DOI:10.19476/j.ysxb.1004.0609.2019.02.10

激光喷丸强化铜锌合金及其疲劳行为

刘 麟1, 2, 3,盛圆圆1, 3,詹普杰1, 3,迟 蕊1, 3,周建忠2

(1. 常州大学 机械工程学院,常州 213164;

2. 江苏大学 机械工程学院,镇江 212013;

3. 常州大学 江苏省绿色过程装备实验室,常州 213164)

摘 要:以铜锌合金为研究对象分别进行2.5 J和4.5 J能量下的激光喷丸强化实验,对喷丸前后试样的显微硬度、残余应力及疲劳特性进行研究。结果表明:试样经激光喷丸强化后深度方向的硬度和残余应力均明显提高,且喷丸能量越大两者提高幅度越明显。2.5 J、4.5 J激光能量处理下试样的疲劳寿命较未喷丸试样的分别提高1.27~1.49倍、1.42~1.66倍。疲劳断口形貌分析发现激光喷丸缓解试样表面缺陷等区域的应力集中,疲劳裂纹源位置内移;裂纹扩展区疲劳条带间距随着喷丸能量的增加逐渐减小,使得扩展区裂纹扩展速率显著降低;瞬断区等轴韧窝尺寸和深度随激光能量的增加而增加,从而提高铜锌合金的疲劳寿命。

关键词:铜锌合金;激光喷丸;残余应力;疲劳寿命;疲劳断口

文章编号:1004-0609(2019)-02-0295-08 中图分类号:TN249 文献标志码:A

铜合金由于具有良好的导热、导电、耐磨损和抗疲劳等性能,所以在机械设备的传动、制动等关键零部件制造领域具有广阔的应用前景[1-4]。随着现代工业的飞速发展,高速、高温和重载等苛刻工作条件对轴承等传动、制动部件提出了新的要求,这些部件同时应具备高抗疲劳、高耐磨、高强度以及高导热等优良的综合性能。轴承等传动、制动零部件在服役期间的失效主要原因是表面疲劳和磨损[5]。研究表明,机械零部件在服役过程中由交变载荷造成的疲劳破坏占50%~90%[6],而疲劳失效大多始于材料表面,所以提高材料的表面性能、延长材料的疲劳寿命具有非常重要的意义[7-10]。

表面强化是提高金属材料疲劳强度的一种有效方法,工业中常用的方法有机械喷丸、滚压强化、表面研磨强化等,近年来激光喷丸因其表面塑性变形强化效果显著而受到越来越多的关注[11-14]。激光喷丸采用高功率密度、短脉冲的强激光在金属靶表面诱导高幅冲击波压力使其表层发生塑性变形和形变硬化,同时在处理区域产生理想的残余应力分布,从而有效减少表面裂纹萌生,延缓裂纹扩展速率,达到强化的目的[15-18]。目前,激光喷丸强化已成功应用于铝合金、钛合金、镁合金等金属材料[1, 12, 19],随着铜合金作为机械设备传动、制动部件的工况条件越来越苛刻,对其表面强化及其疲劳性能具有重要的工程应用价值,而对激光喷丸强化铜合金及其疲劳特性的研究尚未见报道。

本文作者以铜锌合金为研究对象,深入分析了铜锌合金激光喷丸前后的显微硬度、残余应力、疲劳断口形貌及疲劳寿命的变化规律和特性,研究了激光喷丸强化对铜锌合金疲劳性能的影响,以期为提高铜锌合金抗疲劳性能提供新的方法和借鉴。

1 实验

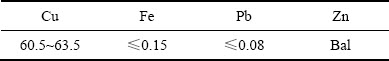

选取退火态CuZn38为研究对象,化学成分及主要性能参数见表1和表2,其中: 为抗拉强度;

为抗拉强度; 为屈服强度;

为屈服强度; 为伸长率;E为弹性模量。

为伸长率;E为弹性模量。

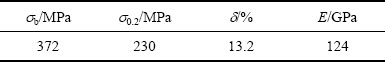

实验选用波长1060 nm,脉冲宽度10 ns,重复频率0.5 Hz的钕玻璃脉冲激光器,激光器型号为GAIA -1064。激光喷丸能量分别为2.5 J和4.5 J,搭接率50%,光斑直径3 mm,吸收层为0.1 mm厚的铝箔,约束层为1.5 mm厚的纯水。疲劳试样如图1所示,喷丸区域为22.5 mm×9 mm。试样加工和激光喷丸强化的工艺流程为:线切割成外形尺寸,300 ℃退火处理45 min,试样表面经400#~2200#金相砂纸打磨抛光,激光喷丸强化冲击处理。疲劳实验在EHF-EG250-50L岛津疲劳实验机上进行,采用拉-拉正弦波载荷谱轴向加载,应力比R=0.1,实验频率f=20 Hz,最大应力smax=340 MPa,实验环境为空气和室温条件。疲劳性能实验分激光喷丸前1组和激光喷丸后2组进行,每组实验采用6个试样。

表1 CuZn38合金化学成分

Table 1 Chemical composition of CuZn38 alloy (mass fraction,%)

表2 CuZn38合金主要性能参数

Table 2 Performance parameter of CuZn38 alloy

图1 激光喷丸强化及高周疲劳试样

Fig. 1 Shape of laser peening and plain fatigue specimen (Unit: mm)

分别采用HV-1000型显微硬度计和X-350A型衍射分析仪测量试样沿深度方向的硬度分布和残余应力分布,采用“成组对比法”对激光喷丸强化后的疲劳寿命进行了定量分析,采用GSM-6510型扫描电子显微镜分析试样疲劳断口微观形貌。

2 结果与分析

2.1 显微硬度

铜锌合金试样激光喷丸前后沿深度方向的显微硬度如图2所示,所用载荷0.49 N,饱载时间15 s,深度方向测量间隔20 μm,每个深度位置测3次并取平均值。由图2可知,未激光喷丸试样的显微硬度沿深度方向保持相对稳定,变化范围137~146 HV,平均值约为142 HV;2.5 J激光喷丸处理试样硬度变化范围140~180 HV,最大硬度值在表面处,为180 HV;4.5 J激光喷丸处理试样显微硬度变化范围在142~215 HV,其最大硬度值也位于试样表面,为215 HV。经2.5 J和4.5 J激光能量喷丸后试样表面硬度较基体硬度分别提高了25%和51%,而后沿深度方向逐渐降低,2.5 J和4.5 J激光能量喷丸后试样的显微硬度影响层分别约为57 mm和143 mm。激光喷丸后铜锌合金表层的显微硬度明显增加,主要是由于激光高压冲击波在铜锌合金表层产生了高应变和应变率,使得原始晶粒内部和晶体间的位错密度增加,位错间交互作用增强,相互发生缠结,位错运动受阻进而使晶粒产生细化,晶界增多,铜锌合金的塑性变形抗力也随之提高[20]。

图2 试样沿深度方向的显微硬度分布

Fig. 2 Micro-hardness distribution of samples through depth

图3 试样沿深度方向的残余应力分布

Fig. 3 Residual stress distribution of samples through depth

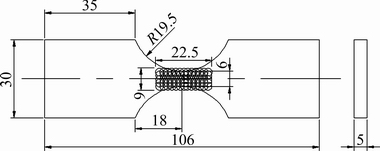

2.2 残余应力

试样在激光喷丸前后的残余应力值如图3所示。采用电解抛光剥层法对沿深度方向残余应力进行测试,电解抛光液为硝酸和乙醇(体积比1:2),电流密度0.06 A/cm3,剥层间隔深度10 μm;每层表面残余应力测试的扫描方式为固定Ψ法,Ψ为0°~45°,管电压20 kV,管电流5 mA,采用Cu Kα辐射,衍射晶面选择(220),对应应力常数151。结果如图3所示,未激光喷丸试样的残余应力沿深度方向基本一致,约为14 MPa的残余拉应力。2.5 J和4.5 J两种不同激光能量喷丸的试样残余应力最大值分布于表面,数值分别为-67.8 MPa和-89.5 MPa,为残余压应力,且距离试样表面越远,残余应力逐渐减小。2.5 J和4.5 J喷丸处理试样分别在距表面约45 mm和109 mm处的残余应力由“压”变为“拉”。此外,在距表面分别约为60 mm和145 mm深度之后,激光喷丸试样的残余应力值与基体残余应力基本保持一致。激光高能量等离子体的冲击波在试样表层产生严重的塑性变形,导致了表层位错结构累积和晶粒细化,从而引入了较高的残余压应力[1],随着深度的增加,激光高能量等离子体的冲击效应减弱,残余压应力也随之逐渐降低。

2.3 疲劳实验结果及疲劳寿命预测

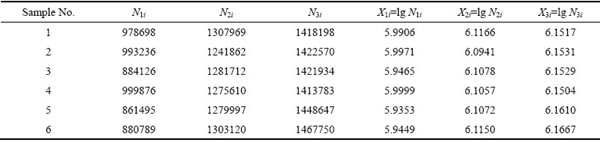

疲劳实验结果如表3所列,N1i、N2i和N3i分别表示未喷丸、2.5 J和4.5 J激光能量处理后试样的疲劳 寿命,X1i、X2i和X3i分别表示未喷丸、2.5 J和4.5 J激光能量处理后试样的对数疲劳寿命。从表3可见激光喷丸后试样疲劳寿命明显提高,为进一步研究激光喷丸强化对合金疲劳寿命的影响,采用“成组对比法”进行进一步的统计分析[21-22],即假设疲劳寿命服从正态分布,分析试样在同一应力水平下的对数寿命平均值和子样标准差,从而对激光喷丸前后试样的疲劳寿命进行预测。由表中疲劳实验数据计算出样本平均值 和标准差s。样本平均值

和标准差s。样本平均值 和标准差s的计算公式分别为:

和标准差s的计算公式分别为:

(1)

(1)

(2)

(2)

式中:i表示不同的处理方式,i取1、2、3时分别表示未喷丸、2.5 J激光喷丸处理、4.5 J激光喷丸处理;j表示每种处理方式下试样编号,每组疲劳试样有6个,j的取值为1~6。将表3中的数据代入式(1)、(2)分别得到 、

、 、

、 和s1、s2、s3。

和s1、s2、s3。

表3 试样疲劳实验数据

Table 3 Fatigue test results of specimens

取置信度g为95%,查t分布表可得t∞=2.571,显然t2-1和t3-1均大于t∞,故可知激光喷丸试样寿命较未喷丸试样疲劳寿命有显著提高,喷丸试样对数疲劳寿命母体平均值m2和m3均大于未喷丸试样对数疲劳寿命母体平均值m1。区间估计式为

<

< <

< (3)

(3)

<

< <

< (4)

(4)

可得置信度g为95%时的区间估计式分别为

0.1049< <0.1725 (5)

<0.1725 (5)

0.1534< <0.2204 (6)

<0.2204 (6)

[N50]1、[N50]2、[N50]3分别表示未喷丸、2.5 J激光喷丸、4.5 J激光喷丸处理后试样的中值疲劳寿命,则得:

0.1049< <0.1725 (7)

<0.1725 (7)

0.1534< <0.2204 (8)

<0.2204 (8)

对式(7)、(8)均取反对数,则有:

1.27< <1.49 (9)

<1.49 (9)

1.42< <1.66 (10)

<1.66 (10)

由式(9)、(10)可知,经过2.5 J激光喷丸强化冲击试样的疲劳寿命域为未喷丸试样的1.27~1.49倍;经过4.5 J激光喷丸强化冲击试样的疲劳寿命域为未喷丸试样的1.42~1.66倍。由此可见,激光喷丸强化铜锌合金能够有效提高其疲劳寿命。

2.4 疲劳断口形貌分析

图4所示为试样疲劳断裂后的断口形貌图,其中图4(a)、(b)和(c)所示分别是未处理、2.5 J和4.5 J激光喷丸能量强化下的断口形貌图。由图可知,3种疲劳断口均可各自分为3个不同区域,即裂纹源区、裂纹扩展区和瞬时断裂区。图4(a)可见裂纹起裂于试样表面,疲劳源数目较多,如图中椭圆框所示,并伴随有裂缝产生,如图中箭头所示。未喷丸试样表面原始微观缺陷在外部疲劳载荷作用下逐渐弱化,与周围基体产生了变形不协调,导致应力集中,使试样在表面处发生微观失效,形成裂纹源[23]。断口处裂缝的产生表明试样内部存在较多的应力集中和组织不均匀,使得裂纹扩展过程中出现局部或瞬时的断裂现象[24]。由图4(b)可见裂纹亦起裂于试样表面,但裂纹源数目有所减少,如图中椭圆框所示,裂纹源区较图4(a)更加平坦光亮;图4(c)可见裂纹源位置明显内移,起裂于试样次表面,如图中椭圆框所示,裂纹源数目更少,同时裂纹源平坦区域明显增加。图4(b)和(c)中方箭头方向为裂纹扩展方向,从中可见裂纹以扇面辐射方式向前扩展。图4(c)中裂纹源位置内移,裂纹形核区域出现在材料的次表层。激光喷丸后试样表面裂纹源内移的主要原因有两方面:一方面,激光喷丸引入的残余压应力有效缓解了试样表面的应力集中,残余应力与外加载荷相互叠加提高了试样表面的疲劳极限,使得裂纹萌生所需的“有效应力”由表面转移至次表面;另一方面,激光喷丸使试样表层发生严重的塑性变形,位错运动在此区域受阻,逐渐形成位错堆积或驻留滑移带[25],使得裂纹扩展在此区域受阻。随着外载荷的不断作用,诱导了裂纹核在离强化层较远、相对脆弱的试样次表面形成。此外,对比图4中(a)、(b)、(c) 3图还可以看到裂纹源区形貌逐渐变平整光滑,这主要是由于激光喷丸引入的残余压应力增加了裂纹尖端的闭合效应,有效减小了疲劳载荷作用下裂纹的张开和闭合趋势,并引起断口表面的摩擦,使得裂纹源区较为平整光滑,从而缓解了裂纹尖端的扩张趋势和速率。

图4 不同处理方式下试样疲劳裂纹源区形貌

Fig. 4 Morphologies of fatigue crack initiation region of specimens with different treatments

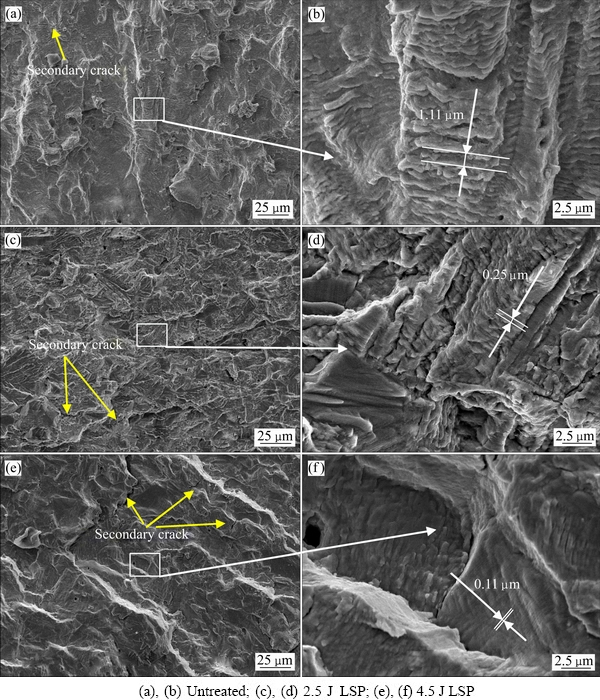

图5所示为试样在激光喷丸前后疲劳断口裂纹扩展区形貌图。由图5(b)可知,未喷丸试样裂纹扩展区呈现多簇分布于不同平面内的疲劳条带,每个平面内的疲劳条带相互平行、间距均称排列,条带间距约为1.11 mm。2.5J激光喷丸疲劳试样(见图5(d))的疲劳条带间距较图5(b)中的间距变短,约为0.25 mm;随着激光能量的增大,4.5J激光喷丸疲劳试样的疲劳条带进一步变细增密,间距更短,约为0.11 mm(见图5(f))。疲劳条带间距是疲劳循环载荷产生的裂纹扩展量,反映了裂纹扩展速率的快慢,疲劳条带间距会随应力强度因子的增大而增大;对比图5(b)、(d)和(f)可知,未喷丸试样所对应的应力强度因子较大,2.5 J试样次之,4.5 J试样最小。在裂纹扩展过程中,外载荷引起的应力强度因子为Kw,激光喷丸产生的残余压应力引起的应力强度因子为Krs,二者叠加使得裂纹尖端的应力强度因子减小,裂纹扩展速率降低[26]。并且由于材料内部显微组织(晶粒取向、晶界和第二相粒子等)的差异,使得裂纹扩展由一个平面转移至另一个平面,由此导致不同区域的疲劳条带簇会分布在高度不同、方向有别的平面上。从图5中可看到在疲劳断口扩展区有二次裂纹出现,未喷丸试样断口扩展区二次裂纹较少(见图5(a)),随着激光能量的增加,断口扩展区的二次裂纹的数量、裂纹长度和深度均逐渐有增加(见图5(c)和(e))。二次裂纹是从主裂纹扩展路径中分生出的更细小、数量更多的新扩展路径,二次裂纹在萌生和扩展过程中分担主裂纹扩展所需的部分能量[17],减少应力集中,同时降低主裂纹扩展的驱动力,使裂纹尖端变钝,减缓裂纹扩展速率。此外,通过对比图5中(a)、(c)和(e)还发现3种试样的裂纹扩展路径有所不同。图5(a)中裂纹路径较平坦,未见明显起伏,图5(c)、(e)的裂纹路径较图5(a)的裂纹路径弯曲和复杂。图5(c)中裂纹扩展路径大致沿右上方进行,图5(e)中裂纹扩展路径大致沿左下方进行,而图5(a)中却未见明显的扩展路径。由此可见,未喷丸试样内部存在着较多缺陷,裂纹在扩展过程中很难沿着某一主要方向进行。激光喷丸引入的残余压应力在裂纹扩展阶段还未完全消失,使得裂纹扩展所需克服的阻力增加,当裂纹越过晶界,从一个晶粒的某个滑移面转而在下一个晶粒的某个滑移面上继续扩展时,势必要发生弯曲,造成附近晶体点阵发生弯曲畸变,晶界处产生了裂纹沿此方向扩展的阻力[27]。故喷丸后的试样裂纹扩展遇到晶界时会受到阻碍,从而转向薄弱位置继续扩展,使得原有扩展路径变得弯曲复杂。这种从“平坦”到“曲折”扩展路径的改变延缓了裂纹的扩展速率,阻碍了裂纹的进一步扩展。

图5 不同处理方式下试样疲劳裂纹扩展区形貌

Fig. 5 Morphologies of fatigue crack propagation region of specimens with different treatments

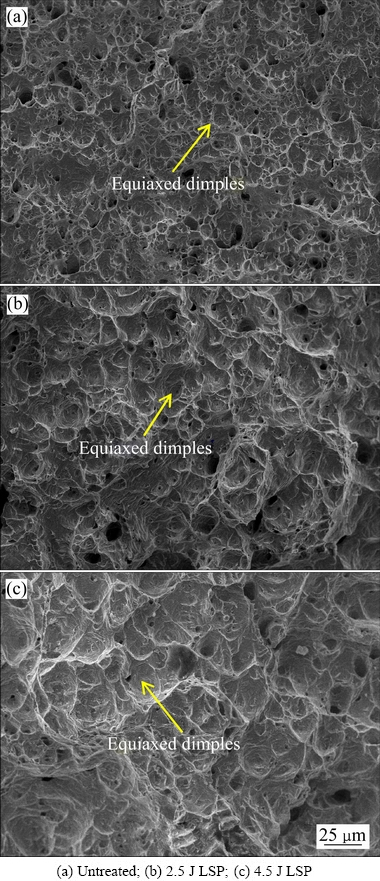

图6 不同处理方式下试样疲劳裂纹瞬断区形貌

Fig. 6 Morphologies of fatigue crack fracture region of specimens by different treatments

图6(a)、(b)和(c)所示分别为未喷丸、2.5 J和4.5 J喷丸试样的瞬断区形貌图。图中均可见有等轴韧窝存在。由于铜锌合金在疲劳载荷作用下,夹杂、第二相粒子与基体的界面处形成了微裂纹,随着疲劳载荷的持续作用,微裂纹逐渐聚合形成微孔洞,这些孔洞不断形核、长大,最终相互聚集形成等轴韧窝。图6(a)中的瞬断区韧窝尺寸相对较小,直径约为10 mm,且深度较浅;图6(b)中韧窝尺寸有所增加,直径约为15 mm,深度也有所增加;图6(c)中韧窝尺寸最大,其直径达到了20 mm左右,深度相对最深。韧窝尺寸是材料塑性变形能力强弱的重要标志,韧窝尺寸越大说明材料的塑性变形能力越好,可见激光喷丸能使铜锌合金疲劳瞬断区的塑性也有所提高,从而进一步改善其抗疲劳性能。

3 结论

1) 激光喷丸强化使得试样表层的显微硬度和残余应力显著增加,且激光能量越高,试样表层显微硬度和残余应力的增加幅度和影响深度越大。

2) 在应力比R=0.1、实验频率f=20 Hz、最大应力smax=340 MPa的实验条件下,试样经2.5 J激光喷丸处理后的疲劳寿命是未喷丸试样的1.27~1.49倍;试样经4.5J激光喷丸处理后的疲劳寿命是未喷丸试样的1.42~1.66倍。

3) 激光喷丸引入的残余压应力有效缓解了试样表面的应力集中,阻碍了表面裂纹的扩展,使得铜锌合金试样的疲劳裂纹源位置内移,残余压应力还增加了裂纹尖端的闭合效应,缓解了裂纹尖端的扩张趋势和速率;激光喷丸能量越大,试样裂纹扩展区的疲劳条带间距越小、二次裂纹数量越多、裂纹扩展路径越复杂,从而使得断口扩展区裂纹扩展速率显著降低;瞬断区等轴韧窝尺寸和深度随激光能量增加而增加,可见瞬断区塑性有所提高,从而使得铜锌合金的抗疲劳性能得到进一步改善。

REFERENCES

[1] 黄 舒, 周建忠, 蒋素琴, 盛 杰, 徐增闯, 阮鸿雁. AZ镁合金激光喷丸后的形变强化及疲劳断口分析[J]. 中国激光, 2011, 38(8): 70-76.

HUANG Shu, ZHOU Jian-zhong, JIANG Su-qin, SHENG Jie, Xü Zeng-chuang, RUAN Hong-yan. Study on strain hardening and fatigue fracture of AZ31B magnesium alloy after laser shot peening[J]. Chinese Journal of Lasers, 2011, 38(8): 70-76.

[2] 宋谋胜, 冉茂武, 孔园园, 宴登扬. 铸造A356铝合金的低周疲劳行为[J]. 中国有色金属学报, 2011, 21(3): 538-545.

SONG Mou-sheng, RAN Mao-wu, KONG Yuan-yuan, YAN Deng-yang. Low cycle fatigue behavior of cast A356 aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(3): 538-545.

[3] GAZIZOV M, KAIBYSHEV R. High cyclic fatigue performance of Al-Cu-Mg-Ag alloy under T6 and T840 conditions[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(6): 1215-1223.

[4] TANG K, HE C, HUANG Q, HUANG Z Y, WANG C, WANG Q Y, LIU Y J, ZHONG B. Very high cycle fatigue behaviors of a turbine engine blade alloy at various stress ratios[J]. International Journal of Fatigue, 2017, 99: 35-43.

[5] 周 昆, 李云卿. Al-Zn-Mg-Cu合金应变疲劳行为及位错结构演变[J]. 中国有色金属学报, 1997(4): 79-83.

ZHOU Kun, LI Yun-qing. Strain-fatigue beheavior and evolution of dislocation substructure of Al-Zn-Mg-Cu alloy[J]. The Chinese Journal of Nonferrous Metals, 1997(4): 79-83.

[6] 刘翠云, 李焕喜, 马朝利. TC18钛合金耳片的断口形貌及疲劳性能[J]. 中国有色金属学报, 2010, 20(s1): s1073-s1077.

LIU Cui-yun, LI Huan-xi, MA Chao-li. Fractograph and fatigue behavior of TC18 titanium alloy lugs[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(s1): s1073-s1077.

[7] 周 宁, 郑津洋, 盛水平, 韩树新, 陈海云, 刘延雷, 缪存坚. 铜制压力容器轻量化研究[J]. 压力容器, 2010, 27(11): 8-12.

ZHOU Ning, ZHENG Jing-yang, SHENG Shui-ping, HAN Shu-xin, CHEN Hai-yun, LIU Yan-lei, MIAO Cun-jian. Light-weight research of Copper pressure vessels[J]. Pressure Vessel, 2010, 27(11): 8-12.

[8] 吕海霆. 机械零件疲劳寿命问题研究[J]. 制造业自动化, 2011, 33(23): 130-132.

Lü Hai-ting. Study on fatigue life of mechanical parts[J]. Manufacturing Automation, 2011, 33(23): 130-132.

[9] 罗新民, 张静文, 赵广志, 任旭东, 张永康. 激光冲击强化对2A02铝合金疲劳行为的影响[J]. 中国激光, 2009, 36(12): 3323-3328.

LUO Xin-min, ZHANG Jing-wen, ZHAO Guang-zhi, REN Xu-dong, ZHANG Yong-kang. Effect of laser shock strengthening on fatigue behaviors of 2A02 aluminum alloy[J]. Chinese Journal of Lasers, 2009, 36(12): 3323-3328.

[10] 赵振兴, 孙红亮, 黄泽文. 长期热暴露对不同表面状态的Ti-44Al-5Nb-1W-1B合金疲劳性能的影响[J]. 中国有色金属学报, 2015(6): 1458-1464.

ZHAO Zhen-xing, SUN Hong-liang, HUANG Ze-wen. Effects of long-term thermal exposure on fatigue behavior of Ti-44Al-5Nb-1W-1B alloy with varied surface conditions[J]. The Chinese Journal of Nonferrous Metals, 2015(6): 1458-1464.

[11] 高玉魁, 仲 政, 雷力明. 激光冲击强化和喷丸强化对FGH97高温合金疲劳性能的影响[J]. 稀有金属材料与工程, 2016, 45(5): 1230-1234.

GAO Yu-kui, ZHONG Zheng, LEI Li-ming. Influence of laser peening and shot peening on fatigue properties of FGH97 superalloy[J]. Rare Metal Materials and Engineering, 2016, 45(5): 1230-1234.

[12] 周建忠, 王呈栋, 黄 舒, 杨小东, 徐增闯, 杨 晶, 朱 伟. 6061-T6铝合金紧凑拉伸试样激光喷丸强化后的疲劳裂纹扩展性能研究[J]. 中国激光, 2011, 38(7): 146-151.

ZHOU Jian-zhong, WANG Cheng-dong, HUANG Shu, YANG Xiao-dong, XU Zeng-chuang, YANG Jing, ZHU Wei. Study on fatigue crack growth performance of 6061-T6 aluminum alloy after laser shot peening[J]. Chinese Journal of Lasers, 2011, 38(7): 146-151.

[13] 刘 帅, 吴冬冬, 柴东升, 周思雨, 马广义, 周 平, 吴东江. Hastelloy C-276薄板激光焊接接头疲劳性能[J].中国有色金属学报, 2016, 26(12): 2555-2563.

LIU Shuai, WU Dong-dong, CAI Dong-sheng, ZHOU Si-yu, MA Guang-yi, ZHOU Ping, WU Dong-jiang. Fatigue property of laser welded joints of Hastelloy C-276 thin sheet[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(12): 2555-2563.

[14] 高玉魁. 喷丸对Ti-10V-2Fe-3Al钛合金拉-拉疲劳性能的影响[J]. 中国有色金属学报, 2004, 14(1): 60-63.

GAO Yu-kui. Influence of shot peening on tension-tension fatigue properties in Ti-10V-2Fe-3Al titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 60-63.

[15] SHENG J, HUANG S, ZHOU J Z, LU J Z, XU S Q, ZHANG H F. Effect of laser peening with different energies on fatigue fracture evolution of 6061-T6 aluminum alloy[J]. Optics & Laser Technology, 2016, 77: 169-176.

[16] NIE X, HE W, ZANG S, WANG X, ZHAO J. Effect study and application to improve high cycle fatigue resistance of TC11 titanium alloy by laser shock peening with multiple impacts[J]. Surface & Coatings Technology, 2014, 253(9): 68-75.

[17] YUE Y, DAI L Y, ZHONG H, ZHANG X Y, LIANG S X, MA M Z, LIU R P. Effect of microstructure on high cycle fatigue behavior of Ti-20Zr-6.5Al-4V alloy[J]. Journal of Alloys & Compounds, 2016, 696: 663-669.

[18] KAHLIN M, ANSELL H, MOVERARE J J. Fatigue behaviour of notched additive manufactured Ti6Al4V with as-built surfaces[J]. International Journal of Fatigue, 2017, 101: 51-60.

[19] 李 媛, 何卫锋, 聂祥樊, 游 熙, 周留成. 激光冲击TC17钛合金疲劳裂纹扩展试验[J]. 中国表面工程, 2017, 30(3): 40-47.

LI Yuan, HE Wei-feng, NIE Xiang-xi, YOUXi, ZHOU Liu-cheng. Fatigue crack growth behavior of TC17 titanium alloy with laser shock peening[J]. China Surface Engineering, 2017, 30(3): 40-47.

[20] ZHANG Y, GU Y, ZHANG X, SHI J, ZHOU J. Study of the mechanism of overlays acting on laser shock waves[J]. Journal of Applied Physics, 2006, 100(10): 103517.

[21] 高镇同. 疲劳应用统计学[M]. 北京: 国防工业出版社, 1986.

GAO Zhen-tong. Fatigue applied statistics[M]. Beijing: National Defence Industry Press, 1986.

[22] 罗 刚, 范引鹤, 梁尤疆. 高温合金焊接接头应力分析与疲劳寿命预测[J]. 航空动力学报, 2007, 22(2): 327-331.

LUO Gang, FAN Yin-he, LIANG You-jiang. Stress analysis and fatigue life estimation of four kinds of super-alloy welded joints[J]. Journal of Aerospace Power, 2007, 22(2): 327-331.

[23] 孟天利. 金属材料疲劳形核研究[J]. 兰州工业学院学报, 2016, 23(4): 75-81.

MENG Tian-li. The study on fatigue crack nucleation of metal material[J]. Journal of Lanzhou Institute of Technology, 2016, 23(4): 75-81.

[24] 钟群鹏, 赵子华. 断口学[M]. 北京: 高等教育出版社, 2006.

ZHONG Jun-peng, ZHAO Zi-hua. Fractography[M]. Beijing: Higher Education Press, 2006.

[25] 李 勇, 李守新, 李广义.疲劳过程中垂直晶界Cu双晶形变带中位错组态与裂纹形核[J]. 金属学报, 2004, 40(5): 462-466.

LI Yong, LI Shou-xin, LI Guang-yi. Dislocation pattern in deformation band and crack nucleation in a fatigued copper bicrystal with perpendicular grain boundary[J]. Acta Metallurgica Sinica, 2004, 40(5): 462-466.

[26] 黄 舒. 激光喷丸强化铝合金的疲劳裂纹扩展特性及延寿机理研究[D]. 镇江: 江苏大学, 2012: 34-40.

HUANG Su. Investigation of laser peening on the fatigue crack growth properties and life extension mechanism of 6061-T6 aluminum alloy[D]. Zhengjiang: Jiangsu University, 2012: 34-40.

[27] 蒋金星, 唐 荻, 武会宾, 张 杰, 杨 柳. E550海洋平台用钢二次裂纹扩展机理研究[J]. 材料工程, 2013(6): 35-39.

JIANG Jin-xing, TANG Di, WU Hui-bin, ZHANG Jie, YANG Liu. Analysis is of propagation behavior of secondary cracks in the E550 offshore platform steel[J]. Journal of Materials Engineering, 2013(6): 35-39.

Laser shot peening on brass and its fatigue behavior

LIU Lin1, 2, 3, SHENG Yuan-yuan1, 3, ZHAN Pu-jie1, 3, CHI Rui1, 3, ZHOU Jian-zhong2

(1. School of Mechanical Engineering, Changzhou University, Changzhou 213164, China;

2. School of Mechanical Engineering, Jiangsu University, Zhenjiang 212013, China;

3. Jiangsu Key Laboratory of Green Process Equipment, Changzhou University, Changzhou 213164, China)

Abstract: The brass was induced by laser shot peening (LSP) with the laser pulse energy of 2.5 J and 4.5 J, respectively. The micro-hardness, residual stress and fatigue properties of brass induced by LSP were investigated systematically. The results indicate that micro-hardness and residual stress significant increasing along depth are accompanied by improving laser pulse energy. Compared with the untreated, the fatigue lives of brass induced by 2.5 J LSP and 4.5 J LSP increase by 1.27-1.49 times and 1.42-1.66 times, respectively. Fatigue fracture morphologies indicate that the stress concentration on surface defects of brass is relieved after LSP. Meanwhile, the location of the fatigue crack initiation shifts inwards. Fatigue striation space in the crack propagation region decreases gradually, which causes crack growth rate reduces effectively, with increase of laser energy. The size and depth of the dimples in the fracture region distend with the increase of the energy, which improve the fatigue life of the brass.

Key words: brass; laser shot peening; residual stress; fatigue life; fatigue fracture

Foundation item: Projects(51601021, 51671037) supported by the Natural Science Foundation of China; Project (BK201402620) supported by the Natural Science Foundation of Jiangsu Province, China; Project (17KJA460002) supported by the Natural Science Foundation of Jiangsu Higher Education Institutions, China; Project(2017M611718) supported by China Postdoctoral Science Foundation, China; Project (GDZB-002) supported by Qing Lan Project of Jiangsu Province and “Six Talent Peaks” of Jiangsu Province, China

Received date: 2017-12-03; Accepted date: 2018-02-08

Corresponding author: LIU Lin; Tel: +86-519-81169803; E-mail: liulin@cczu.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51601021,51671037);江苏省自然科学基金资助项目(BK20140262);江苏省高校自然科学研究重大项目(17KJA460002);中国博士后科学基金项目(2017M611718);2017年江苏省“青蓝工程”项目;2017年江苏省“六大人才高峰”项目(GDZB-002)

收稿日期:2017-12-03;修订日期:2018-02-08

通信作者:刘 麟,副教授,博士;电话:0519-81169803;E-mail:liulin@cczu.edu.cn