文章编号:1004-0609(2009)08-1398-05

6201铝合金管材的连续流变扩展成形过程

管仁国,李 雪,李江平,肖召辉,朱立杰,温景林

(东北大学 材料与冶金学院,沈阳 110004)

摘 要:采用自行设计的连续流变扩展成形技术装置对6201铝合金管材的制备进行研究。结果表明:连续流变扩展成形可以制备质量良好的6201铝合金管材。制备d80 mm的6201合金管材最佳艺工艺条件为:挤压轮冷却水流量为10~15 L/min;浇注温度为750~780 ℃;模具预热温度为500~560 ℃;挤压轮转速为15 r/min。制品在线水淬固溶并在150 ℃时效10 h后的抗拉强度为300 MPa,伸长率为10.2%,等效导电率为47.4%IACS,抗拉强度比Al-Mg-Si-Cu铝合金管母线提高15%,等效导电率提高3%。

关键词:6201合金;管材;连续流变扩展成形;时效;性能

中图分类号:TG 111.4; TG 244.1 文献标识码: A

Continuous extending rheo-extrusion process for producing 6201 alloy tube

GUAN Ren-guo, LI Xue, LI Jiang-ping, XIAO Zhao-hui, ZHU Li-jie, WEN Jing-lin

(School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China)

Abstract: Continuous extending rheo-extrusion process for producing 6201 alloy tube was investigated by using a self-designed setup. The results show that 6201 alloy tube with good performance can be successfully manufactured by the proposed technique. The optimal process conditions for producing 6201 alloy tube with d80 mm are obtained as follows: the velocity of roll cooling water is 10?15 L/min; the casting temperature is 750?780 ℃; the mould preheating temperature is 500?560 ℃; the velocity of the roll is 15 r/min. After being water quenched for solid solution and artificial aging at 150 ℃ for 10 h, the tensile strength of the product reaches 300 MPa, the elongation is 10.2% and the equivalent conductivity reaches 47.4%IACS. Comparing with the conducting tube of Al-Mg-Si-Cu alloy, the tensile strength is improved by 15% and the equivalent conductivity is improved by 3%.

Key words: 6201 alloy; tube; continuous extending rheo-extrusion; aging; property

半固态成形技术被誉为21世纪最具应用前景的绿色加工技术,流变成形技术属于半固态成形技术领域的先进加工技术,由于它具有短流程、节能节材、产品质量好等优点,受到世界各国高度重视[1?2]。目前比较成功的流变成形技术是射注技术,该技术借鉴了塑料的注塑技术原理,并在此基础上经过改进和发展而日益成熟起来。但是该技术结构较为复杂,加上技术保护等因素,使该技术造价成本较高,应用也不是非常广泛。因此,开发高效先进的流变成形技术仍是材料成形领域重点研究的热点课题[3?4]。

铝管母线是高压和超高压输变电材料。当前铝管母线配电装置已从500 kV向750和1 000 kV等特高或特超高铝管母线配装置发展,对铝管母线的综合力学性能、导电性能和铝管母线的长度提出了更高的要求。目前国内管母线质量较高的是Al-Mg-Si-Cu合金,其强度为260 MPa,等效导电率为46%IACS;目前采用的生产工艺为空心锭轧制?拉拔或铸锭直接挤压等工艺方法,但采用这样的方法生产时能耗高,而且产品的质量差,生产的长度受限(仅9 000 mm)。实际上220 kV和500 kV管式变电站对铝管母线的长度要求为 27 000 mm以上,因此,安装这样的铝管母线时必须进行焊接,这样既影响铝管母线的导电性能,又提高了铝管母线高压配电装置的成本(焊缝成本:3 000元/个)。而且焊缝的存在往往还是致命的安全隐患。国外采用超大型挤压机生产,产品质量好,但价格昂贵。目前电力行业正在研制750和1 000 kV特超高压配电装置,铝管母线的长度要求达到80 000 mm以上,采用传统大挤压机的铝管母线生产技术已不能满足电力发展的要求[5?6],近年来提出的扩展成形技术可连续生产导电管材,为导电管的制备技术提供了有利的新途径。连续流变扩展成形技术将半固态制浆与连续流变扩展成形相结合,具有低能耗、低成本、产品质量高、导电性能好和产品长度不受限制等优点,因此具有重要的研究价值。本文作者在实验室条件下,对连续流变成形技术制备d80 mm的6201铝合金导电管材进行研究。

1 实验

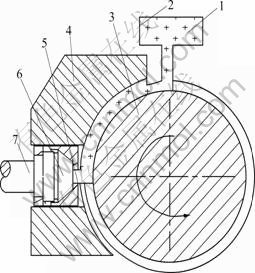

实验设备采用自行设计的D?350型连续流变扩展成形实验装置,其基本原理如图1所示。

图1 连续扩展成形原理示意图

Fig.1 Schematic diagram of continuous extending rheo- extrusion: 1—Alloy melt; 2—Pouring basket; 3—Rotation roll; 4—Fixed shoe; 5—Barrier block; 6—Extending mould; 7—Tube

熔化后的合金液体1经中间包2流入到由转动的挤压轮3和静止的靴座4构成的挤压型腔内,在挤压轮的内冷却水的作用下,合金液体不断发生凝固,合金在挤压轮剪切/冷却的作用下,形成具有非枝晶固相颗粒的半固态浆料,当半固态浆料到达档料块5时合金的流动方向发生90?转变,连续填充到扩展组合模6;合金先在扩展模中进行填充,扩展后经分流孔进入到焊合腔,最后经下模的模孔与分流模模芯构成的孔道中流出,经焊合室形成大口径管材7,从而“小口径填充、大口径成形”。成形主机由直流双向可变速电机驱动,经过一级变速器变速。挤压模具采用d80的扩展分流组合模,其结构如图2所示。分流组合模是由上模、下模、定位销、连接螺钉4部分组成。该技术具有如下特点[6?9]:1) 短流程、节能节材,实现了浆料的制备和管材扩展挤压成形的一体化和连续化,这对于传统的管材挤压工艺无疑是重大突破,不但节省了传统管材生产中的铸棒、锯切、挤压锭坯的加热均匀化处理等工序,而且节省了能源,降低了生产成本,还避免了常规铸造合金的成分偏析、表面缺陷和铸造组织的二次加热长大,提高了6201合金的加工性能,同时大大提高管材的成材率;2) 半固态成形可充分利用制品在出口的余热,实现制品的在线固溶,改善制品的组织性能;3) 通过扩展,可生产铝合金大断面管型材。

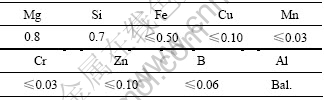

实验材料采用自行熔炼配置的6201铝合金。由纯度为99.99%的铝锭、Al-Si中间合金和Mg等合金配置而成。为保证合金管材具有较高的综合力学性能和导电性能,严格控制合金元素镁硅及杂质含量,形成硅过剩6201铝合金,以提高6201合金的加工性能和时效强化性能。必须避免镁过剩,否则Mg2Si在铝基体中的固溶度下降,合金的拉伸强度下降。6201合金的成分如表1所示,其固相线温度为607 ℃,液相线温度为650 ℃。合金熔化后用六氯乙烷精炼3~5 min,除去铝合金中的氧化物、夹杂和氢气,保温静置20 min,确保铝合金熔体充分合金化。合金精练后在740~800 ℃保温,同时将流变扩展挤压模预热到500~560 ℃,然后浇注,进行流变扩展成形实验。通过不同浇注温度、不同挤压轮转速、不同模具预热温度和冷却水流量的条件下实验,研究各工艺参数对流变扩展成形的影响。

表1 实验6201合金的化学成分

Table 1 Chemical compositions of experimental 6201 aluminum alloy(mass fraction, %)

图2 扩展挤压模具图

Fig.2 Diagram of extended extrusion die: (a) Extended die; (b) Divergent die; (c) Fixed die

对连续流变扩展成形管材制品经过在线固溶后对其进行人工时效,时效温度在150~190 ℃,时效时间为4~10 h。按照JB/T8640—1997标准的要求,制备标准电性能试样,在20 ℃恒温条件下,采用QJ36型两用直流电桥测量试样的电阻值,取电阻的最大值计算等效导电率。采用CMT5105微机控制电子万能试验机在5 mm/min的条件下测量时效后制品的拉伸力学性能。每种条件下合金测试3个试样,然后取3个测定值的平均值。

2 结果与分析

2.1 浇注温度对连续流变扩展成形及制品质量的影响

由于合金浇注时,流槽、工作辊、挤压靴和扩展组合模等温度较低,铝合金熔体与其接触导致铝液温度下降。如果浇注温度太低,在扩展腔合金固相率太高,合金就难以充满扩展腔,从而造成充模口或者定径带出口堵塞而难以得到制品。图3所示为在740 ℃浇注6201合金在定径带出口时的状态。由图3可以看出,合金在定径带出口阻塞,只有少量合金被挤压出定径带。这是因为,在较低温度条件下小流量浇注,合金由于固相率高,流动性能差,合金即使充满扩展腔,也难以流出挤压模定径带而难于成形。另外,浇注温度太低,不仅合金难于流动,而且无法获得具有淬火特殊性的在线固溶体,无法实现在线固溶。

图3 740 ℃浇注时6201合金在定径带出口的堵塞状态

Fig.3 Blockage state of 6201 alloy at calibrating strap when casting at 740 ℃

另一方面,在较高的浇注温度条件下,虽然合金能够顺利实现扩展成形,但是会降低制品的力学性能,而且浇注温度过高,合金液相率太高而不能成形。如果铝合金熔体温度超过780 ℃后,熔体过热倾向增大,熔体在浇注的过程中与空气等接触氧化与吸气量剧烈增大,导致合金熔体的纯洁度下降,降低合金的性能。图4所示为760 ℃时浇注连续扩展成形管材的表面形貌。由图4可见,管材的表面质量较好。实验证明,为顺利实现连续流变扩展成形,在冷却水流量为10~15 L/min的条件下,合理的浇注温度范围为750~780 ℃。

图4 760 ℃时浇注管材的表面形貌

Fig.4 Surface of tube when casting at 760 ℃

2.2 挤压轮转速对连续流变扩展成形及制品质量的影响

为了充分利用流变成形过程中金属变形抗力低、变形大的特点,挤压速度应尽可能高一些,以实现低耗、高产和节能的目的[10?12]。但是由于在成形过程中,合金靠近挤压轮流动速度快,而靠近靴子侧流动速度慢,在浇注温度和冷却水流量一定的条件下,如果挤压轮转速控制不当会引起合金充模流动不均匀,在定径带金属下层流动速度大于上层,使管材上部金属受到拉应力的作用,产生向上翘曲缺陷,最终造成制品在出口翘曲。图5所示为挤压轮转速为22 r/min时制品在定径带出口形成的翘曲。另外,挤压速度过高时,由于高速转动容易引起挤压轮振动,从而使合金流动速度发送波动,容易引起挤压失稳,最终导致制品形成波浪形表面。实验证明,挤压轮的转速为15 r/min时,合金能够均匀地填充扩展腔,如图6所示,制品质量较好。

图5 挤压转速较高时管材翘曲

Fig.5 Tube curling at high roll rotating velocity

图6 工作辊的转速为15 r/min时合金均匀填充扩展腔

Fig.6 Uniformly filling extending cavity of alloy at roll rotating velocity of 15 r/min

2.3 模具预热温度对连续流变扩展成形及制品质量的影响

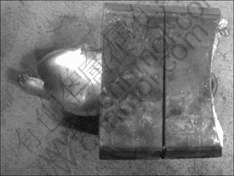

为了防止合金温度下降太快引起合金出模困难,合金的浇注温度不能太低,同时,必须对工模具进行合理预热;如果模具预热温度太低,使合金固相率较高,合金难以填充扩展腔而顺利实现挤压成形。但是模具预热温度过高,合金进入到变形区时完全为液相,成品管材会因其中残存部分铸造组织而成为废品;实验证明,在浇注温度为750~780 ℃和挤压轮冷却水流量为10~15 L/min的条件下,如果在模具预热温度超过560 ℃,会造成合金固相率太低,而在出口出现液体状金属液流淌,不能实现成形。经过反复试验发现,在挤压轮冷却水流量为10~15 L/min,浇注温度为750~780 ℃范围,模具预热温度为500~560 ℃的条件下,产品质量较好,表面光洁,无横向裂纹和表面气泡,可以制备出具有良好表面质量的d80 mm的6201铝合金导电管材,如图7所示。

图7 780 ℃浇注时的制品

Fig.7 Product when casting at 780 ℃

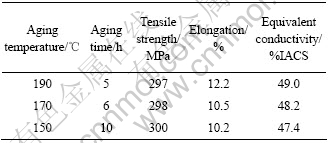

2.4 热处理对制品性能的影响

制品经过在线冷却固溶并在T6条件下进行人工时效,时效后制品性能如表2所列。随着时效时间延长,由于主要强化相元素Mg和Si从6201铝合金的铝基体中析出,在α(Al)基体中形成Mg2Si,并弥散分布于基体中,对位错运动产生钉扎和阻碍作用,使位错以奥罗万切过机制运动,阻力增大,强度提高[13?15]。150 ℃时效10 h后管材的抗拉强度为300 MPa,伸长率为10.2%,等效导电率为47.4 IACS(电阻率36.4 nΩ?m),其抗拉强度比目前Al-Mg-Si-Cu铝合金管母线(抗拉强度260 MPa,等效导电率46IACS)提高了15%,等效导电率提高了3%。

表2 制品时效过程与性能

Table 2 Artificial aging process and properties

3 结论

1) 采用自行设计的连续流变扩展成形技术装置成功地制备出质量良好的6201铝合金导电管材,连续流变扩展成形技术具有流程短、节能节材、可连续化生产大断面管型材的优点。

2) 获得了工艺条件对合金成形性能和制品质量的影响规律,制备d80 mm的6201合金管材最佳工艺条件为:挤压轮冷却水流量10~15 L/min;浇注温度750~780 ℃;模具预热温度500~560 ℃;挤压轮转速15 r/min。

3) 经过在线水淬固溶并在150 ℃时效10 h后,制品的抗拉强度为300 MPa,伸长率为10.2%,等效导电率为47.4%IACS,抗拉强度比Al-Mg-Si-Cu铝合金管母线提高了15%,等效导电率提高了3%。

REFERENCES

[1] FLEMINGS M C. Behavior of metal alloys in the semisolid state[J]. Metall Trans, 1991, 22A: 957?781.

[2] KIRKWOOD D H. Semisolid metal processing[J]. International Materials Reviews, 1994, 39: 173?178.

[3] HAGA T. Simple rheocasting processes[J]. Journal of Materials Processing Technology, 2002, 130/131: 594?598.

[4] GUAN Ren-guo, WEN Jing-lin, LIU Xiang-hua. FEM analysis of aluminum AA2017 alloy thermal/fluid multiple fields during a single-roll stirring process[J]. Mater Sci Tech, 2003, 19(4): 503?506.

[5] MARUYAMA N, UEMORI R, HASHIMOTO N. Effect of silicon addition on the composition and structure of fine-scale precipitates in Al-Mg-Si alloys[J]. Script Mater, 1997, 36(1): 89.

[6] 周天国, 温景林, 陈彦博, 李英龙. 6201铝合金管材半固态连续扩展成形实验研究[J]. 东北大学学报: 自然科学版, 2004, 25(8): 778?781.

ZHOU Tian-guo, WEN Jing-lin, CHEN Yan-bo, LI Ying-long. Experimental study on continuous semi-solid expansion forming process of 6201 Al-alloy tubes[J]. Journal of Northeastern University: Natural Science, 2004, 25(8): 778?781.

[7] GUAN Ren-guo, WANG Shun-cheng, WEN Jing-lin. A continuous semisolid extending-extrusion process for producing AA2017 aluminum alloy flat bar[J]. Mater Sci Tech., 2006, 22(6): 706?712.

[8] 管仁国, 李英龙, 王顺成, 刘相华, 温景林. 半固态扩展挤压A2017合金过程中金属流动的有限元分析[J]. 中国有色金属学报, 2004, 14(9): 1540?1544.

GUAN Ren-guo, LI Ying-long, WANG Shun-cheng, LIU Xiang-hua, WEN Jing-lin. Finite element modelling analysis of metal flowing during process of extending extruding semisolid A2017 alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(9): 1540?1544.

[9] EMBURY J D. Strengthening mechanisms in Al alloys-an overview of natural limits and engineering possibilities[J]. Materials Science Forum, 1996, 217/222: 57.

[10] SIDDIQUI R A, ABDULLAH H A, AL-BELUSHI K R. Influence of aging parameters on the mechanical properties of 6063 aluminum alloy[J]. Journal of Materials Processing Technology, 2000, 102: 234?240.

[11] MAO Wei-min, CUI Cheng-lin, ZHAO Ai-min, YANG Ji-lian, ZHONG Xue-you. Effect of pouring process on the microstructures of semi-solid AlSi7Mg alloy[J]. Journal of Materials Science & Technology, 2001, 17(6): 615?619.

[12] XIA M X, ZHENG H X, YUAN S, LI J G. Recrystallization of preformed AZ91D magnesium alloys in the semisolid state[J]. Materials and Design, 2005, 26: 343?349.

[13] GUAN Ren-guo, WANG Chao. Semisolid metal forming by novel late[J]. Trans Nonferrous Met Soc China, 2006, 16(S3): 1265?1258.

[14] JI S, FAN Z, BEVIS M J. Semi-solid processing of engineering alloys by a twin-screw rheomolding process[J]. Mater Sci Eng A, 2001, 299: 210?217.

[15] MAO W M, ZHEN Z S, CHEN H T, ZHONG Xue-you. Microstructure of electromagnetic stirred semi-solid AZ91D alloy[J]. Trans Nonferrous Met Soc China, 2004, 14(5): 846?850.

基金项目:国家高技术研究发展计划资助项目(2007AA03Z111);国家自然科学基金资助项目(50604007)

收稿日期:2008-08-21;修订日期:2009-02-12

通讯作者:管仁国,教授,博士;电话:024-83681463;E-mail: guanrg@smm.neu.edu.cn

(编辑 何学锋)