文章编号:1004-0609(2009)11-1928-06

Al2O3弥散粒子对Cu-Al2O3合金高温退火显微组织的影响

程建奕1, 2,敖学文1,汪明朴3,郭明星3

(1. 南昌大学 材料科学与工程学院,南昌 330031;

2. 九江学院 机械与材料工程学院,九江 332005;

3. 中南大学 材料科学与工程学院,长沙 410083)

摘 要:利用TEM研究弥散Al2O3粒子对变形Cu-Al2O3弥散强化铜合金高温退火显微组织的影响。结果表明:弥散强化铜合金等时(1 h)退火时,显微硬度HV呈缓慢下降趋势,没有发生突降现象;弥散铜高温退火主要以位错亚结构回复为主,而亚晶较为少见;粒子弥散参数和胞壁性质对退火时的回复产生非常重要的影响;Al2O3弥散粒子影响位错在胞壁内的运动,阻碍胞壁内位错重排、迁移,使得胞壁很难通过运动而获得位向差的积累,从而阻碍大角晶界的形成;随合金中弥散粒子含量的增大和粒子间距的减小,亚晶形核更加困难;Cu-Al2O3合金冷轧过程中形成的胞组织的胞壁具有较小的平均位向差,导致弥散铜合金高温退火时难以形成具有明晰边界的亚晶组织。

关键词:Al2O3弥散粒子;弥散强化铜;显微组织;退火;回复

中图分类号:TG 146.11;TG 113.2 文献标识码:A

Effect of Al2O3 disperoid on microstructure of Cu-Al2O3 alloy annealed at elevated temperatures

CHENG Jian-yi1, 2, AO Xue-wen1, WANG Ming-pu3, GUO Ming-xing3

(1. School of Materials Science and Engineering, Nanchang University, Nanchang 330031, China;

2. School of Mechanical and Materials Engineering, Jiujiang University, Jiujiang 332005,China;

3. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The effect of Al2O3 disperoid on the dislocation structure of deformed and annealed Cu-Al2O3 alloys at elevated temperature was studied by TEM. The results show that the microhardness (HV) of the Cu-Al2O3 alloys decreases slowly with increasing annealing temperature under the condition of the same annealing time (1 h). The annealing microstructure features with a large amount of dislocation cells and few subgrains. The dispersion parameters and the nature of cell wall have a significant effect on the recovery of dislocation cells. The Al2O3 particle dispersion can interfere with the movement and rearrangement of dislocations in the cell walls. The prevention of long range motion of dislocations prohibits the accumulation of misorientation of the cell walls and then inhibits the formation of the high angle boundaries. The formation of subgrains becomes more difficult with the increase of the concentration of Al2O3 particle and decrease of the interparticle spacing. The cell walls formed in the as deformed alloys are of small average misorientation. As a result, the formation of well-defined subgrains is difficult during the annealing.

Key words: Al2O3 disperoid; dispersion strengthened copper; microstructure; annealing; recovering

Cu-Al2O3弥散强化铜合金具有高强高导和优异的高温强度等特性[1]。Al2O3强化相粒子熔点高、高温稳定性好、硬度高,这些弥散相粒子以纳米级尺寸均匀弥散分布于铜基体内,它们与析出强化型铜合金时效析出的金属间化合物粒子不同,在接近于铜基体熔点的高温下也不会溶解或粗化,因此,可以有效地阻碍位错运动和晶界滑移,提高合金的室温和高温强度,同时又不明显降低合金的导电性[2-6]。在欧美等发达国家,它已成为先进的微波雷达制导监控和拦截系统,大功率微波通讯干扰系统和大功率微波杀伤系统等的关键材料。另外,还已广泛应用于大规模集成电路引线框架、电阻焊电极、灯丝引线、电触头材料、连铸机结晶器、火箭喷嘴和燃烧室内衬等部件中[1, 7]。

弥散强化铜合金第二相粒子的存在,在变形过程中会引起位错密度增加的同时也会改变其变形亚结构,从而影响合金回复、再结晶过程。而影响程度主要与粒子尺寸以及粒子间距有关[8-11]。不同浓度的Cu-Al2O3 弥散强化铜合金中弥散分布的Al2O3 粒子的尺寸以及间距会相差较大,为了详细研究粒子尺寸与间距对合金回复再结晶过程的影响,本文作者对两种不同Al2O3含量的变形Cu-Al2O3 弥散强化铜合金在不同温度下的退火行为进行了对比研究。

1 实验

实验用合金是采用内氧化工艺制备的挤压态Cu-0.54Al2O3和Cu-2.25Al2O3合金,弥散强化铜合金采用如下的短流程制备工艺如下:Cu-Al 熔炼→氮气雾化制粉→与适量氧化剂混合→在N2气氛条件下内氧化(条件为900 ℃,1 h)→真空热压(27 MPa,950 ℃,4 h)→热挤压成棒材(挤压比50?1,挤压温度930 ℃)。作为对比用的纯铜为退火态TU1无氧铜,二者均制成厚3 mm的板片状样品。弥散铜合金在900 ℃、1 h和纯铜400 ℃、1 h退火后,再分别经变形量为50%的冷轧,样品分别经不同温度1 h退火处理后进行硬度测定和TEM显微组织观察。电镜样品减薄在MTP21 上进行,双喷液为n(硝酸)?n(乙醇)=3?7 , 精细显微组织观察在H800透射电镜上进行,工作电压为200 kV。

2 实验结果

2.1 Cu-Al2O3合金等时退火曲线

冷轧变形量为50%的弥散强化铜合金和无氧铜在不同温度下氢气保护退火1 h后硬度的变化如图1所示。从图1可以看到,两种弥散强化铜合金的等时退火曲线均呈缓慢下降的趋势,没有发生突降现象。这意味着两种弥散强化铜合金在1 020 ℃以下高温退火时均主要以位错亚结构的回复为主。而无氧铜在200~400 ℃时硬度值突然下降,发生明显的再结晶现象。因此,弥散强化铜合金具有比无氧铜更优越的抗高温软化性能。

图1 冷轧变形量为50%的Cu-Al2O3合金和无氧铜在不同温度下退火1 h后的硬度变化

Fig.1 Hardness (HV) variation of Cu-Al2O3 and oxygen-free copper after 50% cold rolled and annealed for 1 h at different temperatures

2.2 Cu-Al2O3合金600 ℃、1 h退火后的显微组织

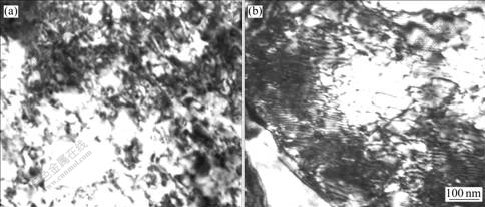

对变形量为50%的Cu-0.54Al2O3合金600 ℃、1 h退火后的显微组织观察发现,合金显微组织主要为变形时产生的位错胞,而退火形成的亚晶并不多见,亚晶粒选区电子衍射花样没有斑点的拉长或分裂现象(见图2(a)和(b)),但跨越胞壁的小范围选区电子衍射花样则显示了斑点的分裂现象,意味着胞壁具有较小的位向差。与变形态的胞组织相比,胞壁发生了较明显的回复(见图2(c)),过剩位错明显减少,缠结的位错已经松开,并通过几组不同的位错反应形成了网络,但粒子的钉扎作用阻碍了位错的进一步回复,稳定了位错的结构。Cu-2.25 Al2O3合金600 ℃、1 h退火后的显微组织与Cu-0.54Al2O3合金相比没有很大的区别,但回复形成的亚晶组织更少,亚晶的尺寸更细小,残留的胞组织更多(见图3)。

图2 冷轧变形量为50%的Cu-0.54Al2O3合金600 ℃、1 h退火后的TEM像

Fig.2 TEM images of Cu-0.54Al2O3 with 50% cold rolled after annealing at 600 ℃ for 1 h: (a) Subgrain formed by recovering; (b) SAD pattern of (a); (c) Residual cell; (d) SAD pattern of small area across cell wall

图3 冷轧变形量为50%的Cu-2.25Al2O3合金600 ℃、1 h退火后的TEM像

Fig.3 TEM images of Cu-2.25Al2O3 with 50% cold rolled after annealing at 600 ℃for 1 h: (a) Fine subgrain; (b) Residual cell

2.3 Cu-0.54Al2O3合金900 ℃、1 h退火后的显微组织变化

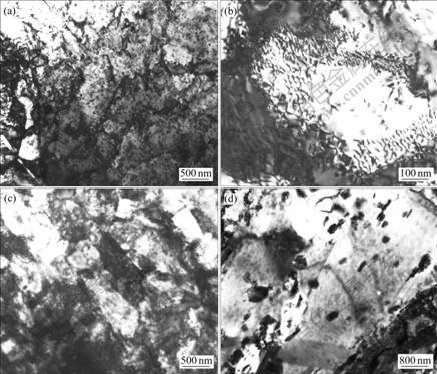

对Cu-0.54Al2O3合金900 ℃、1 h退火后的显微组织观察发现,退火态样品中仍保留高度拉长变形的条带状组织,这些条带与轧制方向一致。合金中随处可见呈杂乱分布的位错胞组织(见图4(a))及部分回复的亚晶组织(见图4(b)),而具有明晰边界的亚晶组织并不多见(见图4(c)),但相对于600 ℃、1 h退火合金亚晶数量还是有所增加。观察还发现,这两种亚晶各有特点,回复的亚晶组织其胞内和胞壁都含有弥散分布的细小Al2O3粒子,而具有明晰边界的亚晶内部不含有细小的弥散相Al2O3粒子或含有少量较粗大的Al2O3粒子,合金中一些亚晶已合并长大,形成了大角度晶界,成为再结晶核心(见图4(d))。总体上,合金中位错数量已减少,但变形位错亚结构仍处于回复阶段。

图4 冷轧变形量为50%的Cu-0.54Al2O3合金900 ℃、1 h退火后的TEM像

Fig.4 TEM images of Cu-0.54Al2O3 with 50% cold rolled after annealing at 900 ℃for 1 h: (a) Residual cell; (b) Small angle boundary consisting of dislocation network; (c) Subgrain with distinct interface; (d) Recrystalline nuclei containing coarse particles

Cu-2.25Al2O3合金900 ℃、1 h退火后,虽然回复使部分过剩位错消失,但仍保持较高的位错密度(见图5(a)),位错胞组织保留较多。回复形成的亚晶界中的位错网络更加无序(见图5(b)),一些不含有粒子或者含有粗大粒子(见图5(c)中箭头所指)的反常再结晶亚晶也偶尔可见[12](见图5(c))。少数亚晶正在合并长大,并逐步向大角度晶界转变(见图5(d))。

图5 冷轧变形量为50%的Cu-2.25Al

2O

3合金900 ℃、1 h退火后的TEM像

Fig.5 TEM images of Cu-2.25Al2O3 with 50% cold rolled after annealing at 900 ℃for 1 h: (a) Heavy dislocation in alloy; (b) Subgrain with few of particle; (c) Subgrain with coarse particle; (d) Merging subgrain

3 讨论

3.1 弥散粒子对退火行为的影响

弥散粒子对变形和退火行为有如下3个方面的重要影响[13]:1) 增加形变储能而增加回复、再结晶的驱动力,这是因为弥散粒子使形变后的结构复杂,使位错密度增加;2) 由于粒子细小,形变时弥散粒子使位错分布变得均匀稳定,亚晶间的平均位向差很小,因而不利于高温退火时的再结晶形核,而在变形时粗大的粒子附近出现更多的不均匀形变区,特别是这些区域有很大的显微位向差,从而促发再结晶形核;3) 弥散稠密分布的第二相粒子钉扎晶界,阻碍晶界的迁移。在弥散强化铜合金退火过程中,后两个方面显然是主导因素。

3.2 弥散参数的影响

在大变形的样品退火过程中,粒子弥散参数(包括弥散粒子的大小、间距)对回复有非常重要的影响。由于实验Cu-Al2O3合金中粒子间距较小,粒子可以影响位错在胞壁内的运动,阻碍胞壁内位错重排,因此,粒子浓度高的弥散铜更难形成界面明锐的亚晶界,甚至回复也难以进行。另外,粒子间距的减小,在每个亚晶能发展成为有效核心之前就和粒子相遇,使得形核困难,同时也限制了应变诱发晶界迁移形核的实现。

3.3 胞壁性质的影响

在弥散铜合金高温退火过程中,难于形成明晰的亚晶部分是由于胞壁的性质所造成的。胞壁中具有较多的同号位错是位错胞形成亚晶的必要条件。亚晶边界比漫散胞壁具有更大的位向差,这意味着高密度的单一符号占优势的位错有利于亚晶界的形成[8, 14]。而在变形态的Cu-Al2O3合金中,胞壁具有较小的平均位向差,因此,亚晶的形成变得非常困难。高温退火时亚晶仅在具有明确胞结构且胞壁两边位向差稍大的地方才有可能形成。

另外,相同变形量的Cu-0.54Al2O3合金在分别经600 ℃和900 ℃、1 h退火后,合金中亚晶并没有明显的长大,亚晶长大缓慢归因于亚晶界活动性较低。这无疑与退火过程中胞壁缺陷和位向差被吸收而引起的结构变化有关。Cu-Al2O3合金中亚晶界两边的位向差较小,这种小角度晶界本质上比大角晶界更不易迁移。对于小角晶界来说,相邻晶粒间位向差的大小决定了晶界能的高低,位向差越大晶界能越高。但对大角晶界来说,晶界能基本上不随位向差而变化,除非达到某些特殊角度的晶界。晶界能越高,晶界的扩散系数就越大,所以晶界的活动性也应越大。一般情况下,大角度晶界的活动性总是大于小角晶界的活动 性[15]。Cu-Al2O3合金中亚晶粒保留小角度晶界的趋势是由于胞壁内位错受到粒子的钉扎、亚晶界不容易地通过位错运动而迁移,因此,很难通过亚晶界运动而获得位向差的积累,从而阻碍了大角晶界的形成,即弥散铜很难发生再结晶。

4 结论

1) Cu-Al2O3合金高温退火后,显微硬度HV呈缓慢下降趋势,没有发生突降现象。高温退火后显微组织以位错胞为主,亚晶较少。

2) 粒子弥散参数对合金的高温退火回复产生非常重要的影响。由于Cu-Al2O3合金中粒子间距小于胞壁厚度,粒子可以影响位错在胞壁内的运动,阻碍胞壁内位错重排,因此,粒子浓度高的弥散铜更难形成界面明锐的亚晶界。

3) Cu-Al2O3合金冷轧过程中形成的胞组织其胞壁具有较小的平均位向差,胞壁的这种特性造成弥散铜合金高温退火难于形成明晰边界的亚晶。

REFERENCES

[1] NADKARNI A V. High conductivity copper and aluminum alloys[C]//LING E, TAUBENBLAT W. Metall Soc AIME, PA: Warrendale, 1984: 77-101.

[2] KIM S H, LEE D N. The effect of rolling conditions on the strength and microstructure of dispersion strengthened copper strips[J]. Mater Sci Eng A, 2001, 319/321: 471-474.

[3] 李红霞, 田保红, 宋克兴, 刘 平. 内氧化法制备A12O3/Cu复合材料[J]. 兵器材料科学与工程, 2004, 27(5): 64-68.

LI Hong-xia, TIAN Bao-hong, SONG Ke-xing, LIU Ping. Research on A12O3/Cu prepared by internal oxidation[J]. Ordnance Material Science and Engineering, 2004, 27(5): 64-68.

[4] GROZA J. Heat-resistant dispersion strengthened copper alloys[J]. J Mater Eng and Perf, 1992, 1(1): 113-116.

[5] 程建奕, 汪明朴. 高强高导高耐热弥散强化铜合金的研究现状[J]. 材料导报, 2004, 18(2): 38-41.

CHENG Jian-yi, WANG Ming-pu. Progress in research on high-strengthening high-conductivity and high-heat resistance dispersion strengthened copper alloy[J]. Materials Review, 2004, 18(2): 38-41.

[6] CHENG Jian-yi, WANG Ming-pu, LI Zhou, WANG Yan-hui, XIAO Cong-wen, HONG Bin. Fabrication and properties of low oxygen grade A12O3 dispersion strengthened copper alloy[J]. Trans Nonferrous Met Soc China, 2004, 14(1): 121-126.

[7] GUO Ming-xing, WANG Ming-pu, SHEN Kun. Effect of cold rolling on properties and microstructures of dispersion strengthened copper alloys[J]. Trans Nonferrous Met Soc China, 2008, 18(2): 333-339.

[8] LEWIS M H, MARTIN J W. Yielding and work-hardening in internally oxidised copper alloys[J]. Acta Metallurgica, 1963, 11: 1207-1214.

[9] BRIMHALL J L, KLEIN M J, HUGGINS R A. Influence of a finely dispersed second phase on recrystallizaion[J]. Acta Metallurgica, 1966, 14: 459-466.

[10] MANDAL D, BAKER I. On the effect of fine second-phase particles on primary recrystallization as a function of strain[J]. Acta Materialia, 1997, 45(2): 453-461.

[11] KIM S H, LEE D N. Annealing behavior of alumina dispersion-strengthened copper strips rolled under different conditions[J]. Metall Mater Trans A, 2002, 33(6): 1605-1616.

[12] AFSHER A., SIMCHI A. Abnormal grain growth in alumina dispersion-strengthened copper produced by an internal oxidation process[J]. Scripta Materialia, 2008, 58(11): 966-969.

[13] KIM S H, LEE D N. Rolling and annealing textures of dispersion strengthened copper strips[J]. Materials Science Forum, 2002, 408/412: 631-636.

[14] BRIMHALL J L, HUGGINS R A. Electron-microscopic observation of deformed internally oxidized alloy[J]. Transactions of the Metallurgical Society of AIME, 1965, 233: 1076-1080

[15] 余永宁. 金属学原理[M]. 北京: 冶金工业出版社, 2003: 364.

YU Yong-ning. Principle of metallurgy[M]. Beijing: Metallurgical Industry Press, 2003: 364.

基金项目:国家高技术研究发展计划资助项目(2002AA302505);江西省教育厅科技计划资助项目(赣教技字[2006]271号)

收稿日期:2008-12-12;修订日期:2009-04-15

通信作者:程建奕,博士,副教授;电话:0791-5198260;E-mail: bigchengjianyi@163.com

(编辑 李向群)