文章编号:1004-0609(2016)-08-1615-09

Si相对铸造Al-Si合金低温拉伸断裂行为的影响

马广辉,李润霞,白彦华,李荣德

(沈阳工业大学 材料科学与工程学院,沈阳 110870)

摘 要:对Al-1Si-0.3Mg和Al-7Si-0.3Mg合金在-80~20 ℃拉伸过程中的断裂行为进行研究。结果表明:随着温度的降低Al-1Si-0.3Mg合金的抗拉强度、屈服强度及伸长率均呈上升趋势;Al-7Si-0.3Mg合金的抗拉强度和屈服强度上升,伸长率却明显下降;拉伸过程中Al-1Si-0.3Mg合金中位错在晶界塞积,易使相邻晶粒内位错源启动,使合金具有较高的塑性;Al-7Si-0.3Mg合金的位错在Si相边界塞积,使相邻晶粒内位错源难以启动,从而造成合金具有较高的强度。

关键词:铝硅合金;低温;拉伸性能;位错;硅相

中图分类号:TG146.3 文献标志码:A

铸造Al-Si合金作为常用的结构材料受到国内外学者的广泛关注[1-6]。大量研究表明,在Al-Si合金的塑性变形过程中,Si相发生断裂形成微裂纹[1-2, 7-12]。JIEN等[11]研究发现[11],Si相破裂只发生在Al-Si合金的塑性变形阶段。DOGLIONE等[12]对A356合金研究发现,影响Si相断裂的主要因素有:Si相的尺寸、长宽比和Si相的分布情况。CACERES等[13-14]认为,在常温条件下共晶Si相的断裂数量跟形变量成正比,在拉伸过程中尺寸和长宽比较大的Si相最先发生断裂,随着合金的形变量不断增加,尺寸较小的Si相也开始发生断裂,当断开的Si相达到一定程度时拉伸试样发生断裂。

随着国内高速铁路的迅速发展,越来越多的Al-Si合金铸件(如枕梁)应用于高速列车。由于我国北方天气寒冷,这些Al-Si合金铸件的长期在低温环境中工作,因此Al-Si合金的低温性能的研究十分重要。但是国内外对铝合金低温性能的研究主要集中于变形铝合金。刘瑛等[15-16]对2519、2219、及7039合金在77 K时的拉伸性能研究表明:这3种铝合金的屈服强度、抗拉强度和伸长率均有所提高。陈鼎等[17]对除了Al-Si合金之外的其他铝合金的低温力学性能进行了统计,结果表明:这些铝合金的强度和伸长率都有一定程度的提高。大量研究认为,随着温度的降低变形铝合金的强度增,加硬化指数升高,塑性变形趋于均匀化,从而合金的伸长率提高[18-21]。随着Al-Si合金应用范围日益广泛,其低温性能开始受到人们的重视。RINCON等[22-23]对A319合金的研究发现,随着温度的降低该合金的强度升高,而伸长率呈下降趋势。GOKHALE等[24]在-50~120 ℃的温度下对A356合金进行拉伸测试发现,Si相破裂数量随着温度的降低而增加。OSAMU等[25-26]通过反复变形热处理方法细化过共晶铝硅合金中的初生Si相,使低温伸长率显著提高。关于铸造Al-Si合金低温性能发生变化的原因却鲜有研究报道。本文作者通过对铸造Al-1.0Si-0.3Mg和Al-7Si-0.3Mg合金在低温条件下拉伸性能的分析,讨论Si相对铸造Al-Si合金低温下强度和塑性的影响规律及原因。

1 实验

实验材料分别为Al-1Si-0.3Mg和Al-7Si-0.3Mg合金,其化学成分如表1所列。合金熔炼在电阻炉内进行,熔化温度控制在730 ℃,随后将Mg以中间合金的形式加入熔体中,采用AlSr5中间合金进行变质处理。通入氩气进行精炼搅拌后重力浇注成坯锭试样后进行T6热处理。热处理工艺为:在525 ℃下进行8 h固溶处理,将试样从炉中取出后立刻在水中淬火,然后在165 ℃下进行6 h时效处理。

表1 合金的化学成分

Table 1 Chemical composition of alloys (mass fraction, %)

按照GB/T 13239—2006标准制成拉伸试样,其中部分试样经过抛光后进行拉伸,然后观察拉伸变形中的位错滑移带。拉伸实验分别在-80~20 ℃环境下进行,拉伸试验机配备液氮冷却低温保温箱,试样在实验温度下保温15 min后进行拉伸实验,速率为2mm/min。获得的实验结果均为同条件下3个试样测试值的平均值。

利用TM3030型扫描电子显微镜观察拉伸试样的断口形貌及位错滑移带分布。在断口附近垂直于断口方向取样,经过镶嵌、研磨抛光后制成金相试样。利用OLYMPUS-GX51型光学金相显微镜对试样的断口截面组织形貌进行观察。

2 实验结果

2.1 低温拉伸性能

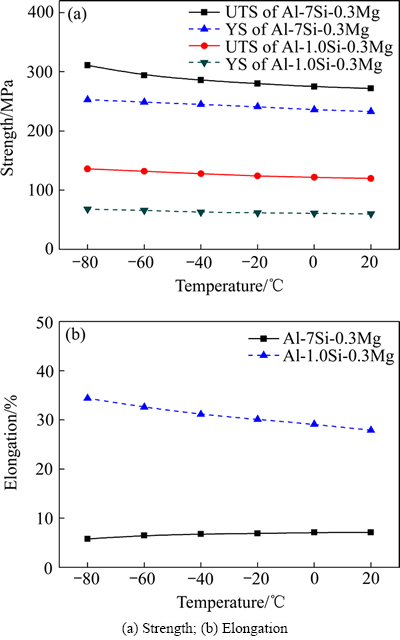

图1所示为Al-Si合金的低温拉伸性能,其中抗拉强度(UTS)和屈服强度(YS)均为工程强度。从图1(a)可以看出,当拉伸温度由20 ℃下降到-80 ℃时,Al-1Si- 0.3Mg合金的抗拉强度由120 MPa上升到136 MPa,屈服强度由60 MPa上升到68 MPa;而Al-7Si-0.3Mg合金的抗拉强度由272 MPa上升到311 MPa,屈服强度由233 MPa上升到253 MPa。从图1(b)可以看出,当拉伸温度由20 ℃下降到-80 ℃时,Al-1Si-0.3Mg合金的伸长率有明显升高,由27.9%升高到34.4%;而Al-7Si- 0.3Mg合金的伸长率略有降低由7.1%下降到5.8%。

2.2 断口组织及形貌

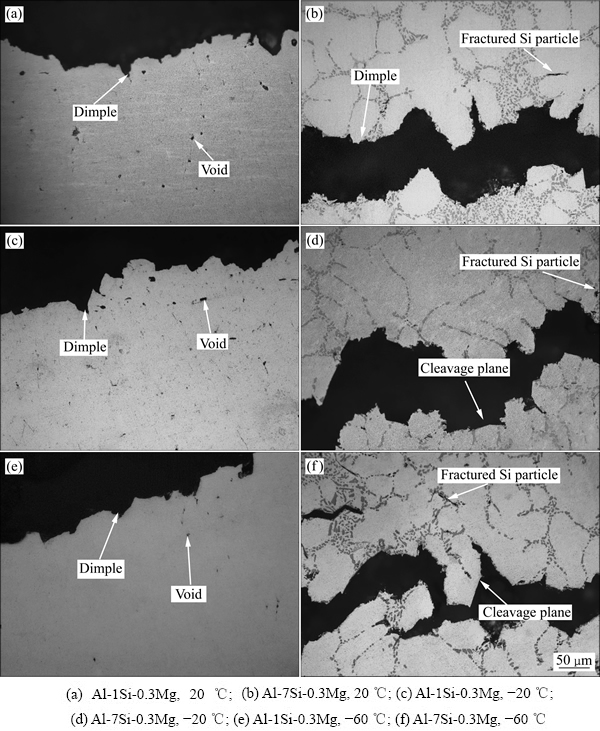

图2所示为Al-Si合金不同温度下拉伸断口的组织形貌。从图2中可以看出,Al-1Si-0.3Mg合金组织以初生α(Al)为主,在初生α(Al)晶粒晶界附近稀疏分布着细小Si相;而Al-7Si-0.3Mg合金的组织主要包括共晶组织和初生α(Al)枝晶,Si相均为颗粒状和短棒状,拉伸试样的断面穿过断裂的Si相沿着共晶区扩展,并未撕裂初生α(Al)枝晶。20 ℃时Al-1Si-0.3Mg合金断口处为明显的韧窝凹坑,在断口附近的Si相颗处出现大量孔洞(见图2(a))。Al-7Si-0.3Mg合金的断口中初生α(Al)枝晶发生较大塑性变形,断裂的Si相附近铝基体有明显的撕裂特征,并在断口外存在少量的破裂Si相和裂纹(见图2(b))。-20 ℃时Al-1Si-0.3Mg合金断口附近的孔洞数量减少(见图2(c))。Al-7Si-0.3Mg合金断口处有大面积的硅相发生解理断裂,相邻的断裂硅相之间铝基体开始出现解理平面特征(见图2(d))。-60 ℃时该Al-1Si-0.3Mg合金的断口上韧窝底部形貌趋于平缓,铝基体中孔洞数量进一步减少(见图2(e))。Al-7Si-0.3Mg合金中相邻的断裂硅相之间铝基体出现更大面积的解理平面,并且在断口外出现大量破裂的Si相和裂纹(见图2(f))。

图1 Al-Si合金低温拉伸性能

Fig. 1 Tensile properties of Al-Si alloys at low temperature

图3所示为Al-Si合金在不同温度下的拉伸断口形貌,从图3中可以看出,Al-1Si-0.3Mg合金是韧性断裂,而Al-7Si-0.3Mg合金是混合型断裂。20 ℃时Al-1Si-0.3Mg合金断口中出现较多细小韧窝,并密集的分布在尺寸较大的韧窝周围(见图3(a))。Al-7Si-0.3Mg合金断口形貌主要由韧窝和撕裂岭组成,韧窝的底部是Si相解理断裂产生的小平面(见图3(b))。-20 ℃时Al-1Si-0.3Mg合金断口出现撕裂岭形貌,大韧窝周围分布的细小韧窝数量减少(见图3(c))。Al-7Si-0.3Mg合金的断口中铝基体处开始出现准解理特征,撕裂岭的数量增加(见图3(d))。-60 ℃时Al-1Si-0.3Mg合金的断口大韧窝的尺寸较浅,在韧窝壁和撕裂岭上出现大量条纹棱(见图3(e))。Al-7Si-0.3Mg合金的断口形貌中韧窝的数量减少,解理面积增加(见图3(f))。

图2 Al-Si合金不同温度下拉伸断口截面形貌

Fig. 2 Cross-sectional tensile fracture morphologies of Al-Si alloys at different temperatures

3 分析与讨论

3.1 Si相对裂纹的影响

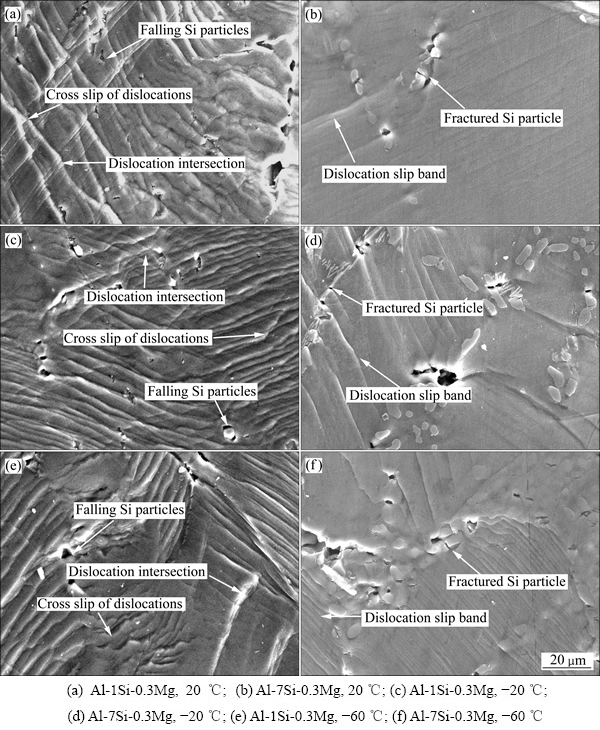

Al-1Si-0.3Mg和Al-7Si-0.3Mg合金的断裂行为具有明显区别。图4所示为Al-Si合金在不同温度下断口附近的位错滑移带分布情况。从图4中可以看出,Al-1Si-0.3Mg合金在塑性变形过程中产生大量位错滑移,在位错塞积作用下Si相与基体脱离产生微孔洞。Al-7Si-0.3Mg合金在塑性变形过程中产生的位错滑移较少,位错在Si相塞积产生应力,使Si相发生断裂形成微裂纹。20 ℃时Al-1Si-0.3Mg合金断口附近的位错滑移带分布密集并发生大量交割和交滑移,形成的微孔洞数量较多(见图4(a))。Al-7Si-0.3Mg合金断口附近仅有少量形态较浅的位错滑移带,且断裂Si相的数量较少(见图4(b))。-20 ℃时Al-1Si-0.3Mg合金中位错交割形成的割阶和交滑移形成的弯曲减少,Si相脱落形成的微孔洞减少(见图4(c))。Al-7Si-0.3Mg合金断口附近的位错滑移带数量增加且形态变深,同时破裂Si相数量增加(见图4(d))。-60 ℃时该Al-1Si-0.3Mg合金中的微孔洞继续减少,位错的交割和交滑移受到抑制(见图4(e))。Al-7Si-0.3Mg合金中出现大量的破裂Si相和形态较深的位错滑移带(见图4(f))。

图3 Al-Si合金在不同温度下的拉伸断口形貌

Fig. 3 Tensile fracture morphologies of Al-Si alloys at different temperatures

3.2 Si相对断裂行为的影响

图5所示为Al-1Si-0.3Mg合金和Al-7Si-0.3Mg在不同温度下拉伸的真实应力应变曲线。由图5可以看出,随着温度的降低Al-Si合金的强度和弹性模量E增加。合金的剪切模量μ与弹性模量E的关系可以表示为

(1)

(1)

式中:E为弹性模量; 为泊松比。在低温下泊松比ν略有降低,由式(1)可知,随着弹性模量E的增加,剪切模量μ增大。

为泊松比。在低温下泊松比ν略有降低,由式(1)可知,随着弹性模量E的增加,剪切模量μ增大。

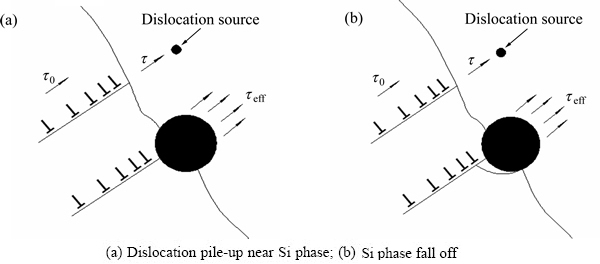

图6所示为Al-1.0Si-0.3Mg合金中硅相附近的位错塞积示意图。Al-1Si-0.3Mg合金在塑性变形过程中位错主要在晶界塞积(见图6(a))。铝基体中位错受到的点阵阻力(Peirls-Nabarro force)对温度变化敏感,在外加切应力 作用下,位错塞积的作用力

作用下,位错塞积的作用力 大小为

大小为

(2)

(2)

图4 Al-Si合金在不同温度下拉伸的微裂纹和位错滑移带分布情况

Fig. 4 Images of dislocation slip bands and micro cracks in Al-Si alloy at different temperatures

图5 Al-Si在不同温度下拉伸的真实应力-应变曲线

Fig. 5 True stress-strain curve of Al-Si alloys at different temperatures

式中:n为滑移面上的位错数量;b为柏氏矢量; 为泊松比;μ为剪切模量;a为滑移面间距;

为泊松比;μ为剪切模量;a为滑移面间距; 为位错应力场产生的阻力;

为位错应力场产生的阻力; 为其他对温度不敏感的位错阻力。其中

为其他对温度不敏感的位错阻力。其中 的大小可以表示为

的大小可以表示为

(3)

(3)

式中: 是试验常数。相邻晶粒内Frank-Read位错源启动的临界应力可以表示为

是试验常数。相邻晶粒内Frank-Read位错源启动的临界应力可以表示为

(4)

(4)

式中:L为位错源两顶点距离。随着温度的降低剪切模量μ增大,滑移面间距a减小,位错源两顶点距离L减小,由式(2)~(4)可知,此时位错塞积的作用力 降低,而位错源临界应力

降低,而位错源临界应力 增加。因此在低温下合金中的位错源不易启动,即合金的强度增加。

增加。因此在低温下合金中的位错源不易启动,即合金的强度增加。

Al-1Si-0.3Mg合金中Si相尺寸较小且沿晶界稀疏分布,Si相在少量位错塞积的作用下很难发生破裂,从铝基体中脱落形成微孔洞(见图6(b))。位错通过Si相对相邻晶粒产生的有效作用力可以表示为:

(5)

(5)

式中:A为Si相对相邻晶粒的作用面积; 为位错塞积对Si相的作用面积。由式(5)可知,Si相对合金产生强化作用,其大小与Si相对相邻晶粒的作用面积有关。

为位错塞积对Si相的作用面积。由式(5)可知,Si相对合金产生强化作用,其大小与Si相对相邻晶粒的作用面积有关。

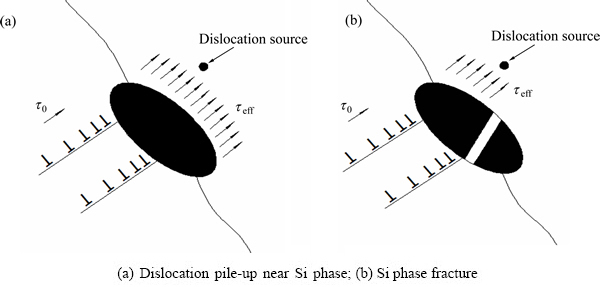

图7所示为Al-7Si-0.3Mg合金中硅相附近的位错塞积示意图。Al-7Si-0.3Mg合金中Si相尺寸较大并紧密分布在初生α(Al)枝晶周围,在塑性变形阶段铝基体内产生大量位错在Si相附近塞积(见图7(a))。由式(2)~(5)可知,随着Si相对相邻晶粒的作用面积增大,Si相对合金产生的强化作用增强,因此Al-7Si-0.3Mg 合金的低温抗拉强度明显升高。大量的位错塞积在Si相处产生应力集中,导致Si相发生破裂(见图7(b))。

图8所示为Al-Si合金在不同温度下的裂纹扩展示意图。Al-1Si-0.3Mg合金在室温环境的拉伸过程中Si相脱落形成应力集中,并在微孔洞之间产生局部变形(见图8(a))。此时,局部变形区产生大量的位错塞积和缠结。随着形变量的增加,局部变形区的位错密度 迅速增大,由式(3)可知,位错应力场产生的阻力τμ增大,使位错增殖和运动困难,导致非局部变形区的位错运动。在低温下合金的剪切模量μ上升,由式(3)可知,随着位错密度

迅速增大,由式(3)可知,位错应力场产生的阻力τμ增大,使位错增殖和运动困难,导致非局部变形区的位错运动。在低温下合金的剪切模量μ上升,由式(3)可知,随着位错密度 增加,位错阻力τμ的上升趋势加剧,即低温下Al-1Si-0.3Mg合金的加工硬化指数增大。与室温环境相比Al-1Si-0.3Mg合金在仅有较小的局部变形时,非局部变形区内便产生更多的位错滑移,使合金整体的塑性变形更均匀(见图8(b))。因此Al-1Si-0.3Mg合金在低温下拉伸的断后伸长率升高。

增加,位错阻力τμ的上升趋势加剧,即低温下Al-1Si-0.3Mg合金的加工硬化指数增大。与室温环境相比Al-1Si-0.3Mg合金在仅有较小的局部变形时,非局部变形区内便产生更多的位错滑移,使合金整体的塑性变形更均匀(见图8(b))。因此Al-1Si-0.3Mg合金在低温下拉伸的断后伸长率升高。

图6 Al-1Si-0.3Mg合金中硅相附近的位错塞积示意图

Fig. 6 Schematic illustration of dislocation pile-up near Si phase in Al-1Si-0.3Mg alloy

图7 Al-7Si-0.3Mg合金中硅相附近的位错塞积示意图

Fig. 7 Schematic illustration of dislocation pile-up near Si phase in Al-7Si-0.3Mg alloy

图8 Al-Si合金在不同温度下的裂纹扩展示意图

Fig. 8 Schematic illustration of crack extension in Al-Si alloys at different temperatures

Al-7Si-0.3Mg合金在室温环境的拉伸过程中Si相破裂形成应力集中,并产生局部变形形成韧窝(见图8(c))。随着温度的降低,合金的抗拉强度,屈服强度和加工硬化指数迅速提高,使在Si相断裂的瞬间形成较大的应力集中 。当应力集中

。当应力集中 大于铝原子结合力的临界值时,铝基体来不及利用塑性变形释放应力发生准解理断裂,从而导致合金低温塑性下降(见图8(d))。同时,低温下Al-7Si-0.3Mg合金塑性变形均匀化也是断口附近Si相断裂数量增加的主要原因。

大于铝原子结合力的临界值时,铝基体来不及利用塑性变形释放应力发生准解理断裂,从而导致合金低温塑性下降(见图8(d))。同时,低温下Al-7Si-0.3Mg合金塑性变形均匀化也是断口附近Si相断裂数量增加的主要原因。

4 结论

1) 当温度由20 ℃下降至-80 ℃时,Al-1Si-0.3Mg合金的抗拉强度、屈服强度和伸长率均出现不同程度的提高,而Al-7Si-0.3Mg合金的抗拉强度和屈服强度上升,伸长率下降。

2) Al-1Si-0.3Mg合金中微孔洞主要是由Si相脱落形成的,拉伸过程中位错容易在晶界塞积所产生的应力集中易使相邻晶粒内位错源启动导致合金具有较高的塑性。

3) Al-7Si-0.3Mg合金中微裂纹主要是由Si相破裂形成,拉伸过程中位错在Si相边缘塞积减小了位错塞积形成的应力集中,使合金的抗拉强度得到明显提高。

REFERENCES

[1] JOSEPH S, KUMAR S. Finite element analysis of stress evolution in Al-Si alloy[J]. Journal of Materials Engineering and Performance, 2015, 24(1): 253-260.

[2] DOMINIK B, STEFAN P, MARC H, WERNER F, PETER J U, MATHIAS G, HEINZ W H. Secondary Al-Si-Mg high-pressure die casting alloys with enhanced ductility[J]. Metallurgical and Materials Transactions A, 2015, 46: 1035-1045.

[3] CUI G R, NI D R, MA Z Y, LI S X. Effects of friction stir processing parameters and In Situ passes on microstructure and tensile properties of Al-Si-Mg casting[J]. Metallurgical and Materials Transactions A, 2014, 45(A): 5318-5331.

[4] SRIVASTAVA V C, OJHA S N. Microstructure and wear characteristics of spray formed and hot extruded Al-Si alloys[J]. Materials Science and Technology, 2004, 20: 1632-1638.

[5] 黄晓峰, 冯 凯, 谢 锐. Mg及Mn元素对Al-Si合金显微组织和力学性能的影响[J]. 中国有色金属学报, 2012, 22(8): 2196-2204.

HUANG Xiao-Feng, FENG Kai, XIE Rui. Effects of Mg and Mn element on microstructure and mechanical properties of Al-Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(8): 2196-2204.

[6] XU R F, ZHENG H L, LUO J, DING S P, ZHANG S P, TIAN X L. Role of tensile forces in hot tearing formation of cast Al-Si alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2203-2207.

[7] LADOS D A. Fatigue crack growth mechanisms in Al-Si-Mg alloys[J]. Surface Engineering, 2004, 20(6):416-424.

[8] HAFIZ M F, KOBAYASHI T. Fracture toughness of eutectic Al-Si casting alloy with different microstructural features[J]. Journal of Materials Science, 1996, 31: 6195-6200.

[9] WAN D Q. Si phase morphology and mechanical properties of ZL107 Al alloy improved by La modification and heat treatment[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(5): 1051-1054.

[10] 石 磊, 王有祁, 王 英, 苏 辉, 甄立玲. 固溶处理对准共晶Al-Si合金显微组织及力学性能的影响[J]. 中国有色金属学报, 2012, 22(12): 3372-3377.

SHI Lei, WANG You-qi, WANG Ying, SU Hui, ZHEN Li-ling. Effect of solution treatment on microstructure and mechanical properties of quasi eutectic Al-Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(12): 3372-3377.

[11] JIEN W Y, WEN P L. The cracking mechanism of silicon particles in an A357 aluminum alloy[J]. Metallurgical and Materials Transactions A, 1996, 27: 3558-3568.

[12] DOGLIONE R, DOUZIECH J L, BERDIN C, FRANCOIS D. Microstructure and damage mechanisms in A356-T6 alloy[J]. Materials Science Forum, 1996(217/222): 1435-1440.

[13] CACERES C H, GRIFFITHS J R. Damage by the cracking of silicon particles in an Al-7Si-0.4Mg casting alloy[J]. Acta Materialia, 1996, 44(1):25-33.

[14] WANG Q G, CACERES C H, GRIFFITHS J R. Damage by eutectic particle cracking in aluminum casting alloys A356/357[J]. Metallurgical and Materials Transactions A, 2003(34): 2901-2912.

[15] 刘 瑛, 张新明, 李慧中, 高 慧, 刘 波, 李惠杰. 2519铝合金的低温拉伸力学性能[J]. 中南大学学报(自然科学版), 2006, 37(4): 641-645.

LIU Ying, ZHANG Xin-ming, LI Hui-zhong, GAO Hui, LIU Bo, LI Hui-jie. Tensile properties of 2519 aluminum alloy at low temperature[J]. Journal of Central South University (Science and Technology), 2006, 37(4): 641-645.

[16] 刘 瑛, 张新明, 李慧中, 刘 波, 高 慧, 李惠杰. 3种高强铝合金的低温拉伸力学性能研究[J]. 金属热处理, 2007, 32(1): 53-55, 56.

LIU Ying, ZHANG Xin-ming, LI Hui-zhong, LIU Bo, GAO Hui, LI Hui-jie. Tensile properties of three kinds of aluminum alloys at low temperature[J]. Heat Treatment of Metals, 2007, 32(1): 53-55, 56.

[17] 陈 鼎, 陈振华. 铝合金在低温下的力学性能[J]. 宇航材料工艺. 2000(4): 1-7.

CHEN Ding, CHEN Zhenhua. Mechanical properties of pure aluminum alloys at cryogenic temperatures[J]. Aerospace Materials & Technology, 2000(4): 1-7.

[18] ISAEV N V, ZABRODIN P A, RUSAKOVA A V. Localization of plastic deformation in ultra-fine grained Al and Al-Li at temperatures of 4.2-350K[J]. Low Temperature Physics, 2012, 38(10): 973-979.

[19] LEE C G, KIM K J, LEE S, CHO K. Effect of test temperature on the dynamic torsional deformation behavior of two Aluminum-Lithium alloys[J]. Metallurgical and Materials Transactions A, 1998, 29: 469-476.

[20] MOREN V E, PEREZ P M T, MURASHKIN M Y. Effect of grain refinement on the mechanical behavior of an Al6061 alloy at cryogenic temperatures[C]// The 14th International ESAFORM Conference on Material Forming. 2011:505-510.

[21] SENKOVA S V, SENKOV O N, MIRACLE D B. Cryogenic and elevated temperature strengths of an Al-Zn-Mg-Cu alloy modified with Sc and Zr[J]. Metallurgical And Materials Transactions A, 2006, 37: 3569-3575.

[22] RINCON E, LOPEZ H F, CISNEROS M M. Effect of temperature on the tensile properties of an as-cast aluminum alloy A319[J]. Materials Science and Engineering A, 2007, 452/453: 682-687.

[23] RINCON E, LOPEZ H F, CISNEROS M M. Temperature effects on the tensile properties of cast and heat treated aluminum alloy A319[J]. Materials Science and Engineering A, 2009, 519: 128-140.

[24] GOKHALE A M, DIGHE M D, HORSTEMEYER M. Effect of temperature on silicon particle damage in A356 alloy[J]. Metallurgical and Materials Transactions A, 1998, 29: 905-907.

[25] OSAMU U. Mechanical properties of thermomechanical treated hyper-eutectic Al-Si-(Fe,Mn,Cu) materials[J]. Materials Transactions, 2005, 46(12): 2616-2623.

[26] HISANAGA Y, OSAMU U, KOTOBU N, KUNIO K. Hot extrusion for Al-Si-(Fe,Cu) hyper-eutectic cast alloys[C]// The Fourth International Conference on ECOMATERIALS. Japan: Kogakuin University, 1999: 491-494.

Effect of silicon phase on tensile fracture of Al-Si alloys at low temperature

MA Guang-hui, LI Run-xia, BAI Yan-hua, LI Rong-de

(School of Materials Science and Engineering, Shenyang University of Technology, Shenyang 110870, China)

Abstract: The tensile mechanical properties of Al-7Si-0.3Mg and Al-1.0Si-0.3Mg alloys at -80-20 ℃were investigated. The mechanisms of crack initiation and extension at low temperature were analyzed. The results show that the tensile strength, yield strength and ductility of Al-1.0Si-0.3Mg alloy increase with decrease of temperature. The tensile strength and yield strength of Al-7Si-0.3Mg alloy increase, but the ductility of Al-7Si-0.3Mg alloy decreases with the decrease of temperature. During the low temperature tensile process, the dislocations pile up along the boundaries of grains in Al-1.0Si-0.3Mg alloy, which make dislocation sources to trigger easily in the adjacent grains, so the ductility of Al-1.0Si-0.3Mg alloy is improved. But the dislocations pile up at the Si particles in Al-7Si-0.3Mg alloy, which prevents the dislocation sources to trigger in the adjacent grains, so, the strengths of Al-7Si-0.3Mg alloy is greater.

Key words: Al-Si alloy; low temperature; tensile property; dislocation; Si phase

Foundation item: Project(LT2002004) supported by the Innovation Team Project in Liaoning Province, China

Received date: 2016-03-04; Accepted date: 2016-05-06

Corresponding author: LI Run-xia; Tel: +86-24-25496308; E-mail: runxiali@163.com

(编辑 王 超)

基金项目:辽宁省创新团队项目(LT2002004)

收稿日期:2016-03-04;修订日期:2016-05-06

通信作者:李润霞,教授,博士;电话:024-25496308;E-mail: runxiali@163.com