DOI: 10.11817/j.ysxb.1004.0609.2020-39575

TC4合金焊接熔池微观组织演变的数值模拟与分析

张 敏,黄 超,郭宇飞,张立胜,李继红

(西安理工大学 材料科学与工程学院,西安 710048)

摘 要:在MATLAB模拟平台上基于CA-FE法(元胞自动机-有限元)结合晶粒的形核与生长理论,建立了TC4钛合金瞬态焊接温度场下熔池内微观组织演变的数值计算模型,基于该模型对焊接瞬态温度场及其作用下的微观组织演变进行了模拟。结果表明:温度场的计算结果符合焊接热过程局部热量集中且高度动态变化的特点,熔池边缘先形核,在温度梯度作用下晶粒以柱状晶的形式向熔池中心生长,最后形成粗大的柱状晶组织,固态相变阶段,熔池内组织迅速转变为α'马氏体。对模拟结果进行验证性实验,模拟结果与实验结果吻合性良好,显示所建数值计算模型可靠性较高。

关键词:TC4合金;熔池;微观组织;数值模拟;CA-FE法

文章编号:1004-0609(2020)-08-1876-11 中图分类号:TG402 文献标志码:A

TC4(Ti-6Al-4V)钛合金作为一种重要的工程材料,具有优良的综合性能,被广泛应用于航空航天、生物医学等领域[1-2]。作为TC4合金结构的主要连接方法,焊接因其灵活性及适应性具有不可比拟的优势[3],而焊接接头的微观组织与最终性能之间存在很强的依存关系。但受制于研究成本、周期等因素,基于传统的实验方法难以对复杂的微观组织演化过程进行分析[4]。近年来,计算科学在各领域的深入发展,为相关研究提供了新的思路,且已在金属材料凝固领域得到了许多成功的应用[5]。

利用CA法,刘波祖[6]研究了Al-Si-Cu合金不同过冷度及冷却速率下单个和多个晶粒的生长过程;ZHAN等[7]通过优化元胞捕获规则,建立不同择优方向单个等轴晶及恒定温度梯度作用下多个等轴晶生长的计算模型;ZHU等[8]分析了理想温度场作用下Al-4%Cu合金等轴晶及柱状晶的形貌演化过程及溶质浓度变化;薛覃[9]通过规定熔池形状、熔池初始温度场和边界散热条件,将焊接熔池凝固过程简化为微小尺寸的铸造过程,模拟了熔池的CET(柱状晶-等轴晶)转变。上述研究表明CA法在凝固领域适用性很强,但仅采用CA法只能处理简单热过程作用下组织演变的模拟。而GANDIN等[10]提出的CA-FE法提供了一种新的手段,该方法采用CA(元胞自动机)模型计算晶粒生长,FE(有限元)模型计算温度场。基于该方法,YIN等[11]研究了不同局部冷却和工艺条件下激光工程化净成形(LENS)过程中熔池内枝晶形貌的演变机制;HAN等[12-13]讨论了焊接工艺参数与组织形貌之间的关系,并对焊缝中柱状晶向等轴晶的转变机理进行分析;李晗嫣等[14]研究了不同阶段的温度场对TC4合金固液转变的影响;AMIR等[15]模拟了激光熔化过程中晶粒竞争生长,并分析了激光扫描速度对最终显微组织的影响机理;TIAN等[16]研究了激光沉积成形(LDS)过程中熔池的微观组织演变,并讨论了工艺参数与组织形貌之间的关系;魏雷等[17]改进元胞捕获规则和界面曲率计算方法,建立了适用于激光立体成形的数值模型,该模型能对微观组织凝固进行较准确的计算。但焊接接头的最终性能还与凝固后微观组织的固态相变有关,目前还鲜见相关模拟报道。因此,对焊接瞬态温度场和其作用下的微观组织演变及凝固后固态相变整个过程进行模拟具有很强的现实意义。

本文结合相关理论及仿真软件,在MATLAB模拟平台上建立TC4合金焊接熔池微观组织转变的CA-FE计算模型,基于所建模型对焊接热过程及微观组织的转变过程进行了模拟,并结合实验手段验证和分析模拟结果。

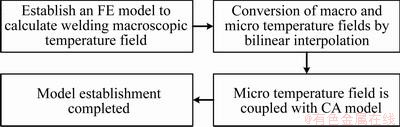

CA-FE模型的建立流程如图1所示。

图1 CA-FE模型的建立流程

Fig.1 CA-FE model establishment process

1 有限元计算模型

1.1 有限元几何模型

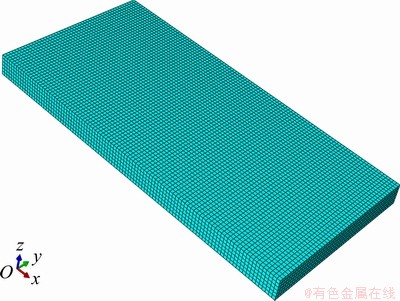

利用商业有限元软件ABAQUS完成有限元计算模型的建立,焊接试板的几何尺寸为100 mm×50 mm×6 mm,将其划分为30000个大小相同的有限元单元,单元类型选择8节点3维实体类型C3D8T,几何模型如图2所示。

图2 焊接试板几何模型及网格划分

Fig. 2 Geometric model and meshing of welding test plate

1.2 定义材料属性

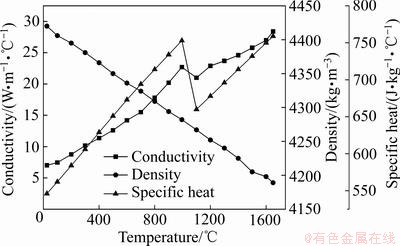

在有限元计算过程中,针对不同材料需要给有限元单元赋予不同的热物理性能参数,其直接关系到最终模拟结果的准确性,温度场计算需要的参数有热导率、密度及比热容,TC4合金的热物理参数如图3所示。

1.3 设定边界条件

图3 材料热物理参数

Fig. 3 Thermal properties of material

整个焊接加热及焊后冷却过程中,焊件主要通过对流和辐射的方式向周围环境散热,因此需要设置对流和辐射边界条件以模拟实际工况,焊件表面通过对流和辐射散失的热通量表达式为

(1)

(1)

(2)

(2)

式中: 为焊件表面温度,℃;

为焊件表面温度,℃; 为环境温度,℃;设定为25 ℃;

为环境温度,℃;设定为25 ℃; 为绝对温度,℃;σ为史蒂芬-玻尔兹曼常数,5.68×10-8 J·(K4·m2·s)-1;ε为辐射发射率值,为0.85。

为绝对温度,℃;σ为史蒂芬-玻尔兹曼常数,5.68×10-8 J·(K4·m2·s)-1;ε为辐射发射率值,为0.85。

1.4 焊接热源模型

不同焊接方法的热源对焊件的作用方式不同,因此实际热模拟研究中常将焊接热源简化为点热源、面热源和体热源。本文采用的焊接方法为TIG焊,其焊接电弧的热流在焊件上一定区域内分布,可将其视为面热源,故选用高斯平面热源模型,其数学表达式如下:

(3)

(3)

式中:qm为热源中心处的最大热流密度;r为距离电弧加热斑点的距离;rh为电弧有效热源半径。

2 元胞自动机模型

2.1 温度场宏微观耦合模型

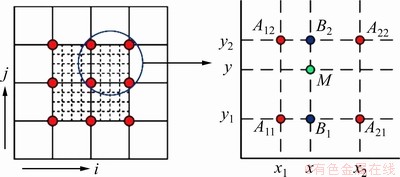

由于在尺度上量级不同,有限元计算得到的宏观温度场(毫米级)不能直接用于计算微观组织(微米级)演变,因此需要将其转换为微观温度场,利用插值原理可以很好地转换,本文采用双线性插值法对宏微观温度场进行转换[18],其原理如图4所示。

图4中,A11、A12、A21、A22代表宏观网格节点,M为微观网格节点,θ(Aij)和θ(M)分别表示宏微观尺度节点对应的温度值。插值方程如下所示:

(4)

(4)

图4 双线性插值方法的示意图

Fig. 4 Schematic diagram of linear interpolation method

2.2 形核模型

采用形核密度基于高斯分布函数的准连续形核模型[19],在某一过冷度Δθ下,形成的晶粒密度n(Δθ)为:

(5)

(5)

dn/d(Δθ)表达式如下:

(6)

(6)

式中:nmax为非均匀形核密度的最大值;Δθα为标准曲率过冷度;Δθmax为最大形核过冷度。

2.3 生长模型

晶核形成后,固液界面向前推进晶粒开始生长,tn时刻界面生长速率与过冷度之间的关系为

(7)

(7)

式中:μk(θ)为界面动力学系数。

固液界面的推进,伴随着元胞单元固相率的变化,固相率的增长与界面生长速率成正比,其可由式(8)表示:

(8)

(8)

式中:Δx为元胞单元尺寸;Δt为单个计算时间步长;G为邻位网格状态参数[20];A为扰动因子;rand为0~1的随机数。

G是为更好地再现晶粒择优生长方向任意性而引入的,由下式计算:

(9)

(9)

式中:b为经验值;S1m和S2m分别为最邻近和次近邻元胞的状态值,邻近元胞为固相时值为1,邻近元胞为液相或界面时值为0。

界面元胞转变为固相元胞过程中,固相率不断增加,时间t内,某一界面元胞的固相率为:

(10)

(10)

式中:N为迭代次数;Δt为时间步长;当fs(t)=1时,元胞状态转变为固相。

溶质的守恒是合金凝固数值模拟的基本原则之一,凝固过程中的溶质再分配现象是维持该原则的关键,就CA法原理而言,元胞状态转变为固相后,其多余的溶质需排向周围的邻胞,溶质的扩散通过求解如下非稳态扩散方程:

(11)

(11)

式中:CL为液相溶质浓度;DL为液相扩散系数。

3 模拟结果与分析

3.1 宏观温度场

在ABAQUS有限元计算平台上通过划分网格、赋予模型材料属性等步骤完成有限元模型的构建,初始环境温度场设定为25 ℃。焊接参数分别为:焊接电压14 V,焊接电流75 A,焊接速率1.5 mm/s,焊接热效率0.8;由于焊件的长度为100 mm,所以焊接热源的移动时间设定为66.6 s,有限元计算的总时长设定为133.2 s,0~66.6 s处于焊接加热阶段,66.6~133.2 s处于焊后冷却阶段。

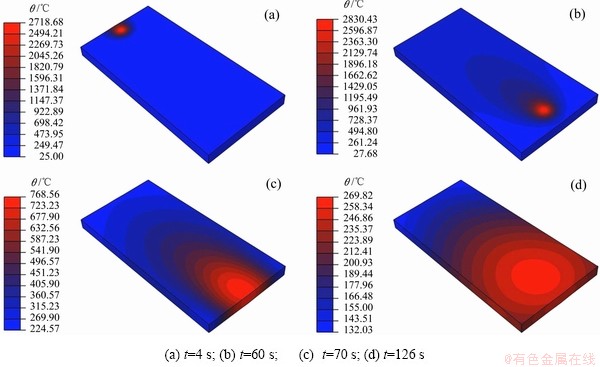

图5所示分别为4~126 s时焊件宏观温度场的分布情况。从图5(a)可以看出,焊接刚开始4 s时,焊接热源周围温度迅速上升,由于热输入总量有限,远离热源中心区域,温度保持在初始温度几乎不发生变化。随着焊接热源的移动(见图5(b)),在60 s时,热源中心附近的温度始终保持在较高水平,由于热量的积累以及焊件内部的热传导,焊件整体温度上升。随着热源的离开,焊接过程结束,焊件进入冷却阶段(见图5(c)),在70 s时,冷却过程开始,焊件后部由于在焊接后期一直处于加热状态,温度相对于焊件其余区域较高,保持在220~770 ℃之间。整个加热及冷却过程中焊件一直通过辐射和对流向周围环境中散热(见图5(d)),在126 s时,整体温度继续下降,焊件的温度降至130~270 ℃,且温度梯度明显趋缓,温度场更加均匀。

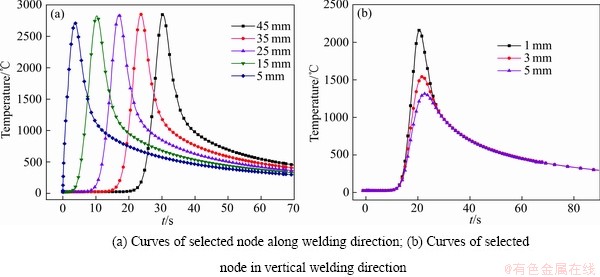

为进一步研究瞬态温度场的不均匀性,分别在焊件上表面沿焊缝中心方向和焊缝横截面上提取部分节点的热循环曲线,如图6(a)和(b)所示。

图5 不同时刻焊件宏观温度场分布模拟结果

Fig. 5 Simulation results of macroscopic temperature field distribution of weldments at different times

图6 不同节点焊接热循环曲线

Fig. 6 Welding thermal cycle curves of different nodes

由于焊接热源热量集中且加热速率快,故在短时间内温度达到极值。沿焊缝方向,随着热源的移动,各节点依次开始热循环过程,且热循环曲线的趋势一致,图6(a)所示为距起焊点不同位置的热循环曲线,由图6(a)可知,随着距起焊点距离的增加,峰值温度略有上升,这是焊件热量累计的结果。垂直焊缝方向(见图6(b)),各节点升温与降温过程同步发生,但随着距加热中心距离的增大,温度峰值降低,符合实际焊接温度场的变化规律。本文采用的建模方法的可行性已在前期研究中被证明[21],故不再赘述。

3.2 微观温度场

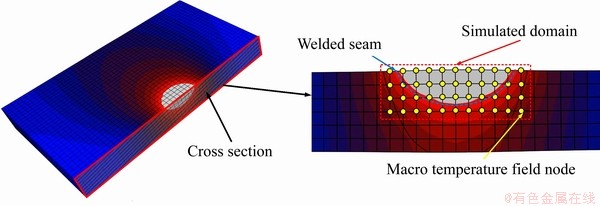

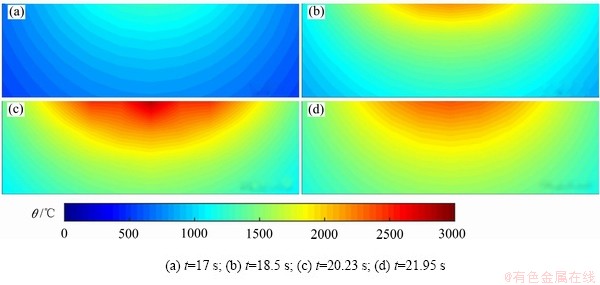

焊接方向上不同位置焊缝横截面上微观组织变化不大,故以其横截面为组织演变的研究对象。首先需要求解焊缝横截面的微观温度场,由于本文只针对焊缝进行研究,故只需提取部分宏观节点的温度值,取值示意图如图7所示。

模拟区域的大小为10 mm×3 mm,共30个宏观单元,将每个宏观温度场单元划分为100×100个微观单元,每个微观单元的面积为1×10-4 mm2,利用双线性插值原理,将宏观温度场转换为微观温度场。图8所示为17~21.95 s时的微观温度场,由图8可知,随着时间的进行微观温度场整体先升后降,连续性良好,且在空间分布上,不同区域之间温度过渡平滑,不存在突变的情况,符合实际焊接温度场的变化及分布规律,证明了利用插值原理获取微观温度场的可行性,可作为微观组织模拟的温度条件。

3.3 微观组织演变

图7 微观温度场模拟区域节点选取示意图

Fig. 7 The schematic diagram of node selection in simulation region of microcosmic temperature field

图8 不同时刻微观温度场模拟结果

Fig. 8 Simulation results of microcosmic temperature field at different time

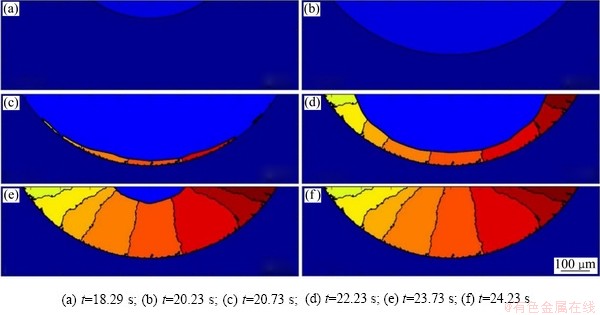

图9 不同时刻焊接熔池微观组织演化模拟结果

Fig. 9 Simulation results of microstructure evolution of welding pool at different time

图9所示为18.29~24.23 s焊接熔池凝固过程中微观组织的演变过程。整个演变过程可以分为两个阶段。在第一阶段(见图9(a)和(b)),其中蓝色代表液相,深蓝色代表固相;随着热源的接近,母材温度快速达到熔点并开始熔化,形成熔池,熔池在热源的持续作用下迅速扩大;由于熔池一直处于过热状态,无法达到晶粒的形核条件,故在熔池内无晶粒产生。在第二阶段,随着热源的远离,熔池通过向周围母材导热及与环境换热使整体温度下降,熔池边缘的散热速率更快,温度较熔池中心更低;当过冷度达到一定值时(见图9(c)),熔池边缘首先达到形核条件,晶粒以熔池边缘为衬底形核,其中熔池边缘底部导热距离更短,温度下降更快,故较边缘其他区域,底部形核更快;随着温度的进一步降低,更多晶粒在熔池边缘形核,符合非自发形核的规律。当晶粒形核后(见图9(d)、(e)和(f)),在瞬态温度场作用下会以柱状晶的形式向熔池中心生长,生长方向与温度梯度方向一致的晶粒具有更快的生长速率,在演化过程中取得优势并逐步占据熔池空间;生长方向与温度梯度方向不一致的晶粒,处于不利地位,晶粒的生长受到限制。

仔细观察可以发现,熔池中并没有出现焊接熔池凝固过程中常见的CET转变(柱状晶向等轴晶转变)现象。这主要是因为TC4是一种耐热合金,其比热容大,且热导率小,熔池处于过热状态的时间长,而熔池边缘散热更快,同一时刻温度更低,且有异质形核衬底作依托,从而率先达到形核条件,并沿着温度梯度方向朝熔池中心生长。与此同时,熔池中心温度还处于较高的水平,加之熔池中心形核衬底较少导致形核困难,并且溶质Al和V具有很高的溶质分配系数(接近于1)[22]。为进一步量化高分配系数对固相溶质浓度分布情况的影响,沿图10(a)所示的路径提取数据并绘制曲线。图10(b)显示整个焊缝中溶质分布较均匀,偏析程度不明显,Al的固相溶质浓度在5%~7%之间,V的固相溶质浓度在3.5%~4.5%之间,反映了固液转变伴随的溶质再分配过程中固液界面前沿溶质富集现象不明显,进而导致成分过冷度小,造成柱状晶前沿等轴晶形核困难,无等轴晶与柱状晶的竞争生长。故温度过冷就在晶粒的形核与生长过程中占主导地位,柱状晶可沿温度梯度方向一直生长到熔池中心。

图10 凝固后固相溶质浓度分布

Fig. 10 Solid phase solute concentration distribution after solidification

图11 不同溶质分配系数下的枝晶生长

Fig. 11 Dendritic growth under different solute partition coefficients

另一值得注意的现象是柱状晶无明显的二次及高次枝晶产生,这同样与溶质分配系数高导致成分过冷小有关系,为验证这一分析,利用所建立的CA模型对不同溶质分配系数下单个等轴晶的形貌进行模拟。图11所示分别为溶质分配系数k为0.5、0.7、0.9时单个等轴晶的生长形貌,当k值较小时(见图11(a)),主枝晶臂上有明显的二次枝晶产生,越靠近晶粒中心二次枝晶越粗大。这是由于枝晶生长过程中会将多余的溶质排向周围液相,从而在枝晶周围一定区域内出现溶质富集现象,进而产生一个成分过冷区;主枝晶臂上细小的凸起是由于处在过冷熔体中,在过冷度的作用下继续长大形成明显的二次枝晶。在二次枝晶臂上同样存在三次枝晶,产生原理与二次枝晶一致。随着k值的增大(见图11(b)),枝晶分支明显减少,枝晶的边界区域光滑,当k为0.9时,晶粒形貌为规整的菱形,无枝晶臂产生。由此可见,溶质分配系数越大晶粒分枝越不明显。

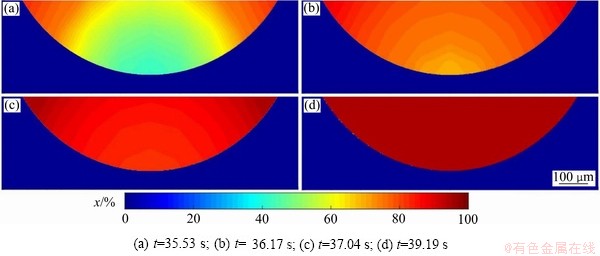

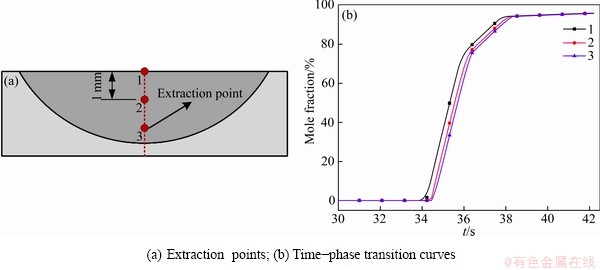

随着固液相变完成,焊件快速冷却,开始进入固态相变阶段。本文采用材料性能模拟软件Jmatpro计算焊接瞬态温度场条件下的相转变,并将其耦合入所建立的CA-FE模型,最终完成可视化处理。图12所示分别为35.53~39.19 s时固态相变过程中马氏体转变的宏观分布图,可见虽然最终得到的组织相同但各区域相变转变速率存在差异。为分析原因,绘制图13(a)所示位置的时间-相变曲线。由图13(b)可知,固液转变在很短时间完成后,α′马氏体的转变并没有马上开始;当温度降至825 ℃左右的相变点时,α′马氏体转变迅速发生。由于焊接温度场冷却速率大,故在很短的时间内熔池内微观组织全部转变为α′马氏体;且由于焊缝不同位置散热及导热的条件不同,故热过程有所区别,表现在固态相变过程有一定差异,转变开始时间点1>点2>点3。

图12 TC4合金焊接熔池凝固过程固态相变模拟结果

Fig. 12 Simulation results of solid phase transformation in solidification process of TC4 alloy welding pool

图13 焊接熔池固态相变点的位置选取及其时间-相变曲线

Fig. 13 Location selection of solid phase transition points in welding pool and their time-phase transition curves

4 实验研究

4.1 实验方法

为了进一步验证所建数值计算模型的准确性,采用TIG焊对尺寸与几何模型一致的TC4合金板进行焊接实验。焊接参数与模拟参数一致,焊接过程中采用热电偶法测试焊件上选定点的热循环曲线;焊后利用线切割将焊接接头加工成金相试样,抛光腐蚀后利用金相仪观察其微观组织。

4.2 结果和讨论

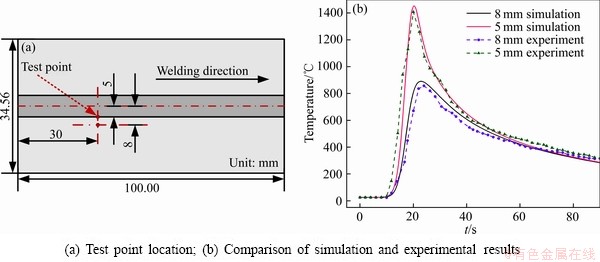

由于焊接过程中焊缝处于熔化状态故无法放置热电偶丝,故测试点布置在焊缝之外,测试点位置如图14(a)所示。将测得的热循环数据与模拟结果对比,如图14(b)所示。由于实验过程中现场环境的不确定性,会使结果出现一定的偏差,但模拟结果与实验结果的变化趋势基本一致,峰值温度偏差不大。热源通过时测试点的温度迅速上升,热源离开后测试点温度迅速下降;所测两点处于同一横截面上,故达到峰值的时间基本一致,符合焊接瞬态温度场的特点,证明温度场模拟结果较为准确。

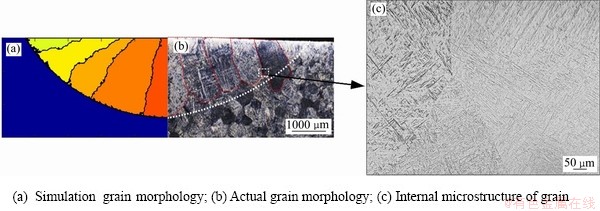

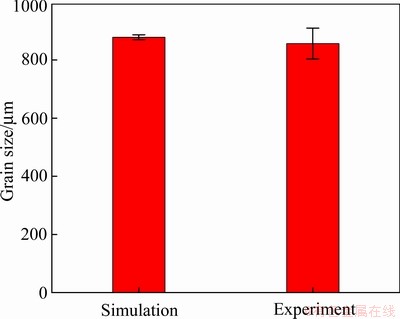

模拟结果与实验结果的对比如图15所示。由图15可知,模拟结果的熔池形貌与实验结果的金相组织吻合良好,凝固阶段焊缝区晶粒依附于熔池边缘粗大等轴晶形核,形成粗大的β柱状晶;冷却阶段α′马氏体在初始柱状晶晶界上形核并向晶粒内生长,由于冷速较快,无法发生β -α转变,故焊缝内的组织全为α′马氏体。为进一步探究所建模型的可靠性,多次模拟及实验后对晶粒尺寸大小进行比较,结果如图16所示。由图16可见,模拟与实验结果的晶粒平均尺寸差别仅有22 μm,晶粒尺寸差别很小,但模拟结果较实验结果明显稳定。这主要是因为现有计算模型虽然在某些环节考虑了随机性影响,但无法将所有因素考虑其中,而且前面提到初始β相依附于熔合线附近等轴晶形核,等轴晶的晶粒尺寸本身就存在很大的差别,故依附其形核生长的柱状晶尺寸也不稳定。总体而言,采用CA-FE法能较准确地模拟微观组织转变过程。

图14 焊接热循环曲线实验

Fig. 14 Measurement of welding thermal cycle curve

图15 焊接熔池微观组织模拟结果与实验结果对比图

Fig. 15 Comparison between simulation results and experimental results of weld pool microstructure

图16 模拟与实验晶粒尺寸的对比

Fig. 16 Grain size comparison between simulation and experiment

5 结论

1) 宏观温度场的模拟结果表明,整个焊接过程中由于焊接热源的移动,焊件温度场处于高度动态变化状态,而后冷却过程中趋于平稳,利用双线性差插值原理计算得到的微观温度场过渡平滑,适用于微观组织演变的计算。

2) 焊接瞬态温度场作用下,微观组织的凝固过程分为三个过程:熔池的形成,晶粒的形核,晶粒的长大。成分过冷小造成熔池内全为粗大的柱状晶晶粒,且无枝晶分支产生;凝固后温度降低至相变点后,开始固态相变过程,并在很短的时间内完成转变,冷却后熔池内组织都为α′马氏体。

3) 焊接热循环的模拟结果与实验结果基本一致,实验结果金相组织在熔池形貌与微观组织上与模拟结果吻合性良好,验证了所建CA-FE模型的可靠性。

REFERENCES

[1] SUN Yi, LUO Guo-qing, ZHANG Jian, WU Chuan-dong, LI Jun, SHEN Qiang, ZHANG Lian-meng. Phase transition, microstructure and mechanical properties of TC4 titanium alloy prepared by plasma activated sintering[J]. Journal of Alloys and Compounds, 2018, 741: 918-926.

[2] GHOSH S, MCREYNOLDS K, GUYER J E, BANERJEE D. Simulation of temperature, stress and microstructure fields during laser deposition of Ti-6Al-4V[J]. Modelling and Simulation in Materials Science and Engineering, 2018, 26(7): 075005.

[3] 张喜燕, 赵永庆, 白晨光. 钛合金及应用[M]. 北京: 化学工业出版社, 2005: 190-191.

ZHANG Xi-yan, ZHAO Yong-qing, BAI Chen-guang. Titanium alloy and its application[M]. Beijing: Chemical Industry Press, 2005: 190-191.

[4] 周祥曼, 田启华, 杜义贤, 柏兴旺, 张海鸥. 电弧增材成形单道两层熔积过程中的晶粒生长模拟[J]. 机械工程学报, 2018, 54(22): 86-94.

ZHOU Xiang-man, TIAN Qi-hua, DU Yi-xian, BAI Xing-wang, ZHANG Hai-ou. Simulation of grain growth in single-pass and two-layer deposition of arc welding based additive forming process[J]. Journal of Mechanical Engineering, 2018, 54(22): 86-94.

[5] ZHAN Xiao-hong, LIN Xin, GAO Zhuan-ni, GU Dong-dong. Modeling and simulation of the columnar-to-equiaxed transition during laser melting deposition of Invar alloy[J]. Journal of Alloys and Compounds, 2018, 755: 123-134.

[6] 刘波祖. 合金凝固过程枝晶生长的界面前沿跟踪法模 拟[D]. 济南: 山东建筑大学, 2016: 31-50.

LIU Bo-zu. Simulation of dendritic growth during multicomponent alloy solidification with a front-tracking method[D]. Jinan: Shandong Jianzhu University, 2016: 31-50.

[7] ZHAN Xiao-hong, WEI Yan-hong, DONG Zhi-bo. Cellular automaton simulation of grain growth with different orientation angles during solidification process[J]. Journal of Materials Processing Technology, 2008, 208(1-3): 1-8.

[8] ZHU M F, STEFANESCU D M. Virtual front tracking model for the quantitative modeling of dendritic growth in solidification of alloys[J]. Acta Materialia, 2007, 55(5): 1741-1755.

[9] 薛 覃. Ti-45%Al合金焊接熔池凝固过程的数值模拟[D]. 西安: 西安理工大学, 2017: 43-50.

XUE Qin. Numerical simulation of solidification process in welded molten pool of Ti-45%Al alloy[D]. Xi’an: Xi’an University of Technology, 2017: 43-50.

[10] LOPEZ-BOTELO O, MARTINEZ-HERNANDEZ U, RAMIREZ J, PINNA C, MUMTAZ K. Two-dimensional simulation of grain structure growth within selective laser melted AA-2024[J]. Materials & Design, 2017, 113: 369-376.

[11] YIN H, FELICELLI S D. Dendrite growth simulation during solidification in the LENS process[J]. Acta Materialia, 2010, 58(4): 1455-1465.

[12] HAN Ri-hong, LI Yi-yi, LU Shan-ping. Macro-micro modeling and simulation for the morphological evolution of the solidification structures in the entire weld[J]. International Journal of Heat and Mass Transfer, 2017, 106: 1345-1355.

[13] HAN Ri-hong, LU Shan-ping, DONG Wen-chao, LI Dian-zhong, LI Yi-yi. The morphological evolution of the axial structure and the curved columnar grain in the weld[J]. Journal of Crystal Growth, 2015, 431: 49-59.

[14] 李晗嫣, 陈文革, 张飞奇, 高红梅, 任澍忻. 基于CAFE模拟钛合金丝材电弧增材制造凝固过程的组织演变[J]. 中国有色金属学报, 2018, 28(9): 1775-1783.

LI Han-yan, CHEN Wen-ge, ZHANG Fei-qi, GAO Hong-mei, REN Shu-xin. Evolution of wire+arc additive manufactured titanium alloy during solidification process based on CAFE simulation[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(9): 1775-1783.

[15] DEZFOLI A R A, HWANG W S, HUANG W C, TSAI T W. Determination and controlling of grain structure of metals after laser incidence: Theoretical approach[J]. Scientific Reports, 2017, 7: 41527.

[16] TIAN Feng-jie, LI Zhen-guo, SONG Jian-xin. Solidification of laser deposition shaping for TC4 alloy based on cellular automation[J]. Journal of Alloys and Compounds, 2016, 676: 542-550.

[17] 魏 雷, 林 鑫, 王 猛, 黄卫东. 激光立体成形中熔池凝固微观组织的元胞自动机模拟[J]. 物理学报, 2015, 64(1): 356-363.

WEI Lei, LIN Xin, WANG Meng, HUANG Wei-Dong. Cellular automaton simulation of the molten pool of laser solid forming process[J]. Acta Physica Sinica, 2015, 64(1): 356-363.

[18] ZHOU Xiang-man, ZHANG Hai-ou, WANG Gui-lian, BAI Xing-wang, FU You-heng, ZHAO Jing-yi. Simulation of microstructure evolution during hybrid deposition and micro-rolling process[J]. Journal of Materials Science, 2016, 51(14): 6735-6749.

[19] LIU Peng-wei, WANG Zhou, XIAO Yao-hong, HORSTEMEYER M F, CUI Xiang-yang, CHNE Lei. Insight into the mechanisms of columnar to equiaxed grain transition during metallic additive manufacturing[J]. Additive Manufacturing, 2019, 26: 22-29.

[20] ZHU M F, CAO W, CHEN S L, CHANG Y A. Modeling of microstructure and microsegregation in solidification of multi-component alloys[J]. Journal of Phase Equilibria and Diffusion, 2007, 28(1): 130-138.

[21] ZHANG Min, ZHOU Yu-lan, HUANG Chao, CHU Qiao-ling, ZHANG Wen-hui, LI Ji-hong. Simulation of temperature distribution and microstructure evolution in the molten pool of GTAW Ti-6Al-4V alloy[J]. Materials, 2018, 11(11): 2288-2304.

[22] ZINOVIEVA O, ZINOVIEV A, PLOSHIKHIN V. Three-dimensional modeling of the microstructure evolution during metal additive manufacturing[J]. Computational Materials Science, 2018, 141: 207-220.

Numerical simulation and analysis of microstructure evolution of TC4 Alloy weld pool

ZHANG Min, HUANG Chao, GUO Yu-fei, ZHANG Li-sheng, LI Ji-hong

(School of Material Science and Engineering, Xi’an University of Technology, Xi’an 710048, China)

Abstract: Based on the CA-FE method (cell automaton-finite element) combined with grain nucleation and growth theory, a numerical calculation model for microstructure evolution in TC4 titanium alloy molten pool under transient welding temperature field was established on MATLAB simulation platform. Based on the model, the welding transient temperature field and the microstructure evolution under its influence were simulated. The results show that, the calculation results of the temperature field are consistent with the characteristics of local heat concentration and high dynamic changes in the welding heat process. The edge of the molten pool is first nucleated, and under the action of the temperature gradient, the crystal grains grow in the form of columnar crystals to the center of the molten pool and finally form a coarse columnar crystal structure. The microstructure in the molten pool rapidly transforms into α' martensite in the solid phase transformation stage. The verification experiment was carried out on the simulation results, and the simulation results are in good agreement with the experimental results, indicating that the model is highly reliable.

Key words: TC4 alloy; molten pool; microstructure; numerical simulation; CA-FE method

Foundation item: Project(51974243) supported by National Natural Science Foundation of China; Project(2019JZ-31) supported by Natural Science Foundation of Shaanxi Provincial Department, China; Project (201805037YD15CG21(16)) supported by Xi’an Municipal Science and Technology Planning Project, China

Received date: 2019-09-11; Accepted date: 2019-11-30

Corresponding author: ZHANG Min; Tel: +86-29-82312205; E-mail: zhmmn@xaut.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51974243);陕西省自然科学基础研究计划项目(2019JZ-31);西安市科技计划项目(201805037YD15CG21(16))

收稿日期:2019-09-11;修订日期:2019-11-30

通信作者:张 敏,教授,博士;电话:029-82312205;E-mail:zhmmn@xaut.edu.cn