泡孔横截面用黑色光亮漆进行喷漆处理以增加布拉德边界和泡壁同泡孔底部之间的对比度,将喷漆后晾干的样品用砂纸打磨并抛光,样品干燥后对泡孔表面形貌进行扫描。将添加适量Mg粉的前驱体在一定温度下加热,采用XRD物相分析来鉴定是否有新的物相生成。利用光学显微镜(OM)和扫描电子显微镜(SEM)分析布拉德边界和泡壁上的物质分布情况并对SEM中的物相采用EDS元素分析,用来确定其物相组成。

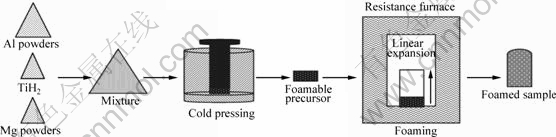

1.3 实验方法

将工业纯Al粉、不同添加量的Mg粉和0.6%(质量分数)的氢化钛在KQM-X4B/B型行星式四头快速球磨机上混料2 h。混合物在YES-2000型数显式压力试验机上通过单轴向冷压压制成直径为50 mm,高度为20 mm的可发泡前驱体材料。采用的压制压力为400 MPa,保压时间为10 min。将压制后的前驱体放入预先加热到1 073 K的电阻炉内进行发泡实验。发泡时间控制在100~160 s。对于没有添加Mg粉的前驱体,发泡时间为140~150 s;添加了Mg粉的前驱体发泡时间控制在100~110 s,实验工艺流程示意图如图1所示。

2 结果与讨论

2.1 Mg粉添加量对膨胀率的影响

本实验中采用的Mg粉添加量为0、0.2%、0.6%、1.0%、1.4%和1.8%。为了更加准确地描述泡沫铝膨胀行为,采用膨胀率计算公式:

(1)

(1)

式中:RE为膨胀率;hP为泡沫体发泡前高度;hF为泡沫体发泡后高度。

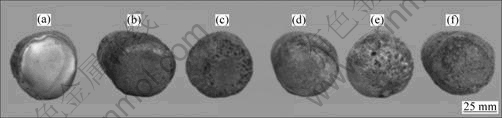

图2所示为含有不同Mg含量泡沫铝发泡后的外观照片。在实验过程中,有Mg粉的前驱体的发泡时间为105 s,没有Mg粉的发泡时间为145 s(这是由于在105 s的情况下,发泡时没有Mg粉的前驱体的上表面氧化严重而导致不能出现明显的膨胀,见图2(a)顶部所示)。从图2可以看出,随着Mg粉含量的增加,膨胀率也明显增大。当Mg添加量达到0.6%时,膨胀率最大;当达到1.0%时,出现了小幅度的减小,随后又出现了小幅度增大。当Mg粉添加量为0.6%时,利用式(1)可计算出其最大膨胀率大约为472%。因此,从膨胀行为上看,Mg粉添加量在0.2%以上就可以了。

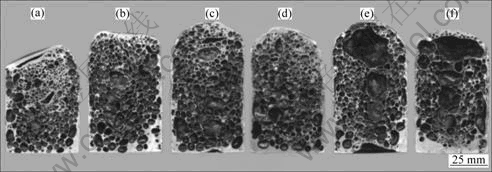

2.2 Mg粉添加量对泡孔结构的影响

图3所示为不同Mg含量的泡沫铝的纵剖面照片,可以发现随着Mg含量的增加,泡孔结构发生了明显改变。在图3(a)中可以发现泡孔结构极不均匀,而且形成了底部实铝层。图3(b)所示的泡孔结构有所改善,但是底部实铝层还是比较明显。这说明了少量Mg的添加没有有效地阻止重力排液。然而,从图3(c)和(d)可以发现,在Mg含量为0.6%~1.0%时泡沫铝的膨胀行为增强,泡孔结构相对均匀,而且更为重要的是底部实铝层基本消失了,这也是粉末冶金法能够制备近净成形泡沫铝部件的原因之一。过多添加Mg粉,即当Mg含量大于1.0%之后,气泡大量地合并,这是因为过多Mg粉同铝熔体之间形成部分镁铝合金相,降低了基体材料的熔点。因此,在相同发泡温度下合金熔体的表观黏度就会降低,在重力作用下加剧了金属液体沿着布拉德边界和泡壁形成的通道垂直向下流动,使底部实铝层明显变厚;添加过多Mg粉还会导致合金熔体的表面张力增加,使布拉德边界对泡壁的吮吸作用增强,加速了气泡壁变薄,进而导致气泡破裂和合并,出现如图3(e)和(f)所示的气泡合并和实铝层的出现。

2.3 稳定性机理分析

由于前驱体上端面在发泡过程中完全处于空气中,因此上端面是前驱体接触空气最多的也是氧浓度最高的地方,所以发泡后泡沫体顶部形貌能够反应泡沫体的表面氧化程度。对于极易氧化的铝,顶部氧化程度决定了泡沫体膨胀的高低。图4所示为6种不同Mg含量样品发泡后没有切割的顶部视图,可以发现随着Mg含量的增加,在相同时间下(除了没有添加

图1 粉末冶金法制备泡沫铝流程示意图

Fig.1 Schematic diagram of preparation of Al foams by powder metallurgy route

图2 不同Mg含量的泡沫铝宏观照片(发泡温度为1 073 K)

Fig.2 Macrographs of Al foams with different mass fractions of Mg at foaming temperature of 1 073 K: (a) Without Mg; (b) 0.2% Mg; (c) 0.6% Mg; (d) 1.0% Mg; (e) 1.4% Mg; (f) 1.8% Mg

图3 不同Mg含量的泡沫铝的泡孔表面形貌

Fig.3 Surface morphologies of cell walls of Al foams with different mass fractions of Mg: (a) Without Mg; (b) 0.2% Mg; (c) 0.6% Mg; (d) 1.0% Mg; (e) 1.4% Mg; (f) 1.8% Mg

图4 不同Mg添加量的泡沫铝的顶部视图

Fig.4 Top views of Al foams with different mass fractions of Mg: (a) Without Mg; (b) 0.2% Mg; (c) 0.6% Mg; (d) 1.0% Mg; (e) 1.4% Mg; (f) 1.8% Mg

Mg的团块发泡时间为145 s外)顶部氧化程度逐渐减小,但当Mg添加量超过了0.6%时会发现顶部形貌已经没有太大变化。图4(a)所示的样品顶部氧化比较严重,这是由于在没有Mg的情况下,Al粉表面氧化铝不能跟铝液自身润湿,只能在熔融铝液中相互团聚形成大块氧化物或者被排斥到泡沫体的表面。因此,在 1 073 K的炉温条件下,没有添加Mg粉的前驱体上部由于处在空气中,排出的氧化物加上本来已经处在高温下的表面,使得氧化变得更加容易,再加上从铝熔体中排除出来的氧化铝,使得在泡沫体顶部形成了致密氧化层。在图4(b)所示的添加0.2%Mg粉的泡沫体上部已经没有出现图4(a)所示的光亮的氧化层,只出现含麻点的氧化层,说明添加Mg有效地减少了顶部泡沫体的氧化。

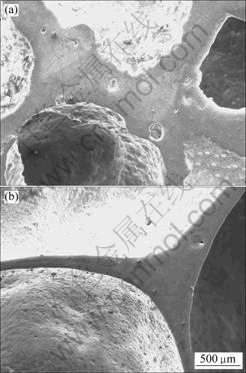

图5所示为没有添加Mg与添加了1.0%Mg的泡孔的SEM像。采用孔圆形度来表征图5中的泡孔形貌,孔圆形度定义为[15]

,

, (2)

(2)

式中:c为孔圆形度ci的平均值;li为泡孔边界长度;

图5 不同Mg含量泡沫铝的泡孔的布拉德边界的SEM像

Fig.5 SEM images of Al foams with different mass fractions of Mg at Plateau borders: (a) Without Mg;(b) With 1.0% Mg

Ai为泡孔面积;n为泡孔的数目。ci=1的泡孔是圆孔。c越大,则偏离圆形的程度越大。

目前,文献所报道的稳定的液态金属泡孔结构为五角十二面体[16],因此,圆孔或者其他孔型都是极不稳定的。从图5(a)看出,没有添加Mg粉的泡沫体气泡泡壁较厚,泡孔较小,布拉德边界几乎连成一片,出现多处分叉结构,泡壁厚度同布拉德边界厚度几乎相当,泡壁边缘呈不规则形状,由公式(2)可知圆形度c接近1。而图5(b)所示的属于典型的金属泡沫布拉德边界,主要形成的是具有最低能量的近似正五边形 泡孔[16]。

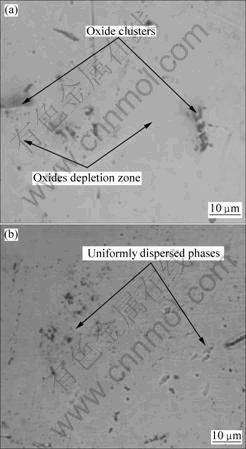

由原位反应颗粒稳定机理可以知道,通过添加高反应元素同基体材料中的物质反应所形成的细小氧化物颗粒同熔体之间的润湿性好坏是相当重要的。润湿性差的颗粒由于熔体的排斥作用将会以机械力的结合方式附着在泡孔内表面或者排斥到熔体表面,起不到稳定泡沫的作用,只有完全润湿性的颗粒才能够延缓气泡壁变薄,减小重力排液和毛细作用的负面影响而稳定泡沫。图6(a)所示为没有添加Mg的布拉德边界上的氧化物分布情况。在没有添加镁的情况下,前驱体中只有空气雾化Al粉表面所形成的致密氧化铝层。在发泡期间,这些氧化物同熔融铝液之间差的润湿性导致了大量的氧化铝之间的相互团聚并结块,进而造成氧化物富集区和无氧区。无氧区的存在使得泡沫极不稳定。对于只有氧化铝存在的前驱体发泡后,氧化物有的在冷却凝固过程中被保留在泡沫体中,有的由于铝熔体的强烈排斥作用而达到泡沫体的表面。这种排斥作用最为明显的表现就是前驱体上端面跟空气充分接触的部分发泡后形成了致密的氧化物层(见图4(a))。图6(b)所示为添加1.0%Mg粉的布拉德边界上的氧化物分布情况,可以看出Mg的添加导致原来团聚结块的氧化物均匀分散。由前面实验可以知道,添加1.0%Mg粉后,液态泡沫的稳定性得到有效提高,而且膨胀率也明显增加,同时减轻了泡沫体顶部氧化程度。

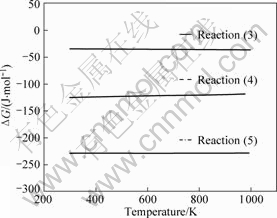

表面有一定程度氧化的Mg粉添加到具有一定氧含量的Al粉中,可能会出现如下反应:

MgO+Al2O3 MgAl2O4 (3)

MgAl2O4 (3)

3Mg+Al2O3 3MgO+2Al (4)

3MgO+2Al (4)

3Mg+4Al2O3 3MgAl2O4+2Al (5)

3MgAl2O4+2Al (5)

图7所示为上述3个反应方程式的吉布斯自由能变化趋势图。从图7中可以看出,3个反应的生成物与反应物的吉布斯自由能的差值在1 000 K以下都是负值。本实验采用的发泡温度为1 073 K,前驱体自身的温度一般在973 K左右,因此说明这3个反应在热力学上都是可行的。在1 073 K的发泡温度下,当表面氧化的Mg粉添加到空气雾化的Al粉中,Mg粉表面的MgO首先跟Al2O3反应生成镁铝尖晶石,当反应进行到有单质Mg出现时,反应(4)开始,生成MgO,生成的MgO反过来又同Al粉表面的Al2O3反应形成镁铝尖晶石。所以可以认为反应式(3)和(4)是(5)的中 间反应过程。从能量最低原理角度,吉布斯自由能的差值越小说明反应的可能性越大,从图7还可以发现反应式(5)的曲线在最下方,说明了其生成物和反应物的DG最小,式(5)是形成MgAl2O4的主要反应。

图6 不同Mg含量的泡沫铝的布拉德边界光学照片

Fig.6 Optical photographs of Al foams at Plateau borders: (a) Without Mg;(b) With 1.0%Mg

图7 反应(3)、(4)和(5)的吉布斯自由能变化

Fig.7 Changes of Gibbs free energies for reaction equations (3), (4) and (5)

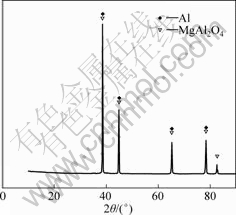

为了进一步证明镁铝尖晶石的存在,对添加了1.0%Mg粉的前驱体(没有添加发泡剂的前驱体)在 793 K空气中烧结1 h,然后进行XRD分析,如图8所示。从图8可以看出,除了基体Al以外,主要物质是MgAl2O4尖晶石相,说明主反应式(5)发生的必然性。

图8 添加1.0%Mg粉的前驱体在793 K烧结1 h后的 XRD谱

Fig.8 XRD pattern of precursor with 1.0% Mg annealed at 793 K for 1 h

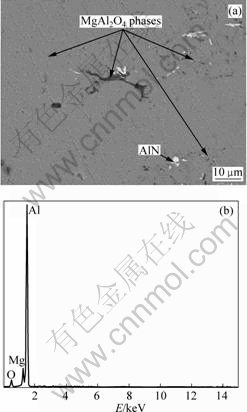

添加1.0%Mg粉的前驱体发泡后泡壁上的SEM像如图9(a)所示。图9(a)中点状和块状物质的EDS谱如图9(b)所示。从图9可以得出,这些灰色均匀分散的点状或者块状物质为镁铝尖晶石;镁铝尖晶石能被铝熔体完全润湿,而且广泛地分布于布拉德边界和泡壁上。图9(a)中少量的白色物质为氮化铝,这主要是由于在空气中发泡,氮气进入铝熔体后,同铝反应形成氮铝化合物,这些物质的存在对于稳定也起到了一定的辅助作用。

添加的Mg粉同铝粉表面的氧化物反应生成镁铝尖晶石,镁铝尖晶石的出现破坏了铝粉表面的氧化物结构和氧化铝颗粒自身之间的结块,形成广泛分布于布拉德边界和泡壁上的均匀分散的细小氧化物颗粒;尖晶石相的生成还提高了其自身同铝熔体之间的润湿性,这样在一定程度上增加了熔体的表观黏度,使得熔体流动性变差,重力排液、毛细作用和气泡流动所带来的不利影响会在一定程度上得到抑制,从而延长了泡沫寿命,提高了液态铝泡沫的稳定性。

图9 添加1.0% Mg的泡沫体泡壁SEM像及EDS谱

Fig.9 SEM image (a) of cell walls in Al foam with 1.0%Mg and EDS spectrum (b) of MgAl2O4 phases

3 结论

1) 没有添加Mg粉的前驱体发泡后样品顶部氧化严重并且形成了致密的氧化层,使得前驱体在高度方向上的自由膨胀受到阻碍,相应地延长了发泡时间。随着Mg粉添加量的增加,发泡后样品表面氧化程度逐渐减轻,膨胀率明显增大。

2) 添加的Mg粉与Al粉表面的Al2O3反应,生成与铝熔体有良好润湿性的MgAl2O4相。MgAl2O4相均匀分散到泡沫体的布拉德边界和泡壁上,部分或完全地消除了无氧区。润湿性的MgAl2O4相增加了熔体的表观黏度,减少了重力排液、毛细作用和气泡流动,延缓了气泡壁变薄,稳定了液态泡沫。

3) 在Al粉含氧量为(0.34±0.01)%的条件下,Mg粉添加量在(0.6%~1.0%)的条件下,能够有效减弱重力排液和毛细作用并可以获得最佳的膨胀率和均匀的泡孔结构。

REFERENCES

[1] BANHART J. Manufacture, characterization and application of cellular metals and metal foams[J]. Prog Mater Sci, 2001, 46: 559-632.

[2] LEHMHUS D, BANHART J. Properties of heat-treated aluminium foams[J]. Mater Sci Eng A, 2003, 349: 98-110.

[3] DUARTE I, BANHART J. A study of aluminium foam formation-kinetics and microstructure[J]. Acta Mater, 2000, 48: 2349-2362.

[4] BANHART J. Metal foam: Production and stability[J]. Adv Eng Mater, 2006, 8(9): 781-794.

[5] KENNEDY A R, ASAVAVISITHCHAI S. Effect of ceramic particle additions on foam expansion and stability in compacted Al-TiH2 powder precursors[J]. Adv Eng Mater, 2004, 6(6): 400-402.

[6] 李 兵, 曹卓坤, 王 永, 姚广春, 华中胜. 泡沫铝制备过程中无泡层的形成与控制[J]. 中国有色金属学报, 2008, 18(7): 1268-1273.

LI Bing, CAO Zhuo-kun, WANG Yong, YAO Guang-chun, HUA Zhong-sheng. Formation and control of bubble-free layer during preparation of Al foam by foaming in melt[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(7): 1268-1273.

[7] SCHWINGEL D, SEELIGER H W, VECCHIONACCI C, ALWES D, DITTRICH J. Aluminium foam sandwich structures for space applications[J]. Acta Astronaut, 2007, 61: 326-330.

[8] FUGANTI A, LORENZI L, HANSSEN A G, LANGSETH M. Aluminium foam for automotive applications[J]. Adv Eng Mater, 2002, 2(4): 200-204.

[9] DUDKA A, GARCIA-MORENO F, WANDERKA N, BANHART J. Structure and distribution of oxides in aluminium foam[J]. Acta Mater, 2008, 56: 3990-4001.

[10] KAPTAY G. Interfacial criteria for stabilization of liquid foams by solid particles[J]. Colloids Surf A, 2002, 230: 67-80.

[11] SUN Y Q, GAO T. The optimum wetting angle for the stabilization of liquid-metal foams by ceramic particles: Experimental simulations[J]. Metall Trans A, 2002, 33: 3285- 3292.

[12] K?RNER C, ARNOLD M, SINGER R F. Metal foam stabilization by oxide network particles[J]. Mater Sci Eng A, 2005, 396: 28-40.

[13] LANDRY K, KALOGEROPOULOU S, EUSTATHOPOULOS N. Wettability of carbon by aluminum and aluminum alloys[J]. Mater Sci Eng A, 1998, 254: 99-111.

[14] LUMLEY R N, SERCOMBE T B, SCHAFFER G B. Surface oxide and the role of magnesium during the sintering of aluminum[J]. Metall Trans A, 1999, 30: 457-463.

[15] BONACCORSI L, PROVERBIO E. Powder compaction effect on foaming behavior of uni-axial pressed PM precursors[J]. Adv Eng Mater, 2006, 8(9): 864-869.

[16] GERGELY V, CLYNE T W. Drainage in standing liquid metal foams: Modeling and experimental observations[J]. Acta Mater, 2004, 52: 3047-3058.

(编辑 杨 华)

基金项目:国家高技术研究发展计划资助项目(2008AA03Z512);国家自然科学基金资助项目(50774021)

收稿日期:2009-05-19;修订日期:2010-04-25

通信作者:姚广春,教授,博士;电话:024-83686462;E-mail:gcyao@mail.neu.edu.cn