文章编号: 1004-0609(2005)12-2003-06

CeCl3对含Ce镁合金精炼过程中Ce损耗量的影响

高洪涛, 吴国华, 樊 昱, 丁文江, 朱燕萍

(上海交通大学 材料科学与工程学院 金属基复合材料国家重点实验室, 上海 200030)

摘 要: 采用含CeCl3的净化熔剂对含Ce的镁合金进行精炼, 研究了CeCl3对合金中Ce损耗量的影响规律。 结果表明: 当熔剂中不含CeCl3时, 合金中的Ce损失高达27.7%; 而当CeCl3的含量达到15%时, 合金中的Ce损失仅为4.5%, CeCl3处理使镁合金中稀土相均匀分布, 使Mg17Al12相细化, 但相组成没有明显变化; 随着CeCl3含量的增加, 合金力学性能提高, 但过多的CeCl3会在合金中引入熔剂夹杂。 并从热力学方面探讨了熔剂与镁液的作用机理, 计算了镁熔体中Mg和Ce的活度及熔剂熔体中MgCl2和CeCl3的活度。 结果表明, 由于CeCl3抑制了合金中Ce与熔剂中MgCl2的反应, 从而降低了Ce 的损耗。

关键词: 镁合金; Ce损耗; 精炼; 热力学 中图分类号: TG146.2

文献标识码: A

Effect of CeCl3 on loss of

Ce in magnesium alloy during refining

GAO Hong-tao, WU Guo-hua, FAN Yu, DING Wen-jiang, ZHU Yan-ping

(State Key Laboratory of Metal Matrix Composites,

School of Materials Science and Engineering,

Shanghai Jiaotong University, Shanghai 200030, China)

Abstract: The effect of CeCl3 in flux on the loss of Ce in magnesium alloy during refining was investigated. The results show when there is no CeCl3 in the flux, the loss of Ce in the magnesium alloy AZ91 is 27.7%. When CeCl3 is added by 15% in the flux, the loss of Ce is only 4.5%, CeCl3 can also make Ce-containing phases distribute evenly and Mg17Al12 phase refine, but the phase composition of the experimental alloys can not change obviously. The mechanical properties of the alloys are improved by CeCl3 processing with the increase of CeCl2 content, and excessive CeCl3 will produce flux inclusions. Furthermore, the reactions between flux and magnesium melt were studied thermodynamically. The activities of Mg and Ce in magnesiun alloy and MgCl2 and CeCl3 in flux were calculated. The results show that CeCl3 restrains the reaction between Ce in magnesium alloy and MgCl2 in flux. Therefore, the loss of Ce in magnesium alloy decreases.

Key words: magnesium alloy; loss of Ce; refining; thermodynamic

镁合金以其优良的性能得到广泛应用[1-3], 但是由于镁合金在高温下易于燃烧, 从而在铸造过程中产生夹杂, 因此镁合金常需要净化[4]。 普通含MgCl2 的熔剂对普通镁合金有很好的净化效果, 但对于含Ce(常见的稀土合金化元素[5, 6])的镁合金不能使用含MgCl2 的熔剂进行净化, 因为MgCl2 会与稀土元素Ce反应, 导致昂贵稀土Ce大量损耗[7-9]。 Emley[10]和张承甫[11]用CaCl2 代替熔剂中MgCl2或添加其它辅助物以减少稀土Ce损失, 但净化效果难以保证。

通过在含MgCl2的普通熔剂中加入活性稀土化合物CeCl3, 以达到既能良好地除杂, 又能降低昂贵Ce损耗的目的, 但该方面的研究尚未见报道。 本文作者研究了CeCl3对含Ce镁合金精炼过程中Ce损耗量的影响规律, 并从热力学上进行了探讨, 对于发展含稀土镁合金的熔剂精炼技术具有十分重要的理论和实践价值。

1 实验

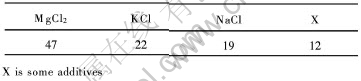

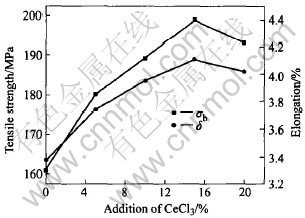

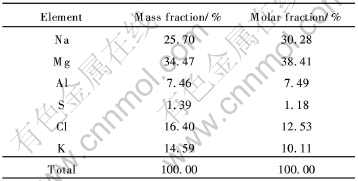

采用工业镁合金AZ91、 纯铈(≥99.9%)。 实验熔剂由自行开发的普通镁合金精炼剂JDMJ与化学纯CeCl3混合而成, 其组分分别列于表1和2。

表1 精炼剂JDMJ的组分

Table 1 Composites of JDMJ flux (mass fraction, %)

表2 实验熔剂的组分

Table 2 Composites of JC series fluxes (mass fraction, %)

在坩埚电阻炉中熔炼镁合金AZ91, 加入1%铈制成含稀土Ce的镁合金。 然后分别用2%的实验熔剂在730~740℃对该稀土镁合金进行精炼处理。 合金化学成份采用电感等离子耦合光谱仪(ICP, IRIS Advantage 1000)测定。 合金组织与相成分采用光学显微镜(OM, Olympus PME3)和带能谱的电子显微镜(SEM, Philip SEM515)分析。 采用X衍射仪(XRD, D/maxⅢA )进行相组成分析。 拉伸实验在Zwick/Roell材料实验机上进行。

2 结果与分析

2.1 Ce损耗量

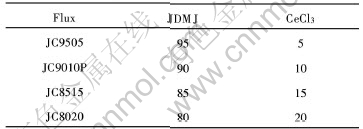

实验熔剂精炼后合金中的Ce含量如图1所示。 Ce损耗量如表3所示。

图1 熔剂中CeCl3的含量与精炼后合金中Ce含量的关系

Fig.1 Relationship between Ce content in alloys after purification and content of CeCl3

表3 合金中Ce的损耗量

Table 3 Mass loss of Ce in experimental alloy

从图1和表3可以看出, 随着熔剂中CeCl3含量的增加, 精炼后合金中的稀土Ce含量几乎呈直线增加, 不含CeCl3的JDMJ熔剂精炼后, 合金中Ce含量只有0.723%, 损耗量达27.7%; 而当采用含15% CeCl3的JC8515熔剂精炼后, 合金中的Ce含量为0.955%, 损耗量仅为4.5%。 由此可见, CeCl3可以显著减少熔剂精炼过程中Ce的损耗。

2.2 组织力学性能

图2所示为CeCl3处理实验镁合金前后的微观组织。 由图2可看出, 净化处理前, 稀土相多偏聚在Mg17Al12相, 且分布不均匀, 粗大杆状很多; 而净化处理后, 稀土相分布更均匀, 粗大杆状相相应减少, 但是相组成并没有明显变化(见图3)。

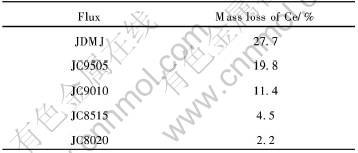

图4所示为CeCl3用量对处理后的镁合金力学性能的影响。 由图4可看出, 随着CeCl3加入量增加, 合金的抗拉强度(σb)和延伸率(δ)都明显提高,这是由于处理后, 镁合金中的夹杂减少, 同时Mg17Al12相细化及稀土相均匀化所致。 由于过量的CeCl3熔剂夹杂引入, 从而导致力学性能降低, 结果如图5所示。 由图5可看出, 能谱分析结果中包含氯离子, 可以肯定为熔剂夹杂。 能谱分析结果如表4所列。

图2 CeCl3处理前(a)和处理后(b)含Ce镁合金的微观组织

Fig.2 Microstructures of Mg alloys with Ce before (a) and after (b) CeCl3 processing

图3 经CeCl3处理后含Ce镁合金相组成的X射线衍射谱

Fig.3 XRD patterns of Mg alloys with Ce after CeCl3 processing

3 讨论

在含CeCl3的熔剂对含Ce镁合金的精炼过程中, 反应如下:

3(MgCl2)+2[Ce]=2(CeCl3)+3[Mg]

ΔG=-270078+170.46TlgT-1203.19T

反应式中圆括弧表示物质在熔剂中, 方括弧表示物质在镁熔体中。

图4 CeCl3添加量对镁合金力学性能的影响

Fig.4 Effect of CeCl3 addition on tensile properties of Mg alloys

图5 熔剂夹杂的SEM像(a)及其能谱分析(b)

Fig.5 SEM image(a) and EDS analysis result (b) of flux inclusion

表4 熔剂夹杂的能谱分析结果

Table 4 EDS analysis results of inclusion in flux

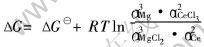

使用相关热力学数据[12, 13], 在标准状态下, 该反应的标准Gibbs自由能变化可计算得

ΔG=-503.0518kJ/mol

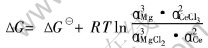

负值说明标准状态下该反应可以发生, 即合金中的Ce会和熔剂中的MgCl2 反应。 而在实际状态下, 该反应的标准Gibbs自由能变化为

式中 αMg, αMgCl2, αCe和αCeCl3分别是Mg, MgCl2, Ce 和 CeCl3 的活度。

上述物质的活度可分别计算如下。

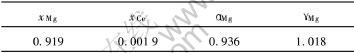

1)镁合金熔体中Mg的活度

计算镁熔体中Mg的活度时, 为简便, 可假定为Mg-Al二元体系, 采用熔化自由能法计算。

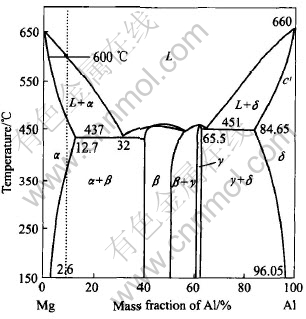

第一步, 先用标准熔化Gibbs自由能求液相线上Mg的活度α1Mg(873K)(根据图6所示相图可知AZ91中的液相线温度约为600℃, 即873K)。

图6 Mg-Al 相图[14]

Fig.6 Phase diagram of binary Mg-Al alloy

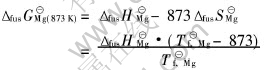

在液相线上, Mg的熔化自由能

ΔfusGMg(873K)=-RTlnα1Mg(873K)

在熔点处, Mg的熔化自由能

ΔfusGMg=ΔfusHMg-T*f, Mg·ΔfusSMg=0

得

假设Mg标准熔化焓ΔfusHMg和标准熔化熵ΔfusSMg随温度变化不大, 则在873K时,

查表得ΔfusHMg=8.71kJ/mol, 标准态Mg的熔点Tf, Mg=922K。

从以上各式联合可得液相线上Mg的活度为α1Mg(873K)=0.938, 活度系数为γMg(873K)=1.021。

第二步, 根据正规溶液性质求实际状态下Mg的活度。

设精炼温度为1008K, 由T1008KlnγMg(1008K)=T873KlnγMg(873K)

可得1008K时的Mg活度系数γMg(1008K)=1.018。

因此, 实际状态下Mg的活度为αMg=0.936。

2)镁合金熔体中Ce的活度

在计算镁熔体中Ce的活度时, 可对熔体进行简化, 只考虑Mg-Ce二元系, 利用a函数进行计算。 镁合金熔体中的相关数据如表5所列。

根据吉布斯-杜安方程

xCedGCe, m+xMgdGMg, m=0

式中 xMg和xCe分别为镁熔体中Mg和Ce的摩尔分数; GMg, m和GCe, m分别是Mg 和Ce的偏摩尔Gibbs自由能。

得

xCedlnαCe+xMgdlnαMg=0

或

xCedγCe+xMgdγMg=0

对上式积分得lnγCe=-aMgxCexMg+

∫xMg0aMgdxMg

式中 , 称为a函数。

, 称为a函数。

为简便起见, 设a函数与xMg成线性关系, 则利用表5中数据可得lnγCe=1.2464或γCe=3.4715。

表5 镁合金熔体中的相关数据

Table 5 Related data of Mg alloy flux

从而得镁熔体中Ce的活度αCe=0.0066。

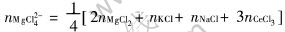

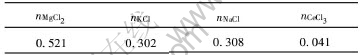

3) 熔剂中CeCl3和MgCl2活度的计算

熔剂中主要组成为MgCl2、 KCl、 NaCl和CeCl3, 根据MgCl2-KCl-NaCl相图(见图7), 精炼温度下熔剂熔体中存在的主要阳离子为Mg2+、 Na+、 K+和Ce3+; 主要阴离子为MgCl2-4。 熔剂中主要物质的摩尔数如表6所列。

图7 MgCl2-KCl-NaCl的相图[15]

Fig.7 Phase diagram of MgCl2-KCl-NaCl

nMgCl2, nKCl, nNaCl和nCeCl3分别是MgCl2、 KCl、 NaCl和CeCl3的摩尔数。

则阴离子的摩尔数为

阳离子摩尔数为nMgCl2+nKCl+nNaCl+nCeCl3-nMgCl2-4

Mg2+的摩尔数为nMg2+=nMgCl2-nMgCl2-4

Ce3+的摩尔数为nCeCl3

则Mg2+的摩尔分数为

Ce3+的摩尔分数为

利用表6中的数据

可得xMg2+=0.106, xCe3+=0.056。

表6 熔剂中主要物质的量

Table 6 Mole number of major substance in flux

为简便, 用摩尔分数代替活度, 即得熔剂熔体中Mg2+和Ce3+的活度分别为αMg2+=0.106和αCe3+=0.056。

最后利用活度值αMg=0.936、 αCe=0.0066、 αMg2+=0.106和αCe3+=0.056得

计算实际状态下反应的Gibbs自由能变为

ΔG=-966827.9+8.314×1008×

ln(49567.6)=-876.2254kJ/mol

虽然Gibbs自由能仍为负值, 但随着αCeCl3的增加, 反应的热力学倾向将会减弱, 即CeCl3抑制反应向右进行。 这就是含CeCl3熔剂降低合金精炼过程中Ce损耗的主要原因。 若同时考虑动力学方面的因素, 在精炼过程中, Mg为本体, CeCl3与Mg的反应动力学条件要比Ce与MgCl2反应的动力学条件优越得多。 因此, 不管是热力学或者动力学, 在实际条件下, 都不利于反应向右进行。

4 结论

1) 含CeCl3的熔剂精炼含Ce的镁合金时, 随着CeCl3含量的增加, 合金中Ce的损失减少, 当熔剂中不含CeCl3时, 合金中Ce损失高达27.7%; 而当CeCl3的含量达到15%时, 合金中Ce损失仅为4.5%。

2) CeCl3处理使镁合金中稀土相均匀分布, 使Mg17Al12相细化, 但相组成没有明显变化。 同时随着CeCl3加入量的增加, 合金力学性能提高, 但过多的CeCl3会在合金中引入熔剂夹杂。

3) 利用熔化自由能法和a函数法计算了镁熔体中Mg和Ce的活度, 利用熔盐离子模型计算了熔剂熔体中MgCl2和CeCl3的活度, 得出αMg=0.936, αCe=0.0066, αMg2+=0.106和αCe3+=0.056。 根据计算结果, 由于CeCl3强烈地抑制了合金中Ce与熔剂中MgCl2的反应, 从而使得含CeCl3熔剂降低镁合金精炼过程中Ce的损耗。

REFERENCES

[1]Froes F H, Eliezer D, Aghion E. The science, technology, and applications of magnesium[J]. JOM, 1998, 50(9): 30-34.

[2]Buch F V, Schumann S, Aghion E, et al. Development of a low-cost, temperature- and creep-resistant magnesium die-casting alloy[A]. Kainer K U. Magnesium Alloys and their Applications[C]. Wernheim: WILEY-VCH Verlag GmbH, 2000. 23-28.

[3]曾荣昌, 柯伟, 徐永波, 等. Mg合金的最新进展及应用前景[J]. 金属学报, 2001, 37(7): 673-685.

ZENG Rong-chang, KE Wei, XU Yong-bo, et al. Recent development and application of magnesium alloys[J]. Acta Metallurgica Sinica, 2001, 37(7): 673-685.

[4]卢晨, 吴国华, 蔡超, 等. 镁合金净化技术研究[J]. 金属成形工艺, 2002, 20(5): 5-7.

LU Chen, WU Guo-hua, CAI Chao, et al. Study on the purification technology of magnesium alloy[J]. Metal Forming Technology, 2002, 20(5): 5-7.

[5]WANG Qu-dong, LU Yi-zhen, ZENG Xiao-qin, et al. Effects of RE on the microstructures and properties of AZ91 magnesium alloy[J]. Trans Nonferrous Met Soc China, 2000, 10(2): 235-239.

[6]闵学刚, 孙扬善, 杜温文, 等. Ca、 Si和RE对AZ91合金的组织和性能的影响[J]. 东南大学学报, 2002, 32(3): 409-414.

MIN Xue-gang, SUN Yang-shan, DU Wen-wen, et al. Effect of Ca, Si and RE additions on the microstructures and mechanical properties of AZ91 based alloys[J]. Journal of Southeast University, 2002, 32(3): 409-414.

[7]王渠东, 吕宜振, 曾小勤, 等. 稀土在铸造镁合金中的应用[J]. 特种铸造及有色合金, 1999(1): 40-43.

WANG Qu-dong, L Yi-zhen, ZENG Xiao-qin, et al. Application of rare earth metals in cast magnesium alloy[J]. Special Cast and Nonferrous Alloys, 1999(1): 40-43.

[8]Ferro R, Saccone A, Borzone G. Rare earth metals in light alloys[J]. Journal of Alloy and Compounds,1995, 220(1-2): 161-166.

[9]Suseelan K N, Mittal M C. Rare earths in magnesium alloys[J]. Materials Science Forum, 1988, 30: 89-104.

[10]Emley E F. Principles of Magnesium Technology[M]. Oxford: Pergamon Press, 1966.

[11]张承甫. 液态金属的净化与变质[M]. 上海: 上海科学技术出版社, 1989.

ZHANG Cheng-fu. Purification and Modification of Liquid Metals[M]. Shanghai: Shanghai Science Press, 1989.

[12]梁英教, 车荫昌, 刘小霞, 等. 无机物热力学数据手册[M]. 沈阳: 东北大学出版社, 1993.

LIANG Ying-jiao, CHE Yin-chang, LIU Xiao-xia, et al. Handbook of Inorganic Thermodynamic Data[M]. Shenyang: Northeastern University Press, 1993.

[13]Turkdogan E T. Physical Chemistry of High Temperature Technology[M]. New York: Academic Press, 1980.

[14]刘正, 张奎, 曾小勤. 镁基轻质合金理论基础及其应用[M]. 北京: 机械工业出版社, 2002.

LIU Zheng, ZHANG Kui, ZENG Xiao-qin. Theory Foundation and Application of Magnesium Based Light Alloys[M]. Beijing: Mechanical Industrial Press, 2002.

[15]李文超. 冶金与材料物理化学[M]. 北京: 冶金工业出版社, 1999.

LI Wen-chao. Metallurgy and Materials Physic Chemistry[M]. Beijing: Metallurgy Industrial Press, 1999.

基金项目: 国家自然科学基金资助项目(50474005); 国家高技术研究发展计划(2002AA331120)

收稿日期: 2005-03-03; 修订日期: 2005-08-24

作者简介: 高洪涛(1976 - ), 男, 博士研究生

通讯作者: 高洪涛, 电话: 021-62932239; 传真: 021-62932113; E-mail: hunter@sjtu.edu.cn

(编辑李艳红)