文章编号:1004-0609(2013)S1-s0673-05

新型超细晶结构Ti/TiC纳米复合材料粉末制备方法

郑逸锋,姚 勋,梁加淼, 张德良

(上海交通大学 金属基复合材料国家重点实验室,上海 200240)

摘 要:采用氢化钛粉(TiH2)和碳纳米管(CNT)为原料,通过高能球磨和真空脱氢的方法制备出具有超细晶结构的Ti粉和Ti/TiC复合材料粉,对比了晶粒细化及增强体对粉末颗粒硬度的影响。结果表明:球磨6 h后,粉末颗粒晶粒尺寸达到10 nm,CNT均匀弥散在粉末颗粒当中。经过650 ℃真空脱氢,CNT与Ti原位生成增强体TiC,粉末最终晶粒尺寸维持在50 nm左右,且粉末颗粒显微硬度较纯钛的明显提高,达到355.17 HV。最后对增强机理进行简要讨论。

关键词:超细晶结构;高能球磨;钛;纳米复合材料;碳纳米管

中图分类号:TG146.2 文献标志码:A

Preparation of ultrafine structured Ti/TiC nanocomposite powders

ZHENG Yi-feng, YAO Xun, LIANG Jia-miao, ZHANG De-liang

(The State Key Laboratory of Metal Matrix Composites, Shanghai Jiao Tong University, Shanghai 200240, China)

Abstract: The ultrafine structured Ti powder and Ti/TiC nanocomposite powders were prepared by high-energy ball milling and dehydrogenation of TiH2 and carbon nanotube (CNT) powders. The influence of grain refinement and reinforcement on the hardness of the powder particles was also studied. The results reveal that the grain size of the powders reaches 10 nm after milling for 6 h and the CNTs are homogenously dispersed in the TiH2 powders. In situ TiC emerges after the as-milled powder was dehydrogenated at 650 ℃, and the ultimate grain size of the powder maintains around 50 nm. The microhardness of Ti/TiC powder reaches 355.17 HV, which is much higher than pure Ti powder. And the strengthening mechanism was briefly discussed.

Key words: ultrafine structure; high-energy ball milling; titanium; nanocomposite; CNT

钛基复合材料由于具有密度小、比强度高、耐热性能好和抗腐蚀能力强等特点,在航空航天、化学工业等领域得到广泛的应用[1]。其中,TiC以其与钛在热力学上相容,密度和热膨胀系数与钛接近及杨氏模量与抗拉强度比钛高等很多优点,成为目前最常用的钛基复合材料增强体之一。

近年来,随着科技的发展,人们对材料的性能要求越来越高,因此,纳米结构复合材料受到越来越多的关注。相比于微尺寸结构钛基复合材料,纳米结构钛基复合材料具有更加优异的力学性能。之前,人们利用高温自蔓延合成(SHS)、放热扩散(EXD)、燃烧辅助铸造(CAC)和反应热压法(RHP)等方式对制备纳米结钛基复合材料进行了许多研究[2-7],但由于钛的熔点高以及钛的氧化性强等特点,使其制备过程十分困难。相比而言,高能球磨法工艺简单,球磨过程在低温或常温下进行,制备出的材料晶粒细小、分布均匀,是目前比较理想的纳米结构材料制备方法。

由于钛具有较高的塑性,球磨过程中,在磨球的高速冲击下很容易相互粘连,因此,在高能球磨钛的过程中往往需要加入一定量的过程控制剂,然而其中的杂质元素在球磨过程中易与钛相互反应而影响最终产品的性能。

本文作者利用脆性的TiH2粉代替传统的脱氢钛粉,克服了粉末粘连的问题,将其与一定量的CNT混合,利用高能球磨将CNT均匀弥散分布在TiH2粉末颗粒中,然后通过真空脱氢的方法以及Ti与CNT的原位反应,制备出具有超细晶结构的Ti/TiC纳米复合材料粉末,并对其力学性能和增强机理进行初步研究。

1 实验

为使最终TiC所占的比例小于10%(体积分数),将TiH2粉(纯度99.9%(质量分数),尺寸<45 μm)和CNT(纯度>99.5%,直径10 nm,长10 μm)以体积比97:3混合放入500 mL不锈钢球磨罐中,在南京大学仪器厂生产的QM-3SP4型行星式球磨机上进行球磨。在球磨过程中通入氩气,防止粉末氧化。实验中所用的磨球为316 L不锈钢,直径为16 mm, 磨球总质量500 g,球料质量比5:1。球磨过程中先以200 r/min的速度混粉2 h,再以500 r/min的速度高能球磨6 h。为对比增强体的增强作用,利用上述同样的工艺参数制备纯的TiH2球磨粉。将球磨过后的TiH2和TiH2/3%CNT粉末分别放入真空烧结炉中在650 ℃的温度下保温1 h进行脱氢处理。用Ultima IV型X射线衍射仪(Cu Kα,λ=0.154 nm)对球磨前后及脱氢后的粉末进行成分分析,利用Sirion 200型扫描电子显微镜(SEM)对粉末颗粒形貌及颗粒内部的物相分布进行表征,并对脱氢后的粉末进行显微硬度测试。

2 结果与讨论

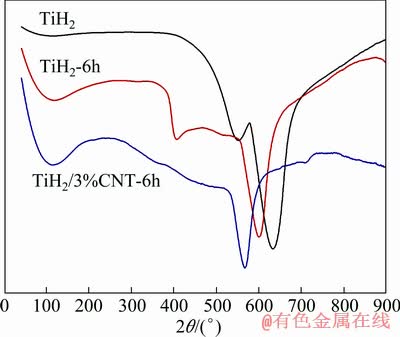

将原始TiH2粉末、球磨6 h后的TiH2和TiH2/3%CNT粉末(为方便表述,将球磨过后的样品后缀球磨时间,脱氢后的样品后缀脱氢温度,如TiH2-6h-650 ℃表示球磨6 h后的TiH2粉在650 ℃脱氢后所得的样品,下同)进行XRD测试,如图1所示。

从图1中可以看出,原始TiH2粉的衍射峰尖锐而狭长,球磨6 h后,TiH2-6h的衍射峰和TiH2/3%CNT-6h的衍射峰出现明显的宽化,说明粉末的晶粒出现明显的细化,且从衍射峰的宽化程度来看,已经达到纳米级别。从图中还可看出,球磨过程中除衍射峰发生宽化,并没有其他的新相形成,由于初始加入的CNT较少,因此在TiH2/3%CNT-6h的XRD曲线上并没有发现碳的存在。

图1 原始TiH2粉、TiH2-6h粉和TiH2/3%CNT-6h粉的XRD谱

Fig.1 XRD patterns of TiH2 powders, TiH2-6h powders and TiH2/3%CNT-6h powders

利用Williamson-Hall方程根据所得的X射线衍射图谱可以粗略计算出球磨不同时间后粉末晶粒的大小,其方程如下:

Bcosθ=Kλ+εsinθ (1)

其中:B为衍射峰的半高宽;θ为衍射角;λ为入射X射线波长(λ=0.1540 56 nm);ε为粉末内应变;K为Scherrer常数(K=0.89)。经过计算,TiH2-6h粉和TiH2/3%CNT-6h粉的平均晶粒尺寸分别达到12 nm和9.5 nm。

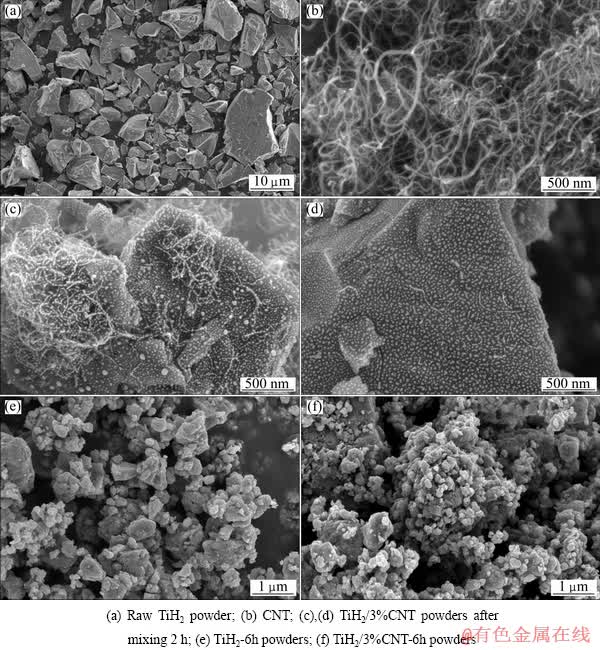

图2所示为不同条件下的粉末颗粒形貌图。从图中可以看出,原始TiH2钛粉为不规则形状,边缘粗糙,平均颗粒大小为20 μm左右,碳纳米管则呈絮状分布团聚在一起。图2(c)和(d)所示为在200 r/min的速度下混粉2 h后的TiH2/3%CNT粉末,发现CNT在混粉的过程中经过磨球反复的冲击,大部分已经破碎成细小的颗粒均匀分布在TiH2颗粒表面,未完全破碎的CNT也断断续续的分布在颗粒之间,说明在此混粉条件下, CNT与TiH2粉能够充分混合均匀。图2(e)所示为TiH2-6h粉的形貌图,可以看出,经过球磨,大部分的粉末被破碎成细小的颗粒,颗粒表面及边缘相比于原始粉末光滑许多,平均颗粒尺寸在1 μm以下。图2(f)所示为TiH2/3%CNT-6h的颗粒形貌,与TiH2-6h粉相似,颗粒表面光滑平整,但颗粒粒度更加细小,大部分颗粒尺寸在几百纳米左右。这可能是由于在球磨的过程中,粉末颗粒不断地承受冲击变形、冷焊、破碎,使得CNT逐步弥散到TiH2颗粒内部,从而进一步增强TiH2粉末的强度,降低塑性,使其更容易被破碎而造成的。

图2 不同条件下的粉末颗粒形貌图

Fig.2 Morphologies of powders with different treatments

图3 TiH2/3%CNT-6h粉末颗粒截面BSE图

Fig.3 BSE image of the cross section of the TiH2/3%CNT-6h powders

为进一步了解球磨过后CNT在TiH2颗粒中的分布情况,将TiH2/3%CNT-6h粉末颗粒试样镶样抛光后利用背散射电子(BSE)衍射进行测试。图3所示为TiH2/3%CNT-6h粉末颗粒截面的BSE像。图中黑色斑点为原子序数较小的碳元素,可以看出,经过6 h球磨后,CNT已经弥散到TiH2的颗粒内部,且分布较为均匀。通过以上表征发现,球磨过后的粉末晶粒细小,且CNT在颗粒中分布均匀,为得到最终的超细晶结构Ti/TiC复合材料粉末,需将球磨过后的粉末进行脱氢处理。为确定3种粉末的脱氢温度,对其进行DSC测试,如图4所示。

从图4中可以看出,3种粉末的的DSC曲线都存在两到三个明显的吸热峰,说明粉末的脱氢过程并不是一个连续过程,可能分为几步转变:TiH2→TiHx→Ti,其中TiHx为亚稳相[8]。原始TiH2粉在630 ℃左右具有最大吸热峰,而TiH2-6h粉和TiH2/3%CNT-6h粉的最大吸热峰都向较低温度移动,如BHOSLE等[9]认为这种现象可能是由于在高能球磨过程中,TiH2粉末颗粒由于受到反复变形、破碎和冷焊,引入大量的晶格缺陷并且晶粒细化所造成的。大量的晶格缺陷和晶界使粉末颗粒自由能升高,同时氢原子的扩散率也增大,造成TiH2脱氢温度降低。本研究也表明TiH2/3%CNT-6h粉末颗粒中TiH2的脱氢温度更低,这和它们的晶粒更细小相一致。为使3种粉末能够完全脱氢且使结果具有可比性,同时尽量避免粉末晶粒的过分长大,将脱氢条件定为650 ℃的温度下真空脱氢1 h。

图4 TiH2原始粉、TiH2-6h粉和TiH2/3%CNT-6h粉的DSC曲线

Fig.4 DSC curves of TiH2 powders, TiH2-6h powders and TiH2/3%CNT-6h powders

由于Ti和C在一定的温度下会反应生成TiC, 因此,计算在650 ℃的温度下,钛与碳反应生成TiC的标准吉布斯自由能变化,其计算公式如下:

△G=-184571.8+41.382T-5.042TlnT+2.425×10-3T2-9.79×105/T (T<1939K)[10] (2)

经过计算,在650 ℃下,Ti与C标准吉布斯自由能的变化为-177.146 kJ/mol,结果表明:在此温度下,Ti与C可以自发的生成TiC。

图5所示为粉末在650 ℃下脱氢1 h后的XRD谱。从图中可以看出,650 ℃脱氢后,3种粉末的TiH2衍射峰均消失不见,不含CNT的TiH2-6h粉末全部转变为HCP结构的钛粉,且无其他相生成,而TiH2/3%CNT-6h粉在脱氢后除生成HCP结构的钛,同时CNT与Ti反应生成TiC,这与之前的热力学计算结果也相一致。

球磨粉脱氢后衍射峰的位置较原始TiH2粉脱氢后的衍射峰位置向小角度偏移,这可能是由于粉末在球磨过程中受磨球的反复冲击而产生一定的内应力,造成晶格的畸变,且TiH2/3%CNT-6h粉在脱氢过程中可能有一部分碳原子进入α-Ti的晶格内部形成间隙固溶体从而使晶格参数变大而造成的。

图5 不同条件下的粉末650 ℃脱氢1 h后的XRD谱

Fig.5 XRD patterns of powders dehydrogenation at 650 ℃ for 1 h

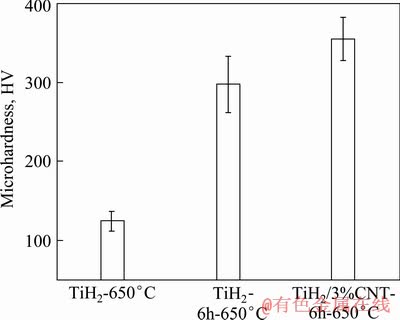

利用Williamson-Hall方程计算脱氢后粉末的晶粒大小, TiH2-6h-650℃粉和TiH2/3%CNT-6h-650℃粉脱氢后平均晶粒尺寸分别长大至51和46 nm。将TiH2- 650℃粉、TiH2-6h-650℃粉和TiH2/3%CNT-6h- 650℃粉镶样进行显微硬度测试,载荷0.1 N,保压15 s,所得数据如图6所示。

图6 3种粉末脱氢后的显微硬度

Fig.6 Micro-hardness of the three powders after dehydrogenation

从图6可以看出,原始TiH2粉末脱氢后所得的Ti粉显微硬度最低,仅为124.21 HV,而球磨过后的TiH2粉,脱氢后显微硬度有明显的提高,达到297.35 HV,这是由于粉末颗粒在高能球磨的过程中晶粒发生细化,晶界强化效应增强造成的。而添加了CNT的粉末在脱氢后显微硬度进一步提高,达到355.17 HV。除细晶强化的作用外,由于CNT和Ti原位生成的TiC在粉末颗粒内部均匀分散,也在一定程度上阻碍位错的运动,起到弥散强化的作用,从而有效地提高粉末颗粒的显微硬度。

3 结论

1) 采用TiH2粉和CNT为原料,在500 r/min下高能球磨6 h,并于650 ℃下真空脱氢1 h,将TiH2中的H完全脱除,成功的制备出具有超细晶结构的Ti粉和Ti/TiC粉,晶粒尺寸分别达到51和46 nm。

2) 添加了3%CNT的TiH2粉在500 r/min下高能球磨6 h后,CNT在粉末颗粒内部分布均匀,在650 ℃真空脱氢后, CNT与Ti反应原位生成增强体TiC。

3) 最终制得的超细结构Ti粉和Ti/TiC粉的颗粒硬度较脱氢后的纯Ti粉有明显提高,Ti/TiC粉的显微硬度达到355.17 HV,细晶强化和弥散强化为主要的增强机理。

REFERENCES

[1] 肖代红, 黄伯云. 原位合成钛基复合材料的研究现状与展望[J]. 粉末冶金技术, 2008, 26(3): 217-229.

XIAO Dai-hong, HUANG Bo-yun. New process on in situ titanium matrix composities[J]. Powder Metallurgy Technology, 2008, 26(3): 217-229.

[2] NAKANE S, YAMADA O, MIYAMOTO Y, et al. Simultaneous synthesis and densification of TiB/α-Ti(N) composite material by self-propagating combustion under nitrogen pressure[J]. Solid State Communications, 1999, 110: 447-450.

[3] MA Z Y, TJONG S C, MENG X M. Creep behavior of in situ dual -scale particles TiB whiskers and TiC particulate reinforced titanium composites[J]. Journal of Materials Research, 2002, 17: 2307-2313.

[4] YANG B, ZHANG E, JIN Y, ZHU Z, ZENG S. Microstructure characteristic of in-situ Ti/TiC composites[J]. Journal of Materials Science and Technology, 2001, 17(1): 103-104.

[5] TSANG H T, CHAO C G, MA C Y. In situ fracture observation of a TiC/Ti MMC produced by combustion synthesis[J]. Scripta Materials, 1996, 35(8): 1007-1012.

[6] KOBAYASHI M, FUNAMI K, SUZUKI S, OUCHI C. Manufacturing process and mechanical properties of fine TiB dispersed Ti-6Al-4V alloy composites obtained by reaction sintering[J]. Materials Science and Engineering A, 1998, 243: 279-284.

[7] MA Z Y, TJONG S C , LI S X. Creep behavior of TiB/Ti in situ composite fabricated by reactive hot pressing[J]. Metallurgical and Materials Transactions A, 2001, 32(4): 1019-1022.

[8] BHOSLE V, BABURAJ E G, MIRANOVA M, SALAMA K. Dehydrogenation of TiH2[J]. Materials Science and Engineering A, 2003, 356: 190-199.

[9] BHOSLE V, BABURAJ E G, MIRANOVA M, SALAMA K. Dehydrogenation of nanocrystalline TiH2 and consequent consolidation to form dense Ti[J]. Metallurgical and Materials Transactions A, 2003, 34: 93-99.

[10] LI S F, SUN B, IMAI H, MIMOTO T, KONDOH K. Powder metallurgy titanium metal matrix composites reinforced with carbon nanotubes and graphite[J]. Composites: Part A, 2013, 48: 57-66.

(编辑 王 超)

基金项目:国家重点基础研究发展计划前期研究专项(2012CB619600)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:张德良,教授,博士;电话:021-54743248;E-mail: zhangdeliang@sjtu.edu.cn