DOI: 10.11817/j.ysxb.1004.0609.2021-41012

不同变形程度下冷轧纯铜的绝热剪切行为

朱志成1,唐 林1,王仁可1,肖 柱1,贺 昕2,陈志永1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 有研亿金新材料有限公司,北京 102200)

摘 要:沿冷轧纯铜板材法向取帽型试样,通过分离式霍普金森压杆(SHPB)进行动态剪切试验,借助光学显微镜(OM)、电子背散射衍射(EBSD)以及透射电子显微镜(TEM)分析手段,研究不同变形程度下冷轧纯铜的绝热剪切行为特征。结果表明:随应变率增大,试样对应峰值应力和流变应力增加,应变率硬化效应更为明显。不同应变量的试样均形成了绝热剪切带(ASB),且剪切带宽度的变化趋势一致;随应变量增加,过渡区的应变梯度增大,剪切带内形成了超细晶。剪切带内晶体 方向趋向于平行宏观剪切方向,晶体 {111}面和{100}面趋向于平行宏观剪切面。基于旋转动态再结晶(RDR)机制,理论计算结果证实剪切带内发生再结晶的热动力学可行性。动力学计算结果表明,超细晶在变形后的冷却阶段没有发生明显长大。

方向趋向于平行宏观剪切方向,晶体 {111}面和{100}面趋向于平行宏观剪切面。基于旋转动态再结晶(RDR)机制,理论计算结果证实剪切带内发生再结晶的热动力学可行性。动力学计算结果表明,超细晶在变形后的冷却阶段没有发生明显长大。

关键词:绝热剪切带;冷轧纯铜;微观组织;微观织构;旋转动态再结晶

文章编号:1004-0609(2021)-07-1809-09 中图分类号:TG146 文献标志码:A

引文格式:朱志成, 唐 林, 王仁可, 等. 不同变形程度下冷轧纯铜的绝热剪切行为[J]. 中国有色金属学报, 2021, 31(7): 1809-1817. DOI: 10.11817/j.ysxb.1004.0609.2021-41012

ZHU Zhi-cheng, TANG Lin, WANG Ren-ke, et al. Adiabatic shear behaviors of cold-rolled pure copper under different deformation degrees[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(7): 1809-1817. DOI: 10.11817/j.ysxb.1004.0609.2021-41012

绝热剪切是材料在高速切削、侵彻、爆炸成型等动态变形过程中常见的一种剪切变形高度局部化现象[1]。一般认为,绝热剪切局部化过程由应变硬化、应变率硬化和热软化3个相互竞争的因素共同决定。当由绝热温升导致的热软化超过应变硬化和应变率硬化时,材料将发生热粘塑性失稳。绝热剪切局部化是一种重要的失效机制,近年来,研究学者对发生绝热剪切局部化的金属及其合金材料进行了大量的研究[2-8]。

纯铜是典型的面心立方结构金属,具有优良的塑性,是高应变率下研究较多的材料。MEYERS等[9]研究了不同晶粒尺寸多晶Cu的动态行为,发现初始晶粒尺寸大的多晶Cu更容易形成剪切局部化。HINES等[10]研究了不同温度下纯铜的绝热剪切变形行为,发现变形温度对其影响很小。CERRETA等[11]研究了材料初始状态对Cu的绝热剪切敏感性的影响,发现冷轧态比退火态更容易导致剪切局部化。陈志永等[12]研究了取样方向对冷轧Cu板强迫剪切变形行为的影响,发现不同取样方向冷轧Cu板的绝热剪切敏感性表现出明显的差异。以上这些研究的重点在于晶粒尺寸、变形温度、材料初始状态、晶体取向等因素对Cu形成绝热剪切带的影响。然而目前关于Cu的绝热剪切带演化过程尚未研究清楚。绝热剪切带的演化与变形程度密切相关,探究不同变形程度下剪切带内的微观结构和微观织构特征对于理解其演化过程至关重要。本文沿冷轧态纯铜板材法向取帽型试样,采用不同大气压对其进行冲击加载,以获得不同变形程度的试样,从而研究其不同变形程度下的绝热剪切力学响应、剪切带内的微观结构和微观织构特征,加深对纯铜绝热剪切行为演化过程的理解。

1 实验

1.1 试验材料与取样

以T2工业纯铜为原料,材料的初始状态为锻态,初始尺寸为200 mm×80 mm×60 mm。将锻态纯铜在真空中随炉升温至700 ℃后保温1 h,冷却到室温后冷轧80%至厚度为12 mm。冷轧后Cu板的微观组织形貌如图1所示。板材的晶粒沿着轧向(Rolling direction, RD)和横向(Transverse direction, TD)被剧烈拉长,已经分辨不清晶界,空间形貌呈现出典型的纤维状组织。然后以板材轧面法向(Normal Direction, ND)为圆柱轴线方向,取3个相同的圆柱帽型试样,帽型试样的外观、尺寸及加载方向如图2所示。黑色箭头与三角形分别表示变形过程中的加载与约束,红色实线表示理想的剪切变形区域。

图1 纯铜冷轧80%后的显微组织形貌

Fig. 1 Microstructure of 80% cold-rolled pure copper sheet

1.2 动态剪切试验

动态剪切试验在分离式霍普金森压杆(Split-Hopkinson pressure bar, SHPB)上进行,采用0.3、0.6和0.9 MPa时对帽型试样进行冲击加载(应变率分别约为2.5×104、4.2×104和5.3×104 s-1),获得3个不同应变量的样品,并分别命名为样品A、B、C。剪切带内剪切应力τ、剪切应变γ以及剪切应变率 可由CULVER和ANDRADE等[13]提出的公式得出:

可由CULVER和ANDRADE等[13]提出的公式得出:

(1)

(1)

式中:E0为压杆的弹性模量;As为入射杆横截面积; 和

和 分别为入射杆与透射杆上应变片记录的入射波与透射波的应变信号,t为记录时刻;h为剪切圆环部分的高度;d1和d2分别为剪切圆环部分的内径和外径;C0为杆内的弹性波速;s为剪切带宽度。

分别为入射杆与透射杆上应变片记录的入射波与透射波的应变信号,t为记录时刻;h为剪切圆环部分的高度;d1和d2分别为剪切圆环部分的内径和外径;C0为杆内的弹性波速;s为剪切带宽度。

图2 纯铜帽型试样

Fig. 2 Cutting(a) and geometric dimensioning schematic illustrations(b) of pure copper hat-shaped samples

1.3 微观组织表征

将变形后的帽型试样沿径向采用电火花线切割获取厚度为0.5 mm的薄片,进行微观组织表征。金相显微观察所使用的腐蚀液配方为5g FeCl3+10 mL盐酸+85 mL蒸馏水。电子背散射衍射(Electron backscatter diffraction, EBSD)实验采用双喷电解抛光法抛光,抛光液为硝酸甲醇溶液(体积比1:4),实验温度维持在-30 ℃左右,电流约为150 mA,双喷时间约为40 s,然后使用TSL-OIM Analysis软件对实验数据进行处理。透射电子显微镜(Transmission electronic microscopy, TEM)实验电解抛光液与EBSD实验一致,温度控制在-35 ℃以下,电压为10~15 V,电流为50 mA。TEM分析是在FEI Tecnai G220ST型透射电镜上进行的,工作电压为200 kV。

2 结果与分析

2.1 动态力学响应

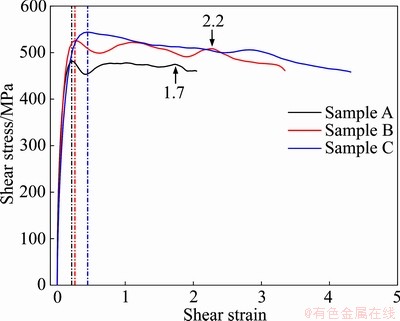

图3所示为帽型试样分别在气压0.3、0.6和0.9 MPa下冲击加载所获得的剪切应力-应变曲线。其中样品A、B、C的最终应变量分别约为2.0、3.4、4.3。观察应力应变曲线特征可知,在变形初期,3个样品的流变应力均随应变的增加而增加且曲线几乎完全重合。然后3个样品都迅速达到了应力峰值。样品C的峰值应力最大,样品B的峰值应力次之,样品A最小。3个样品峰值应力的差异是由于实际应变率的不同造成的,从样品A到样品C,应变率硬化效应明显增强。在应力峰值以后,根据最大剪应力准则[14],变形将进入塑性失稳阶段,应力随应变的增加而下降,这是由于热软化在此阶段占主导作用。样品A和样品B在达到峰值应力以后,流变应力都先迅速下降而后又回升,其后样品A的流变应力变化不大,当应变超过1.7时,流变应力有下降趋势;而样品B流变应力波动较大,在应变超过2.2左右时,流变应力出现了明显下降;样品C在应力峰值以后,其流变应力随应变增加持续下降,并且下降速率也近似恒定。

图3 帽型试样剪切应力-剪切应变曲线

Fig. 3 Shear stress-shear strain curves of hat-shaped samples

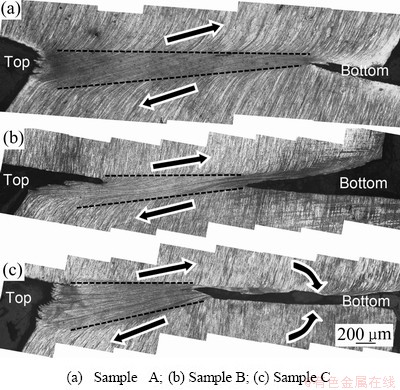

2.2 金相观察

图4所示为帽型试样加载后剪切区域的金相显微观察结果,其中图4(a)、(b)、(c)所示分别为样品A、B、C剪切区域的金相照片,图中左侧对应帽型试样剪切面的顶端,右侧对应底端。显然,3个样品都形成了绝热剪切带(Adiabatic shear band, ASB)。从图4(a)~(c)可以看出,3个样品剪切带的宽度呈现一致的变化趋势,即沿着剪切方向从样品的顶端至底端,剪切带的宽度逐渐减小,可知剪切带内的变形程度不均匀且在应变较大的样品中更为剧烈。再者,随着应变的增大,试样底端的裂纹向剪切区域中部扩展也变得愈加狭长。XUE等[15]认为这是由于帽形试样本身的特点,在冲击载荷作用下,其两端会出现一段豁口。豁口会随着应变的增大向剪切带内不断扩展延长,形成长的裂纹,同时由于有压应力的作用,其宽度却会变得越来越窄。此外值得注意的是,应变较小的样品A中剪切带与基体间的过渡较为平缓;而在应变较大的样品B和C中剪切带与基体间的过渡出现了“拐角”,可知随着应变的增大,邻近剪切带区域的应变梯度增大。

图4 变形后帽型试样剪切区域金相照片

Fig. 4 Optical microstructures of shear region within hat-shaped samples after deformation

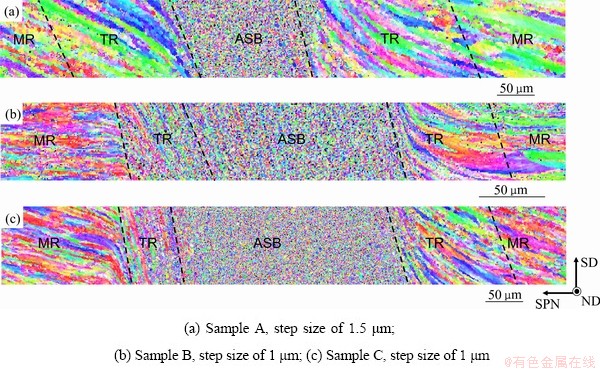

2.3 EBSD分析

图5所示为变形后试样剪切区域整体形貌的EBSD表征结果。为了具有可比性,扫描区域均选择的是靠近底端部分。采用IPF(Inverse pole figure)颜色来显示测试结果,图中SD(Shear direction)代表剪切方向,SPN(Shear plane normal)代表剪切面法向。如图所示,3个样品剪切区域的整体形貌均可划分为3个区域:绝热剪切带区域(ASB),过渡带区域(Transition region, TR)和基体区域(Matrix region, MR)。从基体到剪切带中心,微观组织是逐渐演化和过渡的。图5(a)中,样品A剪切带内的晶粒非常细小,不能被分辨清晰,需要更小的扫描步长。邻近ASB两端的过渡带区域的晶粒大多趋向于沿着SD方向被拉长。随着应变的增大,样品B(见图5(b))剪切带与基体区域之间的过渡带区域变窄,同时该区域内晶粒被拉长细化。样品C(见图5(c))剪切区域内部的塑性变形程度更为剧烈,ASB宽度有所增加。与样品A相比,样品B和样品C的过渡带区域中可以观察到明显的“拐角”,应变梯度更大,这与金相观察的结果一致。此外值得注意的是,每个样品ASB两侧过渡区域的宽度以及变形程度均有所差异。

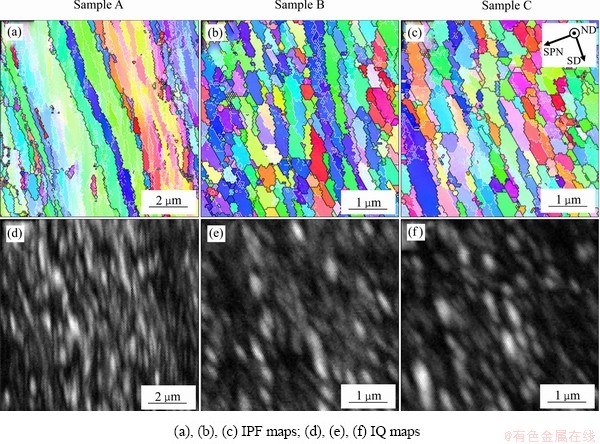

为了更加精确地表征冷轧纯铜剪切带内的微观结构特征,本文采用更小的扫描步长(样品A步长为80 nm,样品B和C步长为50 nm)对图5中的ASB区域进行精细扫描,结果如图6所示。其中图6(a)~(c)所示为IPF图,图6(d)~(f)所示为其对应的IQ(Image quality)图。在IPF图中小角度晶界(2°~15°)用白色实线表示,大角度晶界(>15°)用黑色实线表示。从图6(a)中可以看出,样品A中晶粒沿着剪切方向剧烈拉长,长度有数微米,宽度只有0.5 μm左右。在晶粒内部存在许多被小角度晶界分割的亚晶,这些亚晶也沿着剪切方向拉长,从其对应的IQ图可知,这些亚晶尺寸都在300~500 nm,已经接近亚晶细化的临界尺寸。随着应变的增大,从样品B的IPF图(见图6(b))中可以看出,拉长的亚晶粒得到了进一步细化,剪切带内晶粒大部分为比较均匀的细小晶粒,并且这些晶粒之间为大角度晶界,晶粒内部也很少出现小角度晶界,属于动态再结晶晶粒。同时,从IQ图(见图6(e))中也可以看出其内部晶粒尺寸细小均匀。当应变进一步增大,样品C(见图6(c))的晶粒特征与样品B(见图6(b))相差不大,大部分是动态再结晶晶粒组织,也存在一些还没形成大角度晶界的亚晶。

2.4 微观织构分析

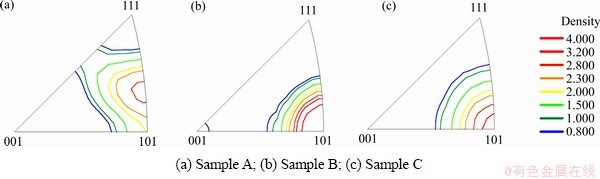

图7和8所示分别为3个样品剪切带内SD方向和SPN方向的IPF图。如图7(a)所示,样品A的SD方向取向密度最大值在 方向附近,可能是由于其应变程度较小,取向密度最大值还并未转到

方向附近,可能是由于其应变程度较小,取向密度最大值还并未转到 方向附近。而从图7(b)和(c)可以看出,随着应变程度的增加,样品B和样品C的SD方向取向密度最大值都已经转到

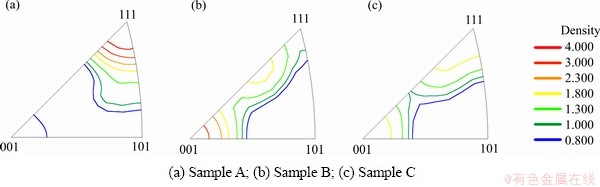

方向附近。而从图7(b)和(c)可以看出,随着应变程度的增加,样品B和样品C的SD方向取向密度最大值都已经转到 方向附近。如图8(a)所示,样品A 的SPN方向取向密度最大值在

方向附近。如图8(a)所示,样品A 的SPN方向取向密度最大值在 方向附近,此外在

方向附近,此外在 方向附近也有少许聚集。样品B(见图8(b))的SPN方向取向密度集中在

方向附近也有少许聚集。样品B(见图8(b))的SPN方向取向密度集中在 与

与 的连线上,最大值在

的连线上,最大值在 方向附近,并且有往

方向附近,并且有往 转动的趋势;随着应变程度进一步增加,如图8(c)所示,样品C的SPN方向取向密度的最大值已经转动到

转动的趋势;随着应变程度进一步增加,如图8(c)所示,样品C的SPN方向取向密度的最大值已经转动到 和

和 处。综上所述,随着应变程度的增加,剪切带内晶体的

处。综上所述,随着应变程度的增加,剪切带内晶体的 方向趋向于平行宏观剪切方向,晶体的{111}面和{100}面趋向于平行宏观剪切面。

方向趋向于平行宏观剪切方向,晶体的{111}面和{100}面趋向于平行宏观剪切面。

图5 变形后帽型试样剪切区域EBSD表征IPF图

Fig. 5 EBSD IPF maps of shear region within hat-shaped samples after deformation

图6 剪切带内部微观结构的EBSD表征结果

Fig. 6 EBSD maps of microstructure within shear bands for three samples

图7 剪切带内SD方向反极图

Fig. 7 IPF maps corresponding to SD of shear bands

图8 剪切带内SPN方向反极图

Fig. 8 IPF maps corresponding to SPN of shear bands

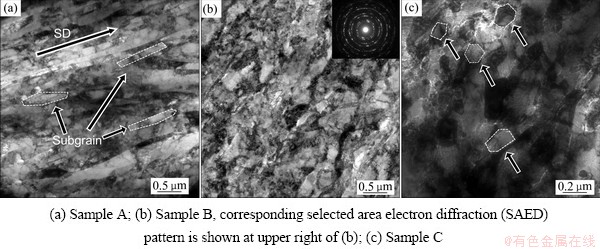

2.5 TEM分析

图9所示为变形后样品剪切带内的TEM像。如图9(a)所示,样品A中有很多沿着剪切方向(SD)拉长的层片状组织。在层片状组织里存在很多亚晶,且沿着剪切方向拉长。在样品B(见图9(b))中,剪切方向已不能分辨,没有明显的拉长晶粒组织。其右上角的选区衍射花样呈现出环状形态,说明晶粒间具有大角度取向差。在样品C(见图9(c))中,虽然TEM像质量不高,但是依然可以发现很多晶界清晰、尺寸细小的动态再结晶晶粒,晶粒尺寸约200 nm。TEM的结果与EBSD相符合。随着应变的增大,剪切带内微观结构的演化经历了形成拉长的亚晶、亚晶的细化和破碎以及形成具有大角度晶界的动态再结晶晶粒几个阶段。

2.6 绝热温升和再结晶动力学讨论

从前述讨论可知,样品B和C剪切带内发生了动态再结晶。材料在高应变速率的条件下,剪切局部化区域的变形可近似为绝热过程,绝大部分(约90%[16])的塑性功转化为热量且来不及散失,导致剪切带内的温度迅速升高。剪切带内的绝热温升可用式(2)进行估算[10]:

(2)

(2)

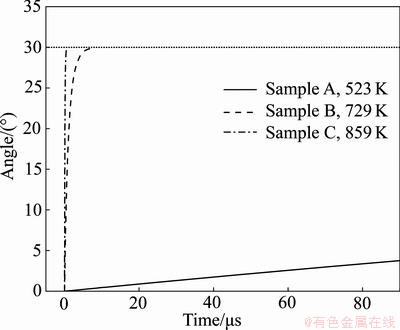

式中:T0为环境温度(293 K);β为热转化系数,对于绝热剪切变形,β取0.9;cV为材料的定容比热容(385 J/(kg·K)),ρ为材料的密度(8940 kg/m3);τ和γ为剪切应力和剪切应变。根据式(2)以及剪切应力-应变曲线数据(见图3)可以估算样品A、B、C绝热剪切带内的温度分别为523 K、729 K和859 K。其中,样品C剪切带内的温度达到了859 K(相当于0.64 Tm),已远远超过材料的再结晶温度(约为0.4 Tm[13]);最小应变的样品A剪切带内的温度(523 K,0.39 Tm)也已经接近再结晶温度。因此剪切带内的绝热温升能够满足动态再结晶的温度需求。

图9 剪切带内的TEM像

Fig. 9 TEM images within shear bands

HINES等[10]从动力学上对纯铜ASB内的再结晶机制进行了研究。结果表明:经典的受扩散控制的再结晶机制在动力学时间上比纯铜动态变形及冷却时间慢好几个数量级,并认为ASB的再结晶机制应该是一种机械力主导的新型机制。NESTERENKO等[17]在研究高应变率下钽的剪切带中微观结构的演化,提出了亚晶旋转动态再结晶(RDR)机制解释剪切带中超细晶粒的形成。本文剪切带内的微观结构演化实验结果与该机制较为吻合。根据RDR机制,破碎的亚晶至少需要旋转30°才能形成等轴的再结晶晶粒,而旋转过程所需要的时间可以用式(3)计算[18]:

(3)

(3)

式中:L1为亚晶粒尺寸;T为剪切带的温度;δ是纯铜的晶界厚度;η是晶界能;D0是与晶界扩散相关的常数;Qb是晶界扩散激活能(Qb=0.5Qv);Qv为晶粒生长的激活能;对于纯铜,式中参数δ=0.5 nm,η=0.625 J/m2,D0=7.8×10-5 m2/s,Qb=0.5Qv=0.5× 211 kJ/mol,R=8.314 J/(mol·K);θ是亚晶的旋转角度(0°~30°),f(θ)可由式(4)表示:

(4)

(4)

由此可以得出轧制态样品的动态再结晶动力学曲线,结果如图10所示。从图10可知,样品A(γ 2.0)由于剪切带内温度较低,发生亚晶旋转形成动态再结晶所需时间远远大于100 μs, 而样品B只需10 μs,样品C所需时间更短。因此,在本实验条件下(加载时间约为80 μs),样品A不能形成明显的动态再结晶晶粒,而样品B和样品C在变形时间内可以通过RDR机制形成细小的动态再结晶晶粒,这与前述EBSD和TEM结果相吻合。

2.0)由于剪切带内温度较低,发生亚晶旋转形成动态再结晶所需时间远远大于100 μs, 而样品B只需10 μs,样品C所需时间更短。因此,在本实验条件下(加载时间约为80 μs),样品A不能形成明显的动态再结晶晶粒,而样品B和样品C在变形时间内可以通过RDR机制形成细小的动态再结晶晶粒,这与前述EBSD和TEM结果相吻合。

图10 亚晶旋转动态再结晶的动力学曲线

Fig. 10 Kinetic curves for rotational dynamic recrystallization (RDR) mechanism

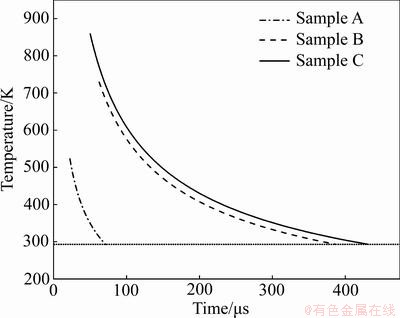

RDR机制的缺陷在于其没有考虑冷却阶段的影响。由于变形结束时剪切带内的温度非常高(样品A、B和C的温度分别为523 K、729 K和859 K),在后续的冷却过程中剪切带内的微观组织可能发生变化。因此,有必要对试样变形后的冷却阶段进行估计。变形后剪切带内的温度与时间的关系可以用式(5)来表示[19]:

(5)

(5)

其中,

式中:K0是铜的热导率;ρ和cp分别是密度与定压比热容。f(x)代表剪切区域的温度分布函数,并有

式中:Ti是变形完成后剪切带内的温度;T0是环境温度;Ri代表剪切带的中心与帽型试样中心的距离(Ri=3.5 mm)。ε是剪切区域的半宽度(约200 μm),由于 <<1,式(5)可以简写为

<<1,式(5)可以简写为

(6)

(6)

式中:ρ=8940 kg/m3;cp=385 J/(kg·K);K0=379 W/(m·K);T0=293 K;x取3.5 mm(考虑剪切带中心温度变化)。将参数代入式(6)中可得样品冷却过程中的温度-时间曲线,结果如图11所示。从图11可知,样品的冷却速度非常快,样品A只需约50 μs就可以冷却至室温(293 K),而剪切带内温度最高的样品C在400 μs内就可以冷却至室温。

图11 变形后样品在冷却阶段剪切带内的温度-时间曲线

Fig. 11 Calculated temperature in shear section at cooling stage after deformation as function of time

在冷却阶段,由于没有剪切力的作用,亚晶不能继续通过旋转形成具有大角度晶界的动态再结晶晶粒。该阶段的晶粒长大主要依靠基于热扩散的晶界迁移机制,温度越高越容易发生。根据文献[18],晶粒长大的尺寸可以由式(7)估算:

(7)

(7)

即在整个冷却阶段内,总的晶粒长大尺寸为

(8)

(8)

式中: 是晶粒尺寸的瞬间变化值;d是晶粒长大尺寸;k0是速度常数(对于纯铜,k0=72.5);Δt是时间长度;n=2;Q是晶界迁移激活能。在冷却时间内,由式(8)可以得到冷却阶段晶粒的长大尺寸。由于样品C剪切带内的温度最高且冷却时间相对较长,因此本文在此只对样品C进行估算,其晶粒长大尺寸为6.4×10-4 μm,相对于样品C剪切带内再结晶晶粒的尺寸(约200 nm)是可以忽略的。因此,变形后剪切带内的晶粒/亚晶在冷却阶段并没有发生明显的长大。

是晶粒尺寸的瞬间变化值;d是晶粒长大尺寸;k0是速度常数(对于纯铜,k0=72.5);Δt是时间长度;n=2;Q是晶界迁移激活能。在冷却时间内,由式(8)可以得到冷却阶段晶粒的长大尺寸。由于样品C剪切带内的温度最高且冷却时间相对较长,因此本文在此只对样品C进行估算,其晶粒长大尺寸为6.4×10-4 μm,相对于样品C剪切带内再结晶晶粒的尺寸(约200 nm)是可以忽略的。因此,变形后剪切带内的晶粒/亚晶在冷却阶段并没有发生明显的长大。

3 结论

1) 随着应变率的增加,样品对应峰值应力和流变应力增加,应变率硬化效应更为明显;不同应变量样品的塑性失稳阶段表现出一定的差异:应变程度较小的样品曲线在一定范围的波动后下降,而应变程度最大的样品曲线基本呈现出持续下降的趋势。

2) 不同应变量的试样均形成了绝热剪切带且剪切带内变形程度不均匀;随应变量增加,剪切带内不均匀变形程度更为剧烈,并且形成了超细晶,邻近剪切带的过渡区域应变梯度增大。结合不同应变下剪切带内的微观结构特征,基于RDR机制,理论计算结果证实了剪切带内发生再结晶的热动力学可行性。动力学计算结果表明超细晶在变形后的冷却阶段没有发生明显的长大。

3) 随着应变的增大,剪切带内微观晶体学取向呈现明显的织构特征,即剪切带内晶体 方向趋向于平行宏观剪切方向,晶体的{111}面和{100}面趋向于平行宏观剪切面。

方向趋向于平行宏观剪切方向,晶体的{111}面和{100}面趋向于平行宏观剪切面。

REFERENCES

[1] MUUR L E, PIZAA C. Dynamic recrystallization: The dynamic deformation regime[J]. Metallurgical and Materials Transactions A, 2007, 38(11): 2611-2628.

[2] TANG Li, CHEN Zhi-yong, ZHAN Cong-kun, et al. Microstructure and microtexture evolution of shear localization in dynamic deformation with different strains in annealed copper[J]. Metallurgical and Materials Transactions A, 2013, 44(2): 793-805.

[3] 李明兵, 王新南, 商国强, 等. 双态组织TC32钛合金的抗弹性能及损伤机制[J]. 中国有色金属学报, 2021, 31(2): 365-372.

LI Ming-bing, WANG Xin-nan, SHANG Guo-qiang, et al. Ballistic properties and failure mechanisms of TC32 titanium alloy with bimodal microstructure[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(2): 365-372.

[4] BOAKYE-YIADOM S, BASSIM N. Microstructural evolution of adiabatic shear bands in pure copper during impact at high strain rates[J]. Materials Science and Engineering A, 2018, 711: 182-194.

[5] WANG Ren-ke, ZHANG Hui, TANG Li, et al. Adiabatic shear deformation behaviors of cold-rolled copper under different impact loading directions[J]. Materials Science and Engineering A, 2019, 754(29): 330-338.

[6] HUANG B, MIAO X F, LUO X, et al. Microstructure and texture evolution near the adiabatic shear band (ASB) in TC17 titanium alloy with starting equiaxed microstructure studied by EBSD[J]. Materials Characterization, 2019, 151: 151-165.

[7] 刘 筱, 杨 辉, 朱必武, 等. 高速冲击载荷下预变形AZ31镁合金的流变行为及本构模型[J]. 中国有色金属学报, 2021, 31(3): 659-668.

LIU Xiao, YANG Hui, ZHU Bi-wu, et al. Flow behavior and constitutive model for pre-deformed AZ31 magnesium alloy under high-speed impact loading[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(3): 659-668.

[8] 杨红斌, 向文丽, 徐 媛, 等. 冷却方式对TC21钛合金绝热剪切敏感性的影响[J]. 中国有色金属学报, 2017, 27(5): 920-926.

YANG Hong-bin, XIANG Wen-li, XU Yuan, et al. Effect of cooling ways on adiabatic shear sensitivity of TC21 titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(5): 920-926.

[9] MEYERS M A, ANDRADE U R, CHOKSHI A H. The effect of grain size on the high-strain, high-strain-rate behavior of copper[J]. Metallurgical and Materials Transactions A, 1995, 26(11): 2881-2893.

[10] HINES J A, VECCHIO K S. Recrystallization kinetics within adiabatic shear bands[J]. Acta Materialia, 1997, 45(2): 635-649.

[11] CERRETA E K, FRANK I J, GRAY Ⅲ G T, et al. The influence of microstructure on the mechanical response of copper in shear[J]. Materials Science and Engineering A, 2009, 501(1/2): 207-219.

[12] 陈志永, 唐 林, 詹从堃, 等. 取样方向对冷轧Cu板动态强迫剪切变形行为的影响[J]. 金属学报, 2012, 48(3): 315-320.

CHEN Zhi-yong, TANG Li, ZHAN Cong-kun, et al. Effects of sample directions on dynamic forced shear deformation behaviors of cold-rolled Cu sheet[J]. Acta Metallurgica Sinica, 2012, 48(3): 315-320.

[13] ANDRADE U, MEYERS M A, VECCHIO K S, et al. Dynamic recrystallization in high-strain, high-strain-rate plastic deformation of copper[J]. Acta Metallurgica et Materialia, 1994, 42(9): 3183-3195.

[14] BAI Y L, MEYERS M A, MURR L E. Shock wave and high-strain-rate phenomena in metals[M]. New York: Plenum Press, 1981: 277-284

[15] XUE Q, GRAY III G T, HENRIE B L, et al. Influence of shock prestraining on the formation of shock localization in 304 stainless steel[J]. Metallurgical and Materials Transactions A, 2005, 36(6): 1471-1486.

[16] JOULE J P. On some thermodynamic properties of solids[J]. Proceedings of the Royal Society of London, 1857, 9: 254.

[17] CHEN Y J, LASALVIA J C, NESTERENKO V F, et al. Shear localization and recrystallization in high-strain, high-strain-rate deformation of tantalum[J]. Materials Science and Engineering A, 1997, 229(1/2): 23-41.

[18] MEYERS M A, NESTERENKO V F, LASALVIA J C, et al. Shear localization in dynamic deformation of materials: Microstructural evolution and self-organization[J]. Materials Science and Engineering A, 2001, 317(1/2): 204-225.

[19] NEMAT-NASSER S, ISAACS J B, LIU M Q. Microstructure of high-strain, high-strain-rate deformed tantalum[J]. Acta Materialia, 1998, 46(4): 1307-1325.

Adiabatic shear behaviors of cold-rolled pure copper under different deformation degrees

ZHU Zhi-cheng1, TANG Lin1, WANG Ren-ke1, XIAO Zhu1, HE Xin2, CHEN Zhi-yong1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. GriKin Advanced Materials Co., Ltd., Beijing 102200, China)

Abstract: The hat-shaped specimens were prepared along the normal direction (ND) of the cold-rolled pure copper sheet. The dynamical shear test was conducted by the Split-Hopkinson pressure bar (SHPB). The adiabatic shear behaviors of cold rolled pure copper under different deformation degrees were systemically investigated by optical microscopy (OM), electron backscatter diffractometry (EBSD) and transmission electron microscopy (TEM). The results show that with the increase of strain rate, the peak stress and flow stress of corresponding to sample increase, and the strain rate hardening effect becomes more obvious. The adiabatic shear band (ASB) forms in the samples with different strains, and the change trend of the width of ASB is consistent. With the increase of strain, the strain gradient of transition region increases and ultrafine grains form within the ASB. The stable grain orientations, in which the crystal  direction tends to align with the local shear direction and the crystal {111} and {100} planes tend to parallel to the local shear plane, develop in the ASB areas. The thermodynamics and kinetics calculated results prove the possibility that the dynamic recrystallization can take place in shear bands based on the rotational dynamic recrystallization mechanism. Kinetic calculations indicate that ultrafine grains do not undergo significant growth during cooling stage after deformation.

direction tends to align with the local shear direction and the crystal {111} and {100} planes tend to parallel to the local shear plane, develop in the ASB areas. The thermodynamics and kinetics calculated results prove the possibility that the dynamic recrystallization can take place in shear bands based on the rotational dynamic recrystallization mechanism. Kinetic calculations indicate that ultrafine grains do not undergo significant growth during cooling stage after deformation.

Key words: adiabatic shear band; cold-rolled pure copper; microstructure; microtexture; rotational dynamic recrystallization

Foundation item: Project(2017YFB0305500) Supported by the Key Research and Development Program of China; Project(50871125) Supported by the National Natural Science Foundation of China

Received date: 2021-01-20; Accepted date: 2021-04-26

Corresponding author: CHEN Zhi-yong; Tel: +86-13974926019; E-mail: czysh@netease.com

(编辑 龙怀中)

基金项目:国家重点研发计划资助项目(2017YFB0305500);国家自然科学基金资助项目(50871125)

收稿日期:2021-01-20;修订日期:2021-04-26

通信作者:陈志永,教授,博士;电话:13974926019;E-mail:czysh@netease.com