低压等离子喷涂NiCoCrAlYTa涂层的

组织结构及抗氧化性能

周宏明,易丹青

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘 要:采用低压等离子喷涂在Co基高温合金K640基体上制备NiCoCrAlYTa涂层,通过XRD,SEM和EDS等方法研究低压等离子喷涂涂层和真空退火后涂层的形貌、相结构及抗氧化性能。研究结果表明:低压等离子喷涂涂层主要由γ-Ni,γ′-AlNi3和极少量的β-NiAl等相组成,元素分布均匀,涂层为典型的片层状结构,沉积界面处存在少量孔洞;真空退火处理过程促进了β-NiAl相的析出,衍射峰尖锐,元素分布不均匀,Al和Y向涂层表面扩散,Cr富集于涂层与基体的界面处;真空热处理涂层表面在氧化初期形成较多孔洞,导致涂层抗氧化能力 降低。

关键词:低压等离子喷涂;NiCoCrAlYTa涂层;真空热处理;组织结构;抗氧化性能

中图分类号:TG174.451 文献标识码:A 文章编号:1672-7207(2008)04-0741-07

Phase structure and oxidation resistance of NiCoCrAlYTa coating prepared by LPPS

ZHOU Hong-ming, YI Dan-qing

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: NiCoCrAlYTa coating on a Co-based high-temperature alloy (K640) substrate was prepared by low-pressure plasma spray (LPPS). The phase structure and oxidation resistance of LPPS and vacuum annealed coating were investigated by XRD, SEM and EDS. The results show that the sprayed NiCoCrAlYTa coating, which consists of a three-phase mixture, i.e., γ-Ni, γ′-AlNi3 and trace of β-NiAl phase, has a homogeneous element distribution, shows a typical layer structure, and has a small amount pore in the deposited interface. After vacuum heat treatment, the NiCoCrAlYTa coating mainly consists of γ-Ni, γ′-AlNi3 and β-NiAl phase; the diffraction peak becomes sharp, and the outermost layer of the coating is rich in Al and Y. However, the layer closed to the substrate of the coating is rich in Cr, and depletes in Al and Ni. Lots of small holes are formed on the surface of the vacuum annealed coating, which decreases the oxidation resistance of NiCoCrAlYTa coating prepared by LPPS.

Key words: low-pressure plasma spray; NiCoCrAlYTa coating; vacuum annealed; phase structure; oxidation resistance

近年来,随着航空燃气涡轮机向高流量比、高推重比、高进口温度方向发展,涡轮前进口温度不断提高,目前已接近2 000 K[1-2]。涡轮发动机一、二级涡轮外环一般选用铸造高温Co基合金。由于在服役过程中遭受高温氧化和热腐蚀破坏,为提高涡轮外环、叶片等高温热端部件的使用寿命,保证燃气轮机的安全稳定运行,除改进高温合金的成分、制备工艺和叶片设计外,使用防护性涂层是目前最有效的办法[3-4]。

国外从20世纪60年代开始对MCrAlY(M为Ni,Co或NiCo)涂层进行研究,70年代已有工业化产品。

MCrAlY具有良好的抗高温氧化和抗热腐蚀性能,而且具有良好的塑性,成分可按要求控制。目前,国内外学者对MCrAlY涂层的研究主要可分为2个方面:一是通过优化涂层设计,如加入Ti,Zr,Hf,Si,Re和Ta等元素,以提高其抗氧化性能,此外,还采用加入扩散障碍层[5-6]、梯度及多相复合涂层等多层设计的方法[7];二是发展新的制备工艺,以获得质量好的涂层并降低生产成本。目前,MCrAlY涂层的制备技术主要有低压等离子喷涂[8]、电子束物理气相沉积[9]、电弧离子镀[10-12]、磁控溅射[13]、高速火焰喷涂[14]和爆炸喷涂[15]等。其中,低压等离子喷涂(LPPS)在真空或保护气氛下进行,制备的涂层孔隙率低,化学纯净度高,在高温应用下抗氧化能力强,在热障涂层制备中应用广泛。

研究表明[5],在MCrAlY中加入Ta可强化γ′-AlNi3相,从而提高涂层使用温度,俘获氧,增加Al的活度。张玉娟等[16-17]对单晶镍基高温合金低压等离子喷涂NiCrAlY涂层的恒温氧化行为和爆炸喷涂NiCrAlYTa涂层的微观组织进行了研究。目前,人们对低压等离子喷涂NiCoCrAlYTa涂层组织结构及高温抗氧化性能的研究很少,对NiCoCrAlYTa涂层/Co合金基体的性能也不了解。为此,本文作者采用低压等离子喷涂在Co基高温合金上沉积NiCoCrAlYTa涂层,对涂层的组织结构和抗氧化性能进行研究,并探讨真空热处理对涂层的组织结构及抗氧化性能的影响,以期为NiCoCrAlYTa涂层的设计、低压等离子喷涂制备以及抗氧化性能的改善提供理论依据。

1 实验方法

试样基材为Co基铸造高温合金K640,成分为Co-24Cr-10Ni-7W(其中数值为质量分数,%,下同),通过低压等离子喷涂在基体上制备NiCoCrAlYTa涂层,成分为Ni-20Co-19Cr-17Al-0.5Y-1.5Ta。制备涂层前,将基材线切割成长×宽×高为10 mm×6 mm× 3 mm的试样。试样经金相砂纸逐级打磨及喷砂(75 μm玻璃丸,湿喷)处理后,用丙酮进行超声清洗。采用广州有色金属研究院组建的低压等离子喷涂系统制备涂层,转移弧清洁基材表面工艺及NiCoCrAlYTa涂层喷涂工艺参数如表1所示。所有试验样品的6个面均喷涂涂层,用于氧化形貌观察和动力学试验。将部分喷涂涂层的试样进行真空热处理(1 000 ℃,4 h),真空度低于0.01 Pa,升温速率为7 ℃/min。

表1 NiCoCrAlYTa涂层的转移弧及LPPS喷涂工艺

Table 1 Transferred arc and LPPS process of NiCoCrAlYTa coating

恒温氧化试验在1 000 ℃空气电炉中进行。试验前,将坩埚在1 200 ℃烧至恒重。在实验过程中,每隔一定时间将样品从炉中取出冷却称重,实验中平行样品不少于3片,天平的感量为50 μg。用Sirion 200型场发射扫描电镜(FESEM)、能谱分析(EDS)及Dmax-2500VB X射线衍射仪(XRD)分析基体合金和涂层及其氧化物的相结构和表面形貌。

2 实验结果及讨论

2.1 涂层退火前、后的XRD分析

采用X射线衍射对NiCoCrAlYTa合金粉末和涂层的沉积态、退火态进行分析,结果如图1所示。

1—NiCoCrAlYTa粉末;2—真空热处理涂层;3—LPPS喷涂涂层

图1 涂层热处理前、后和NiCoCrAlYTa合金粉末的XRD图谱

Fig.1 XRD patterns of NiCoCrAlYTa alloy powder and LPPS sprayed, annealed coatings

从图1可以看出,低压等离子喷涂的NiCoCrAlYTa涂层中β-NiAl相衍射强度比粉末状态时衍射峰强度

低很多,说明喷涂过程使β-NiAl相减少。经真空热处理后,涂层的相结构发生变化,衍射峰变窄,且衍射峰强度增大,β-NiAl相衍射峰强度增强,表明真空热处理过程促进了β-NiAl相的析出。衍射峰宽度的变化可以认为是喷涂态涂层中具有较小的晶粒粒径和较高的微观残余应力所致[12]。

2.2 涂层退火前、后表面的SEM分析

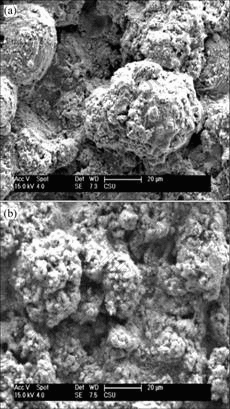

图2(a)和2(b)所示分别为沉积态和真空退火态NiCoCrAlYTa涂层的表面SEM形貌。

(a) 喷涂态涂层表面形貌;(b) 真空退火态涂层表面形貌

图2 喷涂态和真空退火态NiCoCrAlYTa涂层的表面SEM形貌

Fig.2 SEM morphologies of surface for LPPS sprayed and vacuum annealed NiCoCrAlYTa coating

从图2(a)可见,采用低压等离子喷涂技术制备的NiCoCrAlYTa涂层表面比较粗糙,未见微裂纹,粒径不等的颗粒分布在涂层表面。经真空热处理后(见图2(b)),涂层表面的颗粒较溅射态涂层表面的颗粒细小,也更加致密。

2.3 热处理前、后涂层截面SEM和能谱分析

采用场发射电子扫描电镜分析低压等离子喷涂制备的NiCoCrAlYTa涂层的横截面形貌,并对其元素成分进行线扫描,结果如图3所示。

(a) 喷涂态截面形貌;(b) 热处理态截面形貌;(c) 喷涂态元素线扫描;(d) 热处理态元素线扫描

图3 NiCoCrAlYTa涂层的截面形貌和元素线扫描

Fig.3 Cross-sectional SEM images and line scanning results of NiCoCrAlYTa coating

由图3(a)可见,在喷涂态涂层中可见典型的片层状结构,每走枪1次沉积下来的涂层片层与下一次沉积片层的界面清晰,存在未熔粒子,除了沉积界面处存在少量孔洞外,其他区域很致密,粘结界面清晰。能谱分析结果(见表2)显示,浅色区域1为γ'-AlNi3相,深色区域2为β-NiAl相,基体相为γ-Ni固溶体。

表2 NiCoCrAlYTa涂层各点的成分

Table 2 Composition of 1, 2, and precipitate in NiCoCrAlYTa coating

从图3(b)可见,涂层经真空热处理后其组织发生较大变化。β-NiAl相细小均匀弥散分布于基体中,未熔粒子粘结界面消失,这说明真空热处理过程促进了涂层组织的均匀化;基体和涂层没有形成明显的扩散层,但有颗粒状白色析出相。由表2可知,白色析出相中的Ta含量远高于涂层中其他部分的Ta含量,是一种富Ta相。

由图3(c)可知,低压等离子喷涂涂层中Ni和Cr的“平均”浓度分布都比较均匀,只是涂层中Ni和Cr含量比基体的高。在涂层/基体界面处各元素含量陡然变化,表明在低压等离子喷涂过程中,Cr,Ni和Co元素扩散速度低,各元素含量保持低压等离子喷涂时的水平。Y和Ta在涂层和基体中的分布未显示差异,这可能是Y和Ta的含量较少,且测量时Y和Ta的背底值与实测值相近,掩盖了其真实结果。

对比图3(c)和3(d)可知,涂层经真空热处理后,元素浓度沿基体到涂层表面方向发生了不同程度的变化,元素扩散主要发生在临近基体/涂层界面区域和涂层表面。线扫描结果表明,涂层经热处理后,在邻近基体的区域富Cr,贫Al和Ni,涂层中的Cr向基体扩散,形成富Cr的扩散层。这是因为在Ni-Cr合金体系中引入质量分数为5.8%的Al时,会降低Cr的扩散系数[18],界面处Al含量减少,这是造成Cr扩散的主要原因。图3(d)表明,Y和Al在真空热处理后向涂层表面富集。Al向涂层表面富集将有利于表面氧化铝薄膜的形成;而Y向涂层表面富集将改善表面氧化膜的性能,并提高氧化膜的粘附性,形成“楔子”,将氧化膜钉轧在涂层表面[19]。

2.4 氧化动力学

图4所示为Co基合金基体、低压等离子喷涂NiCoCrAlYTa涂层及其真空热处理涂层在1 000 ℃氧化100 h的氧化动力学曲线。

1—喷涂态涂层;2—真空热处理涂层;3—Co基体合金

图4 基体、喷涂态及真空热处理态涂层在1 000 ℃氧化100 h的氧化动力学曲线

Fig.4 Oxidation kinetics curves of substrate, LPPS sprayed and vacuum NiCoCrAlYTa coatings in air at 1 000 ℃ for 100 h

由图4可以看出,Co基合金样品在氧化过程中生成的氧化物不断开裂、剥落,裸露新的表面(基体氧化2 h后,氧化膜部分脱落,如图5所示),形成新的氧化物,如此重复进行,在图4所示的动力学曲线上表现出持续的上升,其氧化增重速率大大高于低压等离子喷涂和真空热处理涂层样品的氧化增重速率。低压等离子喷涂涂层在氧化初期增重迅速,10 h后增重曲线缓慢地过渡到平稳状态,氧化增重速率显著降低。涂层经过真空热处理后,氧化增重速率略高于喷涂态的涂层氧化增重速率,表明真空热处理会对涂层的抗氧化性能产生不利影响。其主要原因可能为:

a. 真空热处理后,Al元素已向表面聚集,沉积界面上预先产生了扩散形成的细孔。在氧化过程中,细孔加快了元素扩散和氧化速度,同时,产生了更多扩散空位,使膜区布满孔洞。

b. 在热处理过程中,Al在涂层表面聚集,易吸附环境中的氧形成微小的Al2O3晶核,分散在涂层表面。在氧化初期,θ-Al2O3优先在这些微量晶核处形核,吸收附近未形核区域的Al快速长大,而这些贫Al区域在周围θ-Al2O3簇拥下形成凹陷,成为表面孔洞(见图6(c)),因而,对表面生成连续α-Al2O3氧化膜起阻碍作用。

图5 Co基合金在1 000 ℃氧化2 h的形貌

Fig.5 Surface morphology of Co-based alloy after oxidation at 1 000 ℃ for 2 h

2.5 涂层表面形貌和相结构分析

喷涂涂层及真空热处理涂层在1000 ℃氧化不同时间后的表面形貌如图6所示。

(a) 喷涂态涂层氧化10 h;(b) 喷涂态涂层氧化50 h; (c) 真空热处理涂层氧化1 h;(d) 真空热处理涂层氧化5 h

图6 喷涂态涂层和真空热处理涂层在1 000 ℃氧化不同时间的表面形貌

Fig.6 Surface morphologies of LPPS sprayed coating after oxidation and vacuum annealed coating at 1 000 ℃ for different time

由图6可见,在氧化初期,涂层表面生成针状的θ-Al2O3(见图6(a)和图6(c)),随着氧化的进行,转变成六角形α-Al2O3,只是在不同温度下,发生转变的时间不同。喷涂态涂层在1 000 ℃氧化10 h,针状θ-Al2O3向α-Al2O3转变,50 h时表面已观察不到θ-Al2O3(见图6(b));真空热处理涂层氧化1 h后可在表面观察到细针状的θ-Al2O3,氧化5 h后便开始发生θ-Al2O3向α-Al2O3的转变(见图6(d))。与喷涂态的涂层相比,真空热处理涂层氧化后生成的θ-Al2O3更加细碎、密集。这是因为在氧化初期,θ-Al2O3优先在热处理时表面生成的微量Al2O3晶粒为晶核,形核速率快。此外,表面有很多孔洞,这些孔洞为氧的扩散提供了捷径,加速了涂层的氧化,从而导致真空热处理后涂层的抗氧化能力降低。这与上述氧化动力学研究结果是一致的。

图7(a)和7(b)表明,低压等离子喷涂涂层和真空热处理涂层在1 000 ℃恒温氧化100 h后,其XRD图谱基本一致,2种涂层的表面氧化物都主要为α-Al2O3,γ′-AlNi3和Ni2(Cr, Co, Al)O4,喷涂态涂层中的γ-Ni和β-NiAl相的衍射峰消失。

(a) 低压等离子喷涂涂层;(b) 真空热处理涂层

图7 喷涂态涂层和真空热处理涂层在1 000 ℃氧化100 h的XRD图谱

Fig.7 XRD patterns for LPPS sprayed coating and vacuum annealed coating oxidized at 1 000 ℃ for 100 h

3 结 论

a. 低压等离子喷涂的NiCoCrAlYTa涂层主要由γ-Ni和γ′-AlNi3相组成,涂层为典型的层状结构,有少量未熔粒子夹杂及沉积孔洞,元素分布均匀,与基体没有扩散。经真空热处理后,涂层中除γ-Ni和γ′-AlNi3相外,还有β-NiAl相析出,并消除了涂层的沉积界面及粘结界面。涂层中Cr向基体扩散,在靠近基体处形成富Cr贫Al和Ni的扩散层;Y和Al向涂层表面富集;颗粒状白色相为富Ta相化合物。

b. 真空热处理涂层在氧化初期,表面形成较多孔洞,加速了涂层的氧化,从而导致涂层抗氧化能力降低。

c. 喷涂态涂层在1 000 ℃氧化10 h时,针状θ-Al2O3向α-Al2O3转变;真空热处理涂层在1 000 ℃氧化1 h时可在表面观察到细针状θ-Al2O3,氧化5 h后θ-Al2O3向α-Al2O3转变。氧化100 h后,2种涂层的XRD图谱基本一致,析出相主要为α-Al2O3,γ′-AlNi3和Ni2(Cr, Co, Al)O4。

参考文献:

[1] Schulz U, Leyens C, Fritscher K, et al. Some recent trends in research and technology of advanced thermal barrier coatings[J]. Aerospace Science and Technology, 2003, 7(1): 73-80.

[2] 周宏明, 易丹青, 余志明. 热障涂层的研究现状与发展方向[J]. 材料导报, 2006, 20(3): 4-8.

ZHOU Hong-ming, YI Dan-qing, YU Zhi-ming. Research status and development tendency of thermal barrier coatings[J]. Materials Review, 2006, 20(3): 4-8.

[3] 孙 超, 王启民, 唐永吉, 等. 电弧离子镀NiCoCrAlY涂层的组织结构及初期氧化[J]. 金属学报, 2005, 41(11): 1167-1173.

SUN Chao, WANG Qi-min, TANG Yong-ji, et al. Microstructure and initial stage oxidation of NioCoCrAlY coatings deposited by arc ion plating technique[J]. Acta Metallurgica Sinica, 2005, 41(11): 1167-1173.

[4] 夏长清, 李 佳, 古 一, 等. NiCrAlY涂层/TC4基体界面反应机理[J]. 中南大学学报: 自然科学版, 2005, 36(4): 550-554.

XIA Chang-qing, LI Jia, GU Yi, et al. Interaction behavior between NiCrAlY coating and TC4 alloy substrate[J]. Journal of Central South University: Science and Technology, 2005, 36(4): 550-554.

[5] Nicoll A R, Wahl G. The effect of alloying additions of M-Cr-Al-Y systems: An experimental study[J]. Thin Solid Films, 1982, 95(1): 21-34.

[6] Nicholls J R, Simms N J, Chan W Y. Smart overlay coatings-concept and practice[J]. Surface and Coating Technology, 2002, 149(2/3): 236-244.

[7] Guo M H, Wang W M, Ke P L. The preparation and hot corrosion resistance of gradient NiCoCrAlYSiB coatings surface and coatings technology[J]. Surface and Coating Technology, 2006, 200(12/13): 3942-3949.

[8] Gudmundsson B, Jacobson B E. The effect of silicon and zirconium additions on the microstructure of vacuum-plasma-sprayed Co-Ni-Cr-Al-Y coating[J]. Materials Science Engineering A, 1989, 108(1): 73-80.

[9] Schulz U, Fritscher K, Peters M. EB-PVD Y2O3- and CeO2/Y2O3- stabilized zirconia thermal barrier coatings crystal habit and phase composition[J]. Surface and Coating Technology, 1996, 82(3): 259-269.

[10] 郝杉杉, 刘海平, 汪晓全. 真空电弧镀沉积NiCrAlY涂层工艺[J]. 材料工程, 1999(2): 40-43.

HAO Shan-shan, LIU Hai-ping, WANG Xiao-quan. Deposition of the NiCrAlY coating by vacuum arc ion plating[J]. Journal of Materials Engineering, 1999(2): 40-43.

[11] Wang Q M, Wu Y N, Ke P L. Hot corrosion behavior of AIP NiCoCrAlY(SiB) coatings on nickel base super-alloys[J]. Surface and Coating Technology, 2004, 186(3): 389-397.

[12] 李美姮, 张重远, 孙晓峰. 真空热处理对镍基单晶高温合金溅射NiCrAlY涂层抗氧化性能的影响[J]. 中国腐蚀与防护学报, 2002, 22(3): 153-157.

LI Mei-heng, ZHANG Zhong-yuan, SUN Xiao-feng. Effect of vacuum heat treatment on oxidation resistance of sputtered NiCrAlY coating on a Ni-base single-crystal super-alloy[J]. Journal of Chinese Society for Corrosion Protection, 2002, 22(3): 153-157.

[13] 徐爱群, 黄海波, 王世栋. 磁控溅射NiCrAlY镀层的组织结构研究[J]. 东南大学学报, 1996, 26(4): 136-138.

XU Ai-qun, HUANG Hai-bo, WANG Shi-dong. Investigation on the structure of magnetron sputtered NiCrAlY coatings[J]. Journal of Southeast University, 1996, 26(4): 136-138.

[14] Brandl W, Toma D, Grabke H J. The characteristics of alumina scales formed on HVOF-sprayed MCrAlY coatings[J]. Surface and Coating Technology, 1998, 108/109(1/3): 10-15.

[15] 武颖娜, 华伟刚, 纪爱玲. 爆炸喷涂技术制备热障涂层的研究[J]. 金属学报, 2002, 38(10): 1082-1086.

WU Ying-na, HUA Wei-gang, JI Ai-ling. Study on the thermal barrier coatings obtained by detonation spraying technology[J]. Acta Metallurgica Sinica, 2002, 38(10): 1082-1086.

[16] 张玉娟, 孙晓峰, 金 涛, 等. 低压等离子喷涂NiCrAlY涂层的恒温氧化特征分析[J]. 材料保护, 2003, 36(1): 14-16.

ZHANG Yu-juan, SUN Xiao-feng, JIN Tao, et al. Isothermal oxidation characteristics of NiCrAlY coating by low pressure plasma spraying[J]. Materials Protection, 2003, 36(1): 14-16.

[17] 张玉娟, 孙晓峰, 金 涛, 等. 爆炸喷涂NiCrAlYTa涂层的微观组织分析[J]. 金属学报, 2003, 39(2): 185-188.

ZHANG Yu-juan, SUN Xiao-feng, JIN Tao, et al. Microstructure of DS NiCrAlYTa coating[J]. Acta Metallurgica Sinica, 2003, 39(2): 185-188.

[18] Luthra K L, Briant C L. Mechanisms of scale-metal adhesion on MCrAlY alloys[J]. Materials Science and Engineering, 1987, 28(4): 438-443.

[19] Rybicki G C, Smialek K L. Effect of the θ→α-Al2O3 transformations on the oxidation behavior of the β-NiAl+Zr[J]. Oxidation of Metals, 1989, 31(3): 275-280.

收稿日期:2007-10-21;修回日期:2008-01-06

基金项目:中国博士后基金资助项目(20060400261)

通信作者:周宏明(1974-),男,湖南茶陵人,博士,副教授,从事高温合金涂层及结构材料研究;电话:0731-8830092;E-mail: ipezhm@yahoo.com.cn