有色金属钨矿和铅锌矿尾矿资源化利用工艺技术研究

来源期刊:中国有色金属学报2021年第4期

论文作者:黄太铭 李圣晨 李晓辉 张鹏举 杨宏斌 阮乐 唐富顺

文章页码:1057 - 1074

关键词:有色金属尾矿;预处理;ZSM-5分子筛;合成工艺

Key words:non-ferrous metal tailings; pretreatment; ZSM-5 zeolite; synthesis technology

摘 要:以有色金属钨矿和铅锌矿尾矿为原料,分别采取酸浸后高温碱熔和无酸浸低温碱溶两种活化预处理,并以常规水热法(CH)和微波水热法(MH)合成ZSM-5分子筛,采用XRF、ICP-AES、FT-IR、XRD、SEM、BET和催化剂活性评价对所得产物进行表征分析。结果表明:合成产物为ZSM-5分子筛,其总比表面积在273.21~350.51 m2/g之间,MH法产物孔径较小;低温碱溶可以得到更高硅铝摩尔比n(SiO2)/n(Al2O3)的前驱液,导致产物形貌由类球形转变为六方棱柱形,并且产物粒径减小;高温碱熔合成产物对干化尾矿SiO2利用率更高,不过工艺复杂,能耗高;活化过程SiO2溶出率的影响因素程度由高到低的顺序为CaO、其他杂质、Fe2O3;合成相同结晶度的ZSM-5分子筛时,MH法所需时间仅为CH法的四分之一左右,并且合成产物粒径更小,表面更洁净,SiO2利用率更高;1 L反应釜工艺放大效应小,搅拌条件有利于合成体系的传质和传热,导致产物粒径减小,产物应用于脱硝反应的NO转化率可达94.31%。

Abstract: The ZSM-5 molecular sieve was synthesized by conventional hydrothermal method (CH) and microwave hydrothermal method (MH), using non-ferrous metal tungsten ore and lead-zinc ore tailings as materials which were activated pretreatment by high-temperature alkali fusing after acid leaching and low-temperature alkali dissolving without acid leaching, respectively. The obtained products were characterizated by XRF, ICP-AES, FT-IR, XRD, SEM, BET and catalyst activity evaluation. The results show that, the synthesized product is ZSM-5 molecular sieve. BET shows that the total specific surface area of the product is between 273.21-350.51 m2/g, and the pore diameter of the product by the MH is small. Low-temperature alkali dissolution activate pretreatment can obtain higher n(SiO2)/n(Al2O3) liquid precursors, which leads to the transformation of the morphology of the product from a spherical shape to a hexagonal prism shape, and the particle size of the product decreases. The product synthesis by activation pretreatment with high-temperature alkali fusion has a higher utilization of the SiO2 of dried tailings, but the process is complicated and the energy consumption is high. The sequence of influence factors of SiO2 dissolution rate during activation from high to low are: CaO, Others, Fe2O3. The required time to synthesize ZSM-5 with the same crystallinity by MH method is only about a quarter of the that of CH method, and the product size by the MH method is smaller, the surface is cleaner, and the SiO2 utilization rate is also higher. The 1 L reactor has a small amplification effect, and the stirring conditions are conducive to the mass and heat transfer of the synthesis system, resulting in a decrease in the particle size of the product, and the NO conversion rate of the product applied to the denitration reaction can reach 94.31%.

DOI: 10.11817/j.ysxb.1004.0609.2021-39637

黄太铭1,李圣晨1,李晓辉3,张鹏举1,杨宏斌2,阮 乐1,唐富顺1

(1. 桂林理工大学 化学与生物工程学院,广西有色金属隐伏矿床勘查及材料开发协同创新中心, 桂林 541004;

2. 广西壮族自治区环境应急与事故调查中心,南宁 530028;

3. 广西壮族自治区固体废物和化学品环境管理中心,南宁 530028)

摘 要:以有色金属钨矿和铅锌矿尾矿为原料,分别采取酸浸后高温碱熔和无酸浸低温碱溶两种活化预处理,并以常规水热法(CH)和微波水热法(MH)合成ZSM-5分子筛,采用XRF、ICP-AES、FT-IR、XRD、SEM、BET和催化剂活性评价对所得产物进行表征分析。结果表明:合成产物为ZSM-5分子筛,其总比表面积在273.21~350.51 m2/g之间,MH法产物孔径较小;低温碱溶可以得到更高硅铝摩尔比n(SiO2)/n(Al2O3)的前驱液,导致产物形貌由类球形转变为六方棱柱形,并且产物粒径减小;高温碱熔合成产物对干化尾矿SiO2利用率更高,不过工艺复杂,能耗高;活化过程SiO2溶出率的影响因素程度由高到低的顺序为CaO、其他杂质、Fe2O3;合成相同结晶度的ZSM-5分子筛时,MH法所需时间仅为CH法的四分之一左右,并且合成产物粒径更小,表面更洁净,SiO2利用率更高;1 L反应釜工艺放大效应小,搅拌条件有利于合成体系的传质和传热,导致产物粒径减小,产物应用于脱硝反应的NO转化率可达94.31%。

关键词:有色金属尾矿;预处理;ZSM-5分子筛;合成工艺

文章编号:1004-0609(2021)-04-1057-17 中图分类号:O643.36 文献标志码:A

引文格式:黄太铭, 李圣晨, 李晓辉, 等. 有色金属钨矿和铅锌矿尾矿资源化利用工艺技术研究[J]. 中国有色金属学报, 2021, 31(4): 1057-1073. DOI: 10.11817/j.ysxb.1004.0609.2021-39637

HUANG Tai-ming, LI Sheng-chen, LI Xiao-hui, et al. Study on resource utilization technology of nonferrous metals tungsten and lead-zinc tailings[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(4): 1057-1073. DOI: 10.11817/j.ysxb.1004.0609.2021-39637

尾矿一般是指矿物加工过程中从磨碎的矿石资源中进行分离与富集后排出的、堆放在尾矿库的“废弃物”,在特定的经济技术条件下尾矿是难以分选的物料[1]。尾矿是个相对概念,不是绝对的废弃物和无用的废料,其中含有一定数量的有用金属和矿物,可视为一种“复合”的硅酸盐、碳酸盐等矿物材料,并具有粒度细、数量大、成本低、可利用性大的特点。如果借助新的选冶技术或创新工艺,回收尾矿及其废水中的有用成分达到资源化利用,不亚于建设一座新的矿山。中国有色金属的年产量居于世界前列,然而由于生产工艺和经营方式的束缚,其尾矿堆存数量逐年递增,极大地浪费资源,破坏生态坏境[2]。目前,有色金属尾矿的传统利用模式主要有回收有价金属(金、银、锡和锌等)和直接利用,直接利用包括采空区充填,复土造田和制作建筑材料(砖材、水泥、路基材料、玻璃和陶瓷等),传统利用模式综合利用率低,高附加值产品少[3]。国家第二次工业污染防治工作会议上强调:“综合利用,变废为宝,既保护国家的资源,又充分利用国家的资源,同时又净化环境,可谓一举多得”。报告高度概括了资源综合利用的必要性和迫切性[4]。在面向21世纪新的历史发展阶段,我国有限的资源将承载着超负荷的人口和环境负担,仅靠拼资源和外延扩大再生产的经济增长模式难以持续发展,结合有色金属尾矿的利用现状和大量尾矿所带来的诸多问题,需要寻求更有效的尾矿资源化利用途径。

以尾矿为原料合成分子筛材料是有色金属尾矿资源化利用的一种新方式[5],有色金属钨矿和铅锌矿尾矿含有硅和铝组分,可以用来资源化利用合成硅铝分子筛。ZSM-5分子筛属于高硅结晶硅铝酸盐沸石,具有高比表面积、固有酸度以及良好的热稳定性,在工业上应用广泛[6]。水热法是传统合成ZSM-5分子筛的主要方法,其优点是生产操作简便,利于工业化,但是其耗时耗能高[7];微波水热法借助微波辐射加热,可以使整个反应容器均匀加热,因此成核更均匀,结晶时间更短,从而降低了反应能耗[8]。但其设备要求相对较高,因此不同的晶化工艺各有利弊,对有色金属尾矿的资源化利用影响也各有不同。另外,在利用尾矿为原料合成ZSM-5分子筛时,首先必须对尾矿进行一定程度的预处理,包括尾矿中杂质组分的去除和硅铝质晶相成分的破坏和活化。杂质组分的去除一般采用酸浸法,硅铝质晶相成分的活化方法有高温活化法、高温碱熔活化法、酸溶液活化法和碱溶液活化法等[9]。本工作拟以有色金属钨矿和铅锌矿尾矿为原料,分别以酸浸除杂后高温碱熔和无酸浸直接低温碱溶两种活化方式处理尾矿,并考察常规水热法和微波水热法对两种尾矿合成ZSM-5分子筛的影响,探讨有色金属钨矿和铅锌矿尾矿资源化工艺技术,为有色金属钨矿及铅锌矿尾矿的高附加值资源化利用提供技术参考信息。

1 实验

1.1 原料与试剂

有色金属钨矿和铅锌矿尾矿分别取自于广西壮族自治区贺州市某尾矿库和岑溪市某尾矿库。两种尾矿料经研磨后湿筛过孔径0.074 mm的筛,并于120 ℃空气氛围下干燥12 h,得到干化矿料。

盐酸(西陇科技股份有限公司,36.0%~38.0%,质量分数,AR),硝酸(西陇化工股份有限公司,65.0%~68.0%,AR),氢氧化钠(上海麦克林生化科技有限公司,95%,AR),乙醇(广东光华科技股份有限公司,≥99.7%,AR),四丙基溴化铵(TPABr,上海麦克林生化科技有限公司,98%,AR),蒸馏水(自制),商品参比样H-ZSM-5(即晶种,定义其结晶度为100%,南开大学催化剂厂,其硅铝摩尔比 n(SiO2)/n(Al2O3)≈50,催化剂级)。

1.2 尾矿活化预处理

1.2.1 低温碱溶活化

按干化尾矿与固体氢氧化钠质量比为1:1.2称取氢氧化钠固体,加入适量蒸馏水溶解成碱溶液,将一定量干化钨矿尾矿或铅锌矿尾矿与氢氧化钠溶液混合于聚四氟乙烯内衬的反应釜内,于190 ℃下自生压力静置热处理4 h,待自然冷却后,釜内物料转移至离心沉降机中,经4000 r/min转速下离心30 min分离得到上清液,即为低温碱溶活化料液。

1.2.2 高温碱熔活化

高温碱熔活化参考文献[5, 10-11]处理。采用质量浓度约为8.2%的盐酸溶液对干化尾矿进行酸浸除杂,矿料与盐酸溶液固液比为1:8(g/mL)。其中钨尾矿与盐酸溶液混合于密封三口烧瓶中,在90 ℃水浴中反应2 h。另外,铅锌尾矿与盐酸溶液混合于聚四氟乙烯为内衬的反应釜中,于170 ℃下静置反应6 h。两种尾矿酸浸后经抽滤固液分离,用蒸馏水洗涤滤饼至滤液呈中性,滤饼置于120 ℃空气氛围下干燥12 h,得到酸浸除杂尾矿。将酸浸除杂尾矿与固体氢氧化钠以质量比1:1.5混合研磨均匀,置于马弗炉内空气氛围下800 ℃煅烧2 h进行活化反应,待炉温降至200 ℃以下后取出,稍加研磨粉碎,得到高温碱熔活化矿料。取一定量高温碱熔活化矿料,加入适量蒸馏水,置于内衬为聚四氟乙烯的反应釜内密封,于120 ℃下静置水解2 h后,釜内物料转移至离心沉降机中,经4000 r/min转速下离心30 min分离得到上清液,即为高温碱熔活化料液。

1.3 ZSM-5分子筛合成

以上述所得活化上清液为全部硅铝源,按照投料摩尔比为n(SiO2):n(C2H5OH):n(TPABr):n(H2O)= 1.00:1.03:0.037:146.52合成ZSM-5分子筛。将低温碱溶或高温碱熔的活化料液在45 ℃磁力搅拌水浴锅中搅拌0.5 h后,按比加入乙醇,搅拌0.5 h,再将配置好的TPABr溶液逐滴加入混合液中,继续搅拌15 min,随后加入0.03 g晶种,以浓HNO3调节合成物料的pH至10.8,继续搅拌1 h后在45 ℃的水浴条件下静置陈化12 h。陈化结束将物料转移至100 mL内衬为聚四氟乙烯的反应釜内密封,在不同条件下进行晶化。晶化反应结束后,待反应釜冷却至室温,然后将釜内产物取出过滤,用蒸馏水洗涤至滤液呈中性。滤饼于120 ℃空气氛围下干燥12 h,然后在马弗炉内空气氛围下550 ℃煅烧4 h,即得到孔道内脱除模板剂的Na型ZSM-5。

实验室小试晶化反应以两种方式进行:1) 常规水热法(Conventional hydrothermal method, CH),以水为反应介质,静置状态下通过外部热源加热高压釜在内部产生高温使溶液处于过饱和状态而析出晶体[12],晶化条件为190 ℃下静置4~8 h;2) 微波水热法(Microwave hydrothermal method, MH),以微波加热使聚四氟乙烯反应釜内达到高温高压状态,使溶液处于过饱和状态而析出晶体[13],晶化条件为:于微波消解仪中200 ℃下微波晶化1.5~2 h,实验所用微波消解仪为XH-800C电脑微波温压双控型。

1.4 小试放大工艺

以酸浸钨矿与铅锌矿尾矿高温碱熔活化矿料作为合成ZSM-5分子筛的原料,采用和实验室小试一样的投料摩尔比配方,放大系数为12倍的小试放大,晶化工艺为动态搅拌常规水热合成,搅拌转速为130 r/min,放大实验所用反应釜为WDF-1L高压釜,威海自控反应釜有限公司生产。

1.5 样品表征

采用美国热电ARL9800XP+型 X 射线荧光光谱仪(XRF)对原尾矿料进行元素种类定性及半定量分析;采用电感耦合等离子体原子发射光谱法(ICP-AES)对原尾矿料、酸浸矿料和产物中所含主要元素进行定量分析;采用X'Pert3 Powder型多功能X-射线衍射仪(XRD,荷兰帕纳科公司,Cu靶,λ=1.54056  )分析样品的晶相结构,测试扫描步长为0.02626°,扫描速度为0.6565 (°)/s,扫描范围为5°~80°。产物相对结晶度的计算采用所合成产物XRD谱中2θ为22.5°~25°与晶种XRD谱中2θ为22.5°~25°的衍射峰面积之比来表示,其中定义晶种的结晶度为100%。采用日立高新热场式场发射扫描电镜SU5000(SEM)对产物形貌进行表征。采用美国 Thermo-Scientific IS10 傅里叶变换红外光谱仪(FT-IR)对合成样品进行骨架结构表征,扫描范围为 4000~400 cm-1。采用精微高博(JW-BK300C)比表面积分析仪(BET)对所得产物比表面积及孔体积分布进行分析(静态容量法);样品预处理条件为300 ℃温度下12 h真空干燥,测试时在-196 ℃条件下对 N2进行吸附-脱附。采用英国Hiden公司的DECRA定量气体分析质谱仪分析产物催化剂对NO的催化转化效率。

)分析样品的晶相结构,测试扫描步长为0.02626°,扫描速度为0.6565 (°)/s,扫描范围为5°~80°。产物相对结晶度的计算采用所合成产物XRD谱中2θ为22.5°~25°与晶种XRD谱中2θ为22.5°~25°的衍射峰面积之比来表示,其中定义晶种的结晶度为100%。采用日立高新热场式场发射扫描电镜SU5000(SEM)对产物形貌进行表征。采用美国 Thermo-Scientific IS10 傅里叶变换红外光谱仪(FT-IR)对合成样品进行骨架结构表征,扫描范围为 4000~400 cm-1。采用精微高博(JW-BK300C)比表面积分析仪(BET)对所得产物比表面积及孔体积分布进行分析(静态容量法);样品预处理条件为300 ℃温度下12 h真空干燥,测试时在-196 ℃条件下对 N2进行吸附-脱附。采用英国Hiden公司的DECRA定量气体分析质谱仪分析产物催化剂对NO的催化转化效率。

尾矿的资源化利用率以SiO2的利用率(K)表示,按式(1)计算:

(1)

(1)

式中:m1为干化矿料质量;x1为干化矿料中SiO2质量分数,%;m2为产物质量;x2为产物中SiO2质量分数,%。

2 结果与讨论

2.1 酸浸除杂对矿料组成的影响

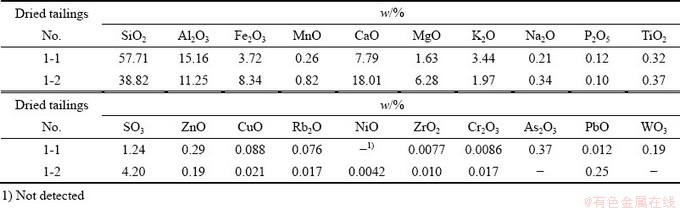

钨矿和铅锌矿尾矿经研磨后湿筛、干燥处理后采用盐酸溶液酸浸除杂得到酸浸尾矿。表1所示为干化尾矿组分的XRF分析结果。尾矿1-1为钨矿尾矿,尾矿1-2为铅锌矿尾矿,组分含量以氧化物表示。由表1可知,两种干化尾矿主要的氧化物组成为SiO2,含量分别为57.71%和38.82%。其次为Al2O3和CaO,两者Al2O3含量分别为15.16%和11.25%;CaO含量分别为7.79%和18.01%。然后是少量的Fe2O3、MnO、MgO、K2O和SO3,这五种氧化物的含量在1.24%~8.34%之间。最后为微量的As2O3、PbO、Cr2O3、Na2O、P2O5、TiO2、ZnO、CuO、Rb2O、NiO、ZrO2、WO3等其他组分。两种尾矿的成分复杂,各种成分的含量均有差异,不过尾矿中利用价值较高的氧化物(SiO2和Al2O3)含量总和高于50%。

表2所示为干化尾矿及其酸浸尾矿组分的ICP分析结果。尾矿1-3为酸浸钨矿尾矿,尾矿1-4为酸浸铅锌矿尾矿,尾矿1-5为除钙铅锌矿尾矿,组分含量以氧化物表示。由表2可知,尾矿1-1和尾矿1-2的元素组成中,除Al2O3含量基本相近外,其他元素的氧化物含量均差异较大。尾矿1-2的SiO2含量比尾矿1-1的SiO2含量低,两者分别为46.78%和63.76%,尾矿1-2的非硅铝质组分Fe2O3和CaO含量是尾矿1-1中Fe2O3和CaO的含量的2.2~2.3倍,表明尾矿1-1的硅铝比更高,杂质更少,可能更易于用来合成ZSM-5等介孔分子筛材料。

图1所示为两种尾矿及酸浸尾矿高温碱熔活化实物图。由图1可知,两种尾矿在未经酸浸除杂时的直接高温碱熔活化(尾矿1-1和1-2)均呈现颜色偏深的烧结板块现象,破碎较困难,酸浸尾矿活化后(尾矿1-3和1-4) 呈现浅蓝色的蓬松状,稍加研磨便可粉碎,因此需在高温碱熔活化前对尾矿进行酸浸除杂处理。

表1 尾矿组分的XRF分析

Table 1 XRF analysis of tailings components

表2 尾矿及酸浸尾矿组分的ICP分析

Table 2 ICP analysis of tailings and acid leaching tailings components

图1 尾矿高温碱熔活化实物图

Fig. 1 Physical diagram of tailings under high temperature alkali fusing activation

为便于进行对比实验,将尾矿1-2以60 ℃酸浸2 h处理后(除去率约28.79%),CaO含量去除至接近于尾矿1-1中CaO含量,定义为尾矿1-5。其虽然也采用酸浸除杂,但由图1(b)可以看出,仍然存在较多深色的烧结板块部分,基于两种尾矿的杂质含量差异,为确保能顺利进行高温碱熔活化,需要分别采用不同的的酸浸条件。尾矿1-1采用90 ℃酸浸2 h(除去率约20.52%)处理后(尾矿1-3)可合成出高结晶度的ZSM-5产物;但以尾矿1-2为原料,在相同的酸浸条件下,则其合成产物相对结晶度只有90.88%。经试验可知,尾矿1-2采用170 ℃酸浸6 h(除去率约43.46%)的除杂处理后(尾矿1-4),可以合成出高结晶度ZSM-5产物。由此可见,不同组成尾矿的酸浸除杂工艺不尽相同,可能是由于杂质组分残留的影响。尾矿1-1与尾矿1-2经过酸浸处理后,其碱性氧化物等杂质的大部分去除,酸浸尾矿的组分含量发生变化,主要表现为SiO2含量的上升,其他非硅铝质组分含量均有所下降,两者酸浸后硅铝摩尔比n(SiO2)/n(Al2O3)大约为原尾矿料的1.6倍,分别为16.50和13.11。

图2所示为尾矿及预处理后矿料的XRD谱。尾矿2-1为酸浸钨尾矿、尾矿2-2为干化钨尾矿、尾矿2-3为酸浸铅锌尾矿、尾矿2-4为干化铅锌尾矿、尾矿2-5为干化钨尾矿低温碱溶活化、尾矿2-6为酸浸钨尾矿高温碱熔活化、尾矿2-7为干化铅锌尾矿低温碱溶活化、尾矿2-8为酸浸铅锌尾矿高温碱熔活化。

由图2(a)和(b)可知,在2θ为20.59°、26.73°、36.59°、39.51°、42.49°、50.21°、54.93°、60.00°和68.19°处为石英(Quartz)的特征衍射峰(PDF#46- 1045),表明尾矿中SiO2主要以晶相石英存在。钨尾矿的XRD谱中,在2θ为8.89°、17.81°和45.48°处为白云母(Muscovite)特征衍射峰(PDF#07-0042),化学组成为KAl2[AlSi3O10](OH)2,含SiO2 45.2%、Al2O3 38.5%、K2O 11.8%、H2O 4.5%[14],因此,钨尾矿中部分SiO2和Al2O3存在于白云母中。

图2 尾矿及预处理后矿料的XRD谱

Fig. 2 XRD patterns of tailings and pre-processed minerals

在图2(a)和(b)中,2θ=29.49°处为方解石(Calcite)特征衍射峰(PDF#83-0578),方解石是天然CaCO3矿物中最常见的一种,理论成分为CaO 56.03%,CO2 43.97%[14],两种尾矿中CaO组分主要以方解石形式存在。图2(b)(铅锌尾矿)所示的方解石特征衍射峰明显高于图2(a)(钨尾矿)中的,与表2中两种尾矿的CaO含量分别为15.12%和6.84%的分析果相吻合。另外,在图2(a)中,2θ=28.28°处为铵石膏(Koktaite)特征衍射峰(PDF#11-0475),其化学组成为(NH4)2Ca(SO4)·H2O,铵石膏中含有的少量钙质是钨尾矿中CaO的另一种存在形式。

在图2(b)中,2θ=12.53°和25.13°处为斜绿泥石(Clinochlore)特征衍射峰(PDF#29-0701),化学组成为(Mg,Fe)4.75Al1.25[Al1.25Si2.75O10](OH)8,铅锌矿尾矿中可能有一部分Al2O3、Fe2O3和Others杂质存在形式为斜绿泥石。2θ=33.05°和56.23°处为黄铁矿(Pyrite)的特征衍射峰(PDF#71-1680),化学组成为Fe[S2],含Fe 46.6%、S 53.4%。

由图2(a)可知,将钨尾矿酸浸除杂后,在2θ=20.59°和26.73°处的石英衍射峰有所增强,表明SiO2含量上升;在2θ=28.28°和29.49°处,铵石膏与方解石的特征衍射峰基本消失,表明钨尾矿中CaO基本去除。根据表2的分析结果,钨尾矿酸浸后SiO2含量由63.76%升高到82.30%,CaO含量由6.84%降低到1.00%,其与XRD谱的分析结果相一致。

由图2(b)可知,将铅锌尾矿酸浸除杂后,在2θ=29.49°处,方解石的特征衍射峰基本消失,表明铅锌尾矿中CaO基本去除。在2θ=33.05°和56.23°处,黄铁矿的衍射峰有所增强,这是因为黄铁矿的溶解特性导致(其可以完全溶解于浓硝酸及王水中并析出硫,但不溶于盐酸和硫酸[14])实验酸浸所采用盐酸溶液不能去除黄铁矿,在其他杂质的除去下,其峰强有所增高。在2θ=12.53°和25.13°处,斜绿泥石的特征衍射峰也基本消失,根据表2铅锌尾矿及酸浸处理之后组分含量的变化(Al2O3基本不变,Fe2O3和Others杂质均减少)可以推测斜绿泥石是铅锌尾矿中一部分Fe2O3和其他杂质(主要是MgO)的存在形式。

两种尾矿不同活化预处理之后的XRD谱如图2(c)和(d)所示,在2θ为17.02°、25.23°、29.56°、35.05°、37.45°、48.31°、52.25°和65.91°处为偏硅酸钠(Na2SiO3)特征衍射峰(PDF#16-0818),表明高温碱熔和低温碱溶活化完全破坏了尾矿中稳定的晶相石英结构,因此可以作为合成ZSM-5分子筛的原料[11]。图2(d)中,2θ为15.53°、31.35°、38.16°、53.80°和55.48°处为氢氧化钠(NaOH)特征衍射峰(PDF#85-0733),2θ为14.92°、30.13°、33.20°、36.17°和39.72°处为氢氧化钠水合物(NaOH(H2O))特征衍射峰(PDF#76-0387),说明铅锌尾矿低温碱溶所用碱量过剩,可能是因为铅锌尾矿杂质含量较多,SiO2含量较少,导致不需要那么多的碱量来活化。

2.2 活化工艺对尾矿料中SiO2溶出的影响

酸浸尾矿采用高温碱熔活化法(High temperature alkali fusion activation),干化尾矿采用低温碱溶活化法(Low temperature alkali soluble activation)。图1表明,干化的钨矿和铅锌矿尾矿直接高温碱熔活化均呈现烧结板块现象,破碎较困难。从表2可知,钨矿和铅锌矿尾矿中分别含6.84%和15.12%的CaO杂质,根据尾矿的XRD结果,尾矿中CaO组分主要以CaCO3的形式存在。由于高温碱熔时容易发生反应:SiO2+CaCO3+2NaOH=Na2CaSiO4+H2O+CO2,生成了难溶于水的硅酸钙钠(Na2CaSiO4),导致煅烧结块现象的出现[15]。相反地,低温碱溶活化是在碱溶液中进行,可以有效避免硅酸钙钠的生成,不会产生结块现象。因此,相比于高温碱熔活化,低温碱溶活化对CaO杂质的包容度比较大,CaO含量较多的尾矿料不需要酸浸除杂即可进行低温碱溶活化,可以简化工艺过程。

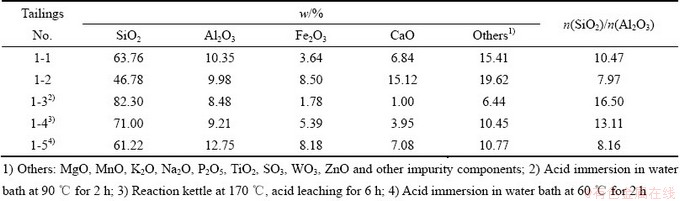

表3所示为尾矿采用两种活化方法处理之后,经过离心的高纯度活化硅铝溶液(前驱液)的化学组成。对于低温碱溶活化,尾矿1-1活化后的SiO2溶出率为51.34%,相比尾矿1-2活化后的SiO2溶出率(23.91%)大1倍多。根据尾矿的成分分析结果(表2),尾矿1-1的非硅铝质组分Fe2O3含量(3.64%)、CaO含量(6.84%)和其他杂质组分(Others)总含量(15.41%)都比尾矿1-2的非硅铝质组分含量低(Fe2O3含量8.50%、CaO含量15.12%、其他杂质组分(Others)总含量19.62%)。因此,尾矿中Fe2O3、CaO和其他杂质组分可能对尾矿中SiO2溶出产生影响。进一步将铅锌矿尾矿60℃酸浸后得到的尾矿1-5进行低温碱溶活化,其SiO2溶出率为56.56%,与尾矿1-1活化后的SiO2溶出率相近。相比1-2中的含量,尾矿1-5中CaO含量为7.08%、Fe2O3含量为8.18%、其他杂质组分总含量为10.77%,Fe2O3含量基本不变,但CaO和其他杂质组分含量降低较大,说明尾矿中CaO和其他杂质组分应是影响尾矿中SiO2溶出的重要因素。对比尾矿1-5与1-1,前者其他杂质组分总含量(10.77%)比后者(15.41%)小近三分之一,但其SiO2溶出率基本相近,说明其他杂质组分对SiO2溶出的影响较小。由此可见,尾矿中CaO组分对尾矿中SiO2溶出的影响较大,尾矿活化过程中对SiO2溶出率的影响因素程度由大到小的顺序为CaO、其他杂质、Fe2O3。

表3 尾矿和酸浸尾矿活化之后前驱液的组成

Table 3 Composition of precursor solution after tailings and acid leaching tailings are activated

不管是钨尾矿还是铅锌尾矿,酸浸尾矿(尾矿1-3和1-4)高温碱熔活化都比干化尾矿(尾矿1-1和1-2)低温碱溶活化的SiO2溶出率高,说明活化方式对SiO2溶出率的影响较大。可以看到,将铅锌矿尾矿(尾矿1-2)以60 ℃酸浸2 h(尾矿1-5)和170 ℃酸浸6 h(尾矿1-4)的不同酸浸方法处理后,CaO含量从15.12%分别降到了7.08%和3.95%,所获得的酸浸尾矿分别以低温碱溶和高温碱融活化后SiO2溶出率分别为56.56%和55.00%,基本相近,说明在去除大部分CaO杂质后,活化方式对SiO2溶出率影响较小,这进一步表明了CaO对SiO2溶出率的影响较大。因此,活化方式不同导致SiO2溶出率差异的原因应主要归于矿料中非硅铝质组分(主要是CaO)的影响。另外,尽管铅锌尾矿两种不同酸浸方法处理后所获得的酸浸尾矿中CaO含量的不同(7.08%和3.95%),但SiO2溶出率却没有明显差异(56.56%和55.00%),这表明低温碱溶活化时CaO杂质对SiO2溶出率的影响要比高温碱熔时的小,其原因是高温碱熔活化会生成难溶于水的硅酸钙钠,而低温碱溶活化可以避免这个现象。

从两种活化方式来看,酸浸尾矿经过高温碱熔活化(尾矿1-3和1-4)处理之后前驱液的n(SiO2)/n(Al2O3)大约为42,然而低温碱溶活化(尾矿1-1、1-2、1-5)处理之后前驱液的n(SiO2)/n(Al2O3)大于100。这说明,本工作中的低温碱溶条件不足以使大部分的晶相Al2O3溶解,导致Al2O3溶出率较低,所以其n(SiO2)/n(Al2O3)比高温碱熔的要高很多。

综上所述,活化过程SiO2溶出率的影响因素程度由高到低的顺序为CaO、其他杂质、Fe2O3,CaO含量对SiO2溶出率的影响最大,低温碱溶活化方式可耐受的CaO杂质影响更好,当含CaO尾矿直接高温碱熔出现烧结块现象时,既可以通过酸浸除杂来解决,又可以通过以低温碱溶活化的方法来解决。另外,在除去大量CaO杂质后,活化方式对SiO2溶出率影响较小,但是却对Al2O3溶出率影响很大,相对于高温碱熔,低温碱溶活化对Al2O3溶出率较低,导致前驱液有更高的n(SiO2)/n(Al2O3)。

2.3 晶化工艺对尾矿合成ZSM-5的影响

常规水热法(CH)和微波水热法(MH)所得ZSM-5产物结果如表3所示。产物XRD谱如图3所示。表3中样品1~4采用的预处理为酸浸尾矿高温碱熔活化,其中样品1和3采用MH法合成,样品2和4采用CH法合成;样品5~8采用的预处理为干化尾矿低温碱溶活化,其中样品5和7采用MH法合成,样品6和8采用CH法合成。

如表4可知,高温碱熔活化预处理时,尾矿1-3采用MH法合成时,仅需2 h的晶化时间就可以达到相对结晶度为115.82%的产物(样品1),采用CH法合成时,其产物(样品2)达到接近于MH法产物的相对结晶度的晶化时间为6 h(111.94%),即CH法合成所用时间为MH法的3倍,表明采用MH法合成可以明显缩短晶化时间。

由图3可以看到,所合成的样品1~8在2θ为7.9°、8.8°、23.2°、23.9°和24.4°处均出现典型的MFI结构特征衍射峰(PDF#44-0003),峰形尖锐,无其他杂质晶相峰,说明晶化合成的产物为ZSM-5分子筛[16]。

表4 不同晶化工艺所得ZSM-5产物的结果

Table 4 Results of ZSM-5product obtained by different synthetic processes

图3 不同合成工艺所得产物的XRD谱

Fig. 3 XRD pattern of ZSM-5 product obtained by different synthetic processes

同样地,尾矿1-4采用两种方法合成出相对结晶度基本相近的产物所需的晶化时间分别为4 h(样品4)和1.5 h(样品3),CH法合成时间是MH法合成的2.6倍。与此相似,当低温碱溶活化预处理时,合成相同品质的产物,MH法合成比CH法合成也需要更少晶化时间。尾矿1-1采用MH法合成相对结晶度125.63%的产物(样品5)需要的晶化时间为 2 h;当采用CH法合成时,晶化时间8 h,其相对结晶度为118.53%(样品6),即CH法晶化时间为MH法的4倍。类似地,对于尾矿1-2,CH法(样品8)所用晶化时间是MH法的2.6倍(样品7)。因此,无论是高温碱熔活化还是低温碱溶活化,或者对于钨尾矿还是铅锌尾矿,相比CH法合成,MH法合成可以有效地缩短晶化时间。这是因为在分子筛合成过程中,前驱液混合均匀后,首先生成处于无序状态下的初始硅铝酸盐凝胶,其处于动态溶解平衡中。而在微波辐射作用下,微波场激活了水分子的转动能级,使得通常以氢键缔合的水分子产生旋转,以场热的形式提供了晶化所需的热能。另一方面,微波辐射破坏缔合氢键而释放出孤立的水分子,由于氧的孤对电子和OH键使得孤立的水分子具有更高的电势能,比由氢键缔合的水分子更容易进攻凝胶颗粒,加速凝胶的溶解,从而促使大量成核。此外,由于微波的高频振荡和场加热方式,将晶化体系中的凝胶分散并形成均一的温度环境,有利于晶化过程的进行。因此在微波辐射下进行晶化时,诱导阶段很短,从而加速了分子筛的晶化过程[17]。并且由于微波辐射可以加速前驱体的溶解,不仅增加前驱体营养物的溶度,而且可以使前驱体更加完全地晶化成ZSM-5,所以MH法合成产物对原尾矿料中SiO2利用率比CH法高出了3%~14%左右。

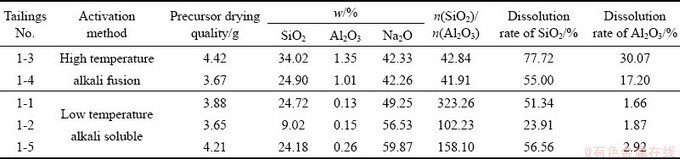

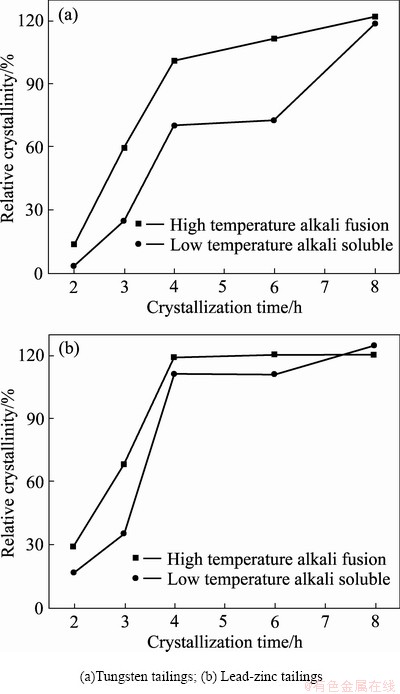

由图3(a)可知,在诱导阶段,酸浸钨尾矿CH法合成晶化时间2 h和3 h时产物的相对结晶度分别为13.46%和59.28%;对比图3(c)可知,晶化2 h和3 h时产物的相对结晶度分别为3.12%和24.67%,可以发现在晶化时间相同的情况下,高温碱熔活化预处理后合成产物的相对结晶度高于低温碱溶活化。同样地,由图3(b)和(d)也可以发现,对于铅锌尾矿,高温碱熔活化预处理后合成产物的相对结晶度更高的规律。

图4所示为两种尾矿不同活化预处理后CH法合成产物的晶化曲线。由图4(a)和(b)均能看到,在诱导阶段,低温碱溶活化预处理的尾矿料所合成的样品相对结晶度和晶化速率偏低,分析活化后矿料的元素组成可以看出(见表4),酸浸钨尾矿和酸浸铅锌尾矿高温碱熔活化后前驱液的硅铝摩尔比n(SiO2)/n(Al2O3)分别为42.84和41.91,钨尾矿和铅锌尾矿低温碱溶活化后n(SiO2)/n(Al2O3)大幅度增加,分别为323.26和102.23,由此可说明,前驱液的n(SiO2)/n(Al2O3)对产物的相对结晶度和晶化速率有影响。这是因为前驱液中n(SiO2)/n(Al2O3)的增大降低了合成体系中硅酸铝溶胶和铝溶胶的浓度,减弱了其与TPA+的静电相互作用,导致模板剂的结构导向能力降低,故在相同的晶化时间内,降低了合成ZSM-5的相对结晶度和晶化速率[18]。

图4 两种尾矿不同活化预处理后常规水热合成产物的晶化曲线

Fig. 4 Crystallization curves of conventional hydrothermal synthesis products after different pretreatments of two tailings

对比图3(c)和(d)可知,钨尾矿低温碱溶活化后晶化4 h产物的相对结晶度为70.33%,然而铅锌尾矿晶化4 h产物的相对结晶度达到了111.10%;结合图4(a)和(b)可以发现,铅锌尾矿晶化速率降低趋势没有钨尾矿的高,并且其前驱液的n(SiO2)/n(Al2O3)分别为323.26和102.23,说明n(SiO2)/n(Al2O3)越高,相对结晶度和晶化速率降低的趋势越明显。

2.4 合成工艺对产物形貌的影响

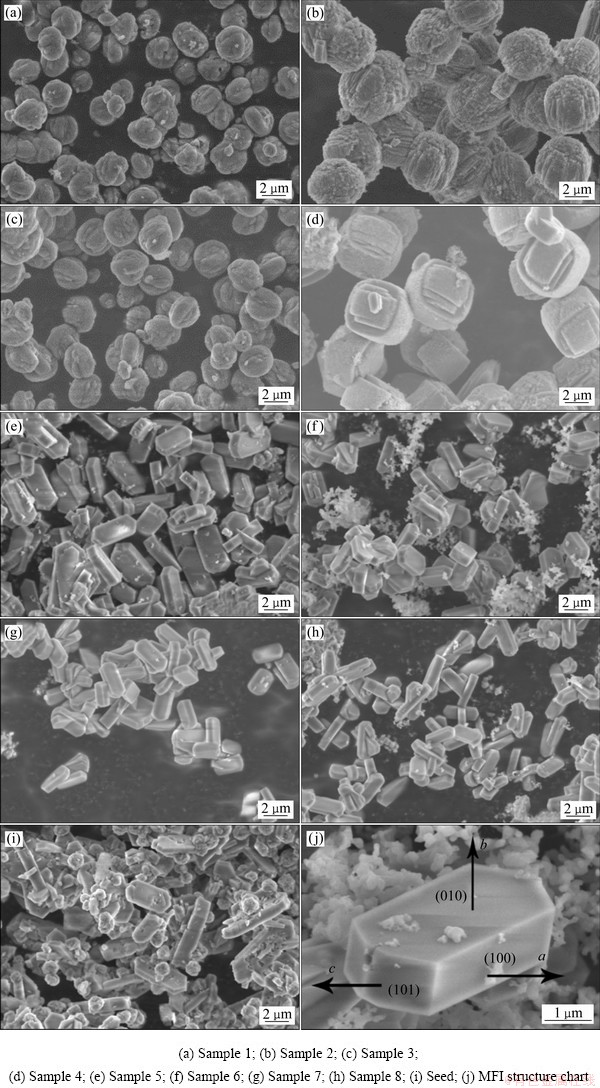

图5所示为钨矿和铅锌矿尾矿采用不同合成工艺所得ZSM-5产物的SEM像。图5(a)~(d)所示为酸浸尾矿高温碱熔活化后合成产物的SEM像,其中,图5(a)和(c)中产物采用MH法合成,图5(b)和(d)中产物采用CH法合成;图5(e)~(h)所示为干化尾矿低温碱溶活化后合成产物的SEM像,其中图5(e)和(g)中产物采用MH法合成,图5(f)和(h)中产物采用CH法合成;图5(i)所示为晶种SEM像,图5(j)所示为MFI型分子筛结构图。由图5(a)~(d)可以看出,在高温碱熔活化处理下,不管是酸浸钨尾矿还是酸浸铅锌尾矿,CH和MH法合成产物的形貌均为类球形,不过前者直径约为后者的两倍,分别约为5.6 μm和2.8 μm。高温碱熔活化所得前驱液的硅铝摩尔比n(SiO2)/n(Al2O3)约为42,说明在此情况下更倾向于形成热力学和动力学稳定的类球形形貌。另外,MH合成产物晶粒变化是因为微波辐射具有促进成核,加速成核速率的作用,使得成核速率大于晶化速率,所以晶粒变小。

图5 不同合成工艺所得ZSM-5产物的SEM像

Fig. 5 SEM images of ZSM-5 products obtained by different synthetic processes

由图5(b)、(d)、(f)和(h)可以看出,采用CH法合成时,不管是酸浸钨尾矿还是酸浸铅锌尾矿,高温碱熔活化处理后的产物形貌均为类球形,直径约5.6 μm;低温碱溶活化处理后的产物形貌均为六方棱柱形,最长边约2.8 μm。由表4可知,从高温碱熔到低温碱溶,前驱液的n(SiO2)/n(Al2O3)大幅度增加,从分子动力学方向来看,硅原子的原子半径(1.46  )比铝原子的(1.82

)比铝原子的(1.82  )小,n(SiO2)/n(Al2O3)增加则半径小的硅含量增多,半径大的铝含量减少,有利于沸石整体粒子的减小[19]。从n(SiO2)/n(Al2O3)对诱导阶段的影响来看,进一步说明前驱液中n(SiO2)/n(Al2O3)的提高会降低晶化速率,导致产物粒径减小,与图4中晶化曲线得出的结论一致。另外,产物形貌从类球形到六方棱柱形的变化可以用ZSM-5的生长机理来作解释:在晶化过程中,前驱液原料首先缩聚成五元环组成的基本结构单元,随着反应的进行,逐渐聚集成链状结构,最后成形成片层结构,这种片层结构表面含有硅羟基,前驱液中n(SiO2)/n(Al2O3) 的增加使得有更多的硅原子与氢氧根形成更大量的硅羟基,从而导致体系pH值降低。pH值较低时,不利于硅羟基缩合反应的进行,影响ZSM-5分子筛在b([010])方向的生长。如图5(j)所示,导致晶体在a方向和c方向上的生长速率大于b方向上的生长速率,最终生成了这种六方棱柱形ZSM-5分子筛[20]。

)小,n(SiO2)/n(Al2O3)增加则半径小的硅含量增多,半径大的铝含量减少,有利于沸石整体粒子的减小[19]。从n(SiO2)/n(Al2O3)对诱导阶段的影响来看,进一步说明前驱液中n(SiO2)/n(Al2O3)的提高会降低晶化速率,导致产物粒径减小,与图4中晶化曲线得出的结论一致。另外,产物形貌从类球形到六方棱柱形的变化可以用ZSM-5的生长机理来作解释:在晶化过程中,前驱液原料首先缩聚成五元环组成的基本结构单元,随着反应的进行,逐渐聚集成链状结构,最后成形成片层结构,这种片层结构表面含有硅羟基,前驱液中n(SiO2)/n(Al2O3) 的增加使得有更多的硅原子与氢氧根形成更大量的硅羟基,从而导致体系pH值降低。pH值较低时,不利于硅羟基缩合反应的进行,影响ZSM-5分子筛在b([010])方向的生长。如图5(j)所示,导致晶体在a方向和c方向上的生长速率大于b方向上的生长速率,最终生成了这种六方棱柱形ZSM-5分子筛[20]。

由图5(e)~(h)可以看出,在低温碱溶活化处理下,不管是MH法还是CH法,产物形貌均为六方棱柱形,最长边约2.8~3.5 μm,形貌与大小无很大差别。在高温碱熔活化处理下,MH法可以通过加速成核速率使产物粒径减小,但是低温碱溶活化下显然这种趋势不明显。由于高温碱熔到低温碱溶的变化使得前驱液n(SiO2)/n(Al2O3)大幅度增加,意味着凝胶体系中有更多的 Si 原子与结构导向剂反应形成晶核,导致晶核数量增加[21],虽然微波辐射也可以加速成核速率,但是作用力还是不如n(SiO2)/n(Al2O3)的增加,所以低温碱溶活化下,MH法和CH法合成产物粒径大小差别不大。但是图5(e)和(g)显示出其产物比图5(f)和(h)的产物更加干净,表面絮状物更少,这可能是由于微波加热能加速前驱体的溶解[22],不仅增加前驱体营养物的溶度,而且可以使前驱体更加完全地晶化成ZSM-5分子筛,这样就导致低温碱溶-MH法合成产物表面更加干净,而且MH法合成产物质量比CH法合成质量多了8%~12%,产物对原尾矿中SiO2利用率多了10%~14%。

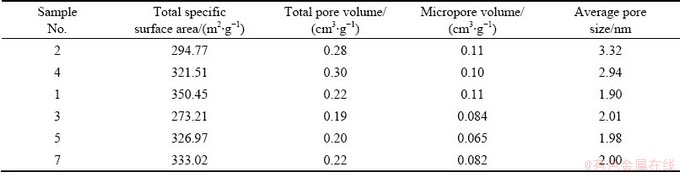

2.5 合成产物的比表面积及孔径分布

表5所示为合成ZSM-5产物样品1、2、3、4、5和7的比表面积及孔体积参数。由表5可知,产物总比表面积在273.21~350.51 m2/g之间,平均孔径在1.90~3.32 nm之间。

表5 产物的比表面积及孔径分布

Table 5 Specific surface area and pore size distribution of products

图6所示为合成ZSM-5产物样品1、2、3、4、5和7的N2吸附/脱附等温线及孔结构分布曲线,可以看出,相对压力(p/p0)在低压端(0~0.1)偏Y轴,材料与N2有较强的作用力,说明具有较多微孔;相对压力(p/p0)在中压端(0.3~0.8)多为N2在材料内的冷凝积聚,介孔分析来源于此。图6(a)、(b)和(c)的N2吸附/脱附等温线吸附类型为布朗诺尔分类的五种等温线类型中的Ⅳ型[23],滞后环分别为H3、H2和H4型,表明样品1、2和4具有介孔结构。图6(d)、(e)和(f)的N2吸附/脱附等温线为Ⅰ型,表明样品3、5和7为微孔结构,说明微波水热法能合成出孔径较小的分子筛产物。

图6 产物N2吸附/脱附等温线及孔结构分布曲线

Fig. 6 N2 adsorption/desorption isotherm and pore structure distribution curves of products

2.6 小试放大工艺对尾矿合成ZSM-5产物的影响

为便于上述试验结果转化为工业生产应用,本工作进一步试验上述尾矿资源化利用工艺的放大,以探索工艺路线的稳定性和可行性,分析控制工艺参数及操作条件的优化设计。小试和小试放大所用的反应釜如图7所示,容积分别为100 mL和1 L。100 mL反应釜为静态晶化反应;1 L反应釜带电机搅拌器,晶化时为动态搅拌晶化,电机搅拌转速为130 r/min。

图7 实验室小试和小试放大所用的反应釜实物图

Fig. 7 Physical diagram of reactor used in laboratory test and scale-up

放大产物样品9和10分别为小试样品2和4(见表4)的12倍放大产物,晶化产物结果如表6所示。实验室小试与放大产物的产量上下浮动约5%,在实验误差之内,放大产物对干化尾矿SiO2利用率都低于小试合成的产物,主要的原因是放大产物SiO2与Al2O3含量降低,不过Al2O3含量降低率(16.6%~18.6%)高于SiO2(5.1%~8.6%),因此,硅铝比摩尔比n(SiO2)/n(Al2O3)略有增高,甚至于铅锌尾矿放大产物中n(SiO2)/n(Al2O3)(43.68)超过了前驱液(41.91),这可能是因为搅拌动态晶化相对于Al原子,更有利于Si原子进入分子筛骨架中[24]。

表6所示为采用ICP对小试放大产物的组分进行分析的结果。由表6可以看出,产物组分主要为SiO2与Al2O3,以及少量的Fe2O3和CaO和微量的重金属氧化物As2O3、PbO和Cr2O3,硅铝摩尔比可达到36.52,SiO2利用率可达43.00%。钨尾矿和铅锌尾矿中含有的少量Fe2O3、CaO与微量重金属氧化物As2O3、PbO、Cr2O3及其他杂质对合成ZSM-5产物的影响不大。

图8(a)所示为小试放大产物样品9和样品10的XRD谱,2θ为7.9°、8.8°、23.2°、23.9°和24.4°处均出现典型的MFI结构特征衍射峰(PDF#44-0003),相对结晶度分别为123.35%和129.33%,说明合成的产物为ZSM-5分子筛[16]。图8(b)所示为小试放大产物的FT-IR谱,在波数分别为:1640 cm-1、1400 cm-1、1200 cm-1、1070 cm-1、793 cm-1、542 cm-1和455 cm-1处皆具有分子筛的特征IR吸收峰,其中波数为455 cm-1处是SiO4和AlO4内四面体的T—O键的振动吸收;542 cm-1处为分子筛结构单元五元环的结构振动,是典型的ZSM-5沸石分子筛结构特征峰;结合XRD的表征结果,进一步说明了所合成的产物为ZSM-5分子筛。小试放大产物的相对结晶度略高于小试产物的相对结晶度,说明放大工艺不会因为放大效应而降低产物的相对结晶度。这说明放大工艺较稳定,放大效应不明显。

图9所示为小试和小试放大合成产物的SEM像。两种尾矿小试和小试放大产物形貌均为类球形,钨尾矿小试放大产物粒径约2 μm,分散较均匀,小试约为5.6 μm,轻微团聚。铅锌尾矿小试放大产物粒径约3~4 μm,大小不一,小试约为5.6 μm,有少许细小颗粒。整体来看,小试放大产物粒径较小,分散性略好,可能是因为搅拌条件有利于该合成体系的传质和传热,使合成体系物种分散均一,加快晶核生成速率,促进晶核的析出,导致产物粒径减小[25]。

图10所示为小试放大产物催化剂对NO转化效果曲线图。在原料气组成为(体积分数):O2 3.06%、NH3 8.36%、NO 7.54%、N2 81.04%;混合气空速为1.0×105 mL/(g·h)的条件下模拟对NO进行脱硝还原。由图10可以看出,样品9产物催化剂的NO转化效率随着温度的提高先升高后趋于平缓,560 ℃时达到最高点,为97.69%,样品10产物催化剂的NO转化效率随着温度的提高先升高后降低,380 ℃达到最高点,为94.31%。说明所合成ZSM-5分子筛产物有较好的催化活性,由表6中产物样品9和10的Fe2O3含量分别为0.37%和0.16%,可以发现Fe2O3含量较高的样品9产物有较好的高温活性。

表6 放大产物组分分析

Table 6 Scale-up products component analysis

图8 放大产物的XRD谱和FT-IR谱

Fig. 8 XRD(a) and FT-IR(b) patterns of scale-up products

图9 放大产物的SEM像

Fig. 9 SEM images of scale-up products

图10 放大产物催化剂的NO转化率

Fig. 10 NO conversion rates of scale-up product catalysts

3 结论

1) 以有色金属钨矿和铅锌矿尾矿为原料、采用常规水热法和微波水热法合成ZSM-5分子筛时,受杂质组分影响,干化尾矿直接高温碱熔出现煅烧结块现象,但合适的酸浸处理可避免煅烧结块,同时低温碱溶活化可在相对较低的温度下活化矿料。杂质组分对尾矿活化过程中SiO2溶出率的影响程度由高到低的顺序为CaO、其他杂质、Fe2O3,相比高温碱熔活化,低温碱溶活化受CaO的影响较小。活化方式对矿料中SiO2和Al2O3的溶出率影响差异性较大,低温碱溶所获得的合成前驱液中硅铝摩尔比n(SiO2)/n(Al2O3) 相对较高,更利于形貌规整的ZSM-5产物生成,但产物粒径减小。酸浸高温碱熔预处理合成ZSM-5产物对尾矿资源化利用率(以SiO2计)可达到45.20%~70.89%,高于低温碱溶活化处理时的22.60%~56.75%,不过其能耗更高,工艺更复杂。

2) 微波水热法可缩短诱导期,加速成核速度,合成相同结晶度的ZSM-5分子筛,微波水热法所需时间仅为常规水热法的四分之一左右,并且合成产物粒径更小,表面更洁净,尾矿的资源化利用率(以SiO2计)也相对要高,所合成产物比表面积在273.21~350.51 m2/g之间。实验室放大试验表明,1 L反应釜工艺放大效应小,工艺稳定,搅拌条件有利于合成体系的传质和传热,导致产物粒径减小,产物催化剂对NO转化率高于94.31%。

REFERENCES

[1] 童 雄. 尾矿资源二次利用的研究与实践[M]. 北京: 科学出版社, 2013.

TONG Xiong, Research and practice of secondary utilization of tailings resources[M]. Beijing: Science Press, 2013.

[2] 曾祥龙. 有色金属尾矿综合利用的研究进展[J]. 世界有色金属, 2019, 16: 284-286.

ZENG Xiang-long. Research progress on comprehensive utilization of non-ferrous metal tailings[J]. Nonferrous Metals of the World, 2019, 16: 284-286.

[3] 刘志远, 刘明宝, 王建英, 等. 中国矿山尾矿资源利用的技术与对策[J]. 煤炭技术, 2014, 33(6): 1-3.

LIU Zhi-yuan, LIU Ming-bao, WANG Jian-ying, et al. Technologies and countermeasures of mining tailings resources in China[J]. Coal technology, 2014, 33(6): 1-3.

[4] 陈江安. 选矿尾矿处理工艺与实践[M]. 北京: 冶金工业出版社, 2018.

CHEN Jiang-an. Processing technology and practice of beneficiation tailings[M]. Beijing: Metallurgical Industry Press, 2018.

[5] 张鹏举, 杨宏斌, 韦夏夏, 等. 有色金属尾矿资源化利用合成ZSM-5分子筛功能材料[J]. 矿业研究与开发, 2019, 39(9): 123-127.

ZHANG Peng-ju, YANG Hong-bin, WEI Xia-xia, et al. Non-ferrous metal tailings resource utilization and synthesis of ZSM-5 molecular sieve functional materials[J]. Mining Research and Development, 2019, 39(9): 123-127.

[6] HASAN Z, JUN J W, KIM C U, et al. Desilication of ZSM-5 zeolites for mesoporosity development using microwave irradiation[J]. Materials Research Bulletin, 2015, 61: 469-474.

[7] 周 茁. 低成本ZSM-5分子筛合成的研究[D]. 上海: 华东理工大学, 2017.

ZHOU Zhuo. Study on synthesis of low-cost ZSM-5 molecular sieve[D]. Shanghai: East China University of Science and Technology, 2017.

[8] PARK S E, KIM D S, CHANG J S, et al. Synthesis of MCM-41 using microwave heating with ethylene glycol[J]. Catalysis Today, 1998, 44(1/4): 301-308.

[9] 张鹏举, 黄太铭, 何华杰, 等. 天然矿物质及工业农业固体废弃物合成ZSM-5技术与发展[J]. 金属矿山, 2018(8): 175-184.

ZHANG Peng-ju, HUANG Tai-ming, HE Hua-jie, et al. ZSM-5 technology and development of natural minerals and industrial agricultural solid waste synthesis[J]. Metal Mine, 2018(8): 175-184.

[10] LIU Hai-yan, SHEN Tong, WANG Wan-wan, et al. From natural aluminosilicate minerals to zeolites: Synthesis of ZSM-5 from rectorites activated via different methods[J]. Applied Clay Science, 2015, 115: 201-211.

[11] 张鹏举, 黄太铭, 何华杰, 等. 以锡矿尾矿为原料ZSM-5分子筛的水热合成[J]. 中国有色金属学报, 2019, 29(8): 1790-1800.

ZHANG Peng-ju, HUANG Tai-ming, HE Hua-jie, et al. Hydrothermal synthesis of ZSM-5 molecular sieve using tin ore tailings as raw material[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(8): 1790-1800.

[12] 谭可心, 栾国颜, 裴东寒. ZSM-5分子筛的合成及改性研究进展[J]. 人工晶体学报, 2016(12): 2895-2901.

TAN Ke-xin, LUAN Guo-yan, PEI Dong-han. Research progress of synthesis and modification of ZSM-5 molecular sieve[J]. Journal of Synthetic Crystals, 2016(12): 2895-2901.

[13] ANUWATTANA R, BALKUS K J, ASAVAPISIT S, et al. Conventional and microwave hydrothermal synthesis of zeolite ZSM-5 from the cupola slag[J]. Microporous and Mesoporous Materials, 2008, 111(1/3): 260-266.

[14] 唐洪明. 矿物岩石学[M]. 北京: 石油工业出版社, 2007.

TANG Hong-ming. Mineralogy[M]. Beijing: Petroleum Industry Press, 2007.

[15] 申献江, 马冬阳, 张 梅, 等. 铝土矿尾矿除杂及合成刚玉-莫来石研究[J]. 耐火材料, 2017, 51(4): 256-259.

SHEN Xian-jiang, MA Dong-yang, ZHANG Mei, et al. Research on bauxite tailings debris removal and synthetic corundum-mullite[J]. Refractory, 2017, 51(4): 256-259.

[16] 王有和, 吴成成, 付春峰, 等. 粉煤灰为原料水热合成ZSM-5沸石的工艺条件[J]. 工业催化, 2018, 26(5): 110-115.

WANG You-he, WU Cheng-cheng, FU Chun-feng, et al. Process conditions for hydrothermal synthesis of ZSM-5 zeolite with fly ash as raw material[J]. Industrial Catalysis, 2018, 26(5): 110-115.

[17] 许 磊, 王公慰, 魏迎旭, 等. MCM-41介孔分子筛合成研究Ⅱ. 微波辐射法[J]. 催化学报, 1999, 20(3): 251-255.

XU Lei, WANG Gong-wei, WEI Ying-xu, et al. Synthesis of MCM-41 mesoporous molecular sieves Ⅱ. Microwave radiation[J]. Journal of Catalysis, 1999, 20(3): 251-255.

[18] 张海荣, 宁掌玄, 刘红艳, 等. 原料硅铝比对ZSM-5分子筛形貌及其甲醇转化制丙烯催化性能的影响[J]. 现代化工, 2017, 37(6): 79-83.

ZHANG Hai-rong, NING Zhang-xuan, LIU Hong-yan, et al. Effect of raw material silicon-aluminum ratio on the morphology of ZSM-5 molecular sieve and its catalytic performance in the conversion of methanol to propylene[J]. Modern Chemical Industry, 2017, 37(6): 79-83.

[19] 王 倩. ZSM-5沸石的调控合成与表征[D]. 大连: 大连理工大学, 2018.

WANG Qian. Regulatory synthesis and characterization of ZSM-5 zeolite[D]. Dalian: Dalian University of Technology, 2018.

[20] 姚小强. 不同形貌ZSM-5分子筛的合成及吸附性能研 究[D]. 北京: 北京化工大学, 2013.

YAO Xiao-qiang. Study on synthesis and adsorption properties of ZSM-5 molecular sieves with different morphologies[D]. Beijing: Beijing University of Chemical Technology, 2013.

[21] OLEKSIAK M D, RIMER J D. Synthesis of zeolites in the absence of organic structure-directing agents: Factors governing crystal selection and polymorphism[J]. Rev Chem Eng, 2014, 30: 1-49.

[22] AZZOLINA J F, POLAERT I, ESTEL L, et al. Enhancement of synthesis of ZSM-11 zeolite by microwave irradiation[J]. Microporous and Mesoporous Materials, 2014, 198: 22-28.

[23] 刘希尧. 工业催化剂分析测试表征[M]. 北京: 轻加工出版社, 1990.

LIU Xi-yao. Industrial catalyst analysis test characterization[M]. Beijing: Light Processing Press, 1990.

[24] 吉向飞, 安转转, 赵娇娇, 等. 动态条件下ZSM-12分子筛的合成[J]. 精细化工, 2016, 33(4): 50-56.

JI Xiang-fei, AN Zhuan-zhuan, ZHAO Jiao-jiao, et al. Synthesis of ZSM-12 molecular sieve under dynamic conditions[J]. Fine Chemicals, 2016, 33(4): 50-56.

[25] 张义华.钛基催化材料的合成、表征和选择氧化性能研 究[D]. 大连: 大连理工大学, 2001.

ZHANG Yi-hua. Study on synthesis, characterization and selective oxidation of titanium-based catalytic materials[D]. Dalian: Dalian University of Technology, 2001.

HUANG Tai-ming1, LI Sheng-chen1, LI Xiao-hui3, ZHANG Peng-ju1, YANG Hong-bin2, RUAN Le1, TANG Fu-shun1

(1. Collaborative Innovation Center for Exploration of Hidden Nonferrous Metal Deposits and Development of New Materials in Guangxi, College of Chemistry and Bioengineering, Guilin University of Technology, Guilin 541004, China;

2. Environmental Emergency and Accident Investigation Center of Guangxi Zhuang Autonomous Region, Nanning 530028, China;

3. Solid Waste and Chemical Environmental Management Center of Guangxi Zhuang Autonomous Region, Nanning 530028, China)

Abstract: The ZSM-5 molecular sieve was synthesized by conventional hydrothermal method (CH) and microwave hydrothermal method (MH), using non-ferrous metal tungsten ore and lead-zinc ore tailings as materials which were activated pretreatment by high-temperature alkali fusing after acid leaching and low-temperature alkali dissolving without acid leaching, respectively. The obtained products were characterizated by XRF, ICP-AES, FT-IR, XRD, SEM, BET and catalyst activity evaluation. The results show that, the synthesized product is ZSM-5 molecular sieve. BET shows that the total specific surface area of the product is between 273.21-350.51 m2/g, and the pore diameter of the product by the MH is small. Low-temperature alkali dissolution activate pretreatment can obtain higher n(SiO2)/n(Al2O3) liquid precursors, which leads to the transformation of the morphology of the product from a spherical shape to a hexagonal prism shape, and the particle size of the product decreases. The product synthesis by activation pretreatment with high-temperature alkali fusion has a higher utilization of the SiO2 of dried tailings, but the process is complicated and the energy consumption is high. The sequence of influence factors of SiO2 dissolution rate during activation from high to low are: CaO, Others, Fe2O3. The required time to synthesize ZSM-5 with the same crystallinity by MH method is only about a quarter of the that of CH method, and the product size by the MH method is smaller, the surface is cleaner, and the SiO2 utilization rate is also higher. The 1 L reactor has a small amplification effect, and the stirring conditions are conducive to the mass and heat transfer of the synthesis system, resulting in a decrease in the particle size of the product, and the NO conversion rate of the product applied to the denitration reaction can reach 94.31%.

Key words: non-ferrous metal tailings; pretreatment; ZSM-5 zeolite; synthesis technology

Foundation item: Projects(AA18118010, AB16380276) supported by the Science and Technology Plan of Guangxi Zhuang Autonomous Region, China

Received date: 2020-01-06; Accepted date: 2020-05-20

Corresponding author: YANG Hong-bin; Tel: +86-13036811838; E-mail: zxcvbnmyhb@163.com

TANG Fu-shun; Tel: +86-18907734789; E-mail: tfushun@163.com

(编辑 龙怀中)

基金项目:广西科技计划资助项目(AA18118010,AB16380276)

收稿日期:2020-01-06;修订日期:2020-05-20

通信作者:杨宏斌,高级工程师;电话:13036811838;E-mail:zxcvbnmyhb@163.com

唐富顺,教授,博士;电话:18907734789;E-mail:tfushun@163.com