Trans. Nonferrous Met. Soc. China 22(2012) s629-s633

Influences of tool plunge speed and tool plunge depth on friction spot joining of AA5454-O aluminum alloy plates with different thicknesses

Sung-Ook YOON1, Myoung-Soo KANG1, Yong-Jai KWON1, Sung-Tae HONG2, Dong-Hwan PARK3, Kwang-Hak LEE1, Chang-Yong LIM4, Jong-Dock SEO4

1. School of Materials Science and Engineering, University of Ulsan, Ulsan 680-794, Korea;

2. School of Mechanical Engineering, University of Ulsan, Ulsan 680-794, Korea;

3. Institute of E-Vehicle Technology, University of Ulsan, Ulsan 680-794, Korea;

4. Technical Research Laboratories, Shin Young Co., Ltd., Yeongcheon 683-360, Korea

Received 21 May 2012; accepted 4 November 2012

Abstract: AA5454-O aluminum alloy plates with the thicknesses of 1.4 and 1.0 mm were friction-spot-joined (FSJed). The plunge speed of the joining tool was changed in a range of 100-500 mm/min under a constant rotation speed of 500 r/min. The plunge depth was ranged from 1.6 mm to 2.2 mm. The tool plunge speed did not make a remarkable effect on the surface appearance and macro-structure of the FSJed zone. The average hardness of the FSJed zone was greater than or equal to that of the base metal. However, there was no remarkable tendency in the average hardness change of the FSJed zone in spite of the variation in the tool plunge speed and tool plunge depth. The increase of the tool plunge depth resulted in the increase of the tensile shear load. However, the change of the tool plunge speed did not lead to the remarkable variation in the tensile shear load of the FSJed plates. It was noteworthy that the FSJed plate exhibited the highest tensile shear load of about 4.0 kN.

Key words: friction spot joining; AA5454-O aluminum alloy; plunge speed; plunge depth; mechanical property

1 Introduction

Recently, the requirements for the automotive industry have become more severe in connection with reduction in weight, fuel consumption and environmental impact. Much attention, therefore, was focused on aluminum and magnesium alloys because of their unique properties, especially lightweight properties. For their practical applications, the bonding and welding technologies should be established aside from alloy design, microstructure control, plastic forming, casting, surface treatment, etc. Friction spot joining (FSJ) process is one of the attractive technologies for welding of a wide variety of metallic materials [1-10].

In this study, AA5454-O aluminum alloy plates with the thicknesses of 1.4 and 1.0 mm were friction-spot-joined (FSJed). And then, the influences of the tool plunge speed and the tool plunge depth on the surface appearance, macrostructure and mechanical properties of the FSJed plates were experimentally investigated.

2 Experimental

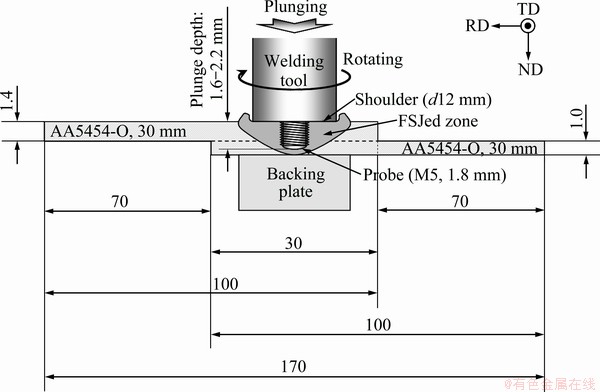

Figure 1 shows the schematic illustration of the FSJ process in this study. The AA5454-O aluminum alloy plates with the thicknesses of 1.4 and 1.0 mm had a width of 30 mm and a length of 100 mm, which were used as the base metals (BM) in this study. The shoulder diameter of the joining tool was 12 mm. The probe had a diameter of 5 mm and a height of 1.8 mm. The plates with the thicknesses of 1.4 and 1.0 mm were fixed on the upper and lower sides, respectively. The tool was rotated in a clockwise direction at a constant speed of 500 r/min. And then, the probe was plunged into the materials with speeds ranging from 100 mm/min to 500 mm/min. The tool plunge depth was also changed in a range of 1.6-2.2 mm. The dwell time was 3 s at the maximum tool plunge depth.

The macrostructural observations and Vickers microhardness tests were performed on an RN plane which was a cross-section parallel to the tool plunge direction. The hardness tests were carried out with a load of 0.98 N for a duration time of 10 s. The tensile shear tests were carried out for the as-FSJed plates at room temperature with a constant crosshead speed of 1 mm/min.

Fig. 1 Schematic illustration of FSJ process (Unit: mm)

3 Results and discussion

3.1 Influences of tool plunge speed

The FSJ processes were carried out in the tool plunge speeds ranging from 100 mm/min to 500 mm/min under a constant tool plunge depth of 1.8 mm. And then, the influences of the tool plunge speed on the characteristics of the FSJed plates were investigated.

3.1.1 Surface appearance

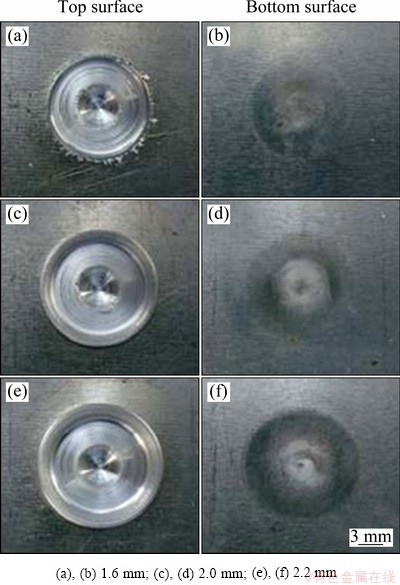

Figure 2 shows the influence of the tool plunge speed on the surface appearance of the FSJed plates. Under the joining conditions, the similar appearances were observed all on the top and bottom surfaces of the FSJed zone, respectively, without a remarkable relationship to the tool plunge speed. Namely, the FSJed zone on the top surface was composed of the burr region with the ring-like appearance, the hole region which was formed at the center by the probe, and the doughnut-shaped region which was formed by the shoulder. On the bottom surface, there were the circular traces with the diameters similar to those of the probe and shoulder of the tool. These results suggest that the tool plunge speed did not make a remarkable effect on the surface appearance of the FSJed zone.

3.1.2 Macro-structures

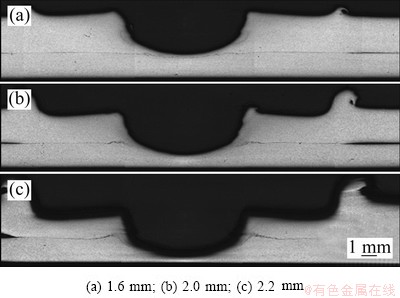

Figure 3 shows the influence of the tool plunge speed on the macro-structure of the FSJed plates. There was no remarkable change in the macro-structure, in spite of the variation of the tool plunge speed. In addition, a clear onion ring structure was not also formed in the FSJed zone for all the joining conditions. These results suggest that the change of the tool plunge speed did not lead to the remarkable variation in the macro-structure of the FSJed zone.

Fig. 2 Influence of tool plunge speed on surface appearance of FSJed aluminum alloy plates

Fig. 3 Influence of tool plunge speed on macro-structure of FSJed aluminum alloy plates

Fig. 4 Influence of tool plunge speed on average Vickers micro-hardness of FSJed zone in FSJed aluminum alloy plates

3.1.3 Average hardness

Figure 4 shows the influence of the tool plunge speed on the average Vickers micro-hardness of the FSJed zones. In all the FSJ conditions, the upper plate exhibited higher average hardness than the lower plate. In addition, the average hardness of the FSJed zone was greater than or equal to that of the BM. The highest average hardness of about HV0.1 68 was obtained in the FSJed zone of the upper plate for the tool plunge speed of 500 mm/min. It was reported that, for non-heat treatable aluminum alloys, this increase of the average hardness results from the grain refinement of the FSJed zone [1,6], friction-stir-welded zone [11-13] or friction- stir-processed zone [14,15]. Therefore, it is believed that, in this study, the high hardness come from the grain refinement in the FSJed zone, as the results of previous researches [1,6]. However, there was no remarkable tendency in the average hardness change of the FSJed zone in spite of the variation in the tool plunge speed.

3.1.4 Tensile shear load

Figure 5 shows the influence of the tool plunge speed on the average maximum tensile shear load of the FSJed plates. In all the FSJ conditions, the FSJed plates exhibited the similar tensile shear load of about 3.6 kN, without a special tendency in spite of the change in the tool plunge speed. This result suggests that the change of the tool plunge speed did not lead to the remarkable variation in the average tensile shear load of the FSJed plates.

Fig. 5 Influence of tool plunge speed on average maximum tensile shear load of FSJed aluminum alloy plates

3.2 Influences of tool plunge depth

The FSJ processes were carried out in the tool plunge depths ranging from 1.6 mm to 2.2 mm under a constant tool plunge speed of 100 mm/min. And then, the influences of the tool plunge depth on the characteristics of the FSJed plates were investigated.

3.2.1 Surface appearance

Figure 6 shows the influence of the tool plunge depth on the surface appearance of the FSJed plates. For the tool plunge depth of 1.8 mm, the top and bottom surface appearances of the FSJed plates were shown in the above-mentioned Figs. 2 (a) and (b), respectively. In all the joining conditions, the FSJed zone on the top surface was composed of the burr region, the hole region and the doughnut-shaped region, when the tool plunge speed was changed (Fig. 2). However, the increase of the tool plunge depth caused the burr region to develop. The circular traces were also formed on the bottom surface, and came into focus with the increase in the tool plunge depth. These results show that the tool plunge depth is a very important parameter for controlling the surface appearance of the FSJed zone.

3.2.2 Macro-structure

Figure 7 shows the influence of the tool plunge depth on the macro-structure of the FSJed plates. For the tool plunge depth of 1.8 mm, the macro-structure of the FSJed plate was shown in the above-mentioned Fig. 3 (a). The macro-structures were similar to those shown in Fig. 3. However, the increase of the tool plunge depth led to the increase in the amount of the burr and the decrease in the thickness at the central region in the FSJed zone of the lower plate. In addition, the gap between the upper and lower plates was increased with the increase of the tool plunge depth. This result suggests that the increase of the tool plunge depth led to the increase of the plastic deformation of the material near the FSJed zone.

Fig. 6 Influence of tool plunge depth on surface appearance of FSJed aluminum alloy plates

Fig. 7 Influence of tool plunge depth on macro-structure of FSJed aluminum alloy plates

3.2.3 Average hardness

Figure 8 shows the influence of the tool plunge depth on the average Vickers micro-hardness of the FSJed zones. A tendency of the average hardness change was similar to that of the above-mentioned Fig. 4. Namely, in all the FSJ conditions, the average hardness of the upper plate is higher than that of the lower plate. In addition, the average hardness of the FSJed zone was greater than or equal to that of the BM. The highest average hardness of about 76 HV0.1 was obtained in the FSJed zone of the upper plate for the tool plunge depth of 1.6 mm. However, there was no remarkable tendency in the average hardness change of the FSJed zone in spite of the change in the tool plunge depth.

3.2.4 Tensile shear load

Figure 9 shows the influence of the tool plunge depth on the average maximum tensile shear load of the FSJed plates. The increase of the tool plunge depth resulted in the increase of the tensile shear load. Especially, for the tool plunge depth of 2.2 mm, the FSJed plate exhibited the highest tensile shear load of about 4.0 kN. This result means that the tool plunge depth is a very important parameter for increasing the tensile shear load of the FSJed plate.

Fig. 8 Influence of tool plunge depth on average Vickers micro-hardness of FSJed zone in FSJed aluminum alloy plates

Fig. 9 Influence of tool plunge depth on average maximum tensile shear load of FSJed aluminum alloy plates

4 Conclusions

1) The tool plunge speed did not make a remarkable effect on the surface appearance and macro-structure of the FSJed zone.

2) The average hardness of the FSJed zone was greater than or equal to that of the BM. However, there was no remarkable tendency in the average hardness change of the FSJed zone in spite of the variation in the tool plunge speed and tool plunge depth.

3) The increase of the tool plunge depth resulted in the increase of the tensile shear load. However, the change of the tool plunge speed did not lead to the remarkable variation in the tensile shear load of the FSJed plates.

Acknowledgement

This research was financially supported by the Ministry of Education, Science Technology (MEST) and National Research Foundation of Korea (NRF) through the Human Resource Training Project for Regional Innovation, and by the development program of local science park funded by the ULSAN Metropolitan City and the Ministry of Education, Science and Technology (MEST).

References

[1] CHO H J, KIM H J, CHEON C K, CHANG W S, BANG K S. Evaluation of friction spot joining weldability of Al alloys for automotive [J]. J. KWJS, 2006, 24(1): 50-55.

[2] ROSENDO T, PARRA B, TIER M A D, DA SILVA A A M, DOS SANTOS J F, STROHAECKER T R, ACANTARA N G. Mechanical and microstructural investigation of friction spot welded AA6181-T4 aluminum alloy [J]. Mater Des, 2011, 32(2): 1094-1100.

[3] OLIVEIRA P H F, AMANCIO-FILHO ST, DOS SANTOS J F, HAGE JR. E. Preliminary study on the feasibility of friction spot welding in PMMA [J]. Mater Lett, 2010, 64(19): 2098-2101.

[4] MERZOUG M, MOHAMED M, BERRAHAL L, IMAD A. Parametric studies of the process of friction spot stir welding of aluminium 6060-T5 alloys [J]. Mater Des, 2010, 31(6): 3023-3028.

[5] LATHABAI S, PAINTER M J, CANTIN G M D, TYAGI V K. Friction spot joining of an extruded Al-Mg-Si alloy [J]. Scr Mater, 2006, 55(10): 899-902.

[6] BOZZI S, HELBERT-ETTER A L, BAUDIN T, KLOSEK V, KERBIGUET J G, CRIQUI B. Influence of FSSW parameters on fracture mechanisms of 5182 aluminium welds [J]. J Mater Process Technol, 2010, 210(11): 1429-1435.

[7] TOZAKI Y, UEMATSU Y, TOKAJI K. Effect of tool geometry on microstructure and static strength in friction stir spot welded aluminium alloys [J]. Int J Mach Tools Manuf, 2009, 5279(1-2): 192-197.

[8] TOZAKI Y, UEMATSU Y, TOKAJI K. A newly developed tool without probe for friction stir spot welding and its performance [J]. J Mater Process Technol, 2010, 210(6-7): 844-851.

[9] LIN B Y, LIN C M, TSAI H L. Effects of process parameters on strength of Mg alloy AZ61 friction stir spot welds [J]. Mater Des, 2012, 35: 350-357.

[10] SUN N, NORTH T H, HU S S. Hook formation and mechanical properties in AZ31 friction stir spot welds [J]. J Mater Process Technol, 2010, 210(14): 2062-2070.

[11] KWOM Y J, SHIM S B, PARK D H. Friction stir welding of 5052 aluminum alloy plates [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(S1): s23-s27.

[12] IMAM M, BISWAS K, RACHERLA V. Effect of weld morphology on mechanical response and failure of friction stir welds in a naturally aged aluminium alloy [J]. Mater Des, 2013, 44: 23-34.

[13] SARKARI KHORRAMI M, KAZEMINEZHAD M, KOBABI A H. Microstructure evolutions after frictionstir welding of severely deformed aluminum sheets [J]. Mater Des, 2012, 40: 364-372.

[14] KWON Y J, SHIGEMATSU I, SAITO N. Production of ultra-fine grained aluminum alloy using friction stir process [J]. Mater Trans, 2003, 44(7): 1343-1350.

[15] YAZDIPOURA A, SHAFIEI MC A, DEHGHANI. Modeling the microstructural evolution and effect of cooling rate on the nanograins formed during the frictionstir processing of Al5083 [J]. Mater Sci Eng A, 2009, 527(1-2): 192-197.

(Edited by HE Xue-feng)

Corresponding author: Yong-Jai KWON; Tel: +82-52-259-1294; E-mail: yongjaikwon@ulsan.ac.kr

DOI: 10.1016/S1003-6326(12)61776-2