DOI:10.19476/j.ysxb.1004.0609.2019.02.08

脉冲超声工艺对ZL205A合金微观组织及偏析的影响

严青松,芦 刚,王 清,段勇标

(南昌航空大学 轻合金加工科学与技术国防重点学科实验室,南昌 330063)

摘 要:通过测试与分析不同脉冲超声功率、施振时间、脉冲超声频率下ZL205A合金微观组织及Cu元素含量,系统研究脉冲超声工艺对ZL205A合金微观组织及偏析的影响。结果表明:脉冲超声工艺对ZL205A合金微观组织及偏析影响的显著。随着的脉冲超声功率、施振时间、脉冲超声频率增大,ZL205A合金的组织越来越细小且圆整,随后ZL205A合金的组织又逐渐粗大且不规则。最佳脉冲超声工艺为脉冲超声功率1200 W、施振时间120 s、脉冲超声频率1.67 Hz。脉冲超声工艺改变Cu元素在a (Al)中的分布曲线,在一定范围内提高Cu元素的有效分配系数ke,对脉冲超声功率与施振时间影响较大,改变Cu元素在凝固过程中溶质再分配行为,改善ZL205A合金微观偏析。

关键词:脉冲超声;ZL205A合金;微观组织;微观偏析

文章编号:1004-0609(2019)-02-0279-07 中图分类号:TG249.2 文献标志码:A

ZL205A合金强度高,综合性能优异,在航空航天领域应用广泛。但由于ZL205A合金结晶温度区间宽,铸造性能较差,易产生缩松、偏析等铸造缺陷[1-3]。微观偏析是枝晶尺度溶质原子的非均匀分布,是合金凝固过程中不可避免的现象,对铸件的后续加工和最终服役性能有重要的影响,控制和改善微观偏析一直是凝固科学的热点。凝固过程中溶质原子的再分配受熔体流动的影响,对糊状区内的熔体施加有效搅拌,如机械搅拌、电磁搅拌、超声振动等,可达到控制合金组织及微观偏析的目的[4-6]。机械搅拌时搅拌叶片与金属熔体直接接触,工艺参数容易控制,可以获得较高的剪切速率,但是搅拌槽内部往往存在搅拌不到的死区,影响均匀性,对金属熔体质量也带来不利的影响。电磁搅拌属于非接触式搅拌技术,利用电磁感应力将初生的枝晶破碎,其特点是金属液纯净,适用于高熔点合金和大批量生产。但由于感应电磁力从熔池边界到熔体中心逐渐衰减,当熔融金属四周有凝固外壳形成时搅拌效果大大减弱。超声振动会使金属熔体中产生强烈的空化、声流、热效应等超声效应,其搅拌作用相比机械搅拌、电磁搅拌对金属熔体影响更有优势,也一直是学者研究的热点。

早在20世纪30年代,各国学者就开始从事超声振动在金属凝固领域的研究工作。ESKIN[7]采用超声波对铝合金的凝固过程进行了较为深入的研究,试验结果表明超声产生的空化效应有利于形核增殖,导致晶粒细化,铝合金经过超声处理后,拉伸强度可以提高6%~10%。同时,认为超声空化处理是熔化和凝固过程中控制合金的质量、结构和特性的一种有效的方式。LEBON等[8]和TZANAKIS等[9]对铝熔体超声处理进行了系统研究,提出了超声毛细效应,并进行了观测与分析,并认为超声空化强度主要受超声源距离、熔体温度和输入功率的影响。HAGHAYEGHI等[10]研究了电磁超声场作用下铝合金组织演变,认为空化现象发生在电磁和超声波源的附近,超声所产生的声流比电磁波更为密集,电磁与超声作用产生的声学振动是导致铝合金晶粒细化的主要原因。JIANG等[11]研究了超声振动下铝合金凝固的晶粒细化机理,认为施加超声场可以改善温度场分布的均匀性,并且能够明显加快熔体的整体凝固进程,超声振动下铝合金的晶粒细化主要归功于超声空化促成的形核增殖与谐振效应抑制了晶体生长。脉冲超声是将超声波以脉冲的形式发出,相比连续超声波,在相同的平均输出功率下,它的脉冲峰值功率更大,具有更高的能量,因此可能进一步改善金属熔体的性能。李健[12]研究了脉冲超声对铝合金组织的影响,发现在一定功率范围内,随着施振功率的增大,组织更加细化,铸件的性能得到提高。而且,在平均输出功率相同的情况下,脉冲波对铝合金晶粒细化效果优于连续波的。黎正华等[13]研究了超声作用下半连铸7050铝合金的偏析行为及形成机制,认为随着超声功率的增加,晶粒细化程度及宏观偏析的弱化效果更好,铝合金熔体偏析弱化的主要原因是由于形核率增加,晶粒细化,两相区液固相相对运动速度减小。

目前,国内外专家对超声振动在凝固条件下合金熔体组织及性能进行了大量的研究,得到了很多有价值的结论,但对超声振动,特别是脉冲超声对合金微观偏析影响的报导仍较少。本文以ZL205A合金为研究对象,采用脉冲超声进行施振实验,研究脉冲超声工艺对ZL205A合金微观组织和Cu元素成分曲线的影响,获得脉冲超声工艺对ZL205A合金微观组织及偏析的影响规律,为脉冲超声在铝合金熔体中的应用奠定理论和技术基础。

1 实验

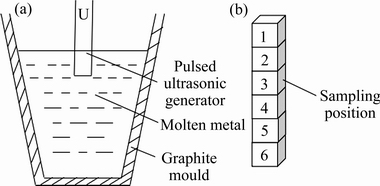

实验材料为 ZL205A合金,其成分如表1所列。铸型采用石墨型,内腔尺寸为d 88 mm×120 mm,铸型预热温度为300℃。在电阻炉中熔炼ZL205A合金精炼处理后,温度达到720 ℃左右浇注到石墨铸型中,采用TJS-3000超声波发生器施加脉冲超声,脉冲超声工具头浸入液面20 mm,脉冲超声施振示意图及取样部位如图1所示,分别采用不同的脉冲超声功率、脉冲超声时间、脉冲超声频率处理铝合金熔体,脉冲超声工艺参数见表2所列。

脉冲超声处理后,ZL205A合金在铸型中完全冷却后在中心处取10 mm×10 mm×10 mm的试样,通过标准方法制样后用于金相观察和能谱分析。试样经过粗磨、精磨、抛光、腐蚀后利用XDJ-200型金相显微镜对试样进行显微组织观察并拍取金相图片,采用截线法和Image-Pro Plus金相分析软件对晶粒大小进行测量。根据文献[14-16]的采用的方法,利用EDS能谱分析测量样品中的Cu元素含量,并绘制成分曲线。测量方法为取样品中1400 μm×1400 μm的区域,在区域内打点测量Cu元素的含量,打点数目为10×10。为了获得固相率,把收集的数据按升序排列,将每个数值和其排序的序号相对应,则该数值对应的固相率为序号与总点数的比值,将数值最小的点作为凝固终止点(固相率fs=1)绘制成分曲线。

图1 脉冲超声施振示意图及取样部位

Fig. 1 Schematic images of pulsed ultrasonic applying vibration(a) and sampling position(b)

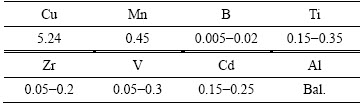

表1 ZL205A合金的主要化学成分

Table 1 Main chemical composition of ZL205A alloy (mass fraction, %)

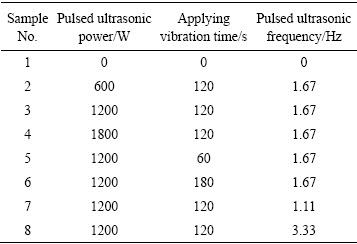

表2 脉冲超声工艺参数

Table 2 Pulsed ultrasonic technical parameters

2 结果及分析

2.1 脉冲超声工艺对ZL205A合金微观组织的影响

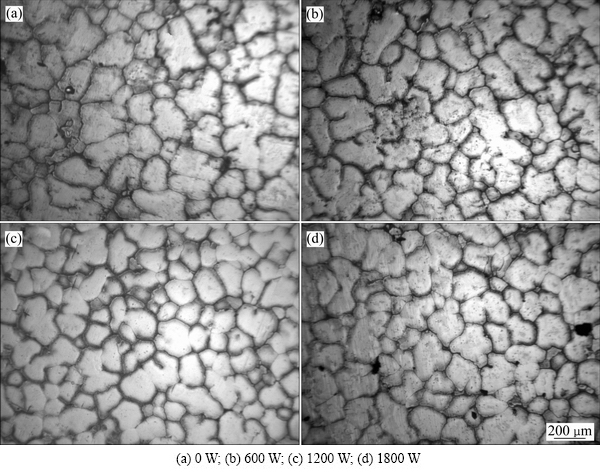

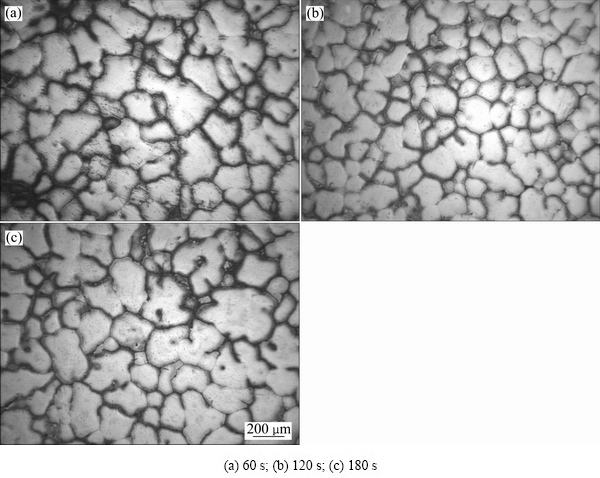

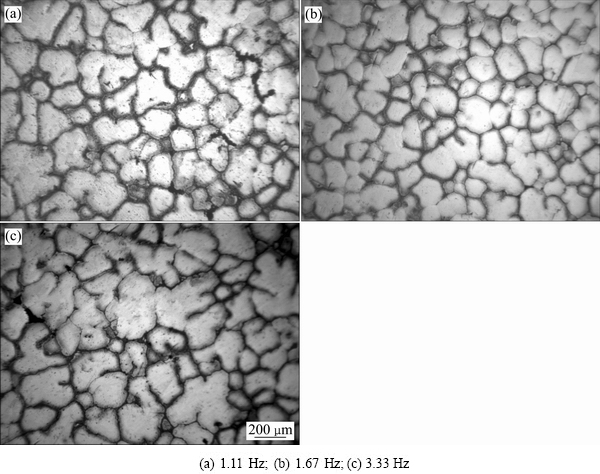

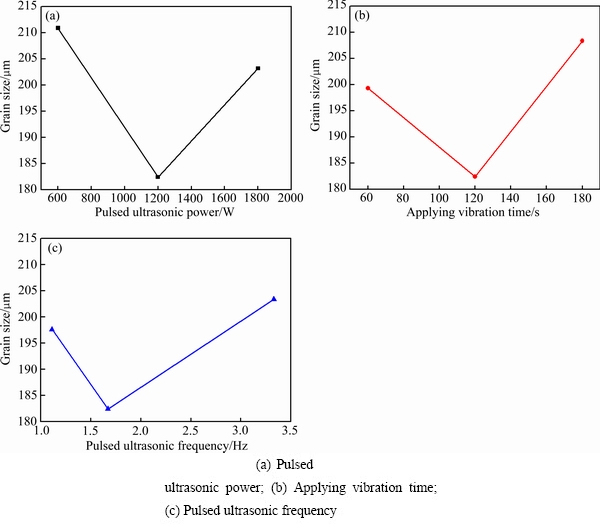

不同脉冲超声功率、施振时间、脉冲超声频率下ZL205A合金的微观组织与晶粒尺寸分别如图2~5所示。当不施加脉冲超声时(即脉冲超声功率为0 W时),ZL205A合金的组织呈现较为粗大的等轴晶晶粒尺寸为253.56 μm。脉冲超声是将超声波以脉冲的形式发出,在超声功率相同的情况下脉冲波的脉冲峰值功率要远大于连续波的峰值功率,同时脉冲波每点的声压幅值也大于连续波相应点处的声压幅值,而声压增大时声压梯度也将随之增大,那么声流搅拌冲击变得更为强烈。而且随着脉冲超声功率、施振时间、脉冲超声频率的增大,脉冲超声在熔体中的有效作用强度、时间、次数增加,ZL205A合金在凝固过程中受到空化效应、声流效应等特殊效应的影响也增大[17-18],游离晶数目增多,提高了合金的形核率,大量的晶核在长大过程中互相竞争、制约,从而使得ZL205A合金的组织越来越细小且圆整,当脉冲超声功率1200 W、施振时间120 s、脉冲超声频率1.67 Hz时,ZL205A合金的组织最细小、均匀且圆整,晶粒尺寸为182.43 μm。随着脉冲超声功率、施振时间、脉冲超声频率进一步增大,脉冲超声振动产生的热效应也会更加显 著[19-20],当热效应的影响大于空化等特殊超声效应时,就会延长晶粒的凝固时间,使得ZL205A合金的组织又逐渐粗大且不规则。因此,最佳脉冲超声工艺为脉冲超声功率1200 W、施振时间120 s、脉冲超声频率1.67 Hz。

图2 不同脉冲超声功率下ZL205A合金微观组织

Fig. 2 Microstructures of ZL205A alloy under different pulsed ultrasonic powers

图3 不同脉冲超声施振时间下ZL205A合金微观组织

Fig. 3 Microstructures of ZL205A alloy under different applying vibration time

图4 不同脉冲超声频率下ZL205A合金微观组织

Fig. 4 Microstructures of ZL205A alloy under different pulsed ultrasonic frequencies

图5 不同脉冲超声工艺下ZL205A合金晶粒尺寸

Fig. 5 Grain size of ZL205A alloy under different pulsed ultrasonic processes

2.2 脉冲超声工艺对ZL205A合金偏析的影响

ZL205A合金结晶温度区间较宽,以糊状方式凝固。当温度降至结晶温度时,开始逐渐形成由粗大的等轴晶相互连接的骨架。随着温度的降低,固态的骨架逐渐长大,液体被分割成一个个小熔池。按照溶质再分配的规律,铸件先凝固的区域溶质含量低,而后凝固的液相中溶质含量高。凝固末期溶质Cu元素富集,在548 ℃发生共晶反应形成Al2Cu共晶,形成的低熔点共晶偏析[21-22]。ZL205A偏析现象严重降低了合金化程度,对合金铸件的组织、力学性能、抗腐蚀性能、物理性能以及铸造工艺性能有极大的影响。

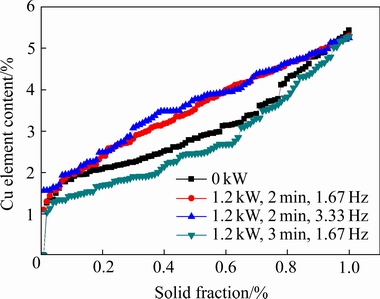

图6所示为不同脉冲工艺下Cu元素的成分曲线。从图6可以看出,Cu元素在ZL205A合金中的含量随着固相率的增大不断增加,成分曲线不断上升。在脉冲超声的作用下,脉冲超声功率与施振时间对Cu元素的分布影响较大,脉冲超声频率对Cu元素的分布影响较小。

图6 不同脉冲工艺下Cu元素的成分曲线

Fig. 6 Composition curves of Cu element under different pulsed ultrasonic processes

合金在凝固中的偏析可以用Scheil方程[23]表示,其表达式为

(1)

(1)

式中:Cs为固相溶质浓度;C0为合金成分;k0为溶质原子的平衡分配系数。

在实际凝固过程中,合金总是在非平衡凝固条件下进行凝固,需用有效分配系数k e代替式中的k 0,得到:

(2)

(2)

将上式转换成线性形式:

(3)

(3)

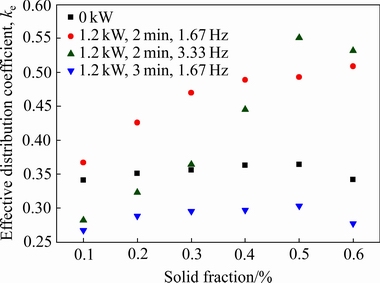

由式(3)可计算不同脉冲超声工艺下ZL205A合金凝固过程中Cu元素的k e,如图7所示。

图7 不同脉冲超声下Cu元素的有效分配系数k e

Fig. 7 Effective distribution coefficient ke of Cu element under different pulsed ultrasonic processes

在凝固后期(即fs>0.6),由于溶质元素在固/液界面前沿大量堆积,液相内溶质浓度上升,因此溶质分配不再用k e表示。由图7可知,当fs≤0.6时,随着固相率的增大,固相内的溶质浓度增大,k e值也在不断变化。在脉冲超声的作用下,脉冲超声功率与施振时间对k e值影响较大,脉冲超声频率对k e值影响较小。脉冲超声作用在一定范围内提高Cu元素的有效分配系数k e,固液界面前沿的富集溶质得到迅速扩散,Cu元素在微观范围内的分布更加均匀,改变了Cu元素在凝固过程中溶质再分配行为[6],改善ZL205A合金合金微观偏析。

3 结论

1) 脉冲超声工艺对ZL205A合金微观组织影响显著。随着脉冲超声功率、施振时间、脉冲超声频率的增大,ZL205A合金的组织越来越细小且圆整;进一步增大,ZL205A合金的组织又逐渐粗大且不规则。最佳脉冲超声工艺为脉冲超声功率1200 W、施振时间120 s、脉冲超声频率1.67 Hz。

2) 脉冲超声工艺改变了Cu元素在a (Al)中的分布曲线,在一定范围内提高Cu元素的有效分配系数k e,脉冲超声功率与施振时间影响较大,改变了Cu元素在凝固过程中溶质再分配行为,改善ZL205A合金微观偏析。

REFERENCES

[1] WANG Ye, WU Shi-ping, XUE Xiang, CHEN Rui-run, ZHANG Jian-bing, XIAO Wen-feng. Formation mechanism and criterion of linear segregation in ZL205A alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(11): 3632-3638.

[2] LI B, SHEN Y F, WEI Y. Casting defects induced fatigue damage in aircraft frames of ZL205A aluminum alloy: A failure analysis[J]. Materials and Design, 2011, 32: 2570-2582.

[3] FAN Xue-yi, WANG Liang, DU Zhi-qiang, SU Yan-qing, ZHANG Jian-bing, LUO Liang-shun, LIU Zu-chuan, XUDa-ming, GUO Jing-jie. Effect of excitation current intensity on mechanical properties of ZL205A castings solidified under a traveling magnetic field[J]. China Foundry, 2015, 12(3): 196-201.

[4] GUO Hong-min, ZHANG Ai-sheng, YANG Xiang-jie, YAN Ming-ming. Grain refinement of Al-5%Cu aluminum alloy under mechanical vibration using meltable vibrating probe[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(8): 2489-2496.

[5] 罗 执, 张 杨, 赵愈亮, 张卫文. 复合场作用下Al-5.0Cu-1.0Fe 合金的显微组织和力学性能[J]. 中国有色金属学报, 2016, 26(4): 707-714.

LUO Zhi, ZHANG Yang, ZHAO Yu-liang, ZHANG Wei-wen. Microstructure and mechanical property of Al-5.0Cu-1.0Fe alloy treated by compound field[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(4): 707-714

[6] 彭洪美, 李晓谦, 蒋日鹏. 熔体超声处理对7050铝合金铸锭微观偏析的影响[J]. 北京理工大学学报, 2016, 36(11): 1105-1110.

PENG Hong-mei, LI Xiao-qian, JIANG Ri-peng. Effect of ultrasonic treatment on ingot microsegregation of 7050 aluminum alloy[J]. Transactions of Beijing Institute of Technology, 2016, 36(11): 1105-1110.

[7] ESKIN G I. Improvement of the structure and properties of ingots and worked aluminum alloy semifinished products by melt ultrasonic treatment in a cavitation regime[J]. Metallurgist, 2010, 54(7): 505-513.

[8] LEBON G S B, ESKIN D G, PERICLEOUS K. Investigation of the factors influencing cavitation intensity during the ultrasonic treatment of molten aluminium[J]. Materials and Design, 2016, 90: 979-983.

[9] TZANAKIS I, XU W W, ESKIN D G, LEE P D, KOTSOVINOS N. In situ observation and analysis of ultrasonic capillary effect in molten aluminium[J]. Ultrasonics Sonochemistry, 2015, 27: 72-80.

[10] HAGHAYEGHI R, EZZATNESHAN E, BAHAI H. Experimental-numerical study of AA5754 microstructural evolution under electromagnetic ultrasonic merged fields[J]. Journal of Materials Processing Technology, 2015, 225: 103-109.

[11] JIANG R P, LI X Q, ZHANG M. Investigation on the mechanism of grain refinement in aluminum alloy solidified under ultrasonic vibration[J]. Metals and Materials International, 2015, 21(1): 104-108.

[12] 李 健. 超声波电源脉冲特性及其试验[D]. 长沙: 中南大学, 2010.

LI Jian. Pulse characteristics and experiment of ultrasonic wave power[D]. Changsha: Central South University, 2010.

[13] 黎正华, 李晓谦, 张 明. 超声作用下半连铸7050铝合金的偏析行为及形成机制[J]. 中国有色金属学报, 2011, 21(2): 318-324.

LI Zheng-hua, LI Xiao-qian, ZHANG Ming. Segregation behavior and formation mechanism of 7050 aluminum alloy produced by semi-continus casting under ultrasonic field[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(2): 318-324.

[14] GANESAN M, THUINET L, DYE D, LEE P D. Quantification of microsegregation in cast Al-Si-Cu alloys[J]. Metallurgical and Materials Transactions B, 2007, 38: 557-566.

[15] 钟 华, 李传军, 王 江, 任忠鸣, 钟云波, 玄伟东. 强磁场对定向凝固Al-4.5Cu合金微观偏析的影响[J].金属学报, 2016, 52(5): 575-582.

ZHONG Hua, LI Chuan-jun, WANG Jiang, REN Zhong-ming, ZHONG Yun-bo, XUAN Wei-dong. Effect of high static magnetic field on microsegregation of directionally solidified Al-4.5Cu alloy[J]. Acta Metallurgica Sinica, 2016, 52(5): 575-582.

[16] 陈丹丹, 张海涛, 王向杰, 崔建忠. 低频电磁铸造Al-4.5%Cu合金微观偏析研究[J]. 金属学报, 2011, 47(2): 185.

CHEN Dan-dan, ZHANG Hai-tao, WANG Xiang-jie, CUI Jian-zhong. Investigation on microsegregation of Al-4.5%Cu alloy produced by low frequency electromagnetic casting[J]. Acta Metallurgica Sinica, 2011, 47(2): 185.

[17] ESKIN G I, MAKAROV G S. Effect of cavitation melt treatment on the structure refinement and property improvement in cast and deformed hypereutectic Al-Si alloys[J]. Materials Science Forum, 1997, 242: 65-70

[18] 严青松, 芦 刚, 李 成, 沈加利. 超声功率-凝固压力协同作用对真空差压铸造铝合金二次枝晶间距的影响[J]. 中国有色金属学报, 2017, 27(1): 51-56.

YAN Qing-song, LU Gang, LI Cheng, SHEN Jia-li. Effect of synergistic action between ultrasonic power and solidification pressure on secondary dendrite arm spacing of vacuum counter-pressure casting aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(1): 51-56.

[19] HUANG Hai-jun, XU Yi-fan, SHU Da, HAN Yan-feng, WANG Jun, SUN Bao-de. Effect of ultrasonic melt treatment on structure refinement of solidified high purity aluminum[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2414-2419.

[20] 何 迁. 功率超声对铝及铝合金凝固过程的影响[D]. 北京: 清华大学, 2008.

HE Qian. Effect of power ultrasonic treatment on solidification process of pure aluminum and aluminum alloy[D]. Beijing: Tsinghua University, 2008.

[21] BENALI A, LACAZE-DUFAURE C, MORILLO J. Density functional study of copper segregation in aluminum[J]. Surface Science, 2011, 605(3): 341-350.

[22] LOKKER J P, BOTTGER A J, SLOOF W G, TICHELAAR F D, JANSSEN G C A M, RADELAAR S. Phase transformations in Al-Cu thin films: Precipitation and copper redistribution[J]. Acta Materialia, 2001, 49(8): 1339-1349.

[23] 戴斌煜, 王薇薇. 金属液态成形原理[M]. 北京: 国防工业出版社, 2010.

DAI Bin-yu, WANG Wei-wei. Liquid metal forming theory[M]. Beijing: National Defence Industry Press, 2010.

Effect of pulsed ultrasonic process on microstructure and microsegregation of ZL205A alloy

YAN Qing-song, LU Gang, WANG Qing, DUAN Yong-biao

(National Defence Key Disciplines Laboratory of Light Alloy Processing Science and Technology, Nanchang Hangkong University, Nanchang 330063, China)

Abstract: The effect of pulsed ultrasonic process on the microstructure and microsegregation of ZL205A alloy was studied systemically through testing and analyzing the microstructure and Cu element content under different pulsed ultrasonic powers, applying vibration time and pulsed ultrasonic frequency. The results indicate that the pulse ultrasonic process has significant effects on the microstructure and microsegregation of ZL205A alloy. With the increase of pulsed ultrasonic power, applying vibration time and pulsed ultrasonic frequency, the microstructures of ZL205A alloy become more and more fine and round, however, with further increasing, the microstructure turns rough and irregular. The optimal pulse ultrasonic process is pulsed ultrasonic power of 1200 W, applying vibration time of 120 s and pulsed ultrasonic frequency of 1.67 Hz. Meanwhile, the pulsed ultrasonic process has changed the distribution curve of Cu element in a(Al), and the effective distribution coefficient ke of Cu element is improved within a certain range, especially, the effects of the pulsed ultrasonic power and applying vibration time are significant, which change the behavior of Cu element solute redistribution in the process of solidification and improve the microsegregation of ZL205A alloy.

Key words: pulsed ultrasound; ZL205A alloy; microstructure; microsegregation

Foundation item: Project(51261025) supported by the National Natural Science Foundation of China; Project (SAST2016046) supported by the Aerospace Science and Technology Innovation Foundation of Shanghai, China

Received date: 2017-11-03; Accepted date: 2018-02-08

Corresponding author: YAN Qing-song; Tel: +86-791-83863787; E-mail: yanqs1973@136.com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51261025);上海航天科技创新基金资助项目(SAST2016046)

收稿日期:2017-11-03;修订日期:2018-02-08

通信作者:严青松,教授,博士;电话:0791-83863787;E-mail:yanqs1973@126.com