DOI: 10.11817/j.ysxb.1004.0609.2020-39379

Ti-Nb合金的物理基本构模型

刘建军1,王克鲁1,鲁世强1,李 鑫1,欧阳德来2,程 静1

(1. 南昌航空大学 航空制造工程学院,南昌 330063;

2. 南昌航空大学 材料科学与工程学院,南昌 330063)

摘 要:采用Gleeble-3500型热模拟机对Ti-Nb合金在应变速率0.001~10 s-1,变形温度1063~1213 K条件下进行热压缩实验,得到流变应力曲线。首先采用综合考虑弹性模量(E)和材料自扩散系数(D)的物理基本构方程建立Ti-Nb合金传统的应变补偿本构模型,再对所建立的本构模型进行修正来提高预测该合金流变应力的能力,最后对修正的本构模型进行简化来进一步提升建立该物理基本构模型的效率。结果表明:传统的应变补偿本构模型的预测能力并不理想,经过修正和简化的本构模型拥有较高的预测精度且两者的预测能力几乎相同。

关键词:Ti-Nb合金;本构关系;热变形

文章编号:1004-0609(2020)-07-1611-09 中图分类号:TG146.2 文献标志码:A

与其他生物医用金属材料相比,医用钛合金具有更低的密度、更高的比强度和更优异的生物相容性 等[1]。目前Ti-Nb基β钛合金是新一代医用钛合金的重要研究方向[2]。Nb被称为生物金属元素且可以稳定β相,因而Ti-Nb合金对人体无毒无害且具有较低的弹性模量,可用于制造人工髋关节、接骨板和螺钉等人体植入体[3-6]。此外,Ti-Nb基合金还具有良好的形状记忆效应,在牙科、骨科等医用领域有重大的应用价值[1, 7]。建立本构模型是进行材料加工与模拟的基础,因而建立高精度的Ti-Nb合金的本构模型对于研究该合金的成形和加工工艺具有指导意义。

CHANG等[8]研究了不同的热处理温度和Nb含量对冷轧Ti-Nb合金的组织演变和力学性能的影响,结果表明该合金的力学性能,特别是弹性模量取决于其化学成分和热处理温度。LAI等[9]研究了Ti-Nb基合金复杂的相变行为,结果揭示了从β相转变到ω相的能垒,其中晶格重排起主要作用。ZHANG等[10]通过向Ti-22Nb合金中分别添加1%的合金元素(Ta、Fe、Zr、Mo、Sn和Si),研究了添加的合金元素对该合金组织、力学性能和超弹性的影响,结果表明添加的所有合金元素都影响了该合金的微观结构,并有效地改善了该合金的超弹性,其中Ta、Fe、Sn和Si元素对该合金中的β相产生了较强的固溶强化效果。姚强等[11]采用密度函数理论的缀加平面波加局域轨道和超晶胞方法,探究了Ti-Nb合金的β结构稳定性和弹性性质与Nb含量的关系,结果显示,随着Nb含量的升高,该合金中的β结构稳定性有所加强。但很少有研究者构建出具有高精度的Ti-Nb合金本构模型。

本文拟采用的是一种综合考虑弹性模量(E)和材料自扩散系数(D)的物理基本构方程。至今,还未出现过用该物理基本构模型来预测Ti-Nb合金流动应力的相关报道。本文在得到了相关材料参数的基础上,先建立了Ti-Nb合金的传统的应变补偿物理基本构模型,再对所建立的本构模型进行了修正来提高预测该合金流变应力的能力,最后对修正的本构模型进行简化来进一步提升建立该物理基本构模型的效率。此外,还对所建立的3个本构模型进行对比分析和误差检验。这将对Ti-Nb合金的热加工工艺提供理论上的指导,还对该合金的进一步研究具有一定的参考价值。

1 实验

实验材料是Ti-Nb合金,其化学成分(质量分数,%)为:46.25 Ti,53.73 Nb,余量为杂质。

在Gleeble-3500型热模拟机上进行热压缩实验,试样尺寸直径8 mm×12 mm。实验的变形温度是1063、1093、1123、1153、1183和1213 K,应变速率是0.001、0.01、0.1、1、10 s-1,合金的压下率是70%,相对应的最大真应变为1.2。

2 结果与讨论

2.1 传统的应变补偿物理基本构方程

采用的是一种综合考虑弹性模量(E)和材料自扩散系数(D)的物理基本构方程,该本构方程的表达式如下[12-13]:

(1)

(1)

(2)

(2)

(3)

(3)

式中: 为应变速率,s-1;B和

为应变速率,s-1;B和 是材料常数;

是材料常数; 为流变应力,MPa;D(T)和E(T)分别为材料自扩散系数和弹性模量与温度之间的关系;E0和G0分别表示材料在温度为300 K时的弹性模量和剪切模量值,MPa;T和Tm分别表示变形温度和材料的熔点,K;D0表示扩散常数;Qsd表示自扩散激活能,J/mol;R为摩尔气体常数,取8.314 J/(mol·K)。

为流变应力,MPa;D(T)和E(T)分别为材料自扩散系数和弹性模量与温度之间的关系;E0和G0分别表示材料在温度为300 K时的弹性模量和剪切模量值,MPa;T和Tm分别表示变形温度和材料的熔点,K;D0表示扩散常数;Qsd表示自扩散激活能,J/mol;R为摩尔气体常数,取8.314 J/(mol·K)。

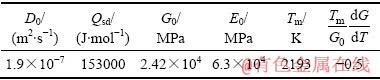

对上述表达式进行综合分析可知,获得式(2)和式(3)中的材料参数是构建此物理基本构模型的关键所在。由Ti-Nb二元相图分析可知,在实验变形温度范围内Ti-Nb合金组织状态为β相。因而由文献[14-15]可查出Ti-Nb合金的相关材料参数,整理结果如表1所列。

因此,把表1中相对应的材料参数分别代入式(2)和式(3)中,即可得Ti-Nb合金的弹性模量(E)和材料自扩散系数(D)两者与温度之间的关系式如下:

(4)

(4)

(5)

(5)

由式(1)再结合式(4)和式(5)分析可知,就只剩下B和 两个材料参数为未知量。先采用稳态应力为例来求解B和

两个材料参数为未知量。先采用稳态应力为例来求解B和 。在此之前先提出两个新的表达式,即:

。在此之前先提出两个新的表达式,即:

(6)

(6)

(7)

(7)

式中:B1、B2、n1和β均为材料常数。

由MIRZADEH等[16]提出的一种方法可求出 的值,即

的值,即 =β/n1。由式(6)和式(7)可知,β和n1的值可分别通过求

=β/n1。由式(6)和式(7)可知,β和n1的值可分别通过求 和

和

的拟合直线的斜率得到,如图1所示。由此可得稳态应力时

的拟合直线的斜率得到,如图1所示。由此可得稳态应力时 =507.3363。

=507.3363。

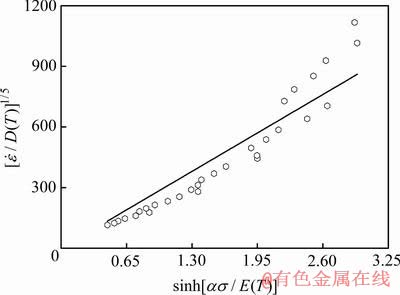

根据式(1),对 拟合出截距为0的直线(y=kx+0)来获得斜率,即可得到B1/5=292.6159,进而可知B=2.14531×1012,如图2所示。

拟合出截距为0的直线(y=kx+0)来获得斜率,即可得到B1/5=292.6159,进而可知B=2.14531×1012,如图2所示。

因此,稳态应力时Ti-Nb合金的物理基表达式为:

(8)

(8)

表1 Ti-Nb合金的相关材料参数[14-15]

Table 1 Related material data of Ti-Nb alloy[14-15]

图1  与

与 、

、 之间的关系

之间的关系

Fig. 1 Relationship among  and

and ,

,

图2  与

与 之间的关系

之间的关系

Fig. 2 Relationship curve between  and

and

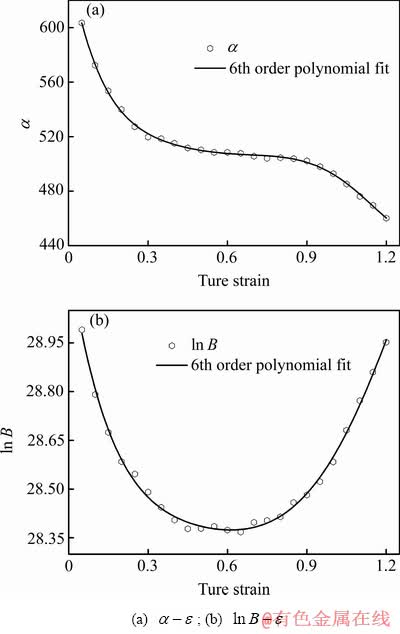

式(8)只考虑了稳态应力,并未充分考虑不同应变下的应力情况。因此,为了使所建立的物理基本构模型适用于所有应变时的情况,需充分考虑应变对 和

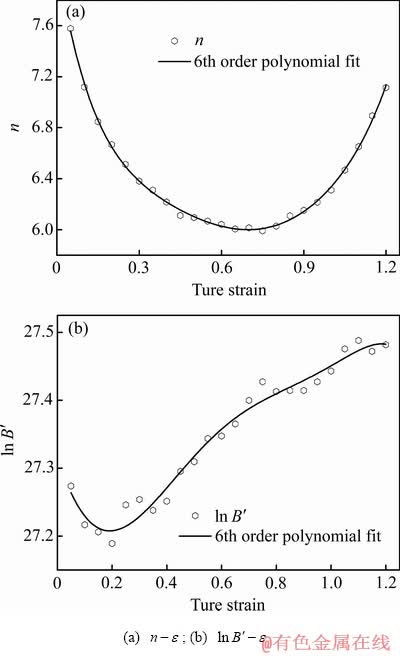

和 值的影响。按照上述方法分别求出应变在0.05~1.2范围内且应变间隔0.05时材料常数β、n1和B1/5的值,进而可知

值的影响。按照上述方法分别求出应变在0.05~1.2范围内且应变间隔0.05时材料常数β、n1和B1/5的值,进而可知 和

和 值。再通过SPSS软件对所求出的

值。再通过SPSS软件对所求出的 和

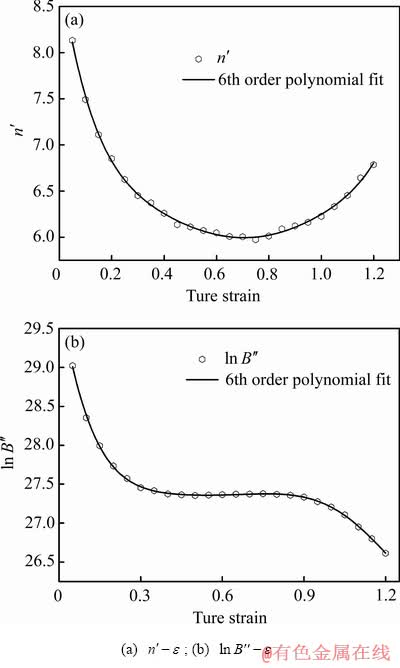

和 值进行2~10次的多项式回归分析,结果显示6次多项式的回归精度最好,如图3所示。因此,决定用6次多项式来表示应变与

值进行2~10次的多项式回归分析,结果显示6次多项式的回归精度最好,如图3所示。因此,决定用6次多项式来表示应变与 和

和 值之间的关系,关系式分别为式(9)和式(10),相对应的系数见表2。

值之间的关系,关系式分别为式(9)和式(10),相对应的系数见表2。

(9)

(9)

(10)

(10)

因此,考虑应变补偿对 和

和 影响的传统物理基本构模型的表达式为:

影响的传统物理基本构模型的表达式为:

(11)

(11)

2.2 修正的应变补偿物理基本构方程

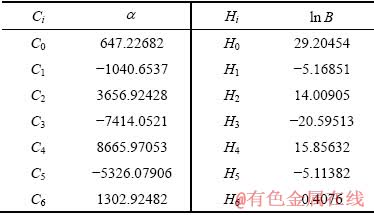

MIRZADEH等研究发现,式(1)中的指数固定为5时会降低该物理基本构模型的预测能力,因而他进一步提出一种方法进行修正可提高预测精度,即把指数定值5看成变量n,新表达式如下[12, 17-18]:

(12)

(12)

式(12)与式(1)中的 相同,即稳态应力下

相同,即稳态应力下 = 507.3363。通过

= 507.3363。通过 -

- 的拟合直线的斜率和截距可分别得到n和

的拟合直线的斜率和截距可分别得到n和 ,如图4所示。最终的拟合结果为

,如图4所示。最终的拟合结果为 =27.3691和n=6.048。文献[12, 19]中对AISI钢、C-Mn钢和C-Mn-V钢所求出来的n值分别为4.9、4.74922和4.73425,全都小于且接近于5,但是本文中所求出来的n值远大于5。这可能归因于在较低变形温度下沉淀物对位错运动的钉扎和抑制作用[20];还可能是由于在较高的应变速率下,变形机制对晶界和空位等缺陷更敏感,这也会阻碍位错运动,

=27.3691和n=6.048。文献[12, 19]中对AISI钢、C-Mn钢和C-Mn-V钢所求出来的n值分别为4.9、4.74922和4.73425,全都小于且接近于5,但是本文中所求出来的n值远大于5。这可能归因于在较低变形温度下沉淀物对位错运动的钉扎和抑制作用[20];还可能是由于在较高的应变速率下,变形机制对晶界和空位等缺陷更敏感,这也会阻碍位错运动,

图3 材料常数 、

、 与

与 的六次多项式拟合关系

的六次多项式拟合关系

Fig. 3 Relationships between  ,

,  and

and  by polynomial fit

by polynomial fit

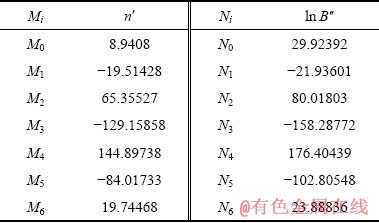

表2 式(9)和式(10)的系数

Table 2 Values of coefficients in Eq. (9) and Eq. (10)

图4  与

与 之间的关系

之间的关系

Fig. 4 Relationship between  and

and

从而导致蠕变指数n的增加[21]。

因此,稳态应力时修正的Ti-Nb合金的物理基表达式为

(13)

(13)

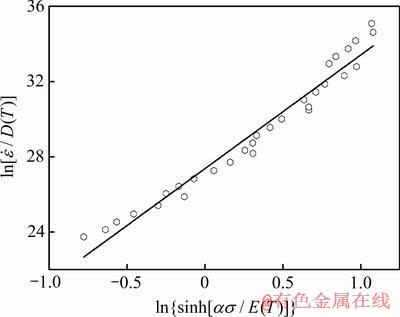

仍然考虑应变对材料常数的影响,即采用前面叙述的方法分别求出应变在0.05~1.2范围内且应变间隔0.05时材料常数 、

、 和n。材料常数

和n。材料常数 与应变之间的关系(见式(9)),相应的系数见表2。依旧采用6次多项式来表示应变与材料常数n和

与应变之间的关系(见式(9)),相应的系数见表2。依旧采用6次多项式来表示应变与材料常数n和 之间的关系,如图5所示;关系式分别为式(14)和式(15)所示,相对应的系数见表3。

之间的关系,如图5所示;关系式分别为式(14)和式(15)所示,相对应的系数见表3。

(14)

(14)

(15)

(15)

因此,适用于所有应变下修正的应变补偿的物理基本构模型的表达式为

(16)

(16)

2.3 简化的应变补偿物理基本构方程

图5 材料常数n、 与

与 的六次多项式拟合关系

的六次多项式拟合关系

Fig. 5 Relationships among n,  and

and  by polynomial fit

by polynomial fit

表3 式(14)和式(15)的系数

Table 3 Values of the coefficients in Eq. (14) and Eq. (15)

由2.1节可知,求解 值的过程较繁琐,需先计算出材料常数β和n1。但可用稳态应力时的

值的过程较繁琐,需先计算出材料常数β和n1。但可用稳态应力时的 值来替代不同应变下

值来替代不同应变下 值的方法来解决这个问题,即由2.1节可知,简化的本构方程中

值的方法来解决这个问题,即由2.1节可知,简化的本构方程中 =507.3363。因此,适用于所有应变下简化的应变补偿物理基本构模型的表达式为

=507.3363。因此,适用于所有应变下简化的应变补偿物理基本构模型的表达式为

(17)

(17)

因此,在简化的应变补偿物理基本构方程中就只需求出不同应变下的 和

和 值,即简化了该物理基本构方程的求解过程,并进一步提升了建立本构模型的效率。采用2.2节中讲述的方法分别求出应变在0.05~1.2范围内且应变间隔0.05时材料常数

值,即简化了该物理基本构方程的求解过程,并进一步提升了建立本构模型的效率。采用2.2节中讲述的方法分别求出应变在0.05~1.2范围内且应变间隔0.05时材料常数 和

和 。仍然通过6次多项式来表示应变与材料常数

。仍然通过6次多项式来表示应变与材料常数 和

和 之间的关系,如图6所示,表达式分别为式(18)和式(19),相对应的系数见表4。

之间的关系,如图6所示,表达式分别为式(18)和式(19),相对应的系数见表4。

(18)

(18)

图6 材料常数 、

、 与

与 的六次多项式拟合关系

的六次多项式拟合关系

Fig. 6 Relationships among  ,

,  and

and  by polynomial fit

by polynomial fit

表4 式(18)和式(19)的系数

Table 4 Values of coefficients in Eq. (18) and Eq. (19)

(19)

(19)

2.4 物理基本构模型的验证

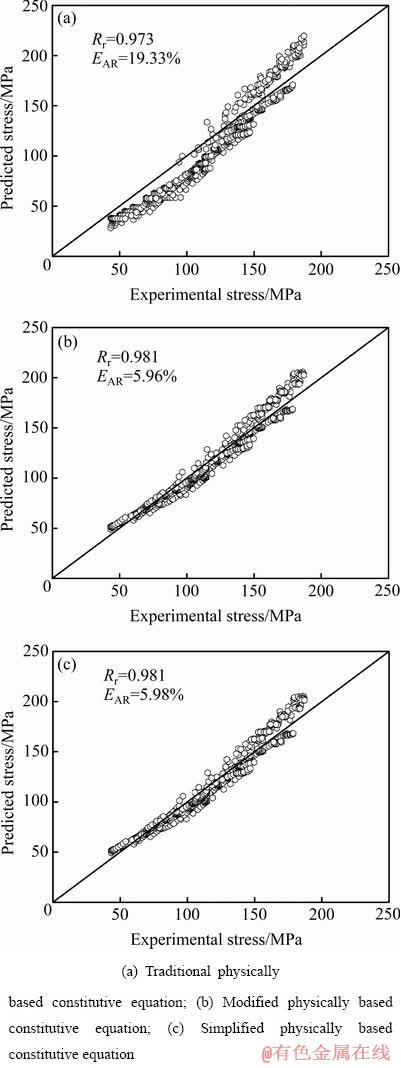

为了验证所建本构模型的精度,将上述三种本构方程所预测的应力值与实验应力值进行对比分析,如图7所示。从图7中整体上来看,修正的和简化的物理基本构模型的预测能力几乎一致,且都较优异,但传统的物理基本构模型的预测精度较差。

在应变速率较高(10 s-1)时,所有的预测应力值明显都高于实验应力值且两者之间的差值,特别是传统的物理基本构模型,会随着应变的增加而变大,也会随着温度的升高而减小。在应变速率较低(1~0.001 s-1)时,实验应力值要高于传统的物理基本构模型所预测的应力值,但与修正的和简化的物理基本构模型所预测的应力值大体上较为吻合。这是由于传统的物理基本构模型中的蠕变系数为5,此时表示材料的变形机制只有滑移和攀移,因而软化过程只能发生动态回 复[20]。但是计算得出实际的蠕变系数n值要远大于5,说明在本文的实验条件下塑性变形过程中Ti-Nb合金的变形机制除了位错的滑移和攀移之外还有其他变形机制。根据文献[22],Ti-Nb基合金在塑性变形过程中会发生机械孪晶变形,这种变形机制可以阻碍位错运动,从而增强加工硬化效果,进而导致蠕变系数n增大。此外,Ti-Nb合金的变形时间会随着应变速率的增加而缩短,进而导致动态回复进行的不彻底,从而加剧了位错之间的缠结和交割,因此位错运动较难进行,也会造成蠕变系数n增大[23]。因此,在传统本构模型的基础上经过修正和简化的本构模型的精度明显提高。

引用平均相对误差(Ear)和相关系数(Rr)来进一步评估所建立的三个物理基本构模型的精度,表达式如下:

(20)

(20)

(21)

(21)

式中:P为预测值;C为实验值; 和

和 分别为P和C的平均值;N为数据总数。

分别为P和C的平均值;N为数据总数。

图7 在不同条件下Ti-Nb合金的实验应力值与预测应力值对比

Fig.7 Comparisons between predicted and experimental flow stress of Ti-Nb alloy under different deformation conditions

用式(20)和式(21)分别计算出所建立的三个物理基本构模型的Ear、Rr值,结果如图8所示。从图8(a)整体上看,传统物理基本构模型所预测的应力数据点与直线比较接近;从图8(b)和(c)总体上看,修正的和简化的物理基本构模型所预测的应力数据点与直线非常靠近。从图8中可知,传统的、修正的和简化的物理基本构模型的Rr、Ear值分别为0.973、19.33%,0.981、5.96%和0.981、5.98%。由此可得,与传统的物理基本构模型相比,修正的和简化的物理基本构模型的精度明显要高不少。

综上可得,由于传统物理基本构模型只考虑了位错的滑移和攀移,导致其预测能力并不理想;经过修正和简化的物理基本构模型综合考虑了其他变形机制的影响,故其预测能力较优异。简化的物理基本构模型比修正的物理基本构模型的建立过程更为简单、高效,且两者之间的预测能力几乎一致,因此在工程应用中可优先采用简化的物理基本构模型来预测材料的应力值。总体来说,该物理基本构模型非常高效和简单且兼具物理和冶金意义,为预测流动应力提供了一种可供选择的方法。

图8 不同本构模型的预测应力值与实验应力值之间的相关性

Fig. 8 Correlation between experimental and predicted stress by different constitutive equations

3 结论

1) 建立了传统的应变补偿物理基本构模型,表达式为 。该模型的平均相对误差为19.33%,相关系数为0.973。

。该模型的平均相对误差为19.33%,相关系数为0.973。

2) 在传统的应变补偿物理基本构模型的基础上进行了模型修正,即用变量n替换了指数常量5。该修正的应变补偿物理基本构模型的表达式为 。该模型的平均相对误差为5.96%,相关系数为0.981。

。该模型的平均相对误差为5.96%,相关系数为0.981。

3) 对修正的应变补偿物理基本构模型进行了简化处理,即 值统一用稳态应力下

值统一用稳态应力下 =507.3363 来代替。该简化的应变补偿物理基本构模型的表达式为

=507.3363 来代替。该简化的应变补偿物理基本构模型的表达式为 。该模型的平均相对误差为5.98%,相关系数为0.981。

。该模型的平均相对误差为5.98%,相关系数为0.981。

4) 传统物理基本构模型由于只考虑了位错的滑移和攀移,导致其预测能力并不理想;然而经过修正和简化的物理基本构模型综合考虑了其他变形机制的影响,其预测能力较优异。简化的物理基本构模型构建过程更为简单且预测精度较高,因此在工程应用中可优先采用简化的物理基本构模型来预测材料的流动应力。

REFERENCES

[1] 武晓峰, 杨会齐, 王春雨. Mn对生物医用Ti-Mo合金组织与力学性能的影响[J]. 中国有色金属学报, 2017, 27(9): 1902-1908.

WU Xiao-feng, YANG Hui-qi, WANG Chun-yu. Effect of manganese addition on microstructure and mechanical properties of Ti-Mo Biomedical alloys[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(9): 1902-1908.

[2] 王 松, 廖振华, 刘伟强. 医用钛合金热氧化处理工艺及其耐磨损、耐腐蚀性能和生物活性的研究进展[J]. 中国有色金属学报, 2015, 24(6): 1466-1473.

WANG Song, LIAO Zhen-hua, LIU Wei-qiang. Research progress on thermal oxidation process and wear, corrosion resistance and bioactivity of biomedical grade titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 24(6): 1466-1473.

[3] WANG Qian, HAN Chang-jun, CHOMA T, WEI Qing-song, YAN Chun-ze, SONG Bo, SHI Yu-sheng. Effect of Nb content on microstructure, property and in vitro apatite-forming capability of Ti-Nb alloys fabricated via selective laser melting[J]. Materials and Design, 2017, 126: 268–277.

[4] GU Yuan-yu, FAN Fu-jun, GUO Yan-hua, XU Guang-long, CHANG Hui, ZHOU Lian, CUI Yu-wen. Diffusion and atomic mobility of BCC Ti-Al-Nb alloys: Experimental determination and computational modeling[J]. Calphad, 2018, 62: 83–91.

[5] 郭爱红, 余 巍, 张永强, 朱雨生. 医用β-Ti30Nb13Zr- 0.5Fe合金的热变形行为[J]. 中国有色金属学报, 2010, 20(S1): s357-s364.

GUO Ai-hong, YUE Wei, ZHANG Yong-qiang, ZHU Yu-sheng. Hot deformation behaviors of biomedical β-Ti30Nb13Zr0.5Fe alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s357-s364.

[6] 朱康平, 祝建雯, 曲恒磊. 国外生物医用钛合金的发展现状[J]. 稀有金属材料与工程, 2012, 41(11): 2058-2063.

ZHU Kang-ping, ZHU Jian-wen, QU Heng-lei. Development and application of biomedical Ti alloys abroad[J]. Rare Metal Materials and Engineering, 2012, 41(11): 2058-2063.

[7] 张鑫明, 李 强, 朱胜利, 崔振铎, 杨贤金. 生物医用Ti-Nb基合金的研究进展[J]. 材料导报, 2012, 26(3): 96-100.

ZHANG Xin-ming, LI Qiang, ZHU Sheng-li, CUI Zhen-duo, YANG Xian-jin. Research developments of bio-medical Ti-Nb based alloys[J]. Materials Review, 2012, 26(3): 96-100.

[8] CHANG L L, WANG Y D, REN Y. In-situ investigation of stress-induced martensitic transformation in Ti-Nb binary alloys with low Young’s modulus[J]. Materials Science and Engineering A, 2016, 651: 442-448.

[9] LAI M J, TASAN C C, ZHANG J, GRABOWSKI B, HUANG L F, RAABE D. Origin of shear induced β to ω transition in Ti-Nb-based alloys[J]. Acta Materialia, 2015, 92: 55-63.

[10] ZHANG D C, MAO Y F, LI Y L, LI J J, YUAN M, LIN J G. Effect of ternary alloying elements on microstructure and superelastictity of Ti-Nb alloys[J]. Materials Science and Engineering A, 2013, 559: 706-710.

[11] 姚 强, 邢 辉, 郭文渊, 孙 坚. Ti-Nb合金β结构稳定性和弹性性质[J]. 中国有色金属学报, 2008, 18(1): 126-131.

YAO Qiang, XING Hui, GUO Wen-yuan, SUN Jian. β phase stability and elastic property of Ti-Nb alloys[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(1): 126-131.

[12] MIRZADEH H. Constitutive modeling and prediction of hot deformation flow stress under dynamic recrystallization conditions[J]. Mechanics of Materials, 2015, 85: 66-79.

[13] MIRZADEH H, CABRERA J M, NAJAFIZADEH A. Constitutive relationships for hot deformation of austenite[J]. Acta Materialia, 2011, 59 (16): 6441-6448.

[14] FROST H J, ASHBY M F. Deformation-mechanism maps: The plasticity and creep of metals and ceramics[M]. Oxford: Pergamon Press, 1982.

[15] 王本力. 医用Ti-Nb基记忆合金的显微组织与性能[D]. 哈尔滨: 哈尔滨工业大学, 2009.

WANG Ben-li. Microstructure and properties of biomedical Ti-Nb based shape memory alloys[D]. Harbin: Harbin Institute of Technology, 2009.

[16] MIRZADEH H, CABRERA J M, NAJAFIZADEH A. Constitutive relationships for hot deformation of austenite[J]. Acta Materialia, 2011, 59 (16): 6441-6448.

[17] MIRZADEH H. A comparative study on the hot flow stress of Mg-Al-Zn magnesium alloys using a simple physically- based approach[J]. Journal of Magnesium and Alloys, 2014, 2(3): 225-229.

[18] MIRZADEH H. Constitutive description of 7075 aluminum alloy during hot deformation by apparent and physically- based approaches[J]. Journal of Materials Engineering and Performance, 2015, 24(3): 1095-1099.

[19] WEI Hai-lian, LIU Guo-quan, ZHANG Ming-he. Physically based constitutive analysis to predict flow stress of medium carbon and vanadium microalloyed steels[J]. Materials Science and Engineering A, 2014, 602: 127-133.

[20] WANG S, LUO J R, HOU L G, ZHANG J S, ZHUANG L Z. Physically based constitutive analysis and microstructural evolution of AA7050 aluminum alloy during hot compression[J]. Materials and Design, 2016, 107: 277-289.

[21] CABRERA J M, JONAS J J, PRADO J M. Flow behaviour of medium carbon microalloyed steel under hot working conditions[J]. Materials Science and Technology, 1996, 12(7): 579-585.

[22] SHIN S, ZHANG Cheng, VECCHIO K S. Phase stability dependence of deformation mode correlated mechanical properties and elastic properties in Ti-Nb gum metal[J]. Materials Science and Engineering A, 2017, 702: 173-183.

[23] WANG S, HOU L G, LUO J R, ZHANG J S,ZHUANG L Z. Characterization of hot workability in AA 7050 aluminum alloy using activation energy and 3-D processing map[J]. Journal of Materials Processing Technology, 2015, 225: 110-121.

Physically-based constitutive model of Ti-Nb alloy

LIU Jian-jun1, WANG Ke-lu1, LU Shi-qiang1, LI Xin1, OUYANG De-lai2, CHENG Jing1

(1. School of Aerospace Manufacturing Engineering, Nanchang Hang Kong University, Nanchang 330063, China;

2. School of Materials Science and Engineering, Nanchang Hang Kong University, Nanchang 330063, China)

Abstract: The flow stress curves of Ti-Nb alloy were acquired by hot compressive tests on Gleeble-3500 thermo-simulation machine at the strain rate range of 0.001-10 s-1 and temperature range of 1063-1213 K. Traditional strain compensation constitutive model of Ti-Nb alloy was firstly established by the physically-based equation of elastic modulus (E) and material self-diffusion coefficient (D), and then modified it to improve the predicted ability of flow stress, finally simplified the modified constitutive model to improve the efficiency of building the physically-based constitutive model. The results show that traditional constitutive model does not have good predicted ability, and the prediction abilities of modified and simplified constitutive models are quite excellent and almost identical.

Key words: Ti-Nb alloy; constitutive relationships; hot deformation

Foundation item: Project(51761029) supported by the National Natural Science Foundation of China; Project (YC2018011) supported by the Special Fund of Postgraduate Innovation of Nanchang Hang Kong University, China

Received date: 2019-05-10; Accepted date: 2019-11-20

Corresponding author: WANG Ke-lu; Tel: +86-791-83863039; E-mail: wangkelu@126.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51761029);南昌航空大学研究生创新专项基金资助项目(YC2018011)

收稿日期:2019-05-10;修订日期:2019-11-20

通信作者:王克鲁,教授,博士;电话:0791-83863039;E-mail:wangkelu@126.com