文章编号:1004-0609(2011)11-2880-08

挤压态7075铝合金高温流变行为及神经网络本构模型

王 煜, 孙志超, 李志颖, 杨 合

(西北工业大学 凝固技术国家重点实验室,材料学院,西安 710072)

摘 要:采用Gleeble1500D热模拟实验机研究挤压态7075铝合金在变形温度为250~450 ℃、应变速率为0.01~10 s-1下单道次压缩过程的高温流变行为。结果表明:材料在350 ℃及以下变形时,流变应力曲线呈动态回复型;在温度为350 ℃以上、应变速率为0.1 s-1时,流变曲线局部陡降明显;当应变速率为10 s-1时,流变曲线发生波动,呈动态再结晶型;挤压态7075铝合金的流变应力曲线峰值应力及稳态应力均高于铸态合金的,且在变形温度较高时,挤压态材料更易于发生动态软化。基于BP神经网络建立挤压态7075铝合金的本构关系模型,预测值与实验值对比表明:所建立的本构模型整体误差在5.35%以内,拟合度为2.48%,该模型可以用于描述7075铝合金的高温变形流变行为,为该合金热变形过程分析和有限元模拟提供基础。

关键词:7075铝合金;流变行为;本构关系;BP神经网络

中图分类号:TG302; TG146 文献标志码:A

High temperature flow stress behavior of

as-extruded 7075 aluminum alloy and neural network constitutive model

WANG Yu, SUN Zhi-chao, LI Zhi-ying, YANG He

(State Key Laboratory of Solidification Processing, School of Materials Science and Engineering,

Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: The flow stress behavior of the as-extruded 7075 aluminum alloy was studied through single-pass compression experiment by using Gleeble 1500D simulator within a temperature range of 250-450 ℃ and a strain rate range of 0.01-10 s-1. The results indicate that the flow stress curves show the characteristics of dynamic recovery when the temperature is no higher than 350 ℃. Above 350 ℃, the dynamic recrystallization occurs in local zone. Compared with the as-cast 7075 alloy, the peak stress and steady stress of the as-extruded 7075 alloy are larger, and the dynamic softening is prone to occur at high temperature. The constitutive relationship model of the as-extruded 7075 alloy was constructed based on BP neural network. The global error is less than 5.35%, while the fitting degree is 2.48%. It is evident that the model can be used to describe the flow stress behavior of the 7075 alloy at high temperature, and can be used for analysis and finite element simulation of 7075 alloy in hot working process.

Key words: 7075 aluminum alloy; flow behavior; constitutive relationship; BP neural network

7075铝合金为Al-Zn-Mg-Cu系可热处理强化的变形铝合金,具有较高的室温强度和良好的综合性能,已被广泛应用于航天、航空、交通、现代武器装备等领域[1-2],但该合金热变形行为复杂,且对变形条件十分敏感。

材料的本构关系是联系材料塑性变形行为与各种成形参数的桥梁,是描述材料变形的基本信息和有限元仿真模拟中必不可少的重要部分。目前,建立本构关系较为方便实用的方法是先通过测量一定应变速率和变形温度范围内的流动应力数据,然后采用合理的经验方程回归以建立材料的本构方程[3-4],利用这种方法建立的本构方程具有模型简单、易于嵌入商用有限元软件中的特点。但是,材料热变形过程是一个非常复杂的非线性问题,变形条件与流变应力的关系很难用简单的数学模型进行准确描述。

人工神经网络具有通过简单的非线性处理单元的复合映射即可获得复杂的非线性处理的能力,特别适用于解决一些繁重复杂的、采用传统方法很难处理的问题。采用人工神经网络,事先不需要给出数学模型,它不仅能够根据不完整和无序的信息得出结论,而且可以从这些信息中概括出规律,是一种有力的模拟手段和预测工具[5]。林启权等[6]利用BP人工神经网络研究了2519铝合金的本构关系,建立的本构模型系统误差较小,拟合度达2.6%。LIU等[7]基于BP人工神经网络研究了2A70铝合金的流变应力预测问题。同时,该方法也广泛应用于钛合金等材料本构关系的建 立[8-10]。

刘文娟等[11]采用经验公式对应力—应变数据进行回归分析,并建立铸态7075铝合金的本构关系模型。林高用等[12]对7075铝合金的高温流变行为进行了研究,利用Zener-Hollomon参数的指数形式描述了7075铝合金的高温流变行为。相比于铸态坯料,挤压态坯料由于其良好的塑性更多地应用于后续的锻造过程,但由于其典型的条带状纤维组织使后续热变形行为更加复杂,故研究挤压态7075铝合金的热变形行为对构件的成形/成性具有重要的意义。因此,本文作者研究了挤压态7075 铝合金高温变形时的流变行为,并基于人工神经网络建立其本构关系模型。

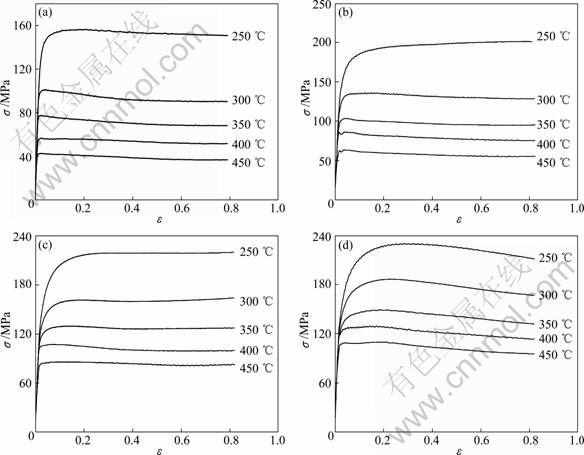

1 实验

实验用原材料为直径80 mm的7075铝合金热挤压棒材,将原始棒料加工成d10 mm×15 mm的压缩试样。实验设备采用Gleeble-1500D热模拟实验机,变形温度为250~450 ℃,应变速率为0.01~10 s-1,压缩量为30%~70%。以10 ℃/s的加热速度将试样加热到所要求的变形温度,保温1 min,随后在指定的变形温度及应变速率下进行压缩,变形结束立即水淬,以保留高温变形组织。通过对实验数据进行摩擦及温度修正处理,获得的真应力—应变曲线如图1所示[13]。采用透射电镜观察样品的微观组织,观察部位为法向与压缩轴垂直的纵截面的中心部位。

2 挤压态7075铝合金高温流变行为

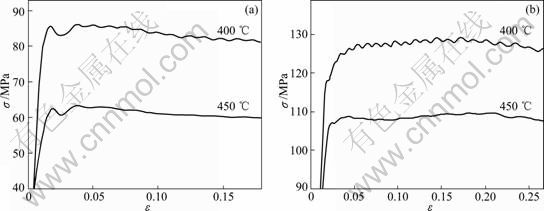

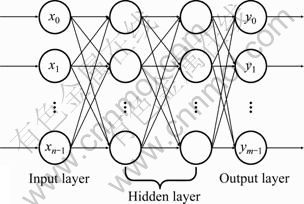

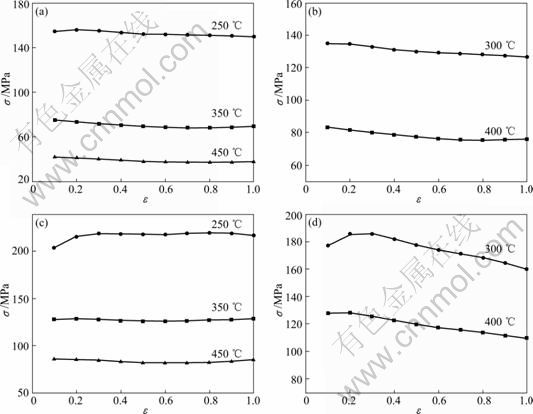

从图1中可发现,当变形温度与应变速率一定时,流变应力随应变的增加先迅速增大,在某一临界应变处达到应力峰值,之后流变应力随着应变的增加呈略微减小的趋势,具有稳态变形的特征。峰值应力及稳态应力随变形温度的降低和应变速率的提高呈增加趋势,且温度越低,增加幅度越明显,表明该合金为正应变速率敏感材料。当变形温度为350 ℃及以下时,7075铝合金的流变应力曲线呈动态回复型[14];通过观察变形温度在350 ℃以上的曲线的细部特征(见图2所示),在应变速率为0.1 s-1、温度为400 ℃时,曲线明显降低,在高应变速率(10 s-1)条件下,曲线出现波动现象,符合动态再结晶型曲线的特征。

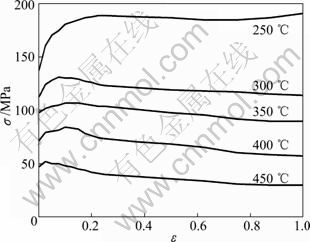

通过与文献[11]中铸态材料的流变应力图(以应变速率0.1 s-1为例,见图3)进行比较可以发现,挤压态材料的峰值应力略高于铸态材料,且随着应变速率的升高和温度的降低,差距逐渐加大。挤压态材料变形时达到峰值应力对应的应变略大于铸态材料的。

材料在热变形过程中微观组织的演化可从材料热变形的真应力—应变曲线的变化上反映出来。7075铝合金在热压缩变形初始阶段,由于位错的交滑移和攀移引起的软化不足以补偿由位错密度增加带来的硬化,因此,流变应力随着应变的增大而急剧增加;随应变增加,晶粒内参与滑移的可动位错数量增加,软化作用增强,与加工硬化趋于平衡,流变应力亦趋于平衡[15]。当应变速率一定时,应力峰值随着变形温度的下降呈增大趋势,且增大的幅度逐渐加大,这主要是由于当变形温度较低时,系统不能提供足够的能量,可动位错数量降低,使加工硬化效果比动态软化更明显。当变形温度保持不变时,应力峰值则随应变速率的提高而增加,且增加的幅度逐渐减小。应变速率的变化对流变应力的影响体现在两个方面,一是影响变形时间,应变速率大,则变形时间短,使动态软化行为来不及进行,从而导致应力相对较高;二是应变速率还可通过影响局部变形温度从而影响流变应力的变化。

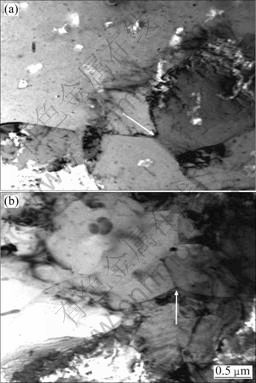

图4所示为变形温度为400 ℃、应变速率分别为0.1 s-1和10 s-1时铝合金的微观组织。由图4可看出,在温度为400 ℃、应变速率为0.1 s-1时,组织中发生了典型的几何动态再结晶[16-17] (见图4中箭头所指)。微观组织的变化表现在流变应力曲线上为应力有一个明显的陡降过程,然后趋于稳定。在应变速率为10 s-1时,微观组织为条带状变形组织与等轴状再结晶组织的混合组织,图4中箭头标示处为大角度晶界等轴晶。在此条件下,组织演化方式为不连续的动态再结晶,反映到曲线上就是曲线的波动现象[14]。

图1 7075铝合金在不同应变速率下热压缩变形的真应力—应变曲线[13]

Fig.1 True stress—strain curves of 7075 aluminum alloy under hot compression at different strain rates[13]: (a) 0.01 s-1; (b) 0.1 s-1; (c) 1 s-1; (d) 10 s-1

图2 不同应变速率时真应力—应变曲线的细部特征

Fig.2 Detail characteristics of true stress—strain curves at different strain rates: (a)  =0.1 s-1; (b)

=0.1 s-1; (b)  =10 s-1

=10 s-1

同样,挤压态与铸态7075铝合金微观组织的不同导致了两者流变曲线的不同。挤压态材料的原始组织为条带状纤维组织,铸态为等轴组织。纤维组织的变形抗力要大于等轴组织的,所以挤压态材料的峰值应力高于铸态的。由于挤压态变形组织中已有部分变形储能,故在热压缩变形时,动态软化过程更容易进行,故达到峰值应力时对应的应变要大于铸态的。在同样的变形条件(变形温度400 ℃、应变速率0.1 s-1)下,挤压态材料发生了几何动态再结晶,而铸态材料则主要是动态回复,这说明高储能条件更易于动态再结晶过程的进行。

图3 应变速率0.1 s-1时铸态7075铝合金的真应力—应变曲线[9]

Fig.3 True stress—strain curves of as-cast 7075 aluminum alloy at  =0.1s-1

=0.1s-1

图4 7075铝合金在不同变形条件下的微观组织

Fig.4 Microstructures of 7075 aluminum alloy under different deformation conditions: (a) 400 ℃, 0.1 s-1; (b) 400 ℃, 10 s-1

3 挤压态7075铝合金人工神经网络本构模型

3.1 BP神经网络原理

BP神经网络即采用BP算法的多层感知器神经网络模型,由输入层、中间层和输出层组成。中间层也叫隐层,可以是一层或多层。BP网络的学习过程可以分为两部分:正向传播和反向传播。当正向传播时,信息从输入层经隐单元层处理后传向输出层,每一层神经元的状态只影响下一层的神经元状态。如果在输出层得不到希望的输出,则转入反向传播,将误差信号沿原来的神经元连接通路返回。返回过程中,逐一修改各层神经元连接的权值。这种过程不断迭代,最后使得误差信号达到允许的范围之内。典型的BP网络结构如图5所示[18]。

图5 BP神经网络模型结构图[18]

Fig.5 Structure of BP artificial neural network[18]

假设BP神经网络的输入矢量为x∈Rn, x=(x0, x1, …, xn-1)T,第一隐层有n1个神经元,它们的输出为x′∈Rn, x′=(x′0, x′1, …, x′n-1)T,第二隐层有n2个神经元,它们的输出为x″∈Rn, x″=(x″0, x″1, …, x″n-1)T,输出层有m个神经元,它们的输出为y∈Rm, y=(y0, y1, …, ym-1)T。设输入层到第一隐层的权值为ωji,阈值为θj,第一隐层到第二隐层的权值为ω′jk,阈值为θ′k,第二隐层到输出层的权值为ω″kl,阈值为θ″l。于是,各层神经元的输出为[18]

显然,它完成了n维空间到m维空间的映射。

本文作者在上述关于BP人工神经网络的理论基础上,参考文献[8]的思路,采用3-10-10-14四层BP神经网络建立挤压态7075铝合金稳态变形的本构关系模型。

3.2 原始数据的处理

将1 000/(t+273)、 和

和 这3个因素作为网络的输入参数,把lnσ作为网络的输出参数,这两组参数组成网络的训练样本对。网络样本对需要包含合适数量的优质样本,以确保在训练和测试过程中能反映样本所包含的内在规律。本研究样本规范如表1所列。

这3个因素作为网络的输入参数,把lnσ作为网络的输出参数,这两组参数组成网络的训练样本对。网络样本对需要包含合适数量的优质样本,以确保在训练和测试过程中能反映样本所包含的内在规律。本研究样本规范如表1所列。

3.3 模型训练

采用MATLAB7.8.0按BP网络的实现过程进行编程,首先随机产生初始权值,采用Bayesian规则化调整法来提高网络的泛化能力,网络的训练函数选择为‘trainbr’;训练目标为10-3,学习率为0.05,经过178次迭代后,系统收敛,系统误差达到训练目标。

表1 不同变形条件下7075铝合金的样本规范

Table 1 Specimen standard of 7075 aluminum alloy under different deformation conditions

3.4 结果分析

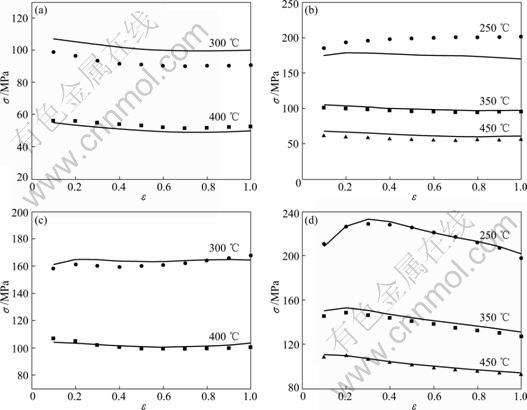

7075铝合金等温压缩实验样本值与网络预测值的比较如图6和7所示,其中,图6所示为训练样本与网络预测值的比较,图7所示为测试样本与网络预测值的比较。

从图6和7可以看出,经过训练的BP神经网络结构模型的本构关系,可以描述材料高温变形过程中稳态流变应力变化现象,能够准确地反映7075铝合金高温动态力学行为。

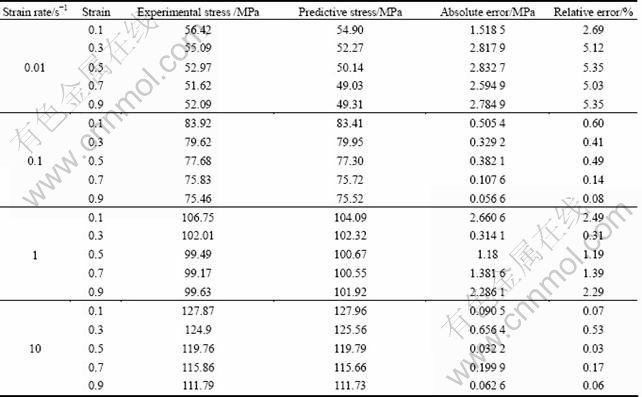

表2所列为温度在400 ℃时不同应变速率、应变下部分流变应力实验值与预测值之间误差的情况。从表2可以看出,实验值与模型预测值的误差较小,均在5.35%之内,且训练样本的误差控制在0.53%之内。

图6 7075铝合金的训练样本与网络预测值的比较

Fig.6 Comparison between train values and ANN predicted values of 7075 aluminum alloy: (a)  =0.01 s-1; (b)

=0.01 s-1; (b)  =0.1 s-1; (c)

=0.1 s-1; (c)  =1 s-1; (d)

=1 s-1; (d)  =10 s-1

=10 s-1

图7 7075铝合金的测试样本与网络预测值的比较

Fig.7 Comparison between test values and ANN predicted values of 7075 aluminum alloy: (a)  =0.01 s-1; (b)

=0.01 s-1; (b)  =0.1 s-1; (c)

=0.1 s-1; (c)  =1 s-1; (d)

=1 s-1; (d)  =10 s-1

=10 s-1

表2 温度为400 ℃时神经网络模型预测值与实验值的对比

Table 2 Comparison of flow stress values predicted by BP artificial neural network (ANN) model and experimental data at 400 ℃

为了全面考察所建立的本构关系模型的精度,根据文献[19]所提供公式计算拟合度δ,公式如下:

式中:σcal(εi)为流动应力模型预测值;σexp(εi)为流动应力实验值;n为所比较的数据点的数量。经过计算可得到7075铝合金本构关系的神经网络模型拟合度为2.48%,这说明所建立的本构关系神经网络模型具备较高的预测精度。

4 结论

1) 挤压态7075铝合金热变形时,流变应力曲线存在稳态流变现象,随变形温度降低和应变速率升高,峰值应力及稳态应力增加。变形温度小于或等于350 ℃时,动态回复为主要的软化机制;大于等于350 ℃时,发生局部几何动态再结晶和不连续动态再结晶现象。与铸态材料相比,挤压态材料的峰值应力较高,且达到峰值应力的应变略大。挤压态铝合金在热变形过程中,动态软化现象更易于发生。

2) 采用不同变形条件下的实验数据作为学习样本所建立7075铝合金本构关系神经网络模型, 具有较高的精度,整个模型的拟合度为2.48%。

REFERENCES

[1] 曾 渝, 尹志民, 潘青林, 郑子樵, 刘志义. 超高强铝合金的研究现状与发展趋势[J]. 中南工业大学学报: 自然科学版, 2002, 33(6): 592-596.

ZENG YU, YIN Zhi-min, PAN Qing-lin, ZHENG Zi-qiao, LIU Zhi-yi. Present research and developing trends of ultra high strength aluminum alloys[J]. Journal of Central South University of Technology: Natural Science, 2002, 33(6): 592-596.

[2] 张 钰. 铝合金在航天航空中的应用[J]. 铝加工, 2009(3): 50-53.

ZHANG Yu. Application of aluminum alloy to aerospace industry[J]. Aluminium Fabrication, 2009(3): 50-53.

[3] RAO K P, HAWBOLT E B. Development of constitutive relationships using compression testing of a medium carbon steel[J]. Transactions of the ASME Journal of Engineering Materials and Technology, 1992, 114: 116-123.

[4] 王少林, 阮雪榆, 俞新陆, 陈森灿, 胡宗式. 金属高温塑性本构方程的研究[J]. 上海交通大学学报, 1996, 30(8): 20-24.

WANG Shao-lin, RUAN Xue-yu, YU Xin-lu, CHEN Sen-can, HU Zong-shi. A research on constitutive equations for hot workings of metals[J]. Journal of Shanghai Jiaotong University, 1996, 30(8): 20-24.

[5] 杨建刚. 人工神经网络实用教程[M]. 杭州: 浙江大学出版社, 2001.

YANG Jian-gang. Practical course on artificial neural networks[M]. Hangzhou: Zhejiang University Press, 2001.

[6] 林启权, 李晓龙, 朱远志, 彭大暑. 2519铝合金本构关系的人工神经网络模型[J]. 湘潭大学自然科学学报, 2004, 26(3): 112-115.

LIN Qi-quan, LI Xiao-long, ZHU Yuan-zhi, PENG Da-shu. A constitutive relationship model of the 2519 aluminum alloy based on artificial neural network[J]. Natural Science Journal of Xiangtan University, 2004, 26(3): 112-115.

[7] LIU Fang, SHAN De-bin, L? Yan, YANG Yu-ying. Prediction of 2A70 aluminum alloy flow stress based on BP artificial neural network[J]. Journal of Harbin Institute of Technology, 2004, 11(4): 368-371.

[8] 沈昌武, 杨 合, 孙志超, 崔军辉. 基于BP神经网络的TA15钛合金本构关系建立[J]. 塑性工程学报, 2007, 14(4): 101-104.

SHEN Chang-wu, YANG He, SUN Zhi-chao, CUI Jun-hui. Based on BP artificial neural network to building the constitutive relationship of TA15 alloy[J]. Journal of Plasticity Engineering, 2007, 14(4): 101-104.

[9] 张兴全, 彭颖红, 阮雪榆. Ti-5Al-2Sn-2Zr-4Mo-4Cr合金本构关系的新模型[J]. 上海交通大学学报, 1999, 33(2): 174-177.

ZHANG Xing-quan, PENG Ying-hong, RUAN Xue-yu. New constitutive relationship model of Ti 5Al 2Sn 2Zr 4Mo 4Cr alloy[J]. Journal of Shanghai Jiaotong University, 1999, 33(2): 174-177.

[10] LIN Qi-quan, PENG Da-shu, ZHU Yuan-zhi. Establishment of constitutive relationship model for 2519 aluminum alloy based on BP artificial neural network[J]. J Cent South Univ Technol, 2005, 12(4): 380-384.

[11] 刘文娟, 韩 冰, 袁鸽成. 7075铝合金高温等温变形的流变应力特征[J]. 广东有色金属学报, 2004, 14(1): 44-47.

LIU Wen-juan, HAN Bing, YUAN Ge-cheng. Flow stress characteristics of isothermal deformation at high temperature for 7075 aluminum alloy[J]. Journal of Guangdong Nonferrous Metals, 2004, 14(1): 44-47.

[12] 林高用, 张 辉, 郭武超, 彭大暑. 7075铝合金热压缩变形流变应力[J]. 中国有色金属学报, 2001, 11(3): 412-415.

LIN Gao-yong, ZHANG Hui, GUO Wu-chao, PENG Da-shu. Flow stress of 7075 aluminum alloy during hot compression deformation[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(3): 412-415.

[13] 李志颖. 7075铝合金三通阀多向加载成形开裂研究[D]. 西安: 西北工业大学, 2010.

LI Zhi-ying. Research on fracture in multi-way loading forming process of 7075 aluminum alloy tee-valve body[D]. Xi’an: Northwest Polytechnical University, 2010.

[14] 周计明, 齐乐华, 陈国定. 热成形中金属本构关系建模方法综述[J]. 机械科学与技术, 2005, 24(2): 212-216.

ZHOU Ji-ming, QI Le-hua, CHEN Guo-ding. Investigation on the constitutive relationship of materials forming in high temperature[J]. Mechanical Science and Technology, 2005, 24(2): 212-216.

[15] 李俊鹏, 沈 健, 闫晓东, 毛柏平, 闫亮明. 温度对7075铝合金热变形显微组织演化的影响[J]. 中国有色金属学报, 2008, 18(11): 1951-1957.

LI Jun-peng, SHEN Jian, YAN Xiao-dong, MAO Bai-ping, YAN Liang-ming. Effect of temperature on microstructure evolution of 7075 alloy during hot deformation[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(11): 1951-1957.

[16] HUMPHREYS F J, HATHERLY M. Recrystallization and related annealing phenomena[M]. Pergamon Press, 1995: 363-483.

[17] 沈 健. AA7005铝合金的热加工变形特性[J]. 中国有色金属学报, 2001, 11(4): 593-597.

SHEN Jian. Hot deformation behaviors of AA7005 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(4): 593-597.

[18] 田雨波. 混合神经网络技术[M]. 北京: 科学出版社, 2009.

TIAN Yu-bo. Technology of hybrid neural network[M]. Beijing: Science Press, 2009.

[19] 鲁世强, 周细林, 王克鲁, 李 鑫, 赵为纲. 基于BP神经网络的2D70铝合金本构关系模型[J]. 锻压技术, 2008, 33(1): 148-151.

LU Shi-qiang, ZHOU Xi-lin, WANG Ke-lu, LI Xin, ZHAO Wei-gang. Model of constitutive relationship for 2D70 aluminum alloy based on BP neural network[J]. Forging & Stamping Technology, 2008, 33(1): 148-151.

(编辑 龙怀中)

基金项目:国家自然科学基金重点项目(50735005);国家自然科学青年基金资助项目(50905145);凝固技术国家重点实验室课题(59-TP-2010)

收稿日期:2010-08-25;修订日期:2011-01-23

通信作者:孙志超,教授;电话:029-88460212-802, E-mail: zcsun@nwpu.edu.cn