J. Cent. South Univ. (2020) 27: 372-380

DOI: https://doi.org/10.1007/s11771-020-4302-5

Simulation and experimental study of 7A09 aluminum alloy milling under double liquid quenching

LUO Heng(罗恒)1, WANG You-qiang(王优强)1, ZHANG Ping(张平)2

1. School of Mechanical and Automotive Engineering, Qingdao University of Technology,Qingdao 266520, China;

2. School of Mechanical and Power Engineering, East China University of Science and Technology,Shanghai 200237, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Abstract: To explore the influence of double liquid quenching on the cutting performance of the 7A09 aluminum alloy, quasi-static compression and dynamic impact tests were carried out on the 7A09 aluminum alloy after double liquid quenching using an MTS810.23 universal testing machine and split-Hopkinson pressure bar (SHPB). The experimental data were fitted to obtain the Johnson–Cook constitutive model parameters of the alloy. Simulations of the machining process were carried out using the Deform-3D finite element software. The results showed that the rheological stress increased with the increase in strain rate and the decrease in temperature. The increase in the cutting speed and feed caused the cutting temperature to rise sharply, whereas the influence of the cutting amount on the cutting temperature was weak. Because of the presence of chip nodules, there was extremum in the cutting force vs cutting speed curves. The increase in the feed and cutting depth increased the cutting area Ac, so the cutting force also increased. The simulation results were verified by experiments. The simulation predictions were in good agreement with the test values, and the cutting force and temperature variations with the cutting parameters were the same. Thus, the correctness of the 7A09 aluminum alloy finite element model was verified.

Key words: 7A09 aluminum alloy; double liquid quenching; dynamic impact performance; cutting; finite element method (FEM)

Cite this article as: LUO Heng, WANG You-qiang, ZHANG Ping. Simulation and experimental study of 7A09 aluminum alloy milling under double liquid quenching [J]. Journal of Central South University, 2020, 27(2): 372-380. DOI: https://doi.org/10.1007/s11771-020-4302-5.

1 Introduction

The 7A09 aluminum alloy belongs to the Al-Zn-Mg-Cu series of heat-treatable multi-element aged alloys. It is developed based on the Al-Zn-Mg tertiary system. Due to its high specific strength, good thermal workability, high toughness, and good corrosion resistance, it has replaced traditional materials for die forging components more and more in recent years. This can reduce the strength losses of the components and the body weights of aircraft, thereby simplifying the aircraft manufacturing process [1-4].

There have been many reports on the heat treatment system, welding properties and corrosion resistance of this alloy. LUO et al [5, 6] studied the influence of the process parameters on the microstructure of the 7A09 aluminum alloy during isothermal compression, and determined the best process parameters for the 7A09 aluminum alloy during thermal compression. CHEN et al [7] studied the microstructural evolution and mechanical properties of the 7A09 aluminum alloy under different processing conditions, such as heat treatment, annealing, and cold extrusion. JI et al [8] studied the cooling shrinkage behavior of the 7A09 aluminum alloy under different cooling rates by means of transmission electron microscopy and X-ray diffraction using thermal simulation experiments. WANG et al [9] studied the effect of solid-solution aging treatment on the mechanical properties of semi-solid metal (SSM) products using the orthogonal test method and analyzed the microstructures and tensile properties under different treatment conditions. Many scholars have also conducted considerable research on the machining of high-strength aluminum alloys [10-13]. Different heat treatments have significant influences on the microstructures and properties of the 7A09 aluminum alloy [14-18], but few studies have examined these in the cutting process. Furthermore, the double liquid quenching method can reduce the deformation and quenching of the workpiece, providing the workpiece with a higher hardness. In view of this, double liquid quenching of the 7A09 aluminum alloy after quasi-static compression and dynamic impact experiments were conducted, and the Johnson-Cook constitutive parameters were obtained by fitting. Finite element simulations of the 7A09 aluminum alloy were studied to examine the machinability. The simulations were verified through experiments using the 7A09 aluminum alloy processing technology, providing a reference for performance optimization.

2 Experimental

The material used in this experiment was a rolled plate of the 7A09 aluminum alloy, whose chemical composition is shown in Table 1. After solid solution treatment at 470 °C for 45 min, the rolled plate was quenched with water and oil and cooled by double liquid quenching (the workpiece was first inserted into water to cool it rapidly to below 300 °C, after which it was inserted into oil to cool slowly), and finally, it was subjected to T6 aging treatment (150°C for 15 h and water quenching). The 7A09 aluminum alloy was formed into cylindrical samples with sizes of d10 mm×20 mm for quasi-static compression testing and d8 mm×6 mm for dynamic impact testing along the rolled surface.

Table 1 Compositions of 7A09 aluminum alloy (wt/%)

At room temperature, the MTS810.23 universal testing machine was used to conduct quasi-static compression test, and the loading speed was controlled to achieve strain rates of 0.001 and 0.01 s-1. Dynamic impact tests were carried out with a split-Hopkinson pressure bar (SHPB) device. Before the test, lubricant was applied on the sample surface and between the pressure head to reduce the adverse effects of friction. The cylindrical sample was placed between the incident and transmission bars, and the velocity of the bullet was controlled by adjusting the pressure of nitrogen in the pressure chamber to achieve the strain rate set by the test. The length of the bullet was 200 mm, the lengths of the incident and transmission bars were 1400 mm, and the diameters of the bullet and pressure bar were 16 mm. The strain rate was 900–5800 s-1, and the temperatures were 20°C, 150 °C, 250°C and 350°C.

3 Experimental results and discussion

3.1 Stress–strain curve of material

Figures 1(a)-(d) show the true stress–strain curves of the 7A09 aluminum alloy at different temperatures and strain rates under the dual-liquid quenching process. In the initial stage of plastic deformation, strain hardening of the 7A09 aluminum alloy was stronger than that of the thermal softening. The stress continued to rise to the maximum. There was a wavy curve at the upper and lower yield points due to the Portevin–Le Chatelier (PLC) effect [19], after which there was a sharp decrease in the stress. As shown in Figures 1(b)-(d), under the high temperature, when the strain rate was 4500 s-1, the 7A09 aluminum alloy was stronger than the thermal softening and strain hardening ones. This caused the stress value to be less than 3300 s-1, which was lower than that at the other strain rates. This phenomenon is shown clearly in Figure 1(c) (at 250 °C and 4500 s-1) when the stress values were less than those at the other strain rates.

Figure 1 True stress-strain curve of 7A09 aluminum alloy under double liquid quenching:

3.2 Johnson-Cook constitutive model of 7A09 aluminum alloy

In the cutting process, the workpiece under the action of the tool into the chip time is very short. The strain, strain rate, and temperature in the cutting layer are not uniformly distributed, and the gradients are sharp. Therefore, selecting a constitutive equation that can reflect the influence of the strain, strain rate, and temperature on the material flow stress is critical in cutting simulations. The Johnson-Cook constitutive model can describe the thermoviscoplastic deformation behaviors of materials under high strain rates. This model is based on the assumption that materials under high strain rates exhibit strain hardening, strain rate hardening and thermal softening effects. The model is expressed as follows:

(1)

(1)

where A is the yield strength under quasi-static conditions; B is the strain hardening parameter; ε is the equivalent plastic strain; n is the hardening index; C is the strain-rate strengthening parameter;  is the equivalent plastic strain rate;

is the equivalent plastic strain rate; is the material reference strain rate; T0is the room temperature, which had a value of 20 °C; Tm is the melting point of the material; m is the thermal softening parameter of the material.

is the material reference strain rate; T0is the room temperature, which had a value of 20 °C; Tm is the melting point of the material; m is the thermal softening parameter of the material.

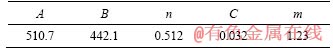

The Johnson–Cook constitutive parameters of the 7A09 aluminum alloy are given in Table 2, which were obtained using nonlinear fitting and the separation of variables method, with  =0.01 s-1 as the reference strain rate and 20 °C as the reference temperature.

=0.01 s-1 as the reference strain rate and 20 °C as the reference temperature.

Table 2 Johnson-Cook constitutive parameters

4 Modeling and mesh generation

In this study, a CNMA432 blade was selected from the Deform Blade Library and used directly. In the analysis, the tool was considered to be rigid, and the internal surface of the workpiece was fully constrained, thereby completely simulating the milling process. Deformation software with an adaptive mesh function was used to automatically adjust the mesh density based on the cutting conditions. In this work, the mesh was determined based on the tool geometry size and workpiece type. The mesh number of the tool was 2.5×104, and the mesh number of the workpiece was 5.5×104. The established geometric model is shown in Figure 2.

Figure 2 Geometric model of tool and workpiece

5 Simulation analysis of machining

5.1 Simulation parameter setting

The specific parameters in the simulation process were as follows. The workpiece material was the 7A09 aluminum alloy after double liquid quenching. The tool was a CNMA432 blade, and the material was WC. The cooling condition was dry cutting, and the initial temperature was 20 °C. The milling parameter ranges were as follows: cutting speed vc=160-320 m/min, feed f=0.10-0.18 mm/r, and cutting depth aP=0.05-0.25 mm.

5.2 Cutting temperature analysis

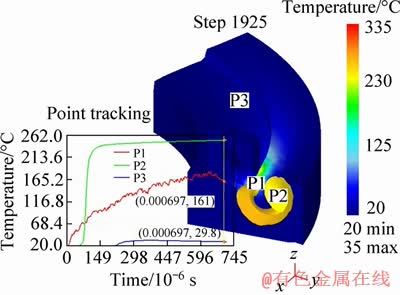

The temperature in the cutting area has a significant influence on the tool wear, the workpiece machining accuracy and the quality of the machined surface. The temperature of the cutting area usually refers to the average temperature of the surface where the chips, workpieces and tool come into contact. The temperatures at each point on the chip, workpiece and tool were different. Figure 3 shows the three-point temperature tracking diagram of the 7A09 aluminum alloy cutting process when the cutting parameters were vc=240 m/min, f=0.14 mm/r, aP=0. 15 mm. Three reference points, P1, P2, and P3, were set on the tool tip, chip, and workpiece, respectively. The workpiece temperature was slightly higher than the normal temperature, while the chip temperature was relatively high. In the early stage, the temperature steadily increased, and in the later stage, the reference point P2 was far from the cutting location, so the temperature tended to decline. The temperature at the top of the three reference points was at P1 (tool tip). When the tool was cut into the workpiece and P1 was in contact with the workpiece, the temperature at the tool tip increased sharply. When the critical value was reached, the temperature at the tool tip remained unchanged. Therefore, in the cutting process, tip temperature > chip temperature > workpiece temperature.

Figure 3 Three points temperature tracing

Figure 4 shows the influence of the cutting parameters vc, f and aP on the cutting temperature. Figure 4(a) shows the effect of the cutting speed on the cutting temperature. As the cutting speed vc increased, R1 and R2 (chip carrying heat ratios) increased, and the shear angle f also increased (i.e., the plastic deformation decreased), causing the unit cutting force p to also decrease. Therefore, as the cutting speed increased, the amount of metal cutting per unit time increased proportionally. However, because the shear angle f increased, the cutting work per unit cutting volume decreased. As shown in the figure, when vc=160 m/min, the cutting temperature was 245 °C. With the increase in the cutting speed, the cutting temperature showed an upward trend. When vc=320 m/min, the cutting temperature reached 317 °C.

Figure 4(b) shows the influence of the feed change on the cutting temperature. The increase in the feed led to a proportional increase in metal cutting per unit time. In addition, the amount of feed affected the movements of the chip. When f increased, ε decreased (i.e., the shear angle f increased), so the cutting work per unit volume of cutting decreased. With the increase in the feed, the shear heat and friction heat removed by the chip also increased. With the increase in the feed, the contact length of the chip lf increased, and the area of heat outflow also increased. Furthermore, the cutting temperature increased with the increase in the feed. When the feed increased from 0.10 to 0.18 mm/r, the cutting temperature changed from 247 to 341°C.

Figure 4 Effect of cutting parameters on cutting temperature:

Figure 4(c) shows the influence of the cutting depth on the cutting temperature. When the cutting depth aP varied, the heat generated and heat dissipation area changed correspondingly, so the cutting depth aP had little influence on the cutting temperature. When the cutting depth increased, the cutting temperature remained unchanged and was stable at 327-333°C.

5.3 Cutting force analysis

In the process of metal cutting, the cutting force arises from overcoming the resistance caused by the processed material, the friction between the chip and the front cutting surface of the tool, and the friction between the tool’s back cutting surface and the machined surface [20]. It is important to analyze the change of the cutting force in the cutting process to improve the machining quality of the workpiece and the tool life. Figure 5 shows the three-way cutting force change of the 7A09 aluminum alloy after double liquid quenching in the cutting process. The variations of the three-way cutting force in the cutting process were basically the same, but the magnitudes of the cutting forces were very different. The order was as follows: cutting force Fc>feeding force Ff>backside force FP.

Figure 5 Three-way cutting force curve

Figures 6(a)-(c) show the influence of the cutting parameters vc, f and aP on the cutting force, respectively. As shown in Figure 6(a), there were the maxima and minima in the force as the cutting speed varied. When vc<240 m/min, the actual front angle of the cutter increased or decreased due to the generation and disappearance of chip nodules, leading to a change of the cutting force. When vc>240 m/min, the cutting force decreased with the increase in the cutting speed. This was because, on the one hand, after the cutting speed increased, the friction coefficient decreased, the shear angle f increased, and the distortion coefficient decreased, thereby reducing the cutting force; On the other hand, the cutting speed increased, also causing the cutting temperature to increase. This caused the processed metal strength and hardness to decrease, and reduced the cutting force.

Figures 6(b) and (c) show the influence of the feed f and cutting depth aP on the cutting force in three directions, respectively. The increase in the feed f and cutting depth aP increased the cutting area Ac, which increased the deformation, friction, and cutting forces in three directions.

Figure 6 Effect of cutting parameters on cutting force:

6 Verification of simulation results

To verify the correctness of the finite element model, the simulation results were verified using experiments. Figure 7 shows the milling test site of the 7A09 aluminum alloy after double liquid quenching. The main instruments used in the test were as follows: KVC800-1 CNC machining center, Kistler9257B three-way dynamometer and Thermovision A20 infrared thermography.

Figures 8 (a)-(c) show the comparison of the main cutting force vs vc, f and aP, respectively, from the simulations and experiments. The main cutting force Fc obtained by the simulations was slightly lower than the experimental value, but the error was approximately 10%. The source of this error may have been related to the work-hardening layer on the surface of the workpiece, the initial residual stress of the workpiece, and the detection error. Discrepancies of the cutting temperature are evident in Figure 8(d). With the increase in the cutting speed, the cutting temperature exhibited a steady growth trend, and the experimental value was slightly lower than the simulation value. The error may have originated from testing in an open environment, causing the temperature measurements to be vulnerable to external environmental disturbances. The maximum error was less than 9.2% because of the presence of environmental factors and equipment errors. This error was within 20%, so the simulations and experiments agreed reasonably well [21]. These results verify the correctness of the finite element model built in this work.

Figure 7 Milling test site

Figure 8 Main cutting force and cutting temperature from simulations and experiments:

7 Conclusions

1) Under double liquid quenching, the stress–strain curve of the 7A09 aluminum alloy under dynamic impact exhibited a PLC effect. The sample was sensitive to the strain rate and temperature, and the rheological stress increased with an increase in the strain rate and a decrease in the temperature. The Johnson–Cook constitutive model of the 7A09 aluminum alloy under double liquid quenching was obtained by nonlinear fitting and the separation of variables method.

2) The Deform-3D finite element software was used to carry out cutting simulation studies on the 7A09 aluminum alloy after double liquid quenching. The cutting speed and feed had significant influence on the cutting temperature, while the effect of the cutting depth was relatively weak. The presence and disappearance of chip accumulation created extremum in the cutting force vs cutting speed curves, and the increase in the feed and cutting depth caused the cutting force to rise steadily. In the cutting process, the cutting force (Fc)>feeding force (Ff)>backside force (Fp), and the knife tip temperature > chip temperature > workpiece temperature.

3) The simulation results were verified by cutting tests that were identical to the simulation conditions. The simulation results were in good agreement with the test values, with an error of no more than 10%, and the variations of the cutting force and cutting temperature were also consistent. Therefore, these experiments verified the correctness of the finite element model established in this work and proved that the predictions of the influences of the simulation parameters on the workpiece cutting temperature and cutting force were reliable.

References

[1] WANG B, LI X B, LIU J, JIANG H. Comparison of atmospheric corrosion behavior of Al-Mn and Al-Zn-Mg-Cu alloys in a tropical coastal environment [J]. Materials and Corrosion, 2017, 69(7): 888-897. DOI: 10.1002/maco. 201709920.

[2] ZHANG Y Q, JIANG S Y, ZHU X M, ZHAO Y A, SHAN D B. Influence of heat treatment on complex-shape rotating disk subjected to isothermal precision forging [J]. Journal of Mechanical Science and Technology, 2017, 31(1): 141-147. DOI: 10.1007/s12206-016-1213-3.

[3] LI F, WU H B, QIN M H. Effects of processing parameters on the extrusion by continuous variable cross-section direct extrusion with 7A09 aluminium alloy [J]. Modern Physics Letters B, 2016, 30(6): 1650053. DOI: 10.1142/ S0217984916500536.

[4] QI X, SUN B, ZHANG X Y, QI W J, WANG C, SONG R G. Effects of cathodic polarization on SCC behavior of AA7003 under various aging treatments [J]. Journal of Central South University, 2018, 25(10): 954-960. DOI: 10.1007/s11771- 018-3914-5.

[5] LUO J, LI M Q, MA D W. The deformation behavior and processing maps in the isothermal compression of 7A09 aluminum alloy [J]. Materials Science and Engineering A, 2012, 532: 548-557. DOI: 10.1016/j.msea.2011. 10.120.

[6] LUO J, LI M Q, MA D W. Microstructure and mechanical properties of 7A09 aluminium alloy after isothermal compression and solution treatment [J]. Journal of Materials Processing Technology, 2012, 212(5): 1039-1048. DOI: 10.1016/j.jmatprotec.2011.12.012.

[7] CHEN Q, XIA X S, YUAN B G, SHU D Y, ZHAO Z D. Microstructure evolution and mechanical properties of 7A09 high strength aluminium alloy processed by backward extrusion at room temperature [J]. Materials Science and Engineering A, 2013, 588: 395-402. DOI: 10.1016/j.msea. 2013.09.040.

[8] JI H Z, YUAN L, SHAN D B. Effect of microstructure on thermal expansion coefficient of 7A09 aluminum alloy [J]. Journal of Materials Science & Technology, 2011, 27(9): 797-801. DOI: 10.1016/S1005-0302(11)60145-X.

[9] WANG W W, JIA B B, LUO S J. Effect of heat treatment on mechanical properties of thixoformed 7A09 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: S337-S342. DOI: 10.1016/S1003-6326(10)60065- 9.

[10] HANYU H, KAMIYA S, ODAGI H, MURAKAMI Y, SAKA M. Development of high performance diamond- coated drills for cutting high silicon aluminum alloy [J]. Thin Solid Films, 2002, 413(1, 2): 139-146. DOI: 10.1016/s0040- 6090(02)00284-5.

[11] ZHANG P, WANG Y Q. A study on chip and microstructure of 7055 aluminum alloy's 3D HSC based on FEM and experiment [J]. Vacuum, 2018, 152: 205-213. DOI: 10.1016/ j.vacuum.2018.03.031.

[12] XIONG Y F, WANG W H, JIANG R S, LIN K Y, SHAO M W. Mechanisms and FEM simulation of chip formation in orthogonal cutting In-Situ TiB2/7050Al MMC [J]. Materials, 2018, 11(4): 606-624. DOI: 10.3390/ma11040606.

[13] YOU J H, LIU S D, ZHANG X M, ZHANG X Y. Influence of quench transfer time on microstructure and mechanical properties of 7055 aluminum alloy [J]. Journal of Central South University of Technology, 2008, 15(2): 153-158. DOI: 10.1007/s11771-008-0030-y.

[14] PRAPAS M, JENNARONG N, WORAPHOT P. Effect of post-weld heat treatment on microstructure and mechanical properties of friction stir welded SSM7075 aluminium alloy [J]. Journal of Wuhan University of Technology-Mater Science Edition, 2017, 32(6): 1420-1425. DOI: 10.1007/ s11595-017-1763-y.

[15] ZHANG P, WANG Y Q. Effects of heat treatment on the nanoscale precipitation behavior of 7055 aluminum alloy under dynamic shock [J]. Vacuum, 2018, 152: 150-155. DOI: 10.1016/j.vacuum.2018.03.016.

[16] LIM Y P, YEO W H, MASITA A. Effect of heat treatment on gravity die-cast Sc-A356 aluminium alloy [J]. Manufacturing Review, 2017, 4: 3. DOI: 10.1051/mfreview/2017003.

[17] LI F, WU H B, ZENG X. Investigation of 7A09 aluminum alloy prepared by continuous variable cross-section direct extrusion (CVCDE) [J]. International Journal of Advanced Manufacturing Technology, 2016, 82(5-8): 1447-1453. DOI: 10.1007/s00170-015-7841-4.

[18] LIU X, YUAN Y Z, WU Z Y, TIAN G D, ZHENG Y G. Synergistic corrosion inhibition behavior of rare-earth cerium ions and serine on carbon steel in 3% NaCl solutions [J]. Journal of Central South University, 2018, 25(8): 1914-1919. DOI: 10.1007/s11771-018-3881-x.

[19] HALIM H, WILKINSON D S, NIEWCZAS M. The Portevin–Le Chatelier (PLC) effect and shear band formation in an AA5754 alloy [J]. Acta Materialia, 2007, 55(12): 4151-4160. DOI: 10.1016/j.actamat.2007.03.007.

[20] WU W G, XIN Z J. Metal cutting theories & tools [M]. National Defence Industry Press, 2009: 46. http://ss. zhizhen.com/detail_38502727e7500f263e804ac44f5031df14f1286b69e31ee31921b0a3ea25510134114c969f2eae5cde9cb7dcd94db448ec2ae651d3c8d534aa2ce836fb57eb316ca121ec6f221c3f145fe9313f40a1e8?. (in Chinese)

[21] ZHANG P, WANG Y Q, LUO H, LONG S W, WEI C. Research on the large plastic deformation damage and shock resistance of 7055 aluminum alloy [J]. JOM, 2019, 71(7): 2380-2387. DOI: 10.1007/s11837-019-03477-w.

(Edited by YANG Hua)

中文导读

7A09铝合金双液淬火的模拟和实验研究

摘要:为了探究双液淬火对7A09铝合金切削加工性能的影响,基于MTS810.23万能试验机和分离式霍普金森压杆设备对双液淬火后的7A09铝合金进行了准静态压缩和动态冲击试验,并对实验数据进行拟合,得到了7A09铝合金的Johnson-Cook本构模型,应用Deform-3D有限元软件对其进行切削加工仿真研究。结果表明:双液淬火处理的7A09铝合金的流变应力随着应变速率的提高和温度的降低而增加;切削速度和进给量的增加会使切削温度急剧上升,而切削深度对切削温度的影响则较弱。因积屑瘤的存在使切削速度对切削力的影响曲线中存在极值,而进给量和切削深度的增大都会使切削面积增大,故切削力也增大。并通过试验对仿真结果进行验证,仿真值与试验值吻合较好,且切削力与切削温度随切削参数的变化趋势也相同,验证了所建7A09铝合金有限元模型的正确性。

关键词:7A09铝合金;双液淬火;动态冲击性能;切削加工;有限元法

Foundation item: Projects(51575289, 51705270) supported by the National Natural Science Foundation of China; Project(2019GHY112068) supported by the Key Research and Development of Shandong, China

Received date: 2019-06-10; Accepted date: 2019-12-02

Corresponding author: WANG You-qiang, PhD, Professor; Tel: +86-17685749750; E-mail: 17685749750@163.com; ORCID: 0000- 0001-8428-8467