Segregation and diffusion behavior of niobium in a highly alloyed nickel-base superalloy

PAN Xiao-lin1, YU Hai-yan1, TU Gan-feng1, SUN Wen-ru2, HU Zhuang-qi2

1. School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China;

2. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China

Received 23 September 2010; accepted 12 April 2011

Abstract: The segregation during solidification and high temperature diffusion during homogenization of niobium in a highly alloyed nickel-base superalloy were investigated. Niobium is seriously segregated into the interdendritic regions with segregation coefficient as high as 4.30. Various niobium-enriched phases including Laves phase, δ phase, (γ+γ′) eutectic, MC and M6C types of carbides precipitated in the interdendritic regions. The soluble temperature of niobium-enriched phases and the degree of dendritic segregation were determined by differential thermal analysis and homogenization treatments at varied temperatures and times. The calculation of elemental diffusion indicates that the diffusion rate of niobium increases remarkably with the homogenization temperature increasing, so that the annealing time can be effectively reduced. A three-step homogenization treatment technology without incipient melting was established to eliminate the segregation of niobium and to obtain a uniform microstructure.

Key words: GH742y superalloy; niobium; segregation; diffusion

1 Introduction

Niobium is an important strengthening element for wrought superalloys, which can enter into γ matrix, γ′ phase, γ″ phase, δ phase and MC carbide [1-6]. However, with increasing alloying degree and niobium content in superalloys, the segregation becomes serious and many detrimental phases are precipitated during solidification [7-10]. To eliminate the elemental segregation and obtain uniform microstructures, homogenization treatment must be performed by high temperature diffusion before hot deformation [11-13].

GH742y alloy is a highly alloyed nickel-base superalloy with total content of aluminum, titanium and niobium up to 8.5%, resulting in the formation of complicated precipitates and serious segregation [14]. However, the segregation of niobium during solidification and its high temperature diffusion during homogenization have not been investigated, which is very important to the hot deformation of as-cast GH742y alloy. The aim of the present work is to study the segregation of niobium and the microstructure evolution during homogenization treatment. Furthermore, the high temperature diffusion behavior of niobium is also discussed in detail.

2 Experimental

The material used in this research was GH742y alloy produced via vacuum induction melting (VIM). The nominal composition was 0.06% C, 11.00% Cr, 14.25% Co, 4.50% Mo, 3.05% Al, 2.70% Ti, 2.75% Ni, 2.50% W, 0.60% V, 0.05% La, 0.01% Ce, 0.05% Mg, 0.005% B and balance Ni (mass fraction).

The soluble temperature of precipitates in as-cast GH742y alloy was determined by differential thermal analysis (DTA) employing a Setsys TG-DTA analyzer using cylindrical samples with size of d3 mm×1 mm. The samples were heated up to 1 450 °C at a rate of 10 °C/min using a dynamic high purity Ar atmosphere. Homogenization treatments were performed between 1 100 °C and 1 180 °C with soaking time from 6 to 48 h. All the samples were quenched by water.

Samples for optical microscopy (OM) and scanning electron microscopy (SEM) were ground to 2000-grit, mechanically polished and finally electro-etched. Transmission electron microscopy (TEM) was utilized to ascertain the precipitates both for as-cast and homogenized samples. Energy disperse X-ray analysis system (EDS) attached to SEM was used to determine the composition of precipitates. Electron probe micro- analyzer (EPMA) was performed to study the segregation degree of elements before and after homogenization treatments. A plane scan by EPMA was employed to exhibit the distribution of niobium in the dendritic microstructure.

3 Results and discussion

3.1 As-cast microstructure

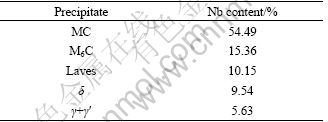

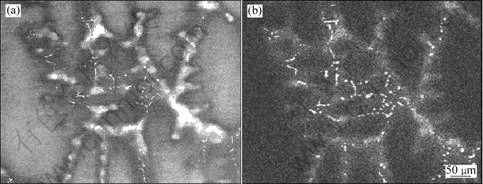

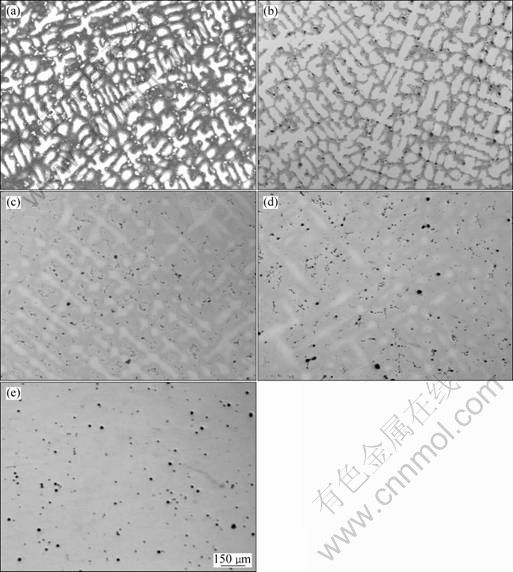

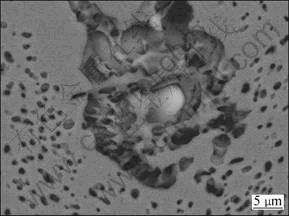

The microstructure of as-cast GH742y alloy consists of dendrite cores and interdendritic regions, as shown in Fig. 1(a). The large area of interdendritic regions indicates that the segregation is greatly serious. It can be also seen from Fig. 1(a) that the phases are mostly precipitated in the interdendritic regions. γ′ phase is the main precipitation strengthening phase as shown in Figs. 2(a) and (b). The morphology and size of γ′ particles in the dendrite cores and interdendritic regions are quite different. They are spherical and small in the dendrite cores while quadrate and much larger in the interdendritic regions. Meanwhile, (γ+γ′) eutectic, δ phase (Fig. 2(c)) and Laves phase (Fig. 2(d)) are precipitated in the interdendritic regions due to the serious segregation. Two kinds of carbides are formed in the interdendritic regions. The major carbides are referred to MC type carbides as clusters of lobed slices with straight edges and sharp angles (Fig. 2(e)). Only a few carbides are precipitated beside Laves phase referred to M6C type carbides (Fig. 2(d)). Due to the addition of rare earth metals, Ni5Ce phase is precipitated next to Laves phase (Fig. 2(d)). In addition, the topologically closed-packed (TCP) σ phase and μ phase are precipitated in the interdendritic regions determined by TEM analysis.

The distribution of Nb in dendritic microstructure as shown in Fig. 1(b) corresponding to Fig. 1(a) indicates that Nb segregates in the interdendritic regions. The composition of main elements in the dendrite cores and interdendritic regions is determined by EPMA. In comparison to the bulk composition, the dendrite cores are enriched by Cr, Co, W, V and Al, and depleted by Nb, Ti and Mo. Conversely, the interdendritic regions are enriched by Nb, Ti and Mo, and depleted by Cr, Co, W, V and Al. Among all the elements without regard to minor elements, Nb is the most serious element with its segregation coefficient (defined as the composition of the interdendritic regions divided by that of the dendrite cores) as high as 4.30. Meanwhile, Nb is enriched in the precipitates such as MC carbide, Laves phase, M6C carbide, δ phase and (γ+γ′) eutectic determined by EDS as listed in Table 1.

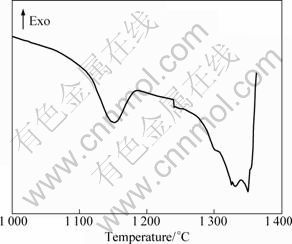

Table 1 Contents of Nb in precipitates of as-cast GH742y alloy (mass fraction, %)

3.2 Homogenization treatment

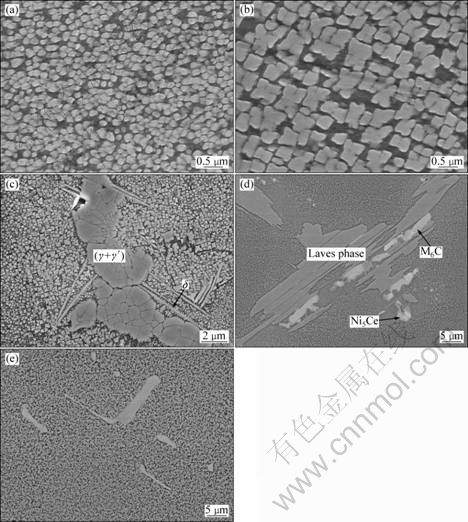

The DTA heating curve of as-cast GH742y alloy is shown in Fig. 3. There is a large endothermic peak between 1 100 and 1 180 °C, which is associated with the dissolution of precipitates in the alloy. Thus, temperatures between 1 100 and 1 180 °C are selected for homogenization treatment to dissolve the precipitates and the analysis of elemental segregation degree.

The microstructure of the as-cast GH742y alloy after homogenization at different temperatures for 24 h is shown in Fig. 4. The segregation between the dendrite cores (light gray) and the interdendritic regions (dark gray) is very obvious at 1 100 °C (Fig. 4(a)) and 1 120 °C (Fig. 4(b)). As the temperature increases to 1 140 °C (Fig. 4(c)) or 1 160 °C (Fig. 4(d)), the dendritic segregation greatly decreases owing to the increase of elemental diffusion rate, although the dendritic microstructure is still discernable. When homogenized at 1 180 °C, no obvious segregation can be observed from the OM image (Fig. 4(e)). Meanwhile, the degree of dendritic segregation is reduced when the homogenization time increases.

Fig. 1 Dendritic microstructure of as-cast GH742y alloy (a) and corresponding Nb map (b)

Fig. 2 SEM images of main precipitates in as-cast GH742y alloy: (a) γ′ phase in dendrite core; (b) γ′ phase in interdendritic region; (c) (γ+γ′) eutectic and δ phase; (d) Laves phase, M6C carbide and Ni5Ce phase; (e) MC carbide

Fig. 3 DTA heating curve of as-cast GH742y alloy

Precipitates such as Ni5Ce phase, M6C carbide, σ phase and μ phase are easier to dissolve when homogenized at 1 100 °C for 24 h. Laves phase starts to dissolve at 1 100 °C, and can completely dissolve when homogenized at 1 120 °C for 24 h. γ′ particles in the dendrite cores dissolve into γ matrix fast at lower temperatures, while the larger γ′ particles, eutectic γ′ and δ phase in the interdendritic regions could not dissolve completely until the temperature reached up to 1 140 °C and homogenized for 24 h. MC carbide begins to dissolve at 1 160 °C, and completely dissolves at 1 180 °C for 24 h (Fig. 4(e)).

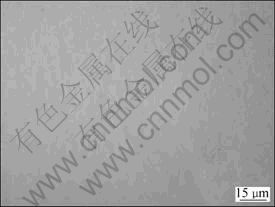

Examination of the microstructure after homogenization indicates that the precipitates are favorable to dissolve into γ matrix at higher temperature, and longer-term heat treatments can result in more complete dissolution of phases. However, the low-melting Ni5Ce phase begins to melt at 1120 °C as shown in Fig. 5. Therefore, one-step homogenization treatment is not available to eliminate the segregation of Nb for the highly alloyed GH742y alloy, and then a three-step homogenization treatment without incipient melting is brought forward. The procedure includes treatment at 1 100 °C for 30 h to remove the low-melting phases, and treatment at 1 160 °C for 40 h to dissolve the precipitates, followed by high temperature diffusion at 1 180 °C for 20 h. A uniform microstructure is obtained after the three-step homogenization treatment, as shown in Fig. 6. The segregation of Nb is almost entirely eliminated as determined by EPMA.

Fig. 4 Microstructures of as-cast GH742y alloy after 24 h homogenization at different temperatures: (a) 1 100 °C; (b) 1 120 °C; (c) 1 140 °C; (d) 1 160 °C; (e) 1 180 °C

Fig. 5 Melting morphology of Ni5Ce phase at 1 120 °C

Fig. 6 OM image of GH742y ingot after three-step homogenization

3.3 Diffusion behavior

At a given temperature during homogenization, the diffusion equation for each element can be expressed as [15]:

(1)

(1)

where L, D and t denote the dendrite spacing, interdiffusion coefficient and annealing time, respectively. The residual segregation index δ is given as:

(2)

(2)

where Ctmax and Ctmin are the maximum and minimum solute concentrations at time t, respectively;  and

and  are the corresponding maximum and minimum solute concentrations at t=0.

are the corresponding maximum and minimum solute concentrations at t=0.

The values of and

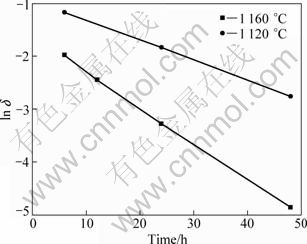

and at different temperatures and times after homogenization were calculated by the results determined by EPMA. The relationship between the natural logarithm of residual segregation index and the annealing time at different temperatures is shown in Fig. 7. There is a linear relationship between ln δ and t at both temperatures. The slopes of both lines at 1 120 and 1 160 °C equal to -4π2D/L2 according to Eq. (1) are calculated to be -0.038 and -0.068, respectively. It can also be seen from Fig. 7 that the segregation degree of Nb decreases with increasing time and temperature, which is in accordance with the microstructure of the as-cast GH742y alloy after homogenization.

at different temperatures and times after homogenization were calculated by the results determined by EPMA. The relationship between the natural logarithm of residual segregation index and the annealing time at different temperatures is shown in Fig. 7. There is a linear relationship between ln δ and t at both temperatures. The slopes of both lines at 1 120 and 1 160 °C equal to -4π2D/L2 according to Eq. (1) are calculated to be -0.038 and -0.068, respectively. It can also be seen from Fig. 7 that the segregation degree of Nb decreases with increasing time and temperature, which is in accordance with the microstructure of the as-cast GH742y alloy after homogenization.

Fig. 7 Relationship between ln δ and time at different temperatures

The average value of L in as-cast GH742y alloy is approximately determined to be 50 μm. The interdiffusion coefficients for Nb at 1 120 and 1160 °C calculated by Eq. (1) are 0.667×10-11 and 1.198× 10-11 cm2/s, respectively. The diffusion rate of Nb at 1 160 °C is much larger than that at 1 120 °C. Consequently, increasing the diffusion temperature is an effective approach to decrease the segregation degree of ingot during homogenization treatment.

4 Conclusions

1) A number of niobium-enriched phases including Laves phase, δ phase, (γ+γ′) eutectic, MC and M6C type carbides are precipitated in the interdendritic regions due to the serious segregation of Nb.

2) Precipitates such as Ni5Ce phase, M6C carbide, σ phase and μ phase are easier to dissolve when homogenized at 1 100 °C. The incipient-melting temperature of Ni5Ce phase is 1 120 °C, while the absolutely soluble temperatures of coarse γ′, eutectic γ′ and δ phase are higher than 1 140 °C. The diffusion rate of Nb at 1 160 °C is much higher than that at 1 120 °C.

3) A three-step homogenization treatment of pretreating at 1 100 °C, dissolving precipitates at 1 160 °C and diffusing at 1 180 °C is established to eliminate the segregation of Nb and to obtain a uniform microstructure.

References

[1] LI R B, YAO M, LIU W C, HE X C. Isolation and determination for δ, γ′ and γ″ phases in Inconel 718 alloy [J]. Scripta Materialia, 2002, 46(9): 635-638.

[2] ZHAO K, LOU L H, MA Y H, HU Z Q. Effect of minor niobium addition on microstructure of a nickel-base directionally solidified superalloy [J]. Materials Science and Engineering A, 2008, 476(1-2): 372-377.

[3] DEVAUX A, NAZ? L, MOINS R, PINEAU A, ORGANISTA A, GU?DOU J Y, UGINET J F, H?RITIER P. Gamma double prime precipitation kinetic in Alloy 718 [J]. Materials Science and Engineering A, 2008, 486(1-2): 117-122.

[4] Lachowicz M, Dudziński W, Haimann K, Podrez- Radziszewska M. Microstructure transformations and cracking in the matrix of γ-γ′ superalloy Inconel 713C melted with electron beam [J]. Materials Science and Engineering A, 2008, 479(1-2): 269-276.

[5] Nakkalil R, Richards N L, Chaturvedi M C. A study of precipitates and insolubles in an Ni-Fe-based superalloy by analytical electron microscopy [J]. Materials Science and Engineering A, 1992, 157(1): 89-100.

[6] GU Y F, YAMABE-MITARAI Y, YU X H, HARADA H. Microstructures and compressive properties of Ni alloyed Rh-15 at.% Nb two-phase refractory superalloys [J]. Materials Letters, 1999, 41(2): 45-51.

[7] DUPONT J N, ROBINO C V, MICHAEL J R, NOTIS M R, MARDER A R. Solidification of Nb-bearing superalloys [J]. Metallurgical and Materials Transactions A, 1998, 29(11): 2785-2796.

[8] SUN W R, GUO S R, LU D Z, HU Z O. Effect of sulfur on the solidification and segregation in Inconel 718 alloy [J]. Materials Letters, 1997, 31(3-6): 195-200.

[9] WANG A C, LI Y Y, FAN C G, YANG K, LI D F, ZHAO X, SHI C X. Effect of p and Si(Mn) on the solidification segregation in an iron-based superalloy [J]. Scripta Metallurgica et Materialia, 1994, 31(12): 1695-1700.

[10] YAN B C, ZHANG J, LOU L H. Effect of boron additions on the microstructure and transverse properties of a directionally solidified superalloy [J]. Materials Science and Engineering A, 2008, 474(1-2): 39-47.

[11] PAN Xiao-lin,SUN Wen-ru, YANG Shu-lin, LI Zhan, GUO Shou-ren, YANG Hong-cai, Hu zhuang-qi. Microstrueture transformation during homogenization treatment in as-cast GH742 alloy [J]. Chinese Journal of Materials Research, 2008, 22(6): 651-656. (in Chinese)

[12] SEMIATIN S L, KRAMB R C, TURNER R E, ZHANG F, ANTONY M M. Analysis of the homogenization of a nickel-base superalloy [J]. Scripta Materialia, 2004, 51(6): 491-495.

[13] KRAMB R C, ANTONY M M, SEMIATIN S L. Homogenization of a nickel-base superalloy ingot material [J]. Scripta Materialia, 2006, 54(9): 1645-1649.

[14] PAN Xiao-lin, SUN Wen-ru, YANG Shu-lin, GUO Shou-ren, LI Zhan, YANG Hong-cai, HU Zhuang-qi. Solidification and segregation behavior of GH742y alloy [J]. The Chinese Journal of Nonferrous Metals, 2008, 18(12): 2158-2165. (in Chinese)

[15] SUN Zhen-yan, LIU Chun-ming. Diffusion and phase transformations in alloys [M]. Shenyang: Northeastern University Press, 2002, 39. (in Chinese)

铌在一种高合金化高温合金中的偏析与扩散行为

潘晓林1,于海燕1,涂赣峰1,孙文儒2,胡壮麒2

1. 东北大学 材料与冶金学院,沈阳 110004;

2. 中国科学院 金属研究所,沈阳 110016

摘 要:研究铌在一种高合金化镍基高温合金凝固过程中的偏析和均匀化过程中的扩散行为。铌严重偏析于枝晶间区域,其偏析系数高达4.30。许多富铌相,包括Laves相、δ相、(γ+γ′)共晶、MC和M6C碳化物等在枝晶间析出。利用差热分析和在不同温度、时间的均匀化处理确定各种富铌相的溶解温度和枝晶偏析的消除程度。元素扩散计算表明:铌的扩散速率随着均匀化温度的提高而显著增加,从而有效地缩短均匀化时间。提出一种无初熔的三步均匀化制度,可以完全消除铌的枝晶偏析,获得均一的组织。

关键词:GH742y合金;铌;偏析;扩散

(Edited by FANG Jing-hua)

Corresponding author: PAN Xiao-lin; Tel/Fax: +86-24-83686460; E-mail: panxl@smm.neu.edu.cn

DOI: 10.1016/S1003-6326(11)61027-3