文章编号:1004-0609(2010)S1-s0198-05

离心熔模精铸TiAl合金与ZrO2型壳的界面反应

陈艳飞,陈玉勇,田 竟,肖树龙,徐丽娟

(哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001)

摘 要:选用CaO增强的ZrO2作为TiAl熔模精密铸造用陶瓷型壳的面层材料,通过OM、SEM、EDS和XRD对TiAl合金界面反应处进行形貌分析和元素线扫描分析,研究离心熔模铸造TiAl合金与ZrO2型壳的界面反应。结果表明:在较低的转速(200 r/min)条件下,ZrO2陶瓷与TiAl合金的反应层厚度较小,大约为5 μm;而在较高的转速(400 r/min)情况下,ZrO2陶瓷与TiAl合金的反应层厚度约为20 μm,界面有轻微粘砂。

关键词:TiAl合金;离心熔模铸造;ZrO2型壳;界面反应

中图分类号:TF 804.3 文献标志码:A

Interfacial reactions between TiAl alloys and ZrO2 mould under centrifugal investment casting conditions

CHEN Yan-fei, CHEN Yu-yong, TIAN Jing, XIAO Shu-long, XU Li-juan

(School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China)

Abstract: ZrO2 (CaO stabilized) was chosen as the face coat materials for the investment casting of TiAl alloys. The interfacial reaction between TiAl alloys and ZrO2 ceramic mould under centrifugal investment casting conditions was analyzed through morphological analysis and elemental lines scanning by OM, SEM, EDS and XRD. The results demonstrate that the thickness of reaction layer is relatively small of about 5 μm at low rotational speed of 200 r/min. When the rotational speed increases to 400 r/min, the thickness of reaction layer is estimated to be about 20 μm and the surface exhibits slight metal penetration defect.

Key words: TiAl alloys; centrifugal investment casting; ZrO2 mould; interfacial reaction

TiAl合金具有较高的比强度和比模量以及良好的高温抗蠕变和抗氧化能力,是一种极具应用前景的轻质耐高温结构材料,有望用于航空、航天领域的飞机发动机涡轮叶片及汽车工业排气阀和涡轮增压器等部件的制作[1-9],大大降低发动机噪音,提高利用率,节省燃油,减少废气排放量,引起世界各国足够重 视[10-12]。但由于TiAl合金室温塑性低、成形性差,所以,采用熔模精密铸造技术是制作TiAl合金构件最可行的方法之一。与其它方法相比,熔模精密铸造可以一次制备形状复杂、薄壁的零件,并且铸件具有较高的尺寸精度和较低的表面粗糙度,成本较较低,适于批量生产。

近年来,采用熔模精密铸造方法制备形状复杂的TiAl合金铸件日益受到科研工作者和工程化应用的重视[13-19]。熔融状态下TiAl合金具有较高的化学活性,几乎与所有的耐火材料发生化学反应,导致合金氧含量增大,恶化铸件的内在和外观质量,影响铸件尺寸精度,严重时甚至造成铸件的报废。钛合金熔模精密铸造的发展历史,从某种程度上说就是型壳的发展历史[20]。可以说,型壳的制备是整个TiAl合金熔模铸造工艺的最大难点,在制壳工艺已相对成熟的情况下,选用合适的面层和临面层涂料显得尤为重要。

国内外学者就氧化物陶瓷型壳面层和临面层材 料如:CaO、ZrO2、Y2O3和ThO2等进行过细致的研究[18, 21-25]。

ZrO2是一种较为稳定的氧化物,具有较高的熔点(2 715 ℃),耐火度也高达2 500 ℃,具有良好的化学稳定性和较小的比热容和导热系数,并且与钛液的润湿性能较差,是TiAl合金熔模精铸用型壳的主要耐火材料。

考虑到TiAl合金熔模精铸的特点,在施加离心力的作用下,可以获得薄截面型腔的精细轮廓。另外,可在型壳中形成抛物线型液态金属自由面,提高金属的利用率。

基于此,本文作者将研究TiAl合金与ZrO2陶瓷型壳面层材料的界面反应,讨论以二醋酸锆作粘结剂,ZrO2作型壳材料,采用SEM、XRD等分析方法,分析熔模精铸件表面的成分组成、TiAl合金与ZrO2型壳材料的界面反应情况,合理选择适于该合金的型壳材料,从而制备优质的TiAl合金铸件具有重要的理论意义和实际工程应用背景。

1 实验

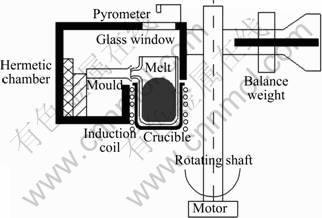

实验用合金名义成分为Ti-47Al (摩尔分数,%),采用ISM熔炼TiAl合金铸锭,用电火花线切割切取

试样,在Linn铸钛机上进行离心熔模浇注,离心铸钛机结构示意图如图1所示。整个熔炼和浇注过程采用抽真空后充氩气保护气氛。选用的陶瓷型壳面层材料是CaO稳定的ZrO2,其制备工艺如表1所列,制得的型壳及显微形貌如图2所示。线切割离心浇注后的TiAl合金试样后,用Olympus金相显微镜和QUANTA-200扫描电镜观察试样界面组织变化和界面反应情况。

图1 离心铸钛机结构示意图

Fig.1 Schematic diagram of titanium centrifugal casting machine

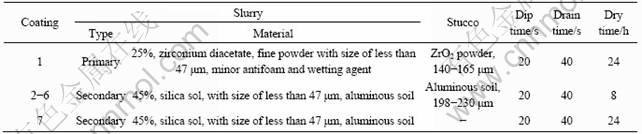

表1 ZrO2陶瓷型壳的制备工艺

Table 1 Fabrication technology of ZrO2 ceramic mould

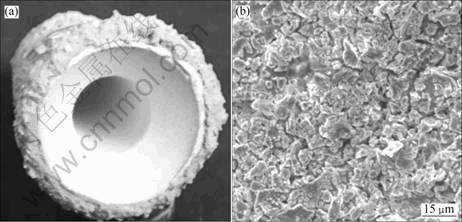

图2 TiAl合金离心浇注用ZrO2陶瓷型壳照片及内表面的显微形貌

Fig.2 Photo of ZrO2 ceramic mould (a) and microstructure of inner face (b) used for centrifugal investment casting of TiAl alloy

2 结果与讨论

2.1 型壳形貌

图2所示为采用表1所示的制备工艺制得的ZrO2陶瓷型壳照片及内表面的显微形貌。由图可知,型壳轮廓清晰,内表面光洁、平整,无明显裂纹和孔洞,这就保证了离心浇注时型壳能经受住TiAl合金熔体的冲刷,从而制备出表面质量良好的TiAl合金铸件。

2.2 浇注前及浇注后型壳内表面的相组成

图3所示为浇注前后ZrO2陶瓷型壳内表面的XRD谱。从图3(a)可以看出,型壳经过制备焙烧后,ZrO2陶瓷型壳内表面全部为Ca0.15Zr0.85O1.85相。Ca0.15Zr0.85O1.85相是在型壳焙烧过程中形成的[26],

ZrO2+CaO→Ca0.15Zr0.85O1.85 (1)

从图3(b)可以看出,ZrO2陶瓷型壳经过浇注TiAl

合金后,型壳内产物主要为CaZrTi2O7和ZrO2,其中CaZrTi2O7具有较高的热力学稳定性[27]。

ZrO2+CaO+Ti→CaZrTi2O7 (2)

图3 浇注前及浇注后型壳内表面的XRD谱

Fig.3 XRD patterns of ZrO2 mould before(a) and after(b) pouring

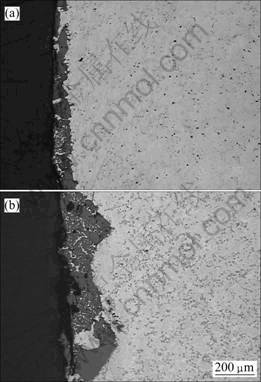

2.4 离心浇注TiAl合金与ZrO2陶瓷型壳的界面反应

图4所示为TiAl合金与ZrO2陶瓷型壳界面反应层的金相照片。由图4可以看出,在转速为200 r/min条件下,TiAl合金界面处有少量粘砂,界面较平直,反应层的厚度较小,即污染层的深度很小。而在400 r/min的离心浇注下,界面粘砂较严重,厚度几乎是前者的两倍,且呈明显的锯齿状。可以看出,虽然材料自身的耐火度没有改变,但是随着离心力的增加,铸件的污染层会进一步增大。ZrO2型壳材料在高温下溶解而产生二者元素间的相互扩散。

在离心铸造条件下,铸件处于一个旋转的体系中,铸件上所有的点在受到重力作用的同时,还受到离心力的作用。同时,由于熔体相对于旋转中心有径向流动。根据运动合成的原理,熔体还受到柯氏力的作用。由于合金液的冲刷作用,型壳表面可能会有少量的微粒脱落,因此也加剧了界面反应。

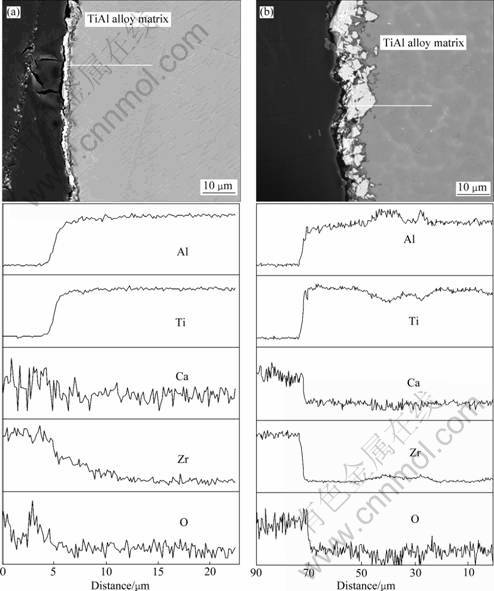

图5所示为界面反应处的元素线扫描分析结果。从图5(a)可以看出,O、Zr和Ca元素在界面处大约有5 μm的扩散层。这与钛合金浇注的界面层厚度相比较 小[28-29]。这可以归因于如下因素:一方面,TiAl合金引入了大量的Al元素,降低了钛合金熔体的活性;另一方面,铸钛机浇注的小尺寸试样,冷却较快,且在较低的离心转速(200 r/min)下,TiAl合金的表面反应层较小。当离心转速增大至400 r/min时(见图5(b)),O、Zr和Ca元素的扩散层厚度增大至20 μm。这是由于在浓度梯度的驱动下,O、Zr和Ca等元素向基体扩散,形成含有O、Zr和Ca等元素的固溶体扩散层。在较大离心力的剧烈冲刷作用下,少量的ZrO2陶瓷颗粒被TiAl合金熔体冲刷裹挟在其中,在TiAl合金铸件表层形成弥散分布的氧化物夹杂质点,从而恶化TiAl合金铸件的力学性能,因此应在实际生产中设法避免[30]。

图4 不同离心转速下TiAl合金与ZrO2陶瓷型壳界面反应的金相组织

Fig.4 Optical microstructures of interfacial reactions between TiAl alloys and ZrO2ceramic mould under different rotational speeds: (a) 200 r/min; (b) 400 r/min

图5 不同转速浇注下TiAl合金与ZrO2陶瓷型壳的界面反应线扫描分析

Fig.5 Line scanning on interfacial reactions between TiAl alloys and ZrO2 ceramic mould at different rotational speed: (a) 200 r/min; (b) 400 r/min

3 结论

1) 制备的TiAl合金熔模精铸用ZrO2陶瓷型壳轮廓清晰,内表面光洁、平整,无明显的裂纹和孔洞。

2) ZrO2陶瓷型壳经过焙烧,ZrO2陶瓷型壳内表面全部为Ca0.15Zr0.85O1.85相,浇注TiAl合金后,型壳内产物主要为CaZrTi2O7和ZrO2。

3) 在200 r/min转速条件下,TiAl合金铸件的表面污染层厚约5 μm,无明显氧化物颗粒夹杂。而在400 r/min转速条件下,O、Zr和Ca元素的扩散层厚度增大至20 μm,且在界面处存在ZrO2陶瓷颗粒弥散分布。

REFERENCES

[1] TETSUI T. Development of a TiAl turbocharger for passenger vehicles[J]. Materials Science and Engineering A, 2002, 329/331: 582-588.

[2] KIM Y W. Intermetallic alloys based on gamma titanium aluminide[J]. JOM, 1989, 41(7): 24-30.

[3] LORIA E A. Gamma titanium aluminides as prospective structural materials[J]. Intermetallics, 2000, 8(9/11): 1339-1345.

[4] LORIA E A. Quo vadis gamma titanium aluminide[J]. Intermetallics, 2001, 9(12): 997-1001.

[5] NODA T. Application of cast gamma TiAl for automobiles[J]. Intermetallics, 1998, 6(7/8): 709-713.

[6] WU X. Review of alloy and process development of TiAl alloys[J]. Intermetallics, 2006, 14(10/11): 1114-1122.

[7] TETSUI T. Application of TiAl in a turbocharger for passenger vehicles[J]. Advanced Engineering Materials, 2001, 3(5): 307-310.

[8] JOVANOVI? M T, DIM?I? B, BOBI? I, ZEC S, MAKSIMOVI? V. Microstructure and mechanical properties of precision cast TiAl turbocharger wheel[J]. Journal of Materials Processing Technology, 2005, 167(1): 14-21.

[9] BLUM M, JARCZYK G, SCHOLZ H, PLEIER S, BUSSE P, LAUDENBERG H-J, SEGTROP K, SIMON R. Prototype plant for the economical mass production of TiAl-valves[J]. Materials Science and Engineering A, 2002, 329/331: 616-620.

[10] JARVIS D J, VOSS D. IMPRESS integrated project—An overview paper[J]. Materials Science and Engineering A, 2005, 413/414: 583-591.

[11] HEPPENER M, MINSTER O, JARVIS D J. First results of ESA's IMPRESS project[J]. Acta Astronautica, 2008, 63(1/4): 20-23.

[12] EGRY I, BROOKS R, HOLLAND-MORITZ D, NOVAKOVIC R, MATSU-SHITA T, RICCI E, SEETHARA-MAN S, WUNDERLICH R, JARVIS D. Thermo-physical properties of γ-titanium aluminide: The European IMPRESS project[J]. International Journal of Thermo-physics, 2007, 28(3): 1026-1036.

[13] SUNG S Y, KIM Y J. Economic net-shape forming of TiAl alloys for automotive parts[J]. Intermetallics, 2006, 14(10/11): 1163-1167.

[14] NAN H, HUANG D, LI Z X, J.Q. Z. Research on investment casting of TiAl alloy agitator treated by HIP and HT[J]. China Foundry, 2007, 4(2): 112-115.

[15] HARDING R. Recent developments in the induction skull melting and investment casting of titanium aluminides[J]. Kovove materialy, 2004, 42(4): 225-241.

[16] CHEN Y Y, XIAO S L, KONG F T, WANG X. Microstructure and interface reaction of investment casting TiAl alloys[J]. Transactions of Nonferrous Metals Society of China, 2006, 16: S1910-S1914.

[17] LARSEN J D E. Status of investment cast gamma titanium aluminides in the USA[J]. Materials Science and Engineering A, 1996, 213(1/2): 128-133.

[18] KUANG J P, HARDING R A, CAMPBELL J. Examination of defects in gamma titanium aluminide investment castings[J]. International Journal of Cast Metals Research, 2000, 13(3): 125-134.

[19] BARBOSA J, PUGA H, RIBEIRO C S, TEODORO O, MONTEIRO A C. Characterisation of metal/mould interface on investment casting of gamma-TiAl[J]. International Journal of Cast Metals Research, 2006, 19(6): 331-338.

[20] 李 飞, 王 飞, 陈 光, 万柏方, 戴炎麟, 陆 敏. 熔模精密铸造TiAl基金属间化合物研究进展[J]. 中国材料进展, 2010(2): 24-30.

LI Fei, WANG Fei, CHEN Guang, WAN Bo-fang, DAI Yan-lin, LU Min. Review of the investment casting of TiAl based intermetallic alloys[J]. Materials China, 2010(2): 24-30.

[21] JIA Q, CUI Y, YANG R. A study of two refractories as mould materials for investment casting TiAl based alloys[J]. Journal of Materials Science, 2006, 41(10): 3045-3049.

[22] YANG R, CUI Y Y, DONG L M, JIA Q. Alloy development and shell mould casting of gamma TiAl[J]. Journal of Materials Processing Technology, 2003, 135(2/3): 179-188.

[23] BARBOSA J, RIBEIRO C S, MONTEIRO A C. Influence of superheating on casting of gamma-TiAl[J]. Intermetallics, 2007, 15(7): 945-955.

[24] GOMES F, BARBOSA J, RIBEIRO C S. Induction melting of gamma-TiAl in CaO crucibles[J]. Intermetallics, 2008, 16(11/12): 1292-1297.

[25] SAHA R L, NANDY T K, MISRA R D K, JACOB K T. On the evaluation of stability of rare earth oxides as face coats for investment casting of titanium[J]. Metallurgical Transactions B, 1990, 21(3): 559-566.

[26] MALGHE Y S, DHARWADKAR S R. Ca0.15Zr0.85O1.85 powder from oxalate precursor: Microwave aided synthesis and thermal characterization[J]. Thermo-chimica Acta, 2008, 476(1/2): 66-68.

[27] P ML P, GEISLER T, KONINGS R J M. High-temperature heat capacity of zirconolite (CaZrTi2O7)[J]. The Journal of Chemical Thermodynamics, 2006, 38(8): 1013-1016.

[28] SUNG S, KIM Y. Alpha-case formation mechanism on titanium investment castings[J]. Materials Science and Engineering A, 2005, 405(1/2): 173-177.

[29] BOETTINGER W, WILLIAMS M, CORIELL S, KATTNER U, MUELLER B. Alpha case thickness modeling in investment castings[J]. Metallurgical and Materials Transactions B, 2000, 31(6): 1419-1427.

[30] TEODORO O M N D, BARBOSA J, NAIA M D, MOUTINHO A M C. Effect of low level contamination on TiAl alloys studied by SIMS[J]. Applied Surface Science, 2004, 231/232: 854-858.

(编辑 龙怀中)

基金项目:高等学校博士学科点专项科研基金资助项目(200802130014)

通信作者:陈艳飞,博士研究生;电话:0451-86418802;E-mail: yanfeichen@hotmail.com