文章编号:1004-0609(2008)12-2127-05

AZ31镁合金挤压薄板织构及力学各向异性

余 琨,芮守泰,王日初,彭超群,薛新颖

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:研究AZ31镁合金挤压薄板的显微组织、织构及室温下板面内各不同方向的力学性能。织构分析表明,挤压薄板主要有{0002}<1`010>和{1`010}<1`120> 2种织构组分。拉伸测试结果显示,沿挤压方向屈服强度最高,达到200.4 MPa,这是由于这种取向基面滑移和{1`012}锥面孪生均不能开动,发生织构强化的结果;与挤压方向呈45?方向伸长率最高达19.0%,这是由于具有{1`010}<1`120>织构组分晶粒的基面滑移开动;与挤压方向呈90?方向屈服强度最低仅为挤压方向相应值的一半左右,这是由于具有{1`010}<1`120>织构组分晶粒发生了{1`012}锥面 孪生。

关键词:AZ31镁合金;挤压;织构;力学各向异性

中图分类号:TG 146.2 文献标识码: A

Texture and mechanical anisotropy of AZ31 extruded sheets

YU Kun, RUI Shou-tai, WANG Ri-chu, PENG Chao-qun, XUE Xin-ying

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The microstructure, texture and mechanical properties in different planar directions of the AZ31 magnesium alloy extruded sheets were investigated. There are two main texture components, that is {0002}<1`010> and {1`010}<1`120>, from texture analysis. The results from the tensile tests at room temperature are as follows: the basal slip as well as the {1`012} pyramidal twinning is inhibited in extrusion direction under the tensile loads, which results in the highest yield strength (200.4 MPa); for the specimen in the direction 45? to the extrusion direction, the basal slip is activated in the grains with {1`010}<1`120> texture component, which results in the highest elongation (19.0%); the yield strength in the direction 90? to the extrusion direction is only half of its counterpart along the extrusion direction because the {1`012} pyramidal twinning is operated in the grains with {1`010}<1`120> texture component.

Key words: AZ31 magnesium alloy; extrusion; texture; mechanical anisotropy

镁合金以其低密度和高比强的突出优点,在汽车及航空工业等领域得到广泛应用[1]。但由于其密排六方(HCP)晶体结构,在室温下仅具有2个独立的基面滑移系,不能满足多晶体均匀变形所需至少5个独立滑移系的要求,导致室温下塑性变形能力很差[2?3]。因此,镁合金的塑性加工一般在高温下进行,以激活非基面滑移。

在变形镁合金产品当中,镁合金板材在各领域有广泛的应用前景,但目前高质量的镁合金板材并不多。镁合金板材通常采用轧制方法生产,由于镁合金塑性变形能力差,所以通常采用多道次、小压下量轧制,并且要经过数次中间加热,导致生产周期长,成本太高,与其它轻合金特别是铝合金相比没有太多竞争优势。近年来,用挤压方法制备镁合金板材开展了较多研究[4?8],来提高板材的综合力学性能并降低成本。但目前国内外对挤压板材的研究主要在其后续轧制方面,挤压板材厚度一般大于10 mm,对于挤压板材特别是挤压薄板本身的研究并不多。挤压板材织构及力学各向异性对其后续轧制或拉深等二次塑性成形具有重要的影响,所以研究挤压板材的织构及力学各向异性有重要的实用价值。目前国内外对这方面的研究很少[9?10],本文作者研究镁合金挤压薄板的织构和室温下板面内各不同方向的力学性能,并从变形机制入手探讨了镁合金力学各向异性与织构之间的关系。

1 实验

实验板材为AZ31镁合金,成分为Mg-3%Al-1% Zn-0.2%Mn,采用800T卧室挤压机挤压获得,铸锭加热温度653 K,挤压比为44.2,最终得到板材厚度1.5 mm,宽度96 mm。采用Polyvar?MET金相显微镜观察板材的显微组织结构。拉伸力学性能测试在CSS44100电子万能材料实验机上进行。在板面内,分别沿挤压方向(ED, extrusion direction);与挤压方向呈45?方向;90?方向,即横向(TD, transverse direction)分别取样进行拉伸测试,如图1所示,试样分别简记为ED, 45?, TD。拉伸试样标距部分尺寸为10 mm×50 mm,拉伸速率为2 mm/min。分别对板材的3个不同面即TD-ED面(简记为ND面),ND-TD面(简记为ED面),ND-ED面(简记为TD面)分别进行X射线衍射分析,X射线衍射分析试样尺寸为15 mm×15 mm×15 mm,由10块15 mm×15 mm×1.5 mm的线切割小块累积拼合而成(拼合时保证各小块取向一致),用Harris方法[11]从所得衍射谱分别做出板材板面法向(ND)、挤压方向(ED)和横向(TD)的反极图,再由反极图分析板材的织构。X射线衍射仪型号为D/max 2500 VB+,采用Cu靶Kα衍射。

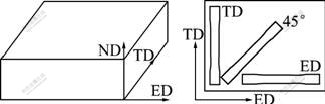

图1 拉伸样品取样方向示意图

Fig.1 Schematic diagram of specimen orientations for tensile tests

2 实验结果

2.1 显微组织结构

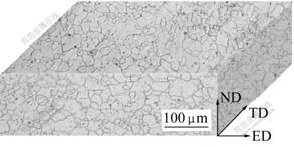

图2所示为板材三维光学显微照片。从图中可见,板材晶粒由较细小的等轴动态再结晶晶粒组成,但晶粒大小分布不是很均匀,平均晶粒尺寸约为37 μm。图3所示为不同方向试样拉伸至8%应变时的光学显

图2 挤压板材三维光学显微照片

Fig.2 Optical micrograph of as-extruded AZ31 sheets

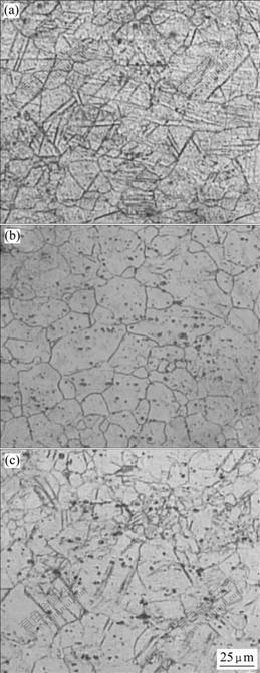

图3 不同方向试样拉伸至8%应变时的显微组织

Fig.3 Microstructures of different specimens during tensile tests to strain of 0.08: (a) ED specimen; (b) 45?specimen; (c) TD specimen

2.2 织构

图4所示为挤压薄板不同方向的反极图。分析图4(a)可知,板材内部晶粒取向可分为2组:一组为{0002}基面平行于板面(ND面),记为ND组分;另外一组为{0002}基面平行于TD面({1`010}柱面平行于板面),记为TD组分。

图4 板材板面法向、挤压方向和横向的反极图

Fig.4 Inverse pole figures of ND(a),ED(b), and TD(c)

图5所示为这两种织构组分相对于板材宏观坐标系的取向分布,这与铸锭热轧之后的织构有很大差别,铸锭热轧之后会形成单一的强基面织构,即绝大多数晶粒的{0002}基面均平行于板面[12]。综合分析图4可以确定ND组分为{0002}<1`010>,TD组分为{1`010}<1`120>,其中ND组分占主导地位。图4(a)表明,TD组分晶粒基面法线朝ND方向约有30?左右的偏转;图4(b)表明,ND组分晶粒基面法向朝ED方向约有15?左右的偏转。

图5 挤压板材内部晶粒取向分布示意图

Fig.5 Schematic diagram relating TD and ND components to specimen coordinate system (Basal planes of two components are shown shaded.)

2.3 室温力学性能

图6所示为板面内各不同方向试样室温拉伸时典型的应力—应变曲线,表1列出了相关的力学性能。由图6可见,板面内力学各向异性明显,ED试样拉伸屈服强度最高,达200.4 MPa,而45?试样和TD试样的屈服强度则分别只有125.2 MPa和107.4 MPa;ED试样和TD试样的极限抗拉强度差别不大,均在280 MPa左右,而45?试样的极限抗拉强度略低,为258.0 MPa;45?试样的断裂伸长率最高,达19.0%。

图6 板面内不同方向典型的室温拉伸应力—应变曲线

Fig.6 Typical stress—strain curves from tensile tests in different planar directions at room temperature

表1 AZ31挤压薄板挤压态的力学性能

Table 1 Mechanical properties of as-extruded AZ31 sheets

3 讨论

镁合金中可以开动的滑移系主要有以下4种:即{0002}<1`120>基面滑移,{1`010} <1`120>柱面滑移,{1`011}<1`120>和{1`012}<1`120>一阶锥面滑移,{1`122}<1`11112`3>二阶锥面滑移[13?14]。室温下,非基面滑移(柱面、锥面)所需临界剪切应力(CRSS)比基面滑移大得多,上述4种的CRSS比值约为1?38?50?100[15];所需激活温度也呈递增趋势,柱面滑移、一阶锥面滑移和二阶锥面滑移所需的激活温度分别为450、623和573 K[16]。镁合金塑性变形除上述4种滑移模式之外,还有2种重要的孪生模式:即{1`012} `<1011>和{1`011}<1`01`2>锥面孪生。{1`012} `<1011>孪晶在c轴受拉应力作用(或垂直于c轴受压应力)作用时产生,即所谓的“拉伸孪晶”,{1`011}<1`01`2>孪晶在c轴受压应力作用(或垂直于c轴受拉应力作用)时产生,通常称之为“压缩孪晶”。{1`012}孪生所需的CRSS仅为2 MPa[16],是最常见的孪生模式;{1`011}孪生所需的CRSS值相对较高,约在76~153 MPa之间[16],所以只有在基面滑移和其它变形模式受到抑制时它才可能被激活。综上所述,在室温下AZ31镁合金的主要变形模式为基面滑移和锥面孪生。

对于ED试样,无论是ND组分还是TD组分,{0002}面法向与拉伸轴夹角均为90?(见图5),基面滑移史密特因子为0,拉伸轴垂直于c轴,{1`012}孪生也不能启动,但这种取向有利于{1`011}孪生,所以ED试样在拉伸过程中出现了较多孪晶(见图3(a))。但{1`011}孪生所需CRSS值较高,而且由于孪生切变量很小,对合金塑性变形贡献不大,所以ED试样的伸长率最低,而屈服强度最高(见图6和表1),这是织构强化的结果。由表1可见,ED试样屈服强度达到200.4 MPa,这除了织构强化之外,还要考虑到“挤压效应”。

对于45?试样,ND组分基面滑移的史密特因子为0,但TD组分基面滑移的史密特因子为0.5(cos45?·cos45?),基面滑移很容易开动,导致45?试样屈服强度较低,极限抗拉强度也有所下降,但伸长率最高。由于基面滑移开动,45?试样拉伸至8%应变时微观组织中几乎观察不到孪晶(见图3(b))。

对于TD试样,ND组分和TD组分基面滑移的史密特因子均为0,基面滑移不能开动;但TD组分晶粒c轴与拉伸轴平行,此时{1`012}孪生的史密特因子为0.498(cos43?·cos47?),此种取向最有利于{1`012}孪生。TD试样屈服强度最低显然与{1`012}孪生有关,对于AZ31镁合金,发生{1`012}孪生时屈服强度仅为织构强化时(本实验中为ED试样)相应值的一半左 右[17?19],与本实验研究结果一致。一般来讲,发生{1`012}孪生之后,极限抗拉强度会较织构强化时有所提高,伸长率会降低,这是因为孪生之后增加的孪晶界会阻碍位错运动;另外考虑到{1`012}孪晶相对基体的86?旋转作用,晶体孪生部分对基面滑移来说依然处于“硬取向”[20]。但从图6可以发现,TD试样与ED试样极限抗拉强度相当,但伸长率反而较ED试样大。这可能是因为:一是只有TD组分晶粒才能发生{1`012}孪生,孪晶数量有限;二是前面织构分析已经表明TD组分晶粒的基面并不严格平行于TD面,而是沿挤压方向有30?左右的偏转,偏转角度较大的一部分晶粒基面滑移开动,导致伸长率升高。

4 结论

1) 挤压薄板主要有{0002}<1`010>和{1`010}<1`120>2种织构组分。

2) 挤压薄板板面内力学各向异性明显,沿挤压方向屈服强度最高达到200.4 MPa,是因为这种取向基面滑移和{1`012}锥面孪生均不能开动,是织构强化的结果;与挤压方向呈45?方向伸长率最高达19.0%,是因为具有{1`010}<1`120>织构组分晶粒的基面滑移开动;与挤压方向呈90?方向屈服强度最低仅为挤压方向相应值的一半左右,是由于具有{1`010}<1`120>织构组分的晶粒发生了{1`012}锥面孪生。

REFERENCES

[1] MORDIKE B L, EBERT T. Magnesium properties-applications- potential[J]. Mater Sci Eng A, 2001, A302(1): 37?45.

[2] PRASAD T V R K, RAO K P. Effect of crystallographic texture on the kinetics of hot deformation of rolled Mg-3Al-1Zn alloy plate[J]. Mater Sci Eng A, 2006, A432(1/2): 170?177.

[3] 余 琨, 黎文献, 王日初. 镁合金塑性变形机制[J]. 中国有色金属学报, 2005, 15(7): 1081?1086.

YU Kun, LI Wen-xian, WANG Ri-chu. Plastic deformation mechanism of magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(7): 1081?1086.

[4] HSIANG Su-hai, KUO Jer-liang. An investigation on the hot extrusion process of magnesium alloy sheet[J]. J Mater Process Tech, 2003, 140(1/3): 6?12.

[5] KOHZU M, HIRONAKA T, NAKATSUKA S, SAITO N, YOSHIDA F, NAKA T, OKAHARA H, HIGASHI K. Effect of texture of AZ31 magnesium alloy sheet on mechanical properties and formability at high strain rate[J]. Mater Trans, 2007, 48(4): 764?768.

[6] DEL VALLE J A, PEREZ-PRADO M T, RUANO O A. Texture evolution during large strain hot rolling of the Mg AZ61 alloy[J]. Mater Sci Eng A, 2003, A355(1/2): 68?78.

[7] KOIKE J, OHYAMA R. Geometrical criterion for the activation of prismatic slip in AZ61 Mg alloy sheets deformed at room temperature[J]. Acta Mater, 2005, 53(7): 1963?1972.

[8] 张青来, 王粒粒, 张士宏, 戴起勋, 王忠堂. AZ31镁合金薄板的制备及其组织性能研究[J]. 金属热处理, 2006, 31(9): 5?10.

ZHANG Qing-lai, WANG Li-li, ZHANG Shi-hong, DAI Qi-xun, WANG Zhong-tang. Preparation of AZ31 Magnesium alloy sheet and its microstructure and property[J]. Metal Heat Treatment, 2006, 31(9): 5?10.

[9] PEREZ-PRADO M T, RUANO O A. Texture evolution during annealing of magnesium AZ31 alloy[J]. Scripta Mater, 2002, 46, (2): 149?155.

[10] KLEINER S, UGGOWITZER P J. Mechanical anisotropy of extruded Mg-6%Al-1%Zn alloy[J]. Mater Sci Eng A, 2004, A379(1/2): 258?263.

[11] HARRIS G B. Quantitative measurements of preferred orientation in rolled uranium bars[J]. Phil Mag, 1952, 43: 113?123.

[12] WANG Y N, HUANG J C. Texture analysis in hexagonal materials[J]. Materials Chemistry and Physics, 2003, 81(1): 11?26.

[13] STYCZYNSKI A, HARTIG C, BOHLEN J, LETZIG D. Cold rolling textures in AZ31 wrought magnesium alloy[J]. Scripta Mater, 2004, 50(7): 943?947.

[14] CAHN R W. Structure and properties of nonferrous alloys[M]. Beijing: Science Press, 1999: 123.

[15] GEHRMAN R, FROMMERT M M, GOTTSTEIN G. Texture effects on plastic deformation of magnesium[J]. Mater Sci Eng A, 2005, A395(1/2): 338?349.

[16] CHINO Y, KIMURA K, HAKAMADA M, MABUCHI M. Mechanical anisotropy due to twinning in an extruded AZ31 Mg alloy[J]. Mater Sci Eng A, 2008, A485(1/2): 311?317.

[17] CHRISTIAN J W, MAHAJAN S. Deformation twinning[J]. Pro Mater Sci, 1995, 39(1/2): 1?157.

[18] BARNETT M R. Twinning and the ductility of magnesium alloys PartⅠ: “Tension” twins[J]. Mater Sci Eng A, 2007, A464(1/2): 1?7.

[19] WANG Y N, HUANG J C. The role of twinning and untwinning in yielding behavior in hot- extruded Mg-Al-Zn alloy[J]. Acta Mater, 2007, 55(3): 897?905.

[20] AGNEW S R, YOO M H. Application of texture simulation to understanding mechanical behavior of Mg and solid solution alloys containing Li or Y[J]. Acta Mater, 2001, 49(20): 4277?4289.

基金项目:国家“十一五”科技支撑计划资助项目(2006BAE04B02-3)

收稿日期:2008-04-15;修订日期:2008-07-25

通讯作者:余 琨,副教授,博士;电话:0731-8879341;传真:0731-8876692;E-mail: kunyugroup@163.com

(编辑 陈爱华)