Trans. Nonferrous Met. Soc. China 23(2013) 1299-1303

Influence of Zr content on microstructure and mechanical properties of implant Ti-35Nb-4Sn-6Mo-xZr alloys

Shi-juan DAI, Yu WANG, Feng CHEN, Xin-quan YU, You-fa ZHANG

Jiangsu Key Laboratory of Advanced Metallic Materials, Southeast University, Nanjing 211189, China

Received 9 April 2012; accepted 15 October 2012

Abstract: The influence of Zr content on the microstructure and mechanical properties of implant Ti-35Nb-4Sn-6Mo-xZr (x=0, 3, 6, 9, 12, 15; mass fraction) alloys was investigated. It is shown that Ti-35Nb-4Sn-6Mo-xZr alloys appear to have equiaxed single β microstructure after solution treatment at 1023 K. It is found that the grains are refined first and then coarsened with the increase of Zr content. It is also found that Zr element added to titanium alloys has both the solution strengthening and fine-grain strengthening effect, and affects the lattice parameters. With increasing the Zr content of the alloys, the strength increases, the elongation decreases, whereas the elastic modulus firstly increases and then decreases. The mechanical properties of Ti-35Nb-4Sn-6Mo-9Zr alloy are as follows: σb=785 MPa, δ=11%, E=68 GPa, which is more suitable for acting as human implant materials compared to the traditional implant Ti-6Al-4V alloy.

Key words: implant titanium alloy; Zr element; elastic modulus; microstructure; solution treatment; mechanical properties

1 Introduction

Titanium and its alloys have excellent biocompatibility, corrosion resistance and high strength and are ideal surgical implant materials [1-3]. However, the elastic moduli of traditional titanium alloys (such as Ti and Ti-6Al-4V) are much higher than those of the human bone, which can cause “stress shielding effect”, leading to atrophy of normal human tissue around implants [4,5]. Moreover, V exhibits high cytotoxicity and Al may induce senile dementia for the widely used Ti-6Al-4V alloy [6,7]. Therefore, the development of non-toxic titanium alloys with good biomechanical properties has become one of the hot topics in recent years.

Elements Nb, Sn, Mo and Zr are all non-toxic to the human body [8]. It is reported that β-type titanium alloys can be formed entirely or partially by the addition of elements Nb, Sn and Mo, which can enhance the strength and reduce the moduli of titanium alloys [9]. It is also found that Zr element can increase the stability and lattice parameters of β-phase [10,11], which implies that Zr element has the potential to reduce the elastic moduli of titanium alloys. So far, the researches on the role of alloying element Zr mainly relate to its influence on the stability of β-phase in titanium alloys [9-12], and there is still lack of the research for its influence on the mechanical properties of β-type titanium alloys. In this work, the influence of Zr addition on the microstructure and mechanical properties of Ti-35Nb-4Sn-6Mo-xZr (x=0, 3, 6, 9, 12, 15; mass friction) alloys are investigated by changing Zr content over a wide range, and it is hoped that a new implant titanium alloy containing non-toxic element and having good biomechanical properties will be obtained.

2 Experimental

Titanium alloys with nominal composition of Ti-35Nb-4Sn-6Mo-xZr (x=0, 3, 6, 9, 12, 15; mass fraction) were prepared by arc-melting method under Ar atmosphere. The ingots were re-melted five times for ensuring homogeneity. Then, they were hot forged to plates with a thickness of 3 mm. The hot-forged plates were finally solution treated at 1023 K for 0.5 h, followed by water quenching.

Using an optical microscope (OM) and transmission electron microscope (TEM, FEI Tecnai G2 T20), the microstructure of the specimen with different component, which was burnished, mechanically polished and eroded, was observed. Then, the phase structures of the alloys were analyzed by an X-ray diffractometer (D8 Discover, Bruker-AXS), and the lattice parameters of β phase were calculated according to the XRD pattern using Jade5.0 software. The mechanical properties of the alloys such as tensile strength σb, yield strength σ0.2 and elongation δ were obtained on an electronic universal test machine (CMT 5105, MTS). The elastic modulus E was calculated according to the slope of the linear portion in the stress—strain curves.

3 Results and discussion

3.1 Microstructures

Figure 1 shows the XRD patterns of Ti-35Nb- 4Sn-6Mo-xZr alloys at room temperature, which were solution treated at 1023 K followed by water quenching. Without the addition of Zr element, the alloy comprises a fully retained β phase (see Fig. 1(a)), which means that the ability of the added elements (Nb, Sn and Mo) for stabilizing β-phase is large enough to make the martensitic transformation start temperature Ms below room temperature, therefore, the β-phase can be retained to room temperature after quenching. With the addition of Zr element, the Ti-35Nb-4Sn-6Mo-xZr (x=3, 6, 9, 12, 15) alloys retain 100% β-phase structure after solution treatment (see Figs. 1(b)-(f)). It is known that Zr is a neutral element for Ti alloys and the effect of Zr on the β stability of the alloys is expected to be negligible. However, some reports [10,11] indicated that Zr acts as a β stabilizer when other β stabilizers coexist in the alloys, such as Mo element. It was reported [10,13] that Mo contents of the alloys with a single β phase are 11% and 14% after quenching for binary Ti-Mo alloys. However, ZHAO et al [14] reported that Ti-30Zr-5Mo alloy was composed of 100% β phase after quenching. Therefore, the β-stabilizing effect of Zr coexisting with Mo is much stronger than the expected one. In other words, when elements Zr and Mo coexist in the Ti alloy, Zr can increase the stability of β phase. Therefore, with increasing the Zr content, the Ti-35Nb-4Sn- 6Mo-xZr alloys still retain 100% β phase.

Fig. 1 XRD patterns of Ti-35Nb-4Sn-6Mo-xZr alloys after solution treatment

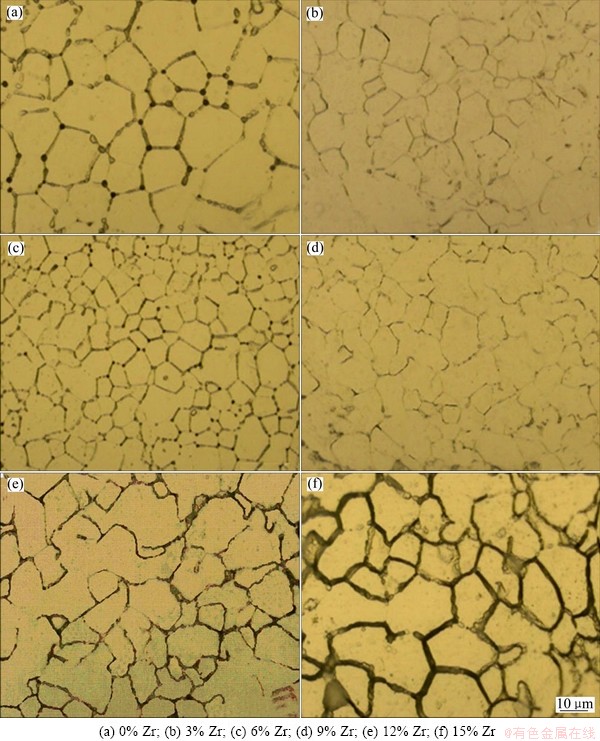

Figure 2 shows the microstructures of Ti-35Nb- 4Sn-6Mo-xZr alloys after solution treatment at 1023 K. As shown in Figs. 2(a)-(f), the alloys appear to have a single phase with equiaxed grain microstructure. The obvious secondary phase is invisible in these alloys. However, a little amount of ω or α′′ phase is sometimes difficult to be detected by XRD and optical microscope, even if it exists actually in metastable β-type titanium alloys. In order to identify the phase constituent of these alloys, TEM measurement was carried out. The results show that the Ti-35Nb-4Sn-6Mo-xZr alloys consist of single β phase. The microstructure and the selected-area electron diffraction (SAED) pattern of Ti-35Nb-4Sn- 6Mo-9Zr alloy are shown in Fig. 3.

From Fig. 2, it is seen that no significant difference in the microstructure was confirmed for the alloys except the grain size. Figure 4 shows the grain size of the β phase in Ti-35Nb-4Sn-6Mo-xZr alloys. The results show that with the increase of Zr element, the grain size of the alloys firstly decreases and then increases. It may be caused by two factors: on one hand, the mechanism of grain refinement is considered in terms of the contribution of Zr as a solute which may affect both the nucleation and growth of recrystallizing grains. Solute may have a strong influence on the recovery processes which may affect the driving force for recrystallization, thereby, influencing the nucleation. Furthermore, the solute can prevent the grain boundary from moving and hence decrease the growth rate of recrystallizing grains [12,15,16]. This result is in good agreement with the result of ZHAN et al [12], which showed that the appropriate addition of Zr element can refine the grains in β-Ti alloys. On the other hand, Zr element, which behaves as a β-stabilizing element, can increase the stability of β-phase when elements Zr and Mo coexist in the alloy [10,11]. With Zr content increasing, the stability of the β-phase enhances remarkably, which may make the (α+β)/β phase transformation temperature reduced significantly, leading to the marked increase of superheat (the solid solution temperature is constant) and obvious coarsening of the β grains after solution treatment.

3.2 Mechanical properties

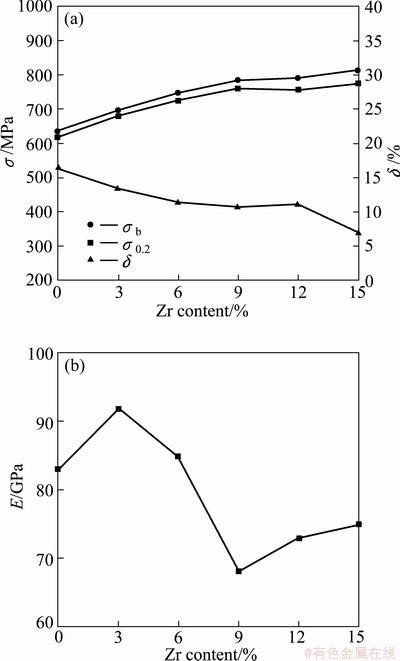

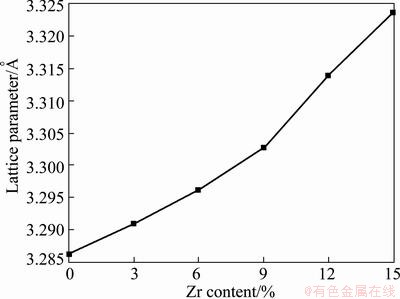

The strength and elongation of Ti-35Nb-4Sn- 6Mo-xZr alloys are plotted in Fig. 5(a). It is known that the strength increases and the elongation decreases gradually with the increase of Zr content. Lattice parameters of β phases in Ti-35Nb-4Sn-6Mo-xZr alloys were calculated by Jade5.0 software according to XRD patterns of the alloys after solution treatment (Fig. 2), as shown in Fig. 6. It is found that the addition of Zr element can cause the distortion of crystal lattice of the β phase. The interaction between the solute atoms Zr with dislocations intensifies due to the distortion of crystal lattice, resulting in the increase of strengthening effect [16]. As shown in Fig. 5(a), the increasing rate in strength with increasing Zr content is faster for the alloys containing Zr from 0 to 6%, which may be due to the strengthening effect and the solution strengthening effect by Zr addition. For the alloys containing Zr from 9% to 15%, the grains become coarsened, which offsets the solution strengthening effect partially, resulting in a lower rate of increase in strength with increasing Zr content.

Fig. 2 OM images of Ti-35Nb-4Sn-6Mo-xZr alloys after solution treatment

Fig. 3 TEM image (a) and corresponding SAED pattern (b) of Ti-35Nb-4Sn-6Mo-9Zr alloy after solution treatment

Fig. 4 Grain size of β phase in Ti-35Nb-4Sn-6Mo-xZr

Fig. 5 Mechanical properties of Ti-35Nb-4Sn-6Mo-xZr alloys

Fig. 6 Lattice parameter of β phases in Ti-35Nb-4Sn- 6Mo-xZr alloys

As shown in Fig. 5(b), the elastic moduli of the alloys firstly increase and then decrease with the increase of Zr element. The elastic modulus of solid solution is related to the crystal structure and the binding force between atoms [17,18]. In this work, the alloys are composed of 100% β phase, so their elastic moduli are related to the bonding force between the atoms. The binding force lies on atomic spacing. As shown in Fig. 6, with the increase of Zr content, the lattice parameters of β-phases increases, resulting in the reduction of binding force between atoms and elastic modulus. In addition, the decrease of elastic modulus is also related to gain refinement. This should be due to gain refinement since the grain boundaries have lower elastic modulus than the grains due to high dense defects [19]. For the alloys containing 0-9% Zr, the gain refinement (Fig. 4) and the decrease of the binding force between atoms lead to the decrease of elastic modulus of the alloy; for the alloys containing 9%-15% Zr, the binding force also decreases; however, the coarsening of grain (Fig. 4) leads to the slight increase of the elastic modulus.

The mechanical properties of the implant titanium alloys are generally required as follows: σb≥600 MPa, δ≥8%, E≤90 GPa [20]. The mechanical properties of Ti-35Nb-4Sn-6Mo-9Zr alloy after solution treatment (σb=785 MPa, δ=11%, E=68 GPa) can meet this requirement. The strength of this alloy is close to that of Ti-6Al-4V, but its elastic modulus is only 60% of the latter, which is suitable for acting as human implant materials.

4 Conclusions

1) Ti-35Nb-4Sn-6Mo-xZr alloys are composed of 100% β phase after solution treatment. With the increase of Zr content, the grains are refined first and then coarsened.

2) Zr element added to titanium alloys has both the solution strengthening and fine-grain strengthening effect, and also affects the lattice parameters of β-phase. With the increase of Zr content, the strength of the alloys increases, the elongation decreases, and the elastic moduli increase first and then decrease.

3) The mechanical properties of Ti-35Nb-4Sn- 6Mo-9Zr alloy are as follows: σb=785 MPa, δ=11%, E=68 GPa, which is suitable for acting as human implant materials.

References

[1] WANG K. The use of titanium for medical applications in USA [J]. Materials Science and Engineering A, 1996, 231(1-2): 134-137.

[2] LONG M, RACK H J. Titanium alloys in total joint replacement—A materials science perspective [J]. Biomaterials, 1998, 19(18): 1621-1639.

[3] ZHOU Y L, NIINOMI M, AKAHORI T. Decomposition of martensite α″ during aging treatments and resulting mechanical properties of Ti-Ta alloys [J]. Materials Science and Engineering A, 2004, 384(1-2): 92-101.

[4] ABDEL-HADY M, HINOSHITA K, MORINAGA M. General approach to phase stability and elastic properties of β-type Ti-alloys using electronic parameters [J]. Scripta Materialia, 2006, 55(5): 477-480.

[5] RACK H J, QAZI J I. Titanium alloys for biomedical applications [J]. Materials Science and Engineering C, 2006, 26(8): 1269-1277.

[6] OKAZAKI Y, RAO S, TATEISHI T, ITO Y. Cytocompatibility of various metals and development of new titanium alloys for medical implants [J]. Materials Science and Engineering A, 1998, 243(1-2): 250-256.

[7] NIINOMI M. Recent research and development in titanium alloys for biomedical applications and healthcare goods [J]. Science and Technology of Advanced Materials, 2003, 4(5): 445-454.

[8] KURODA D, NIINOMI M, MORINAGA M, KATO Y, YASHIRO T. Design and mechanical properties of new type titanium alloys for implant materials [J]. Materials Science and Engineering A, 1998, 243(1-2): 244-249.

[9] SONG Y, XU D S, YANG R, LI D, WU W T, GUO Z X. Theoretical study of the effects of alloying elements on the strength and modulus of β-type bio-titanium alloys [J]. Materials Science and Engineering A, 1999, 260(1-2): 269-274.

[10] MIN X H, EMURA S, ZHANG L, TSUZAKI K. Effect of Fe and Zr additions on ω phase formation in β-type Ti-Mo alloys [J]. Materials Science and Engineering A, 2008, 497(1-2): 74-78.

[11] HAO Y L, LI S J, SUN S Y, YANG R. Effect of Zr and Sn on Young’s modulus and superelasticity of Ti-Nb-based alloys [J]. Materials Science and Engineering A, 2006, 441(1-2): 112-118.

[12] ZHAN Y Z, LI C L, JIANG W P. β-type Ti-10Mo-1.25Si-xZr biomaterials for applications in hard tissue replacements [J]. Materials Science and Engineering C, 2012, 32(6): 1664-1668.

[13] TAKEMOTO Y, SHIMIZU I, SAKAKIBARA A, HIDA M, MANTANI Y. Tensile behavior and cold workability of Ti-Mo alloys [J]. Materials Transactions, 2004, 45(5): 1571-1576.

[14] ZHAO X L, NIINOMI M, NAKAI M, ISHIMOTO T, NAKANO T. Development of high Zr-containing Ti-based alloys with low Young's modulus for use in removable implants [J]. Materials Science and Engineering C, 2011, 31(7): 1436-1444.

[15] CHOE H C, SAJI V S, KO Y M. Mechanical properties and corrosion resistance of low rigidity quaternary titanium alloy for biomedical applications [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(4): 862-865.

[16] OKAZAKI Y, ITO Y, ITO A, TATEISHI T. Effect of alloying elements on mechanical properties of titanium alloys for medical implants [J]. Materials Transactions, 1993, 34(12): 1217-1222.

[17] YANG G T, ZHANG T. Phase transformation and mechanical properties of the Ti50Zr30Nb10Ta10 alloy with low modulus and biocompatible [J]. Journal of Alloys and Compounds, 2005, 392(1-2): 291-94.

[18] ZHOU Y L, LUO D M. Microstructures and mechanical properties of Ti-Mo alloys cold- rolled and heat treated [J]. Materials Characterization, 2011, 62(10): 931-937.

[19] MA Yun-qing, YANG Shui-yuan, JIN Wan-jun, WANG Yun-neng, WANG Cui-ping, LIU Xing-jun. Microstructure, mechanical and shape memory properties of Ti-55Ta-xSi biomedical alloys [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(2): 287-291.

[20] SUMNER D R, GALANTE J O. Determinants of stress shielding: Design versus materials versus interface [J]. Clinical Orthopedics and Related Research, 1992, 274: 202-212.

Zr元素对种植合金Ti-35Nb-4Sn-6Mo-xZr组织和力学性能的影响

戴世娟,王 煜,陈 锋,余新泉,张友法

东南大学 江苏省先进金属材料重点实验室,南京 211189

摘 要:研究Zr元素含量对种植合金Ti-35Nb-4Sn-6Mo-xZr (x=0,3,6,9,12,15;质量分数)组织和力学性能的影响。结果表明,在1023 K下进行固溶处理后,Ti-35Nb-4Sn-6Mo-xZr合金呈现单一的β等轴状组织。随着Zr元素含量的增加,合金的晶粒尺寸先减小后增大。研究还发现,在钛合金中添加Zr元素具有固溶强化和细晶强化的作用,并且影响合金的晶格常数。随着Zr含量的增加,合金的强度逐渐增加,伸长率逐渐降低,合金的弹性模量先升高后降低。与传统的种植合金Ti-6Al-4V相比,Ti-35Nb-4Sn-6Mo-9Zr 合金更适合作为人类的种植材料。该合金的力学性能为:σb=785 MPa,δ=11%,E=68 GPa。

关键词:种植钛合金;Zr元素;弹性模量;组织;固溶处理;力学性能

(Edited by Hua YANG)

Foundation item: Project (BE2011778) supported by Science and Technology Support Program of Jiangsu Province, China; Project (CE20115036) supported by Science and Technology Support Program of Changzhou City, China

Corresponding author: Feng CHEN; Tel: +86-13813811605.E-mail: fengchen@seu.edu.cn

DOI: 10.1016/S1003-6326(13)62597-2