应变速率对GH690高温合金热变形特性的影响

来源期刊:中国有色金属学报(英文版)2017年第3期

论文作者:石照夏 颜晓峰 段春华 赵明汉

文章页码:538 - 550

关键词:GH690 高温合金;热变形;应变速率;动态再结晶

Key words:GH690 superalloy; hot deformation; strain rate; dynamic recrystallization (DRX)

摘 要:为阐明应变速率对GH690高温合金热变形特性的影响,采用Gleeble-3800热力模拟试验机,通过变形温度范围为1000~1200 °C、应变速率范围为0.001~10 s-1的等温热压缩实验研究了该合金的热变形行为。结果表明:流变应力对应变速率变化敏感,动态再结晶是主要的软化机制;0.1 s-1是1000 °C热变形过程中的临界应变速率。绝热温升使得动态再结晶过程与应变速率密切相关;应变速率对热变形过程中的非连续动态再结晶和连续动态再结晶具有显著影响;孪晶可促进动态再结晶形核,Σ3n (n=1, 2, 3)晶界在中等应变速率0.1 s-1条件下含量较低。

Abstract: In order to clarify the effect of strain rate on hot deformation characteristics of GH690 superalloy, the hot deformation behavior of this superalloy was investigated by isothermal compression in the temperature range of 1000-1200 °C and strain rate range of 0.001-10 s-1 on a Gleeble-3800 thermo-mechanical simulator. The results reveal that the flow stress is sensitive to the strain rate, and the dynamic recrystallization (DRX) is the principal softening mechanism. The strain rate of 0.1 s-1 is considered to be the critical point during the hot deformation at 1000 °C. The DRX process is closely related to the strain rate due to the adiabatic temperature rise. The strain rate has an important influence on DDRX and CDRX during hot deformation. The nucleation of DRX can be activated by twin boundaries, and there is a lower fraction of Σ 3n (n=1, 2, 3) boundaries at the intermediate strain rate of 0.1 s-1.

Trans. Nonferrous Met. Soc. China 27(2017) 538-550

Zhao-xia SHI1,2, Xiao-fengYAN1, Chun-hua DUAN1, Ming-han ZHAO1

1. High Temperature Materials Research Institute, Central Iron and Steel Research Institute, Beijing 100081, China;

2. Beijing Key Laboratory of Advanced High Temperature Materials, Central Iron and Steel Research Institute, Beijing 100081, China

Received 26 February 2016; accepted 1 September 2016

Abstract: In order to clarify the effect of strain rate on hot deformation characteristics of GH690 superalloy, the hot deformation behavior of this superalloy was investigated by isothermal compression in the temperature range of 1000-1200 °C and strain rate range of 0.001-10 s-1on a Gleeble-3800 thermo-mechanical simulator. The results reveal that the flow stress is sensitive to the strain rate, and the dynamic recrystallization (DRX) is the principal softening mechanism. The strain rate of 0.1 s-1 is considered to be the critical point during the hot deformation at 1000 °C. The DRX process is closely related to the strain rate due to the adiabatic temperature rise. The strain rate has an important influence on DDRX and CDRX during hot deformation. The nucleation of DRX can be activated by twin boundaries, and there is a lower fraction of Σ 3n(n=1, 2, 3) boundaries at the intermediate strain rate of 0.1 s-1.

Key words: GH690 superalloy; hot deformation; strain rate; dynamic recrystallization (DRX)

1 Introduction

GH690, known as a solid solution strengthened nickel-based superalloy, is a high chromium and low carbon content modification on the base of alloy 600. GH690 superalloy has been widely employed in industries of corrosive, high stress and high temperature environmental conditions such as nuclear, chemical and petrochemical industries, due to its combination of excellent resistance to stress corrosion cracking (SCC) and intergranular attack (IGA), high strength, metallurgical stability and good formability [1-3]. In nuclear power industry, GH690 superalloy is mainly used as steam generator tubes and large forgings applied in pressurized water reactor.

As a kind of effective method to produce GH690 superalloy tubes, the hot extrusion process is used in the industry, which has been investigated in previous work [4]. Over the past few years, many approaches have been proposed for developing constitutive relationship describing the stress-strain behavior and processing map of GH690 [3,5]. Furthermore, a series of hot compression tests have been carried out to investigate the hot deformation behavior of GH690 during high temperature and high strain rate deformation, which can provide support for the optimization of the hot working parameters for hot extrusion process of high temperature and high speed deformation [4].

Hot forging, especially die forging, is the most efficient approach to fabricate large forgings of nickel-based superalloy. Due to the complicated metal-flow pattern and stress state, it can be expected that the dynamic responses of the metals under hot forging, hot rolling and hot extrusion are different, which will result in unruly microstructural characteristics and mechanical performances [6]. To ensure the required product properties for specific application, GH690 forging is usually hot forged and heat-treated to achieve a proper microstructure, in particular, a microstructure with a grain size smaller than ASTM 6 for high tensile strength and ductility. Previous research has suggested that the flow behaviors of GH690 superalloy are very complex during hot deformation, and the obtainable microstructure is strictly dependent on the hot deformation parameters like strain, strain rate and temperature of the workpiece [7,8]. However, there exists limited information in the published literature on the production of GH690 large forgings.

During the hot working process, DRX takes place in alloys with low stacking fault energy (SFE), which is considered to be the main softening mechanism for superalloy [9]. In addition, it is widely accepted that DRX is an effective method to refine the coarse grain size and reduce the deformation resistance. Hence, the microstructures and properties of alloys can be controlled by adjusting the hot deformation parameters, such as temperature, strain rate and strain, which significantly affect the DRX behavior [10-13]. Among the hot working parameters, strain rate seems to have a complex effect on the DRX process, which has been confirmed in the previous studies [12,14]. Therefore, it is of great significance to conduct systematical investigations on the hot deformation characteristics of GH690 superalloy under different strain rates.

This study was aimed to investigate the effect of strain rate on the hot deformation characteristics of nickel-based superalloy GH690, including the flow behavior, microstructure evolution and nucleation mechanism of DRX, which will provide a basis for determining the optimum parameters of hot processing technology and microstructure prediction of workpiece. The microstructure evolution was analyzed by the methods of optical microscopy (OM), transmission electron microscopy (TEM) and electron backscatter diffraction (EBSD). Moreover, the nucleation and the progress of DRX under various strain rates were systematically analyzed by grain boundary misorientation and the evolution of grain boundaries during hot deformation.

2 Experimental

2.1 Specimen

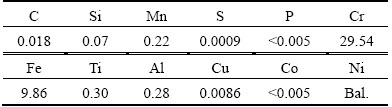

The chemical composition (mass fraction, %) of the GH690 superalloy used in this investigation is listed in Table 1. The material was manufactured by vacuum induction melting and electro-slag remelting process. The ingot was hot forged into a billet with a diameter of 360 mm. Cylindrical specimens of 8 mm in diameter and 12 mm in height were machined from the billet.

Table 1 Chemical composition of GH690 superalloy in this study (mass fraction, %)

2.2 Hot compression test

Hot compression tests were carried out on a Gleeble-3800 thermo-mechanical simulator over the temperature range of 1000-1200 °C with intervals at different strain rates ranging from 0.001 to 10 s-1. The samples were heated to 1200 °C with a heating rate of 20 °C/s and held for 180 s to obtain the identical initial grain size and homogeneous microstructure, followed by cooling down with a cooling rate of 10 °C/s and holding for 30 s at deformation temperature to eliminate thermal gradients. All specimens were subjected to 50% reduction in height corresponding to true strain of 0.7. Then, the deformed specimens were immediately water-quenched to freeze the hot deformed microstructure.

2.3 Microstructure observation

The deformed specimens were sectioned parallel to the compression axis and prepared for microstructure analysis by conventional mechanical grounding. The specimens for metallographic examination were mechanically polished and boiled in a solution of 2.5 g KMnO4+ 10 mL H2SO4+ 90 mL H2O. Metallographic observation was conducted using the Olympus GX71 optical microscope. The volume fraction of DRX was determined by optical metallograph in etched samples, using an image analysis system with Photoshop CS3 software. In order to yield better statistical results, at least five fields of view were taken at different areas of the sample and the average was taken. TEM examination was carried out on the Tecnai G2 F20 field emission transmission electron microscope operated at 200 kV. The microstructures of specimens for EBSD investigation were examined in the maximum deformation zone of the specimens, which were carried out on a JSM-7800F (JEOL, Akishima, Japan) field emission scanning electron microscope equipped with EBSD. The EBSD data were analyzed by the HKL’s channel 5 software. In order to ensure the reliability of the fraction of different boundaries, at least five fields of view were measured and the average was taken.

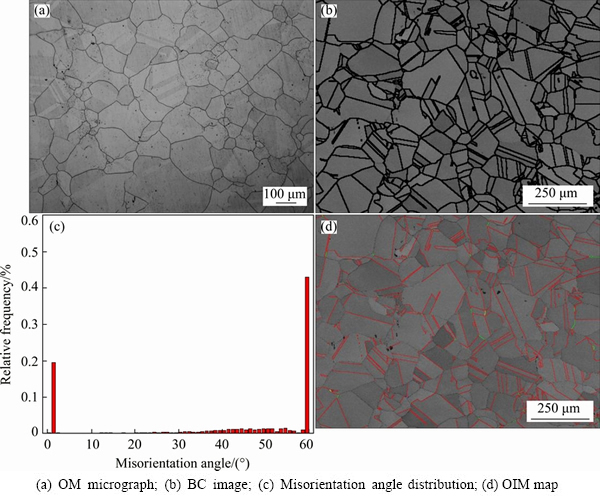

The initial microstructure of the alloy held at 1200 °C for 180 s is shown in Fig. 1. The microstructure exhibits equiaxed grains with average grain size of about 130 μm (Fig. 1(a)). The band contract (BC) image is composed of equiaxed grains and a few annealing twins (Fig. 1(b)). The misorientation angle distribution is shown in Fig. 1(c), from which it can be seen that most of the misorientation angles are larger than 15°, indicating that the majority of grain boundaries are high angle grain boundaries (HAGBs). On the contrary, the fraction of low angle grain boundaries (LAGBs) with the misorientation less than 10° is relatively low. The orientation imaging microscopy (OIM) map is shown in Fig. 1(d), in which Σ3, Σ9 and Σ27 boundaries are represented by red, green and yellow lines, respectively.

Fig. 1 Initial microstructures of alloy held at 1200 °C for 180 s

It should be noted that the fraction of Σ3 boundaries is about 44% in the specimen after being heated at 1200 °C for 180 s.

3 Results and discussion

3.1 Flow behavior

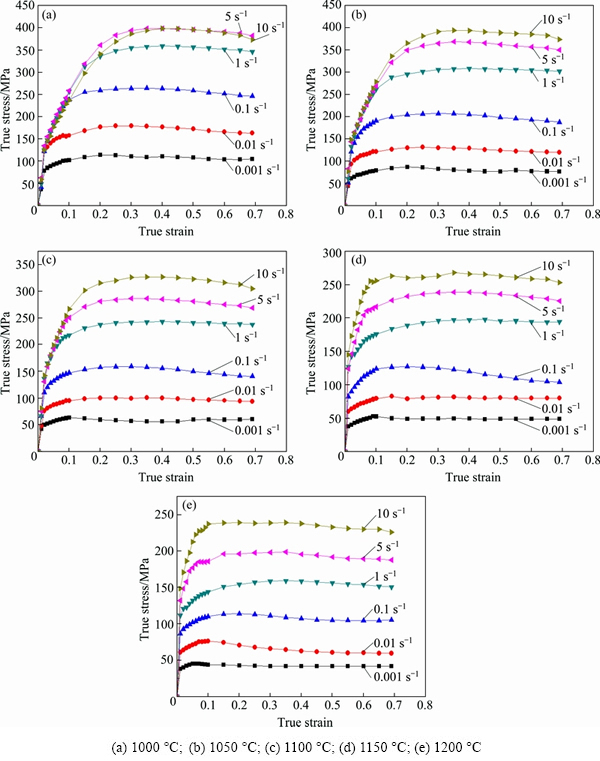

The true stress-true strain curves of GH690 superalloy deformed at various temperatures from 1000 to 1200 °C with strain rates ranging from 0.001 to 10 s-1 are shown in Fig. 2. It can be observed that the flow stress is very sensitive to strain rate and testing temperature. However, as shown in Fig. 2(a), the curves at 1000 °C with strain rate of 5 s-1 and 10 s-1 are overlapped when the strain exceeds 0.4. Similar phenomenon has been observed in the study of IN 718 superalloy [6], which could be supposed to be attributed to the effect of shear band propagation and adiabatic heating. Nevertheless, more in-depth investigation about this phenomenon will be conducted in our future work. It can be seen from Fig. 2 that there is an obvious work-hardening stage, followed by a slow flow softening stage with the increasing strain, then sometimes a steady-state flow at the large strain. Such features of flow behavior prove the occurrence of DRX during hot deformation [15,16]. In the initial stage, the work hardening is caused by the increment of dislocation density and the formation of poorly developed subgrain boundaries [17]. With the increase of strain, the flow stress is determined by the competition between the effect of working hardening and dynamic softening mechanisms. Finally, a steady-state flow stress can be reached when a dynamic balance is achieved by the work hardening and dynamic softening, which can occur simultaneously during hot deformation [16]. However, it is important to note that after reaching peak stress, at relatively high strain rates (≥0.1 s-1), continuous flow softening without reaching a steady-state is revealed in the flow curves, whereas at lower strain rate (<0.1 s-1), steady-state is exhibited in the flow curves, which may be a sign of different DRX mechanisms at low and high strain rates [18]. Similar phenomena have also been reported during hot deformation of other superalloys [19-21], which can be attributed to DRX, flow instability, e.g. flow localization, shear bands or cracking [21]. Nevertheless, it is not very appropriate to predict the deformation mechanism simply based on the basis of the shapes of the flow curves alone, although they may be correlated with the mechanisms established by other methods. Thus, further analysis is required to indentify the deformation mechanisms.

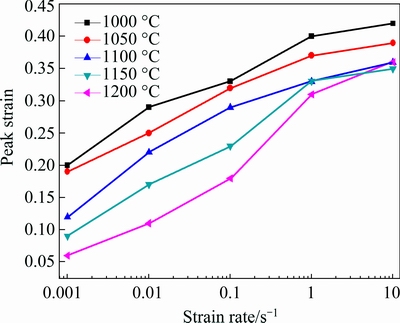

The variations of peak strains with strain rate at different deformation temperatures are shown in Fig. 3, which reveals that strain rate has a significant influence on the peak strain. From Fig. 3, it can be found that at the same deformation temperature, the peak strain obviously increases with increasing the strain rate, indicating that the DRX preferred to occur at lower strain rates.

Fig. 2 True stress-true strain curves for GH690 superalloy deformed at different temperatures with different strain rates

Furthermore, at the strain rates >0.1 s-1, the curves exhibit continuous flow softening, which is similar with the results reported in previous work [22-24]. According to previous work, the effect of adiabatic heating under high strain rate condition during compression has a significant effect on the flow curve, which could not be neglected. Thus, the amount of temperature rise for GH690 superalloy during deformation was calculated by using the following equation [25]:

(1)

(1)

where ρ is the density (8.032 g/m3), cp is the specific heat capacity, and above 1000 °C, cp is 0.592 J/(g·K-1) for the alloy, σ is the flow stress, ε is the true strain, and η is the thermal efficiency, which can be calculated by using the following equations [26]:

(2)

(2)

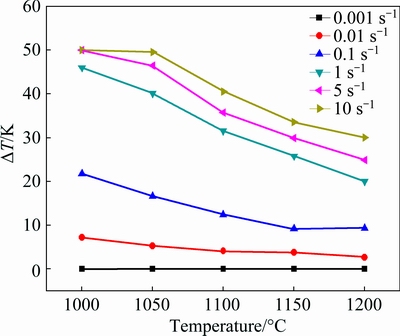

The temperature rise (ΔT) in the alloy deformed with a true strain of 0.7 at all of the deformation temperatures with various strain rates is shown in Fig. 4. The values of ΔT are more than 20 K at the strain rates higher than 0.1 s-1. However, when the strain rates are lower than 0.01 s-1, the values of ΔT are less than 10 K. That is, the adiabatic temperature rise is much more significant in GH690 superalloy deformed at high strain rate.

Fig. 3 Effect of strain rate on peak strain in GH690 superalloy deformed with 0.7 true strain at different deformation temperatures

Fig. 4 Temperature rise (ΔT) in GH690 superalloy deformed with 0.7 true strain at different deformation temperatures and various strain rates

It is well known that the temperature rise during hot deformation can not only stimulate the process of DRX, but also lead to a rapid reduction in the rate of work hardening [27]. At the higher strain rate, a dynamic balance between the work hardening and dynamic softening was not reached during hot deformation, and DRX became dominant due to the effect of adiabatic heating. That is to say, the significant adiabatic temperature rise leads to the intensive DRX behavior of the alloy at high strain rates, which can be confirmed by the further analysis of microstructure in the later section. Thus, it can be concluded that the DRX behavior of the alloy deformed at high strain rates is affected by both of the strain rate and temperature. Moreover, since the dynamic balance between work hardening and dynamic softening was reached for the alloy deformed at the lower strain rates, the effect of adiabatic heating seemed to be weakened. Therefore, the DRX behavior of the alloy deformed at the lower strain rates should be mainly controlled by the strain rate.

3.2 Effect of strain rate on microstructure evolution

3.2.1 Microstructure evolution and volume fraction of DRX grains

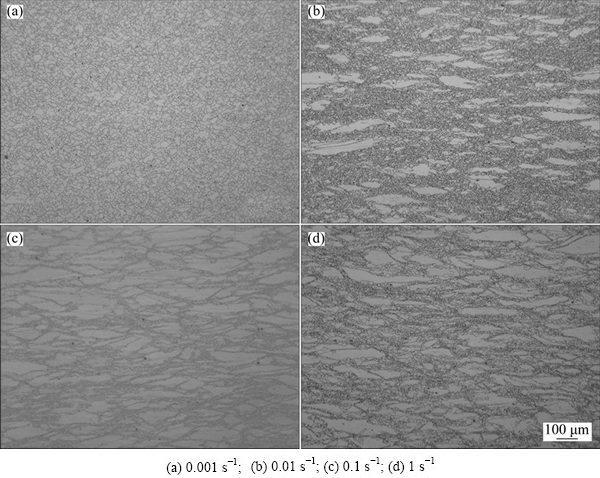

The optical microstructures of GH690 superalloy deformed at 1000 °C with different strain rates are shown in Fig. 5. As shown in Fig. 5, the microstructure evolution of the alloy during hot deformation depends closely on the strain rate. In other words, the nucleation, growing process and the final size of recrystallized grains are strongly influenced by the strain rate. At the deformation strain rate of 0.001 s-1, the specimen has been fully recrystallized during hot deformation, and the microstructure is composed of uniform and DRX grains, which is propitious to the properties of the products (Fig. 5(a)). Incomplete recrystallization occurs in the specimen when deformed with strain rate of 0.01 s-1, as shown in Fig. 5(b). When deformed with strain rate of 0.1 s-1, partial recrystallization occurs with partial recrystallization grains formed at grain boundaries (Fig. 5(c)). It can also be observed that the size of recrystallized grain is the largest at the lowest strain rate of 0.001 s-1. With the further increasing of strain rate, more DRX grains are formed, as shown in Fig. 5(d).

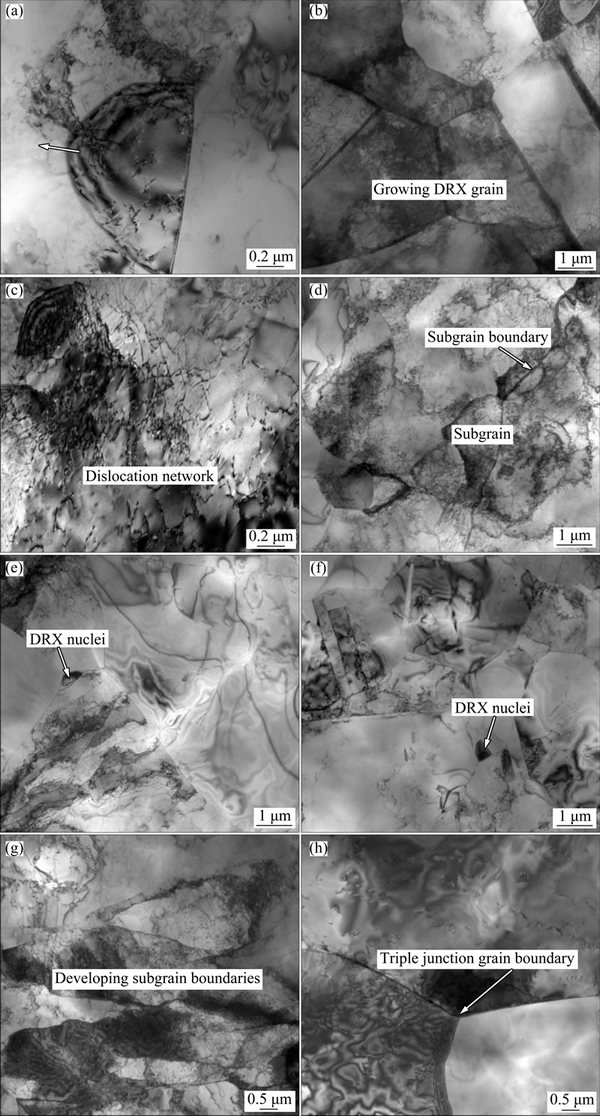

To further analyze the microstructure evolution during DRX, the TEM micrographs of GH690 superalloy deformed to a true strain of 0.7 at 1000 °C with different strain rates are shown in Fig. 6. As shown in Fig. 6(a), bulging out of the grain boundaries is observed, demonstrating that the grain boundary bulging is the nucleation mechanism of DRX for GH690 superalloy [28]. The driving force of grain growth for small DRX grain is the difference of dislocation density with parent grains [29]. DRX grain nucleus grows during hot deformation, while its interior dislocation substructure develops at the same time (Fig. 6(b)). It can be seen from Fig. 6(c) that the high density dislocations are intersected, tangled and stored in the grain interiors, and then the network structure is formed, which make the dislocation slip difficult [30,31]. Due to the relatively low deformation temperature, the vacancy diffusion rates are slow. The rate of dislocation generation increases with the increase of strain rate. Furthermore, some subgrains can also be observed, indicating the occurrence of the dynamic recrystallization (Fig. 6(d)). The appearance of subgrain boundaries indicates that the nucleation mechanisms of subgrain rotation occur during hot deformation, and subgrain boundaries can provide additional nucleation sites for DRX by absorbing dislocations in the interior of original grains [32,33]. The DRX nucleus developed from such subgrain boundaries can be found in Figs. 6(e) and (f). Individual original grain is subdivided by some developing subgrain boundaries, which is exhibited in Fig. 6(g). The division is resulted from the variation of local crystallographic orientations in certain grain induced by strain incompatibilities between neighboring deformed grains, i.e., the rotation of subgrains [33]. In addition, the triple junction grain boundary can be seen in Fig. 6(h). The stress concentration can be relaxed by the progression of DRX at the triple junction grain boundary [34].

Fig. 5 Optical microstructures of GH690 superalloy deformed to true strain of 0.7 at 1000 °C with different strain rates

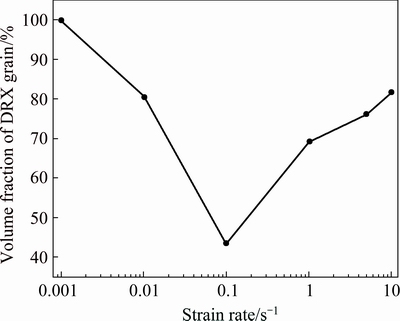

The volume fractions of DRX grains deformed at 1000 °C with different strains rates are shown in Fig. 7. In the strain rate range of 0.001-10 s-1, it can be found that with strain rate increasing the volume fraction of recrystallized grains decreases first and then increases. Since the recrystallization is driven by the potential of distortion stored in the alloy during deformation, there is enough time for the alloy atoms to fully diffuse with the strain rate lower than 0.1 s-1, resulting in sufficient distortion potential to stimulate the nucleation of DRX [24]. However, at the strain rate of 0.1 s-1, the time is insufficient for atom diffusion and grain boundary migration due to the faster strain rate, which leads to the minimum volume fraction of DRX grains. Moreover, when the strain rate is higher than 0.1 s-1, the volume fraction of DRX grains increases with the increasing strain rate. The acceleration of DRX at high strain rate was also observed in alloy 800H [22] and duplex stainless steel [35]. Such phenomenon may be caused by the high stored energy and temperature rise at high strain rates [24]. In conclusion, the strain rate of 0.1 s-1 could be considered to be a vital critical strain rate. When the hot deformation was carried out at the critical strain rate, the effects of time and temperature rise caused by strain rate were not significant, resulting in the least volume fraction of DRX grains.

3.2.2 Nucleation mechanisms of DRX

There are two main nucleation mechanisms of DRX known as discontinuous dynamic recrystallization (DDRX) and continuous dynamic recrystallization (CDRX), which can occur simultaneously [36,37].

Fig. 6 TEM images of specimens deformed to true strain of 0.7 at 1000 °C with strain rates of 0. 001 s-1(a, b), 0.1 s-1(c-f) and 10 s-1(g, h)

Fig. 7 Variation of volume fraction of DRX grains with strain rate of GH690 superalloy deformed to true strain of 0.7 at 1000 °C

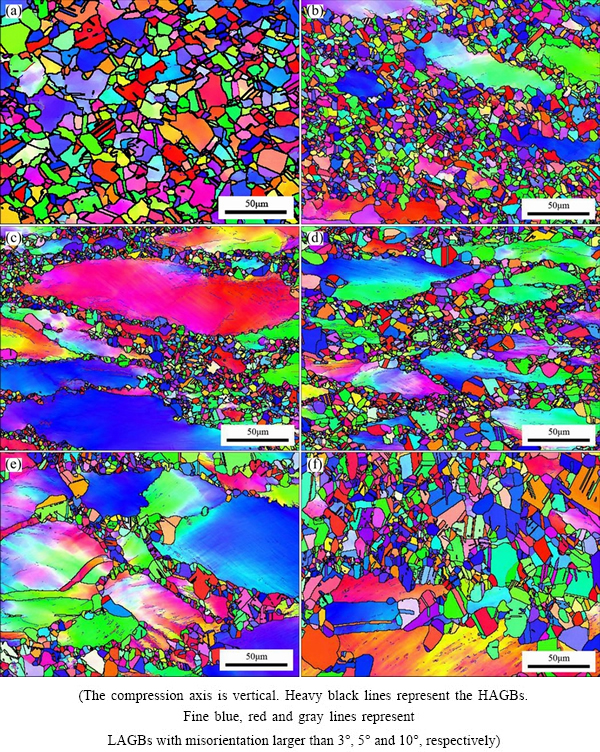

Fig. 8 IPF maps of microstructures deformed at 1000 °C with strain rates of 0.001 s-1(a), 0.01 s-1(b), 0.1 s-1(c), 1 s-1(d), 5 s-1 (e) and 10 s-1(f)

Detailed information about DRX nucleation of GH690 superalloy can be presented by the microstructures in the form of inverse pole figure (IPF) maps (obtained from EBSD data analysis). The typical IPF maps of specimens deformed to a true strain of 0.7 at 1000 °C with various strain rates are shown in Fig. 8. At the strain rate of 0.001 s-1, the microstructure is composed of full DRX grains (Fig. 8(a)). With strain rate increasing, a number of equiaxed DRX grains along with a few elongated initial grains are observed, as shown in Figs. 8(b)-(f). The grain boundaries are mainly characterized by some bulging out of the pre-exisiting grain boundaries HAGBs, which is closely related to the strain induced grain boundary migration [32]. The necklace structure is a result of extensive bulging of grain boundaries due to local migration, which is the main mechanism of recrystallization nucleation [38]. The bulging of some original grain boundaries indicates that DDRX occurs in these processes. Meanwhile, some subgrains with LAGBs and the individual HAGBs are also observed in the interiors of the original grains (Figs. 9(d), (e), (f)). Recrystallization grains observed in the sub-structured regions in the grain interior reflect the alternative mechanism of nucleation the gradual evolution from subgrains to DRX nuclei, which is referred to as CDRX [39]. The above mentioned grain boundary morphologies imply that the nucleation mechanism of GH690 superalloy involves DDRX and CDRX. However, CDRX is only considered to be an assistant nucleation mechanism in the low stacking fault nickel-based superalloy under particular deformation conditions [32,40].

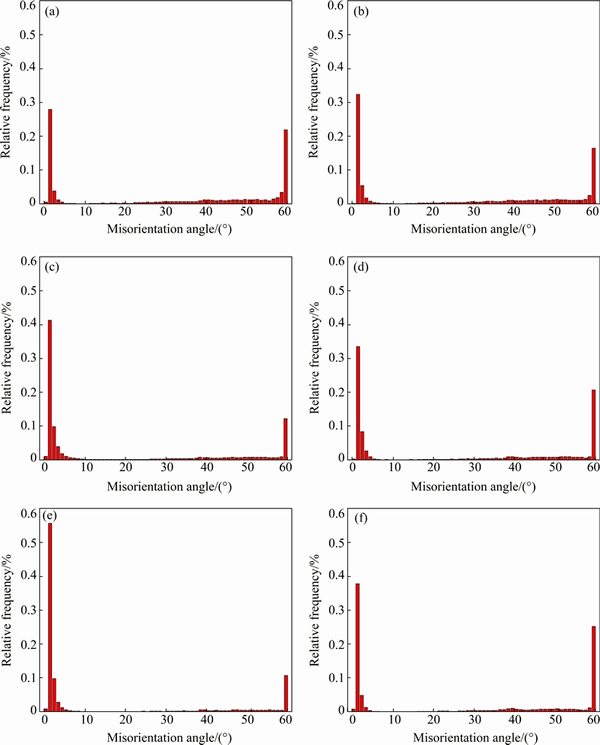

The misorientation angle distribution of hot- deformed GH690 superalloy calculated from OIM maps is shown in Fig. 9. When the strain rate is lower than 0.1 s-1, there is a significant increase of the misorientation at LAGBs with increasing the strain rate (Figs. 9(a)-(c)). However, the relative frequency of the misorientation at LAGBs begins to decrease when the strain rate is larger than 0.1 s-1 (Figs. 9(d)-(f)). It is implied by such a trend that the effect of subgrain rotation is gradually strengthened with the increasing strain rate lower than 0.1 s-1.

Fig. 9 Distribution histogram of grain misorientation angle of GH690 superalloy deformed to true strain of 0.7 at 1000 °C with strain rates of 0.001 s-1(a), 0.01 s-1(b), 0.1 s-1(c), 1 s-1(d), 5 s-1 (e) and 10 s-1(f)

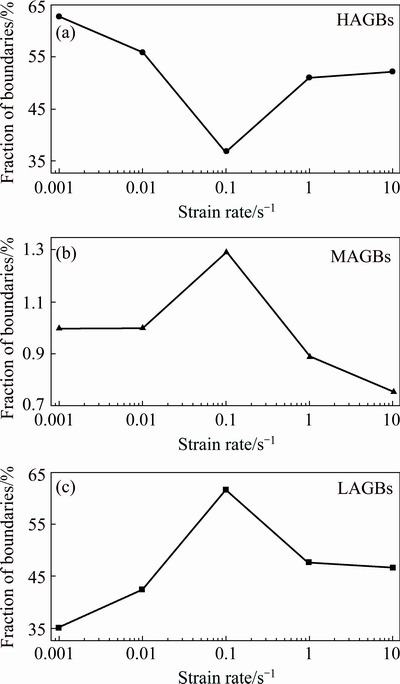

It has been pointed out that the nucleation of CDRX can be operated through progressive subgrain rotation if the misorientation angles between grain boundaries are in the range of 10°-15°, which can be determined as medium angle grain boundaries (MAGBs) [24,41]. Hence, the effect of CDRX during hot deformation with various strain rates can be directly reflected by the fraction of MAGBs [24]. The fractions of grain boundaries with different misorientation angles for GH690 superalloy deformed to a true strain of 0.7 at 1000 °C at various strain rates are shown in Fig. 10. As shown in Fig. 10, when the strain rate is lower than 0.1 s-1, the fraction of MAGBs increases with the increasing strain rate, indicating that the effect of CDRX is strengthened with the increasing strain rate. However, when the strain rate is higher than 0.1 s-1, the fraction of MAGBs decreases with the increasing strain rate, suggesting that the effect of CDRX is weakened again with the increasing strain rate. In the previous work, it was found that the effect of CDRX was weakened due to the increasing temperature [12]. Thus, the above phenomenon can be attributed to the significant temperature rise during hot deformation with high strain rate, as shown in Fig. 3.

It should be noted that the fraction of MAGBs increases from 1.0% to 1.3% with the strain rates ranging from 0.001 to 0.1 s-1, but decreases again when strain rate is higher than 0.1 s-1. Therefore, a progressive subgrain rotation which leads to the formation of DRX nuclei in subgrain structures can only be considered as an assistant nucleation mechanism of DRX for the alloy during hot deformation. In other words, DDRX acts as the primary nucleation mechanism of DRX for GH690 superalloy, which is in accordance with the previous investigations about nickel-based superalloys [12,38]. Furthermore, when the strain rate is lower than 0.1 s-1, the fraction of HAGBs decreases with the increasing strain rate, whereas, it increases then when the strain rate is higher than 0.1 s-1. Conversely, the fraction of LAGBs increases first and then decreases. Since the variation of HAGBs with strain rate is consistent with that of the volume fraction of DRX grains, these opposite trends seem to be correlated with the evolution of DRX grains (Figs. 6 and 10) [24]. Above all, the fraction of HAGBs can be regarded as a measurement for DRX process.

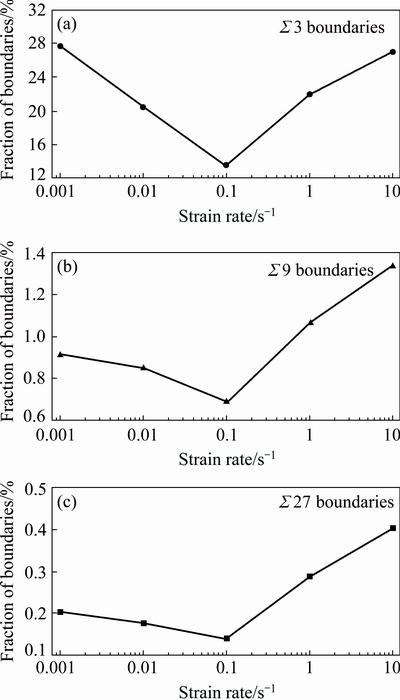

It has been reported that the DRX progress can be accelerated by the primary twins (Σ3) and higher order (Σ9 and Σ27) for materials with low stacking fault energy [42,43]. The fractions of Σ3n (n=1, 2, 3) boundaries for GH690 superalloy deformed to a true strain of 0.7 at 1000 °C with various strain rates are shown in Fig. 11. It is revealed in Fig. 11 that the strain rate has a significant effect on the twin boundaries. The fractions of Σ3 boundaries are higher at the lower strain rates (≤0.01 s-1) and higher strain rates (≥1 s-1). That is to say, the lowest fraction of Σ3 boundaries occurs at the strain rate of 0.1 s-1, demonstrating a sluggish evolution of twins at an intermediate strain rate. The main reasons for such phenomenon may be that at the lower strain rates (≤0.01 s-1) there is more sufficient time for grain boundary migration, which can increase the frequency of growth accidents during DRX process, resulting in the higher fraction of Σ3 boundaries. Moreover, the nucleation of twins can also be accelerated by the higher stored energy [44]. Thus, the fraction of Σ3 boundaries increases again at the higher strain rates (≥1 s-1) due to the higher stored energy in the alloy. Finally, the variations of Σ9 and Σ27 boundaries with strain rates are similar with that of Σ3 boundaries, which is mainly due to the interactions between Σ3 boundaries.

Fig. 10 Fractions of grain boundaries with different misorientation angles for GH690 superalloy deformed to true strain of 0.7 at 1000 °C with various strain rates

Fig. 11 Fractions of Σ3n (n=1, 2, 3) boundaries for GH690 superalloy deformed to true strain of 0.7 at 1000 °C with various strain rates

4 Conclusions

1) The effects of the strain rate on the flow stress are significant. Increasing the strain rate can decrease the flow stress. The flow stress behaviors at strain rates higher than 0.1 s-1are affected by the apparent temperature rise.

2) When the strain rate is lower than 0.1 s-1, the volume fraction of DRX grains decreases with the increasing strain rate because of the shorter time for grain boundary migration; when the strain rate is higher than 0.1 s-1, the volume fraction of DRX grains increases with the increasing strain rate due to the high stored energy and temperature rise.

3) The dominant nucleation mechanism of DRX in GH690 superalloy is DDRX with bulging of the original grain boundaries, while the CDRX with progressive subgrain rotation only acts as a secondary nucleation mechanism. The effects of DDRX and twinning formation are firstly weakened and then strengthened with the increasing strain rate. Conversely, the effect of CDRX is firstly strengthened and then weakened with the increasing strain rate.

References

[1] GUO Sheng-li, LI De-fu, PEN Hai-jian, HU Jie. Hot deformation and processing maps of Inconel 690 superalloy [J]. Journal of Nuclear Materials, 2011, 410(1): 52-58.

[2] LIU Kui, HAO Xian-chao, GAO Ming, WANG Bo-fang. Effect of N content on mechanical properties and microstructure of Alloy 690 [C]//Proceedings of the 17th International Conference on Nuclear Engineering. New York: American Society of Mechanical Engineers, 2009: 327-336.

[3] LEE W S, LIU C Y, SUN T N. Dynamic impact response and microstructural evolution of inconel 690 superalloy at elevated temperatures [J]. International Journal of Impact Engineering, 2005, 32(1): 210-223.

[4] WANG Bin, ZHANG Shi-hong, CHENG Ming, SONG Hong-wu. Dynamic recrystallization mechanism of Inconel 690 superalloy during hot deformation at high strain Rate [J]. Journal of Materials Engineering and Performance, 2013, 22(8): 2382-2388.

[5] SUN Chao-yang, LIU Jin-rong, LI Rui, DONG Jian-xin. Constitutive relationship of IN690 superalloy by using uniaxial compression tests [J]. Rare Metals, 2011, 30(1): 81-86.

[6] CHENG Liang, XUE Xiang-yi, TANG Bin, LIU De-gui, LI Ji-zhen, KOU Hong-chao, LI Jin-shan. Deformation behavior of hot-rolled IN718 superalloy under plane strain compression at elevated temperature [J]. Materials Science and Engineering A, 2014, 606: 24-30.

[7] MANDAL S, SIVAPRASAD P, DUBE R. Kinetics, mechanism and modelling of microstructural evolution during thermomechanical processing of a 15Cr-15Ni-2.2Mo-Ti modified austenitic stainless steel [J]. Journal of Materials Science, 2007, 42(8): 2724-2734.

[8] AMIRI A, BRUSCHI S, SADEGHI M H, BARIANI P. Investigation on hot deformation behavior of Waspaloy [J]. Materials Science and Engineering A, 2013, 562: 77-82.

[9] CHEN X M, LIN Y C, WEN D X, ZHANG J L, HE M. Dynamic recrystallization behavior of a typical nickel-based superalloy during hot deformation [J]. Materials & Design, 2014, 57: 568-577.

[10] ZHANG Chi, ZHANG Li-wen, SHEN Wen-fei, LI Meng-fei, GU Sen-dong. Characterization of hot deformation behavior of Hastelloy C-276 using constitutive equation and processing map [J]. Journal of Materials Engineering and Performance, 2015, 24(1): 149-157.

[11] WANG Y, SHAO W Z, ZHEN L, ZHANG X M. Microstructure evolution during dynamic recrystallization of hot deformed superalloy 718 [J]. Materials Science and Engineering A, 2008, 486(1): 321-332.

[12] GUO Qing-miao, LI De-fu, PENG Hai-jian, GUO Sheng-li, HU Jie, DU Peng. Nucleation mechanisms of dynamic recrystallization in Inconel 625 superalloy deformed with different strain rates [J]. Rare Metals, 2012, 31(3): 215-220.

[13] GUO Qing-miao, LI De-fu, GUO Sheng-li. Microstructural models of dynamic recrystallization in hot-deformed Inconel 625 superalloy [J]. Materials and Manufacturing Processes, 2012, 27(9): 990-995.

[14] WANG Y, SHAO W, ZHEN L, ZHANG X M. Flow behavior and microstructures of superalloy 718 during high temperature deformation [J]. Materials Science and Engineering A, 2008, 497(1): 479-486.

[15] SAMANTARAY D, MANDAL S, JAYALAKSHMI M, ATHREYA C N, BHADURI A K, SUBRAMANYA S. New insights into the relationship between dynamic softening phenomena and efficiency of hot working domains of a nitrogen enhanced 316L (N) stainless steel [J]. Materials Science and Engineering A, 2014, 598: 368-375.

[16] ZHANG Hong-bin, ZHANG Kai-feng, LU Zhen, ZHAO Chang-hong, YANG Xiao-li. Hot deformation behavior and processing map of a γ′-hardened nickel-based superalloy [J]. Materials Science and Engineering A, 2014, 604: 1-8.

[17] CAI Da-yong, XIONG Liang-yin, LIU Wen-chang, SUN Gui-dong, YAO Mei. Development of processing maps for a Ni-based superalloy [J]. Materials Characterization, 2007, 58(10): 941-946.

[18] ZHANG Chi, ZHANG Li-wen, SHEN Wen-fei, LI Meng-fei, GU Sen-dong. Characterization of hot deformation behavior of Hastelloy C-276 using constitutive equation and processing map [J]. Journal of Materials Engineering and Performance, 2014, 24(1): 1-9.

[19] AMIRI A, SADEGHI M H, EBRAHIMI G R. Characterization of hot deformation behavior of AMS 5708 nickel-based superalloy using processing map [J]. Journal of Materials Engineering and Performance, 2013, 22(12): 3940-3945.

[20] NING Y Q, YAO Z K, GUO H Z, FU M W, LI H, XIE X H. Investigation on hot deformation behavior of P/M Ni-base superalloy FGH96 by using processing maps [J]. Materials Science and Engineering A, 2010, 527(26): 6794-6799.

[21] LIU Yi, HU Rui, LI Jin-shan, KOU Hong-chao, LI Hong-wei, CHANG Hui, FU Heng-zhi. Characterization of hot deformation behavior of Haynes230 by using processing maps [J]. Journal of Materials Processing Technology, 2009, 209(8): 4020-4026.

[22] CAO Yu, DI Hong-shuang, ZHANG Jing-qi, ZHANG Jie-cen, MA Tian-jun, MISRA R D K. An electron backscattered diffraction study on the dynamic recrystallization behavior of a nickel–chromium alloy (800H) during hot deformation [J]. Materials Science and Engineering A, 2013, 585: 71-85.

[23] LIU Yi, HU Rui, LI Jin-shan, KOU Hong-chao, LI Hong-wei, CHANG Hui, FU Heng-zhi. Deformation characteristics of as-received Haynes230 nickel base superalloy [J]. Materials Science and Engineering A, 2008, 497(1): 283-289.

[24] ZHANG Hong-bin, ZHANG Kai-feng, ZHOU Hai-ping, LU Zhen, ZHAO Chang-hong, YANG Xiao-li. Effect of strain rate on microstructure evolution of a nickel-based superalloy during hot deformation [J]. Materials & Design, 2015, 80: 51-62.

[25] GOETZ R, SEMIATIN S. The adiabatic correction factor for deformation heating during the uniaxial compression test [J]. Journal of Materials Engineering and Performance, 2001, 10(6): 710-717.

[26] MATAYA M, SACKSCHEWSKY V. Effect of internal heating during hot compression on the stress-strain behavior of alloy 304L [J]. Metallurgical and Materials Transactions A, 1994, 25(12): 2737-2752.

[27] LEE W S, LIN C F. High-temperature deformation behaviour of Ti6Al4V alloy evaluated by high strain-rate compression tests [J]. Journal of Materials Processing Technology, 1998, 75(1): 127-136.

[28] LIU Gui-wu, HAN Ying, SHI Zhong-qi, SUN Jia-peng, ZOU De-ning, QIAO Guan-jun. Hot deformation and optimization of process parameters of an as-cast 6Mo superaustenitic stainless steel: A study with processing map [J]. Materials & Design, 2014, 53: 662-672.

[29] SOMMITSCH C, WIESER V, KLEBER S. A dislocation density model for the simulation of hot forming processes [J]. Journal of Materials Processing Technology, 2002, 125: 130-137.

[30] LIU J, LIU Y G, LIN H, LI M Q. The metadynamic recrystallization in the two-stage isothermal compression of 300M steel [J]. Materials Science and Engineering A, 2013, 565: 126-131.

[31] WEN D X, LIN Y C, CHEN J, CHEN X M, ZHANG J L, LIANG Y J, LI L T. Work-hardening behaviors of typical solution-treated and aged Ni-based superalloys during hot deformation [J]. Journal of Alloys & Compounds, 2015, 618: 372-379.

[32] JIANG He, DONG Jian-xin, ZHANG Mai-cang, ZHENG Lei, YAO Zhi-hao. Hot deformation characteristics of Alloy 617B nickel-based superalloy: A study using processing map [J]. Journal of Alloys & Compounds, 2015, 647: 338-350.

[33] WANG Y L, SHAO W Z, ZHEN L, ZHANG X M. Flow behavior and microstructures of superalloy 718 during high temperature deformation [J]. Materials Science & Engineering A, 2008, 497: 479-486.

[34] ZHOU Hong-wei, HE Yi-zhu, CUI Mian, CEN Yu-wan, JIANG Jian-qing. Dependence of dynamic strain ageing on strain amplitudes during the low-cycle fatigue of TP347H austenitic stainless steel at 550 °C [J]. International Journal of Fatigue, 2013, 56: 1-7.

[35] HAN Ying, ZOU De-ning, CHEN Zhi-yu, ZHANG Wei. Investigation on hot deformation behavior of 00Cr23Ni4N duplex stainless steel under medium–high strain rates [J]. Materials Characterization, 2011, 62(2): 198-203.

[36] BELYAKOV A, TSUZAKI K, MIURA H, SAKAI K. Effect of initial microstructures on grain refinement in a stainless steel by large strain deformation [J]. Acta materialia, 2003, 51(3): 847-861.

[37] MCQUEEN H J. Development of dynamic recrystallization theory [J]. Materials Science and Engineering A, 2004, 387-389(6): 203-208.

[38] MOMENI A, ABBASI S M, MORAKABATI M, BADRI H, WANG X. Dynamic recrystallization behavior and constitutive analysis of Incoloy 901 under hot working condition [J]. Materials Science and Engineering A, 2014, 615: 51-60.

[39] GOURDET S, MONTHEILLET F. An experimental study of the recrystallization mechanism during hot deformation of aluminium [J]. Materials Science and Engineering A, 2000, 283(1): 274-288.

[40] WANG Y L, SHAO W Z, ZHEN L, ZHANG X M. Microstructure evolution during dynamic recrystallization of hot deformed superalloy 718 [J]. Materials Science and Engineering A, 2008, 486(1): 321-332.

[41] LI De-fu, GUO Qing-miao, GUO Sheng-li, WU Zhi-gang. The microstructure evolution and nucleation mechanisms of dynamic recrystallization in hot-deformed Inconel 625 superalloy [J]. Materials & Design, 2011, 32(2): 696-705.

[42] GOTTSTEIN G, KOCKS U F. Dynamic recrystallization and dynamic recovery in single crystals of nickel and copper [J]. Acta Metall, 1983, 31(1): 175-188.

[43] SAMPLE V M, FITZSIMONS G L, DEARDO A J. Dynamic softening of copper during deformation at high temperatures and strain rates [J]. Acta Metall, 1987, 35(2): 367-379.

[44] WANG W, BRISSET F, HELBERT A L, SOLAS D, MATHON M H, BAUDIN T. Influence of stored energy on twin formation during primary recrystallization [J]. Materials Science and Engineering A, 2014, 589(2): 112-118.

石照夏1,2,颜晓峰1,段春华1,赵明汉1

1. 钢铁研究总院 高温材料研究所,北京 100081;

2. 钢铁研究总院 高温合金新材料北京市重点实验室,北京 100081

摘 要:为阐明应变速率对GH690高温合金热变形特性的影响,采用Gleeble-3800热力模拟试验机,通过变形温度范围为1000~1200 °C、应变速率范围为0.001~10 s-1的等温热压缩实验研究了该合金的热变形行为。结果表明:流变应力对应变速率变化敏感,动态再结晶是主要的软化机制;0.1 s-1是1000 °C热变形过程中的临界应变速率。绝热温升使得动态再结晶过程与应变速率密切相关;应变速率对热变形过程中的非连续动态再结晶和连续动态再结晶具有显著影响;孪晶可促进动态再结晶形核,Σ3n (n=1, 2, 3)晶界在中等应变速率0.1 s-1条件下含量较低。

关键词:GH690 高温合金;热变形;应变速率;动态再结晶

(Edited by Xiang-qun LI)

Foundation item: Special Project (2013) supported by China’s National Development and Reform Commission for R&D and Industrialization of New Materials

Corresponding author: Zhao-xia SHI; Tel: +86-10-62183360; E-mail: zxshiustb@163.com

DOI: 10.1016/S1003-6326(17)60082-7