文章编号:1004-0609(2015)06-1648-07

化学气相沉积钨显微组织缺陷的形成与控制

沈艳波1,于晓东1, 2,谭成文1, 2,王富耻1,马红磊2,才鸿年1

(1. 北京理工大学 材料学院,北京 100081;

2. 中国航天员科研与训练中心,北京 100081)

摘 要:以WF6为前驱体,采用化学气相沉积法(CVD)在纯铜基体上沉积出钨涂层。利用光学显微镜(OM)和扫描电镜(SEM)分析研究钨制品组织缺陷的形成。结果表明:反应物浓度起伏对化学气相沉积钨的显微组织具有显著影响。当n(WF6):n(H2)≥1:3时,沉积物为柱状晶组织;当n(WF6):n(H2)<1:3时,该沉积层晶粒明显细化,显微组织为细晶层状结构。另外,沉积过程中杂质形状也显著影响沉积层的显微组织。当基体表面存在一维杂质时,沉积制品表面产生明显的凸起,严重影响制品的表面质量和显微组织的均匀性;当沉积过程中存在零维杂质时,沉积层出现放射状的组织结构。

关键词:WF6;钨;化学气相沉积;反应物浓度起伏;杂质形状;组织缺陷

中图分类号:TG146.4 文献标志码:A

Formation and control of microstructure defects of tungsten prepared by chemical vapor deposition method

SHEN Yan-bo1, YU Xiao-dong1, 2, TAN Cheng-wen1, 2, WANG Fu-chi1, MA Hong-lei2, CAI Hong-nian1

(1. School of Material Science and Engineering, Beijing Institute of Technology, Beijing 100081, China;

2. China Astronaut Research and Training Center, Beijing 100081, China)

Abstract: Tungsten coatings were deposited on pure copper substrates using WF6 as the precursor by chemical vapor deposition (CVD) method. The formation of the microstructure defects of the tungsten deposits was analyzed by OM and SEM. The results show that the reactant concentration fluctuation has a significant impact on the microstructure of tungsten prepared by CVD method. When n(WF6):n(H2)≥1:3, the microstructure of tungsten is columnar grain; when n(WF6):n(H2)<1:3, the grains of the deposited layer are refined and the microstructure presents a fine grains multilayer structure. Moreover, the shapes of the impurities can also influence significantly on microstructure of the layer. When there is one-dimensional impurity on the surface of substrate, the surface of deposition has obvious bulge, which seriously affects the deposits surface quality and microstructure uniformity; when there is zero dimensional impurity during the deposition process, the deposit appears radial structure.

Key words: WF6; tungsten; chemical vapor deposition; reactant concentration fluctuation; impurity shape; microstructure defect

钨是典型的难熔金属,具有高熔点(3410 ℃)、高密度(19.3 g/cm3)、高弹性模量(390~410 GPa)、优异的导电性能、良好的导热性和室温化学稳定性等。钨及其制品以其独特的性能广泛的应用于宇航、军工和微电子等现代科技领域[1-2]。

钨在超高温等恶劣环境的应用对其结构与性能提出了愈加严格的要求。采用传统的粉末冶金方法很难制备出满足此类特殊要求的钨制品[3-4]。而且粉末冶金的办法受到产品尺寸和形状的限制,无法制备薄壁、复杂形状的钨制品。化学气相沉积技术是制备高纯钨制品的重要方法。制备过程中通常使用的前驱体为W(CO)6、WCl6和WF6等。研究人员[5-7]以W(CO)6为前驱体,采用CVD的方法分别在Cu基体和Si基体表面成功沉积出均匀致密的钨薄膜,但是由于W(CO)6在热解过程中C—O键的断裂造成了C、O的夹杂。AMMERLAAN等[8]以WCl6为前驱体,采用冷壁CVD的方式,在压强为5.3 kPa、温度为480~670 ℃时,成功在Si基体表面制备出钨薄膜,但是薄膜均匀性较差、实验可重复性不好。

采用WF6沉积时,由于WF6沸点低(17.5 ℃),在其蒸发阶段就能除去大部分伴生杂质,此外,氢还原的温度也很低,这种方法的金属还原阶段也具有相当大的选择性,具有很大的提纯作用,易制得纯度大于99.99 %的致密钨[9-10]。因此,目前大量研究者致力于以WF6为前驱体的化学气相沉积钨的研究。

难熔金属氟化物氢还原气相沉积时,可能得到5种类型的沉积结构:枝状晶结构、柱状晶结构、细晶结构、层状结构、多孔结构。当过程的控制阶段有中间氟化物的生成时,则会成柱状晶结构,这是一种优良的致密沉积结构[11],而目前研究最为广泛的正是柱状晶结构。

近十几年,国内也有少量的单位利用此CVD方法制备纯钨材料。北京理工大学的研究人员[12-13]采用冷壁沉积的方式,以H2和WF6为原料在纯铜基体上沉积出纯度为99.99 %,抗压强度为1480 MPa的多晶钨材料。该高纯钨具有柱状晶结构,并且沿着生长方向整体呈现标准的三晶区特点。目前,此类材料已经广泛应用于核工业、航天、电子以及兵器工业领域,北京理工大学成为国内仅有的能够批量提供此类材料的机构。采用同样的原理,北京工业大学的研究人员[14-16]以WF6为前驱体制备出高纯度的多晶钨涂层,研究发现:随沉积温度的升高,化学气相沉积钨的速率加快,涂层柱状晶生长取向趋于杂乱,表面形貌发生明显变化,并且在化学气相沉积钨的过程中,通过在基体上周期性地缠绕钨丝而形成的钨晶粒得到了细化,择优取向基本消失,压溃强度也得到了显著提高。

综上所述,国内外对于CVD制备钨涂层的工艺、组织、结构及性能方面已经进行大量的研究。组织缺陷对于涂层的性能具有较大的影响,但在组织缺陷方面的分析还比较少。因此,本文作者开展了钨制品组织缺陷的形成与控制的相关研究工作,本研究对制备高性能钨制品、拓展此类材料的应用领域以及进一步批量稳定生产等具有重要的意义。

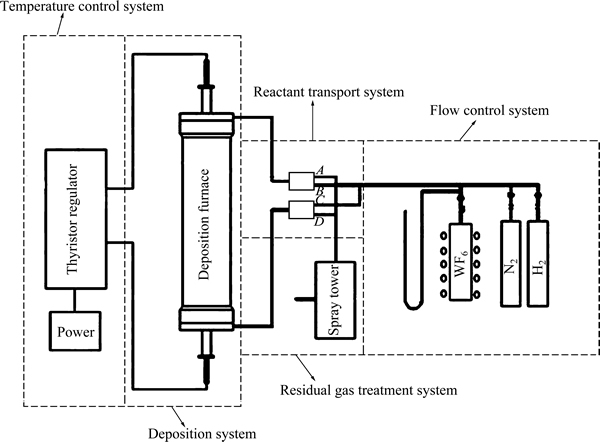

1 实验

采用常压化学气相沉积法,以WF6(纯度为99.99 %)与H2(纯度为99.99 %)为原料,在纯铜基体上沉积纯钨材料。沉积过程在立式不锈钢冷壁沉积炉中进行,沉积炉通过自制电阻丝加热,通过可控硅调压器控制和调节沉积系统功率,采用镍络-镍硅热电偶进行基体温度的测量,采用针阀和流量计控制H2、WF6气体流量,沉积温度为540 ℃左右,混合气体比例为n(WF6):n(H2)=1:3。沉积炉出气端接入喷淋塔,通过加入饱和KOH溶液,中和产生的HF、WF6等尾气,进行无害化处理。化学气相沉积的整个装置主要由控制系统(温度控制系统和反应物输运及流量控制系统)、气相沉积系统(沉积炉)和尾气处理系统(喷淋塔)所组成。图1所示为化学气相沉积多晶钨的实验设备示意图。

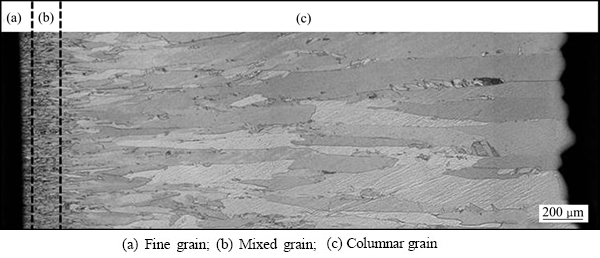

将获得的纯钨制品经打磨、抛光及腐蚀后,采用OLYMPUS BX51M型光学显微镜及S-4800型高分辨扫描电镜观察其显微组织。图2所示为采用CVD技术制备的多晶钨的显微组织。由图2可见,沉积钨呈现三晶区形貌,即细晶区、混合晶区和排列整齐的柱状晶区[13]。

2 结果与讨论

2.1 反应物浓度起伏对沉积层组织缺陷的影响

图3所示为当反应物浓度发生起伏时化学气相沉积钨的OM和SEM像。从图3(a)中可以看出,沉积钨涂层厚度约为1 mm,总体也呈现三晶区形貌,但靠近纯铜基体处存在两条黑色条状组织,厚度为10~30 μm。图3(c)所示为靠近基体处细晶区的SEM像,由图3(c)可以看出,晶粒排列致密、均匀,未发现任何空洞缺陷。图3(b)所示为黑色条状组织处的SEM像,该处n(WF6):n(H2)<1:3。比较发现图3(b)中所示黑色条状组织也为细晶区,并且原始柱状晶区发生分层现象。

当反应物以n(WF6):n(H2)=1:3进行沉积反应时,WF6吸附在基体表面,被H2还原成钨原子,在基体表面形成钨晶核,晶粒各取向均得到较快生长,因此,呈现细小的细晶区。随着涂层厚度的增加,各晶粒的生长出现一定程度的取向一致性,形成了细晶区与柱状晶区混合的晶区。由于沿垂直基体方向反应物的扩散传质距离最短,所以沿着此方向生长最为迅速,其它方向将受到该方向生长的阻碍而不能生长,最终形成所观察到的柱状晶区。

图1 化学气相沉积多晶钨的实验设备示意图

Fig. 1 Schematic diagram of experimental equipment for preparing polycrystalline tungsten by CVD method

图2 采用CVD制备的多晶钨标准的柱状晶组织

Fig. 2 Standard columnar-grain microstructure of polycrystalline tungsten prepared by CVD

若增大WF6气体的浓度,使n(WF6):n(H2)>1:3,过量的WF6几乎完全占据生长表面所有的活化吸附位点,即使增大WF6也不会增加反应速率,此时,生长表面的化学反应为化学气相沉积钨的限速步骤,该沉积过程由表面动力学控制,沉积物能得到更好的性能。

若降低WF6气体的浓度,使n(WF6):n(H2)<1:3,尽管过量的H2会促进WF6向生长表面扩散,但由于WF6浓度的降低,最终沉积生长表面处的WF6处于不足的状态,沉积生长表面还原生成的钨原子开始重新形核并进一步长大,重新形核使得沉积层晶粒明显细化,形成细晶区域,此时,WF6向生长层扩散的速率是化学气相沉积钨的限速步骤,该沉积过程由质量输运控制。当降低WF6浓度时,原有稳态会被破坏,反应物向基体表面的质量输运及基体表面反应的消耗达到平衡状态,基体表面气相组分发生周期性震荡,沉积物会发生分层现象。

因此,反应物浓度的起伏对于CVD制备的钨显微组织具有显著影响。要获得良好的沉积制品组织结构,反应物浓度应保持n(WF6):n(H2)≥1:3。

图3 反应物浓度起伏时沉积层横截面的OM像和SEM像

Fig. 3 Cross-sectional OM image(a) and SEM images((b), (c)) of coating after reactant concentration fluctuations

2.2 杂质形状对沉积层组织缺陷的影响

2.2.1 一维杂质对沉积层组织缺陷的影响

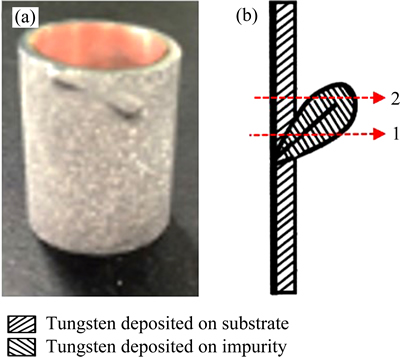

图4(a)所示为用CVD方法制备得到的多晶钨制品的宏观照片。由图4(a)可以看出,涂层表面无明显孔洞及表面裂纹等宏观生长缺陷,但表面状态不佳,有麻点和部分凸起。图4(b)所示为沿凸起纵向切割多晶钨制品的截面示意图。

图4 多晶钨制品的宏观照片与截面示意图

Fig. 4 Macrograph(a) and sectional schematic diagram(b) of polycrystalline tungsten

图5所示为多晶钨制品沿图4(b)中截面1处的显微组织及EDS谱。从图5(a)可以看出,凸起有一个发源位置,对其进行EDS能谱分析,其分析结果如图5(b)所示,能谱图中存在O、Si、Mg、Ca等元素,经分析可以确定发源处为某种纤维杂质。

当向沉积炉中通入反应气体时,沉积初期,WF6被H2还原出钨原子,这些钨原子在基体表面均匀形核成钨晶核,而该纤维状杂质在沉积室中高温活化,为还原出的钨原子提供了形核位点。由于在杂质上形核可减少单位体积的表面能,使临界晶核的原子数较均匀、形核较少,因此,异质形核较均匀形核形核功小,这使得大量钨原子在杂质处形核长大,该部位生长速度较均匀、形核较大,进而获得横向生长空间,并且这种优势在沉积过程中被继续放大,最终在沉积表面产生明显的凸起,严重影响沉积制品的表面质量和制品显微组织的均匀性。随着沉积的进行,生长迅速的异质形核的钨晶粒与生长缓慢的均匀形核的钨晶粒交界,交界处整齐的柱状晶排列被破坏,晶粒生长呈现杂乱状态(见图5(a))。

图5 多晶钨制品沿截面1处的SEM像及EDS谱

Fig. 5 Cross-sectional SEM image(a) and EDS spectrum(b) of polycrystalline tungsten along Section 1

随着沉积时间的延长,钨原子逐渐包覆杂质,并沿着原纤维方向继续延伸异形生长。图6(a)所示为截面2处的SEM像。从图6(a)中可以看出,基体上的多晶钨按照原来的三晶区形貌进行生长,厚度约为1 mm。图6(b)所示为凸起处组织的放大图。由图6(b)可见,晶粒细小。图7所示为多晶钨制品表面的显微组织,由图7可见,晶粒细小,为等轴晶组织。通过与图7的等轴晶组织进行对比发现,图6中的凸起处也为等轴晶组织。这些晶粒与基体上整齐生长出来的柱状晶相遇,晶粒生长呈现杂乱状态。

2.2.2 零维杂质对沉积层组织缺陷的影响

图6 多晶钨制品沿截面2处SEM像及凸起处组织放大图

Fig. 6 Cross-sectional SEM image(a) and high magnification OM image of bulge(b) of polycrystalline tungsten along Section 2

图7 多晶钨制品表面显微组织

Fig. 7 OM image of polycrystalline tungsten surface

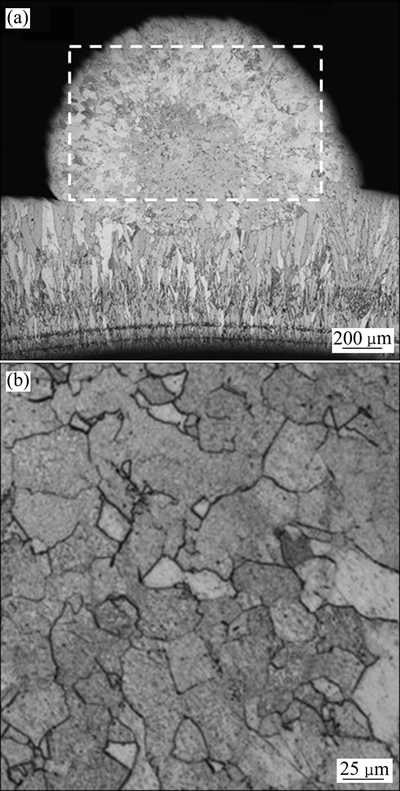

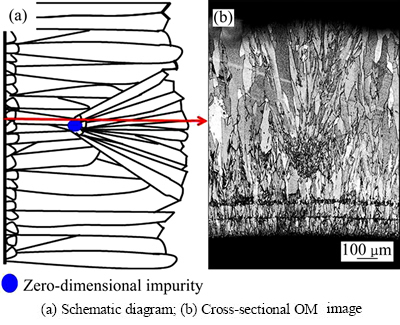

图8 零维杂质对沉积层组织缺陷的影响

Fig. 8 Effect of zero-dimensional impurity on coating microstructure

图8所示为与零维杂质相切处的多晶钨的截面显微组织。图8(a)所示为其截面示意图。从图8(b)可知,沉积过程中出现形如放射状的显微组织。沉积初期,晶粒各取向均得到较快生长,呈现细小的等轴晶;随着涂层厚度的增加,各晶粒按照混合晶区和柱状晶区生长。

随着沉积过程的进行,当沉积层表面落入一个零维杂质时,由于杂质的存在,改变了该部位反应气体的流动状态,还原生成的钨原子以该杂质为形核位点,在杂质表面呈放射状重新形核,形成沉积组织的细晶区域,晶粒进一步长大,相邻细晶逐渐吞并,迅速长大延伸成柱状晶,并阻断了周边柱状晶的生长,形成了放射状组织(见图8(b))。

3 结论

1) 反应物浓度起伏对于CVD钨的显微组织具有显著影响。当n(WF6):n(H2)≥1:3时,沉积过程由表面动力学控制,沉积物得到柱状晶组织;当n(WF6):n(H2)<1:3时,该沉积过程由质量输运控制,沉积层晶粒明显细化,形成细晶区域,发生分层现象。

2) 沉积过程中杂质形状显著的影响沉积层显微组织。当基体表面存在一维杂质时,沉积制品表面产生明显的凸起,凸起处的组织与基体处的组织交界,晶粒杂乱生长,严重影响沉积制品表面质量和组织均匀性;当沉积过程中存在零维杂质时,沉积层中出现形如放射状的显微组织。

REFERENCES

[1] 彭志辉. 稀有金属材料加工工艺学[M]. 长沙: 中南大学出版社, 2003: 5-11.

PENG Zhi-hui. Rare metal materials processing technology[M]. Changsha: Central South University Press, 2003: 5-11.

[2] 印协世. 钨丝生产原理、工艺及其性能[M]. 北京: 冶金工业出版社, 1998: 22-24.

YIN Xie-shi. Production principle, process and capability of tungsten filament[M]. Beijing: Metallurgy Industry Press, 1998: 22-24.

[3] 范景莲, 李鹏飞, 刘 涛, 韩 勇, 吕永齐. 高性能细晶钨及钨合金的研究进展[J]. 中国钨业, 2015, 30(2): 41-48.

FAN Jing-lian, LI Peng-fei, LIU Tao, HAN Yong,  Yong-qi. Advances in fine grained tungsten and tungsten alloys with high performance[J]. China Tungsten Industry, 2015, 30(2): 41-48.

Yong-qi. Advances in fine grained tungsten and tungsten alloys with high performance[J]. China Tungsten Industry, 2015, 30(2): 41-48.

[4] 朱玲旭, 燕青芝, 郎少庭, 徐 磊, 葛昌纯. 钨基面向等离子体材料的研究进展[J]. 中国有色金属学报, 2012, 22(12): 3522-3528.

ZHU Xu-ling, YAN Qing-zhi, LANG Shao-ting, XU Lei, GE Chang-chun. The research progress of tungsten-base of plasma facing materials[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(12): 3522-3528.

[5] LAI K K, LAMB H H. Tungsten chemical vapor deposition using tungsten hexacarbonyl: Microstructure of as-deposited and annealed films[J]. Thin Solid Films, 2000, 370: 114-121.

[6] 李 一, 李金普, 贾成厂, 柳学全, 李发长, 李 楠. 金属有机化学气相沉积W薄膜[J]. 粉末冶金技术, 2011, 29(5): 334-338.

LI Yi, LI Jin-pu, JIA Cheng-chang, LIU Xue-quan, LI Fa-chang, LI Nan. A research on the technique for tungsten films by metal-organic chemical vapor deposition[J]. Powder Metallurgy Technology, 2011, 29(5): 334-338.

[7] REN Xiao-na, ZHOU Hua, GE Chang-chun, LIU Xue-quan, LI Yi, ZHOU Wu-ping, LIU Wei-liang, ZHOU Zhang-jian, ZHANG Xi-geng, XIA Min. Proposal and research on using tungsten carbonyl-CVD process for making W-coating PFMs and W-tubes[J]. Journal of Nuclear Materials, 2014, 455: 582-585.

[8] AMMERLAAN J A M, BOOGAARD D R M, PUT P J, SCHOONMAN J. Chemical vapour deposition of tungsten by H2 reduction of WCl6[J]. Applied Surface Science, 1991, 53: 24-29.

[9] BERKELEY J F, BRENNER A, REID W E. Vapor deposition of tungsten by hydrogen reduction of tungsten hexafluoride[J]. Journal of the Electrochemical Society, 1967, 114(6): 562-568.

[10] 李汉广, 彭志辉. 氟化物CVD法直接制取特纯高致密异形钨制品[J]. 稀有金属材料与工程, 1994, 23(6): 74-77.

LI Han-guang, PENG Zhi-hui. Preparation of high pure compact shaped tungsten products by fluorides CVD methods[J]. Rare Metal Materials and Engineering, 1994, 23(6): 74-77.

[11] 李汉广, 独联体国家的难熔金属氟化物化学气相沉积技术(下)[J]. 稀有金属与硬质合金, 1995, 120: 48-51.

LI Han-guang. Fluorides CVD methods for refractory metal in CIS countries(Ⅱ)[J]. Rare Metals and Cemented Carbides, 1995, 120: 48-51.

[12]  Yan-wei, YU Xiao-dong, TAN Cheng-wen, SUN Tie-feng, MA Kun-song, CAI Hong-nian. Effect of the β phase on compressive mechanical property of CVD tungsten[J]. Rare Metal Materials and Engineering. 2011, 40(7): 1138-1140.

Yan-wei, YU Xiao-dong, TAN Cheng-wen, SUN Tie-feng, MA Kun-song, CAI Hong-nian. Effect of the β phase on compressive mechanical property of CVD tungsten[J]. Rare Metal Materials and Engineering. 2011, 40(7): 1138-1140.

[13] 吕延伟. 化学气相输运法制备特定择优取向的钨单晶涂层研究[D]. 北京: 北京理工大学, 2012: 30-37.

Yan-wei. Study of tungsten monocrystal layers with a preferred crystallographic orientation obtained by chemical vapor transportation deposition[D]. Beijing: Beijing Institute of Technology, 2012: 30-37.

Yan-wei. Study of tungsten monocrystal layers with a preferred crystallographic orientation obtained by chemical vapor transportation deposition[D]. Beijing: Beijing Institute of Technology, 2012: 30-37.

[14] 马 捷, 魏建忠, 王从曾, 范爱玲. 温度对化学气相沉积钨组织与表面形貌的影响[J]. 中国表面工程, 2010, 23(1): 30-33.

MA Jie, WEI Jian-zhong, WANG Cong-zeng, FAN Ai-ling. The effect of temperature on microstructure and surface topography of tungsten prepared via chemical vapor deposition approach[J]. China Surface Engineering, 2010, 23(1): 30-33.

[15] 马 捷, 李 辉, 张永志, 魏建忠, 张 珊. 缠绕钨丝CVD钨管的组织及性能[J]. 中国表面工程, 2012, 25(3): 63-67.

MA Jie, LI Hui, ZHANG Yong-zhi, WEI Jian-zhong, ZHANG Shan. Structure and properties of CVD tungsten tube wound by tungsten wire[J]. China Surface Engineering, 2012, 25(3): 63-67.

[16] 马 捷, 魏建忠, 王从曾, 范爱玲. 化学气相沉积法制备钨管性能研究[J]. 兵工学报, 2011, 32(6): 703-706.

MA Jie, WEI Jian-zhong, WANG Cong-zeng, FAN Ai-ling. The research of performance of tungsten tube prepared by chemical vapor deposition[J]. Acta Armamentarii, 2011, 32(6): 703-706.

(编辑 王 超)

收稿日期:2014-10-30;修订日期:2015-03-25

通信作者:谭成文,教授,博士;电话:010-68912712;E-mail: tanchengwen@bit.edu.cn