Effects of plastic deformation on precipitation behavior and tensile fracture behavior of Mg-Gd-Y-Zr alloy

LIN Dan1, WANG Lei1, LIU Yang1, CUI Jian-zhong2, LE Qi-chi2

1. Key Laboratory for Anisotropy and Texture of Materials, Ministry of Education,

Northeastern University, Shenyang 110004, China;

2. Key Laboratory of Electromagnetic Processing of Materials, Ministry of Education,

Northeastern University, Shenyang 110004, China

Received 30 October 2010; accepted 27 May 2011

Abstract: The effects of plastic deformation on precipitation behavior and tensile fracture behavior of Mg-10Gd-3Y-0.6Zr alloy were investigated. The results indicate that more precipitation cores can be provided by the crystal defects caused by the plastic deformation, as well as increasing the amount of β′ phases, and the formation of precipitations at grain boundaries and interfaces between the twins and matrix. Because of an increase in precipitations, the dislocation slipping during deformation process is effectively hindered and the matrix is strengthened, especially for the 2% deformed alloy which can achieve a good combination of strength and ductility. With increasing the plastic deformation, the microcracks occur at the interface between grain boundary precipitations and matrix, and then propagate intergranularly. When intergranular fracture combines with the formation of smoothing facets on the fracture surface, the tensile properties decrease.

Key words: Mg-Gd-Y-Zr alloy; plastic deformation; fracture behavior; tensile property; microstructure

1 Introduction

Mg-base alloys containing rare-earth elements are becoming more and more attractive in aerospace and automotive industries due to their high strength and creep resistance [1–2]. Recently, Mg-RE alloys with additions of Gd and Y have been developed to achieve even higher strength and better creep-resistance than conventional Al and Mg alloys [3–4]. As precipitation strengthening is reported to be the main strengthening mechanism in Mg-Gd-Y-Zr alloys, the precipitation sequence and relationship between property and precipitation behavior of the alloy under isothermal aging condition are well documented [5-8]. Despite many researches have been done, less work has been carried out to find approaches to improve the mechanical property by controlling precipitation hardening response in Mg-Gd-Y-Zr alloys.

rh Mg-RE alloys, and perform furported to be the main strengthening mechanism in Mg-Gd-Y-Zr alloy, the precipitation sequence anIn Ref. [9], the precipitation hardening response of WE54 alloy was promoted by the cold rolling after solution treatment. This was attributed to the heterogeneous precipitation of β1 phase. Such a thermomechanical processing combined with plastic deformation and arti?cial aging is extensively used in aluminum alloys since a good combination of strength and ductility can be achieved [10–11], but rarely used in magnesium alloys, especially the newly developed Mg-Gd-Y-Zr alloys. In the present research, plastic deformation by cold stretching at room temperature (RT) was performed on as-extruded Mg-10Gd-3Y-0.6Zr alloy, and the effects of plastic deformation on precipitation behavior and tensile fracture behavior were also discussed.

2 Experimental

An alloy ingot with a nominal composition of Mg-10Gd-3Y-0.6Zr (mass fraction, %) was prepared from high pure Mg (99.95%), Mg-25Gd, Mg-25Y and Mg-30Zr master alloys in an electric resistance furnace under the mixed atmosphere of CO2 and SF6. During the process, low-frequency electromagnetic casting (LFEC) technique was used. The actual chemical composition of the alloy was confirmed to be Mg-10.80Gd-3.03Y-0.61Zr (mass fraction, %). The ingot was homogenized at 773 K for 8 h, and primarily extruded at 703 K with an extruded ratio of 11, and then extruded at 653 K with an extruded ratio of 15. Plastic deformation specimens with 6 mm in gauge diameter and 35 mm in gauge length were machined from extruded bar, and then subjected to 1%, 2% and 3% plastic deformation by stretching at room temperature, respectively. Artificial aging was conducted at 523 K.

Hardness measurement was carried out on a 450SVDTM Vickers hardness tester with a load of 49 N and holding time of 15 s. Tensile testing was carried out on a MTS810 type testing machine with a crosshead speed of 0.5 mm/min. Microstructure examination was performed on an optical microscope (OM, OLYMPUS GX71), scanning electron microscope (SEM, JSM-7001F) and transmission electron microscope (TEM, TECNAI G2) operating at 200 kV. The TEM specimens were prepared by electrolytic double-jet thinning in a solution of 1% (volume fraction) perchloric acid in alcohol.

3 Results

3.1 Age-hardening behavior

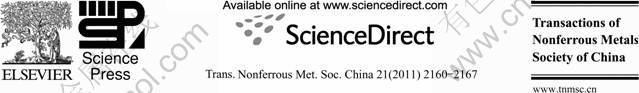

The age-hardening curves of tested alloy aged at 523 K are shown in Fig. 1. The hardness of non-deformed alloy is about HV92.4. It is increased to HV94.6, HV95.6 and HV98.2 after cold stretching deformation by 1%, 2% and 3%, respectively. During aging at 523 K, the hardness of non-deformed alloy increases gradually to the peak value HV112.4 at 6 h. As for the plastic deformed alloys, the maximum hardness is improved and the peak aging time is shifted to 3-4 h.

Fig. 1 Age-hardening curves of alloy with plastic deformation of 0, 1%, 2% and 3% aged at 523 K

3.2 Mechanical properties

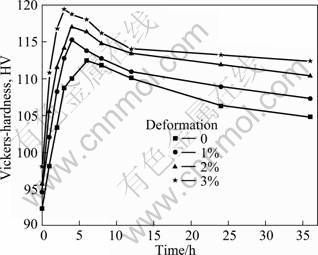

Tensile properties of peak aged alloys with and without plastic deformation at RT are listed in Table 1. It is noted that both of the UTS and YTS are improved with increasing the plastic deformation degree; while the elongation decreases. Based on the comprehensive consideration of strength and plasticity, the deformation degree is better to control at 2%.

Table 1 Tensile properties of alloys after plastic deformation at RT and aging at 523 K for different time

3.3 Fractography

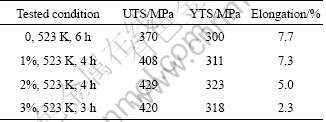

The fractography of peak aged alloy with and without plastic deformation after tensile test at RT is shown in Fig. 2. For alloy aged at (523 K for 6 h), lots of dimples exhibit fracture surface, as shown in Fig. 2(a), which is in accordance with its high elongation of 7.7%. Figure 2(b) shows the fracture surface of the alloy deformed to 1%, then aged at 523 K for 4 h. Its fracture feature is similar to that of the alloy deformed to 0%, then aged at 523 K for 6 h. After the alloy deformed to 2%, then aged at 523 K for 4 h, the smoothing facets are found to appear, as shown in Fig. 2(c), and in some areas, the secondary cracks propagate along the grain boundaries. While, for the alloy deformed to 3%, then aged at 523 K for 3 h, the fracture surface mainly consists of smoothing facets, as shown in Fig. 2(d). It is obvious that the decrease in ductility is associated with the formation of smoothing facets.

4 Discussion

4.1 Precipitation behavior in grains

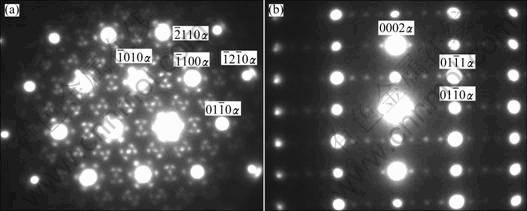

The SAED patterns of precipitates in grains from [0001]α axis zone and [10 0]α axis zone are shown in Fig. 3, where B represents the beam direction. According to the diffraction analysis, the precipitates of peak aged alloys with and without deformation are β′ phase, which is consistent with the base centered orthorhombic structure (BCO, a=0.64 nm, b=2.22 nm, c=0.52 nm) and the orientation relationship between β′ phase and matrix is (001)b'//(0001)α, [100]b '//[10

0]α axis zone are shown in Fig. 3, where B represents the beam direction. According to the diffraction analysis, the precipitates of peak aged alloys with and without deformation are β′ phase, which is consistent with the base centered orthorhombic structure (BCO, a=0.64 nm, b=2.22 nm, c=0.52 nm) and the orientation relationship between β′ phase and matrix is (001)b'//(0001)α, [100]b '//[10 0]α.

0]α.

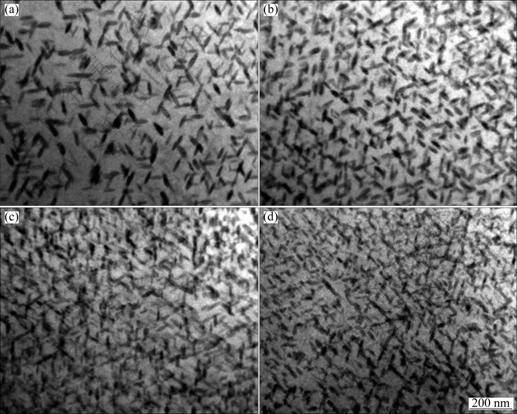

Figure 4 shows the TEM images of β′ phases of the alloy peak aged at 523 K which was viewed from [0001]α axis. It can be seen that the β′ phases become fine and dense in the deformed alloy. As the deformation degree increases, the amount of β′ phases increases to 1.5-3 times that of the non-deformed alloy. Because the more precipitation cores can be provided by the voids and dislocation defects caused by the plastic deformation, the amount of β′ phases increases. As the total amount of β′ phase forming elements is constant, an increase in number of β′ leads to the decrease in size.

Fig. 2 SEM images of fracture surfaces for alloys: (a) Aged at 523 K for 6 h; (b) Deformed to 1%, aged at 523 K for 4 h; (c) Deformed to 2%, aged at 523 K for 4 h; (d) Deformed to 3%, aged at 523 K for 3 h

Fig. 3 SAED patterns of β′ phases: (a) B//[0001]α; (b) B//[10 0]α

0]α

4.2 Precipitation behavior at grain boundary

Figure 5 shows the TEM images of grain boundary precipitates (GBPs) for peak aged alloy with and without deformation. From Fig. 5(a), it can be seen that the GBPs are distributed discontinuously along the grain boundary for non-deformed alloy. For 1% deformed alloy, the grain boundary energy is elevated by the dislocation pile-up, which promotes the nucleation and growth of GBPs during aging process, as shown in Fig. 5(b). With the further increase of deformation degree, the extent of dislocation pile-up is intensified. Thus, the nucleation and growth of GBPs become more obviously, as shown in Figs. 5(c) and (d). As reported by ZHENG et al [12], the GBPs are stable β phases.

Fig. 4 TEM images of β′ phases when B//[0001]α for aged alloys: (a) Aged at 523 K for 6 h; (b) Deformed to 1%, aged at 523 K for 4 h; (c) Deformed to 2%, aged at 523 K for 4 h; (d) Deformed to 3%, aged at 523 K for 3 h

Fig. 5 TEM image of GBPs for alloys: (a) Aged at 523 K for 6 h; (b) Deformed to 1%, aged at 523 K for 4 h; (c) Deformed to 2%, aged at 523 K for 4 h; (d) Deformed to 3%, aged at 523 K for 3 h

4.3 Precipitation behavior at interface between twins and matrix

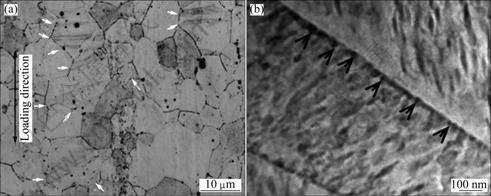

Because of the lack of active slip systems in Mg alloys, twining is needed for deformation of grains compatibly. Microstructures of alloys with and without deformation in longitudinal direction are shown in Fig. 6. It is clear that no twins in matrix can be observed in the non-deformed alloy. With the plastic deformation of 1%, some twins can be found from grain to grain, and the amount of twins becomes more pronounced for the alloys deformed by 2% and 3%.

The cross-section morphology of 3% deformed alloy aged at 523 K for 3 h is shown in Fig. 7(a). It can be seen that the twins in the matrix are straight compared with that in the alloy without artificial aging. Otherwise, precipitation phenomenon can be observed at the interface between the twins and the matrix, as shown in Fig. 7(b). According to SERRA et al’s report, twins are considered barrier of basal slip in HCP metals [13–14]. So stress concentration may occur at the interface between the twins and the matrix and provide the nucleation energy for precipitations.

Fig. 6 Microstructures of alloys with different deformation amount in longitudinal direction: (a) 0; (b) 1%; (c) 2%; (d) 3%

Fig. 7 Cross-section morphology (a) and TEM image showing precipitation at twin boundary (b) for 3% deformed alloy aged at 523 K for 3 h

4.4 Effects of deformation on tensile fracture behavior

Based on the analysis mentioned above, the fracture behavior is influenced by the plastic deformation since the precipitation behavior is changed. The plate-shaped β′ phases, which form on the prismatic planes of the matrix in a dense triangular arrangement, are vertical to basal plane of α-Mg and very stable at high temperature, providing the most effective block for slipping of dislocation [15–18]. Moreover, the finer and denser β′ phases in deformed alloy can further improve the strength according to the classical theory of precipitate strengthening. However, the grain boundaries are weakened as compared with precipitation-hardened matrix. During tensile deformation, the microcrack can nucleate at grain boundary, and this tendency is intensified by the existence of GBPs.

For the aged alloy with deformation amount of 1%, because of the increase of GBP and narrow space between GBPs, stress concentration occurs at some large GBPs. The stress concentration subsequently promotes the growth of microvoids nucleated by the interfaces debonding between GBPs and matrix under a critical stress, as shown in Fig. 8(a) (marked with arrows). Then the coalescence of microvoids causes the final fracture. When the deformation amount increases to 2% or 3%, the stress concentration at grain boundaries cannot be effectively relaxed by the continuous distribution of GBPs, which favors the nucleation of microcrack. Once the microcrack nucleates at the grain boundary, it propagates along the grain boundary as the cohesive strength of the grain boundary is reduced by the existence of GBPs [12]. Therefore, the characteristics of intergranular fracture can be observed by backscattered electron images (BEI) on the fracture surface, as shown in Figs. 8(b) and (c).

The cross-section morphologies of aged alloys with and without deformation after tensile test and the schematic mode for microcracks propagation are shown in Fig. 9. It can be seen that the matrix of the alloy aged at 523 K for 6 h only contains some twins, as shown in Fig. 9(a); while, the secondary crack can be found at the interface between the twin and the matrix for the alloy deformed to 3%, aged at 523 K for 3 h, as shown in Fig. 9(b). The fracture feature of 3% deformed alloy is attributed to the generation of precipitates at the interface between the twins and the matrix [19]. Although the matrix is strengthened as the precipitates can block the dislocation slipping, the cohesive strength of the interface between the twins and the matrix is reduced. Therefore, the microcrack occurs at the interface and propagates along it subsequently.

Fig. 8 SEM images of fracture surface for deformed alloys: (a) Deformed to 1%, aged at 523 K for 4 h; (b) Deformed to 2%, aged at 523 K for 4 h; (c) Deformed to 3%, aged at 523 K for 3 h

For the aged alloy with deformation, the formation of smoothing facets on the fracture surface is schematically illustrated in Fig. 9(c). During the tensile deformation, the forming reason can be mainly classified into two cases: when the precipitates generate at the interface between the twins and the matrix, the microcrack nucleates at the interface and then propagates along it (marked with arrow A); on the other hand, the microracks nucleate at the interface between GBPs and the matrix when the twins intersect with GBPs [20], and then propagate along the interface between the twins and the matrix (marked with arrows B and C). With increasing the plastic deformation, the amount of smoothing facets increases by increasing the twins.

Fig. 9 Cross-section morphologies near fracture surface for alloy aged at 523 K for 6 h (a) and deformed to 3%, aged at 523 K for 3 h (b) and schematic mode for microcracks propagate along interface between twins and matrix (c)

5 Conclusions

1) More precipitation cores can be provided by the crystal defects caused by the plastic deformation, as well as increasing the amount of β′ phases, and the formation of precipitations at grain boundaries and interfaces between the twins and the matrix for Mg-10Gd-3Y-0.6Zr alloy.

2) By increasing the precipitations, the dislocation slipping during deformation process is effectively hindered and the matrix is strengthened, especially for the 2% deformed alloy which can achieve a good combination of strength and ductility.

3) With increasing the plastic deformation, the microcracks occur at the interface between GBPs and matrix, and then propagate intergranularly. When intergranular fracture combines with the formation of facets on the fracture surface, the tensile properties decrease.

References

[1] MORDIKE B L. Creep-resistant magnesium alloys [J]. Materials Science and Engineering A, 2002, 324(1–2): 103–112.

[2] SMOLA B, STULIKOVA I, BUCH F V, MORDIKE B L. Structural aspects of high performance Mg alloys design [J]. Materials Science and Engineering A, 2002, 324(1–2): 113–117.

[3] LIU X B, CHEN R S, HAN E H. Effects of ageing treatment on microstructures and properties of Mg-Gd-Y-Zr alloys with and without Zn additions [J]. Journal of Alloys and Compounds, 2008, 465(1–2): 232–238.

[4] LIN L, CHEN L J, LIU Z. Tensile strength improvement of an Mg-12Gd-3Y (wt%) alloy processed by hot extrusion and free forging [J]. Journal of Materials Science, 2008, 43(13): 4493–4502.

[5] FANG Ling, ZHANG Xiao-lian, TAN Ai-hua, YANG Shao-min. On the law of age-hardening of Mg-Gd-Y-Zr magnesium alloy [J]. Jiangxi Nonferrous Metals, 2008, 22(3): 29–31. (in Chinese)

[6] HE S M, ZENG X Q, PENG L M, GAO X, NIE J F, DING W J. Microstructure and strengthening mechanism of high strength Mg-10Gd-2Y-0.5Zr alloy [J]. Journal of Alloys and Compounds, 2007, 427(1–2): 316–323.

[7] ANTHONY A I, KAMADO S, KOJIMA Y. Aging characteristics and high temperature tensile properties of Mg-Gd-Y-Zr alloys [J]. Materials Transactions, 2001, 42(7): 1206–1211.

[8] LIN Dan, WANG Lei, MENG Fan-qiang, CUI Jian-zhong, LE Qi-chi. Fracture behavior of aged Mg-10Gd-3Y-0.6Zr alloy under tension loading [J]. Journal of University of Science and Technology Beijing, 2010, 32(9): 1193–1198. (in Chinese)

[9] HILDITCH T, NIE J F, MUDDLE B C. The effect of cold work on precipitation in alloy WE54 [C]// MORDIKE B L, KAINER K U. Proceedings of Magnesium Alloys and Their Applications. Frankfurt: Werkstoff-Informationsgesellschaft, 1998: 339-344.

[10] RINGER S P, MUDDLE B C, POLMEAR I J. Effects of cold work on precipitation in Al-Cu-Mg-(Ag) and Al-Cu-Li-(Mg-Ag) alloys [J]. Metallurgical and Materials Transactions A, 1995, 26(7): 1659–1671.

[11] CHATURVEDI M C, CHUNG D W, DOUCETTE R A. Effect of thermomechanical treatment on structure and properties of 2036 aluminum alloy [J]. Materials Science, 1979, 13(1): 34–40.

[12] ZHENG K Y, DONG J, ZENG X Q, DING W J. Effect of precipitation aging on the fracture behavior of Mg-11Gd-2Nd-0.4Zr cast alloy [J]. Materials Characterization, 2008, 59(7): 857–862.

[13] SERRA A, BACON D J. Computer simulation of screw dislocation interactions with twin boundaries in H.C.P. metal [J]. Acta Metallurgica et Materialia, 1995, 43(12): 4465–4481.

[14] SERRA A, BACON D J, POND R C. Twins as barriers to basal slip in hexagonal-close-packed metals [J]. Metallurgical and Materials Transactions A, 2002, 33(3): 809–812.

[15] HONMA T, OHKUBO T, HONO K, KAMADO S. Chemistry of nanoscale precipitates in Mg-2.1Gd-0.6Y-0.2Zr (at.%) alloy investigated by the atom probe technique [J]. Materials Science and Engineering A, 2005, 395(1–2): 301–306.

[16] APPS P J, KARIMZADEH H, KING J F, LORIMER G W. Precipitation reactions in magnesium-rare earth alloys containing yttrium, gadolinium or dysprosium [J]. Scripta Materialia, 2003, 48(8):1023–1028.

[17] NIE J F. Effects of precipitate shape and orientation on dispersion strengthening in magnesium alloys [J]. Scripta Materialia, 2003, 48(8): 1009–1015.

[18] ANTION C, DONNADIEU P, PERRARD F, DESCHAMPS A, TASSIN C, PISCH A. Hardening precipitation in a Mg-4Y-3RE alloy [J]. Acta Materialia, 2003, 51(18): 5335–5348.

[19] FU P H, PENG L M, JIANG H Y, ZHENG Z Y, ZHAI C Q. Fracture behavior and mechanical properties of Mg-4Y-2Nd-1Gd-0.4Zr (wt. %) alloy at room temperature[J]. Materials Science and Engineering A, 2008, 486(1–2): 572–579.

[20] ZHENG K Y, DONG J, ZENG X Q, DING W J. Effect of pre-deformation on aging characteristics and mechanical properties of a Mg-Gd-Nd-Zr alloy [J]. Materials Science and Engineering A, 2008, 491(1–2): 103–109.

塑性变形对Mg-Gd-Y-Zr合金析出行为

及拉伸断裂行为的影响

林 丹1, 王 磊1,刘 杨1, 崔建忠2, 乐启炽2

1. 东北大学 材料各向异性与织构教育部重点实验室,沈阳 110004;

2. 东北大学 材料电磁过程研究教育部重点实验室,沈阳 110004

摘 要:研究塑性变形对Mg-10Gd-3Y-0.6Zr合金析出行为及拉伸断裂行为的影响。结果表明:塑性变形引发的晶体缺陷为时效析出提供了更多的形核核心,不仅使β′相的数量增加,还促进晶界、孪晶与基体界面处析出相的生成。析出相数量的增多可有效阻碍拉伸变形过程中的位错滑移从而强化合金基体,2%变形合金可实现强度与塑性的良好配合。塑性变形量增大,微裂纹在晶界析出相与基体界面处产生并沿晶界扩展,再加之断口表面平滑刻面的形成导致合金的拉伸性能降低。

关键词:Mg-Gd-Y-Zr合金;塑性变形;断裂行为;拉伸性能;显微组织

(Edited by YANG Hua)

Foundation item: Project (IRT0713) supported by the Program for Changjiang Scholars and Innovative Research Team in Chinese University; Projects (2007CB613701, 2007CB613702) supported by the National Basic Research Program of China

Corresponding author: WANG Lei; Tel: +86-24-83687725; Fax: +86-24-23906316; E-mail: wanglei@mail.neu.edu.cn

DOI: 10.1016/S1003-6326(11)60989-8