DOI: 10.11817/j.issn.1672-7207.2017.12.001

生物质炭用于铁精矿球团还原过程中黏结的抑制

易凌云,黄柱成,姜涛,梁之凯,钟荣海

(中南大学 资源加工与生物工程学院,湖南 长沙,410083)

摘要:基于铁精矿球团在竖炉还原过程中易产生黏结而严重影响竖炉顺行,研究物质炭的添加对球团还原过程中黏结的影响,揭示添加生物质炭抑制球团黏结的机理,并在比较表面覆层与配加生物质炭2种抑制措施特点的基础上优化黏结抑制方法。研究结果表明:生物质炭能有效缓解还原过程中球团间的黏结现象,适宜的生物质炭粒度为10 mm,C与Fe物质的量比为0.3;生物质炭在还原过程中表现出的物理阻隔、松动料层、还原剂和强吸热等多重作用可保证它对球团黏结的抑制效果;采用球团表面覆层与配加生物质炭复合作用的方式,克服了表面覆层时还原速度慢的缺点,同时避免了单纯配加生物质炭时黏结抑制偏弱的不良效果,是一种较理想的黏结抑制方法。

关键词:铁精矿球团;直接还原;黏结抑制;生物质炭

中图分类号:TF046.2 文献标志码:A 文章编号:1672-7207(2017)12-3141-06

Application of charcoal in iron ore pellets sticking prevention during reduction process

YI Lingyun, HUANG Zhucheng, JIANG Tao, LIANG Zhikai, ZHONG Ronghai

(School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: Effects of size and dosage of charcoal on sticking of iron ore pellets during reduction process were investigated. The sticking prevention mechanism of charcoal was revealed. In addition, an optimized sticking prevention method was developed based on the characteristics comparison of surface coating and charcoal adding technologies. The results show that charcoal can effectively prevent the sticking between pellets. Suitable particle size and dosage of charcoal is 10 mm, and the molar ratio of C and Fe is 0.3, respectively. Charcoal assumes multiple roles of strong endothermic, physical barrier, burden looser and reducing agent during reduction process, which ensures its sticking prevention result. The composite approach of surface coating with addition of charcoal is an ideal sticking prevention method, which overcomes the disadvantages of low reduction rate and weak sticking prevention effect.

Key words: iron ore pellets; direct reduction; sticking prevention; charcoal

直接还原铁是电炉炼钢的理想原料和必不可少的稀释剂。随着全球电炉钢产量日益增长,世界直接还原铁未来的需求量将会不断增长[1-2],而高品质废钢的供给又严重不足。目前,世界直接还原铁(DRI)总产量约75%由气基竖炉工艺生产[3]。然而,在气基竖炉致竖炉生产失常,生产率下降。铁矿在还原过程中产生的热结概括起来可解释为表面新生金属铁相间的烧结与由低熔点物质(CaO-SiO2-FeO)形成的液相之间黏结2个方面[4-7]。影响球团热结的主要参数包括[4, 8-11]:还原温度;铁矿种类、粒度及形状;脉石含量、还原阶段以及还原气中H2的体积分数等。然而,目前国内外针对球团还原过程中黏结抑制的研究并不多见,且以降低还原温度及在球团表面喷涂脉石矿物覆盖层为主。研究表明,当竖炉还原温度由850 ℃下降至750 ℃时,将导致其产量降低30%~40%[12]。虽然球团表面覆层是一种有效的热结抑制方法[13-14],但在一定程度上降低球团品位,减慢还原速率,从而影响了气基竖炉的产量以及后续电炉的冶炼[14-16]。生物质能作为一种清洁可再生能源,其来源十分丰富且N和S质量分数低,燃烧产生的CO2参与大气碳循环可以有效降低COx,SOx和NOx的排放,被广泛应用于铁矿的烧结、还原等方面[17-19]。为此,本文作者考查生物质炭用量及粒度对球团黏结的影响,揭示其抑制黏结的作用机理,并与球团表面覆层的方式进行综合对比,以便开发出一种以生物质炭抑制还原过程中球团黏结的新方法。

1 原料性能与研究方法

1.1 原料性能

试验所使用的铁精矿球团来自国内某大型球团厂,其化学成分分析见表1。球团的物理性质如下:粒度>20,(16,20],(12,16]和(8,12] mm的铁精矿球团质量分数分别为9.67%,42.69%,42.15%和5.49%;抗压强度为2.973 kN/个,堆密度为1.774 t/m3。

表1 铁精矿球团的主要化学成分(质量分数)

Table 1 Main chemical compositions of oxidized pellets %

由表1可知:研究采用的氧化球团TFe质量分数为 64.24%,SiO2为5.31%,Al2O3 为1.55%;S,P,K2O和Na2O质量分数较低。作为直接还原的原料,其铁品位偏低,脉石质量分数较高。球团粒度均匀,84%以上分布在(12,20] mm内,且具有较高的抗压强度。

试验研究所采用的生物质炭,具有固定炭高(87.34%)、灰分(5.10%)和挥发份低(7.55%)的特点。

1.2 研究方法

试验包括球团的还原和黏结指数的测定2个环节。首先,将500 g球团样品与一定比例的生物质炭混合均匀后,在荷重条件下(模拟竖炉料层),在CO体积分数为90%,CO2体积分数为3%和N2体积分数为7%还原气中于1 000 ℃等温还原90 min,在还原过程中料层高度的变化量由电感位移测定并记录。还原所采用的试验装置如图1所示。

图1 球团荷重还原装置图

Fig. 1 Experimental apparatus for reduction of pellets under load

还原过程中料层高度的变化△H按下式计算:

(1)

(1)

式中:△H为料层高度变化率,%;Ht为还原时间t时时料层的高度,mm;H0为还原开始时料层的高度,mm。

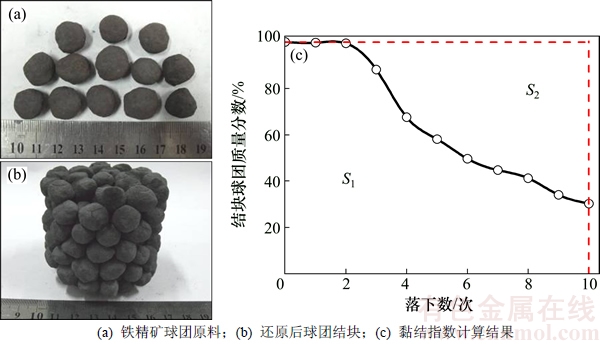

还原结束后样品(见图2(b))在N2保护下冷却至室温,记录球团质量损失、计算还原率并进行黏结指数检测。球团的还原率R可由下式计算:

R=△m/△m0 (2)

其中:△m为还原后球团的质量损失,g;△m0为完全还原时球团的理论质量损失,g。

球团黏结指数的检测方法如下[9, 15-16]:取还原后样品中相互黏结的球团称质量,并从1 m的高度落下10次;记录每次落下后仍黏结在一起的质量,然后用每次落下后的黏结的球团质量对落下次数作图(见图2(c))。定义黏结指数(I)为图中曲线之下面积所占的百分比I=S1/(S1+S2)×100%(其中,S1为图2(c)中曲线下对应的面积,S2为图2(c)中曲线上对应的面积)。若还原后的球团样品无黏结的情况则黏结指数为0,而当落下10次后球团结块的质量无变化时,则认为此时球团还原后的黏结指数为100%。

图2 还原后球团黏结指数计算示意图

Fig. 2 Diagram of sticking index calculation of pellets after reduction

2 试验结果及分析

2.1 生物质炭粒度对球团黏结的影响

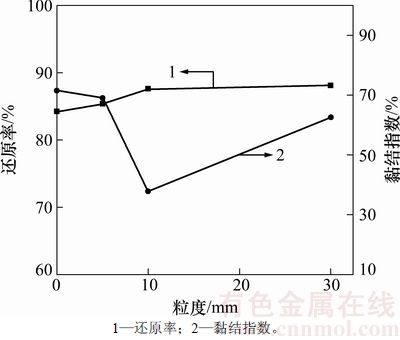

以混合物中生物质炭固定碳与球团内含铁物相的物质的量比(n(C)/n(Fe))确定试验中生物质炭的配加量。在生物质炭的n(C)/n(Fe)为0.3时,考察生物质炭粒度对球团还原率及黏结指数的影响,如图3所示。图3中,粒度为0 mm时代表不添加生物质炭。

图3 生物质炭粒度对球团还原率及黏结指数的影响

Fig. 3 Effect of charcoal size on reduction degree and sticking index of pellets

由图3可知:随着生物质炭的加入,球团还原率略有增加(约3%),其粒度的变化对球团还原度的影响很小;在无生物质炭添加时,球团的黏结指数达71.5%;随着生物质炭的加入,其黏结指数明显减小,并在生物质炭粒度为10 mm时达到最低点37.8%。因此,在铁精矿球团中添加粒度10 mm左右的生物质炭对黏结的抑制效果最明显;当生物质炭粒度过小(≤5 mm)时,易经球团间的空隙流失而导致还原度略低且对黏结的抑制效果较差;当生物质炭粒度过大时,生物质炭在料层中不能均匀分布,其抑制效果同样不甚理想。这说明配加的生物质炭需要有合适的粒度范围,即与铁精矿球团本身粒度大致一致时对黏结具有较好的抑制效果。

2.2 生物质炭用量对球团黏结的影响

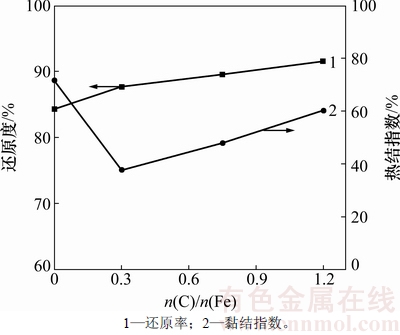

在生物质炭粒度为10 mm时,考察生物质炭配加量即C与Fe的物质的量比(n(C)/n(Fe))对球团还原率及黏结指数的影响,如图4所示。图4中,n(C)/n(Fe)为0时代表不添加生物质炭。

从图4可见:随着生物质炭用量增大,球团还原率出现较明显增大,由不添加生物质炭时的84.24%增大至91.59%;然而,球团的黏结指数则呈现先减小后增大的变化趋势,并在生物质炭配加量n(C)/n(Fe)为0.3时达最小值37.8%,此后,随着n(C)/n(Fe)增大为1.2时而升高至60.2%。其原因是:一方面,适量的生物质炭加入可有效减弱球团的黏结程度;另一方面,大量生物质炭的加入显著促进了还原过程,使得球团表面形成的新生金属铁相增多,黏结加剧;同时,生物质炭残留灰分中所含的CaO和SiO2等在高温下易形成低熔点物质,这也是球团黏结指数回升的因素之一。综上所述,生物质炭配加量n(C)/n(Fe)为0.3时对球团黏结的抑制效果最佳。

图4 生物质炭配加量n(C)/n(Fe)对球团还原率及黏结指数的影响

Fig. 4 Effect of charcoal content on reduction degree and sticking index of pellets

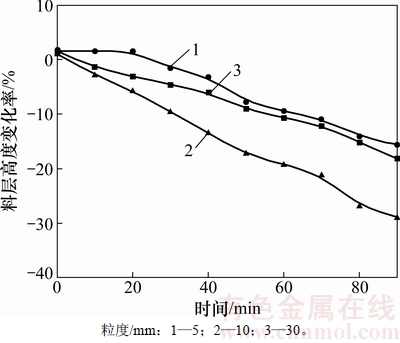

2.3 生物质炭对还原过程中料层变化的影响

在生物质炭的配加量n(C)/n(Fe)为0.3时,料层高度变化率与还原时间的关系如图5所示。图5中,变化率大于0说明料层处于膨胀状态,变化率小于0说明料层处于收缩状态。

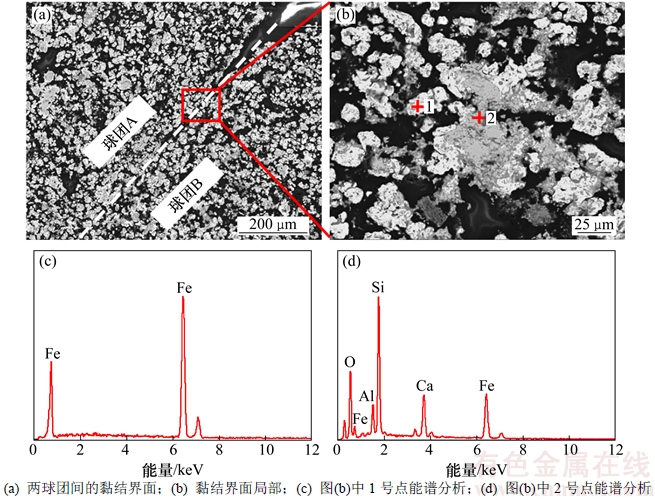

从图5可见:配加粒度为10 mm的生物质炭时料层在还原过程中的收缩程度最大,至90 min还原结束时变化率达到-28.85%;生物质炭粒度为30 mm时料层收缩率次之,其还原90 min后变化率为-18.18%;而配加粒度为5 mm生物质炭时料层收缩最不明显,至90 min后其变化率为-15.63%。料层的收缩表现为2个方面:1) 随着高温还原过程的进行,生物质炭被消耗,其粒度变小甚至消失;2) 在还原后期大量金属铁的生成使得球团本身产生体积收缩。粒度为5 mm的生物质炭易在球团空隙间流失,此时,料层的变化基本由球团本身的体积收缩引起;而生物质炭粒度30 mm过大,在料层中生物炭粒不能均匀分布,因此,也表现出收缩率较小的现象。结合图3可见:在配入生物质炭还原过程中,料层的收缩与球团的黏结指数存在良好的对应关系,即还原过程中料层的收缩量越大,所得球团的黏结指数越小。还原后球团黏结界面的微观结构见图6。

图5 配加生物质炭时还原过程中的料层高度变化率

Fig. 5 Changes of burden height during reduction when charcoal is added

2.4 生物质炭抑制黏结机理分析

基于生物质炭在还原过程中所起到的作用以及料层的变化状态,其抑制球团黏结的机理如下。

1) 配加生物质炭的球团在还原过程中料层的变化行为见图7。粒度适宜的生物质炭与铁精矿球团矿混合后均匀分布在料层中,减少了还原中球团间的接触,起到物理阻隔的作用;在还原过程中经高温、被氧化的作用,生物质炭粒度逐渐变小直至消失并在料层间留下空隙;此后,球团在挤压作用下填充空隙,使得料层间产生松动,球团的黏结强度降低。生物质炭在这一过程中发挥了还原剂、物理阻隔剂和内置松料器的多重作用,然而,其粒度过小易经球团间空隙流失,粒度过大则球团在料层中分布不均匀,均不能取得良好的抑制效果。

2) 生物质炭在料层中作为还原剂可能参与的反应如下(包括C与铁氧化物之间的反应式(3)~(5)和布多尔反应式(6)):

3Fe2O3+C=2Fe3O4+CO+108.9 kJ/mol (3)

Fe3O4+C=3FeO+CO+194.5 kJ/mol (4)

FeO+C=Fe+CO+158.7 kJ/mol (5)

CO2+C=2CO+165.4 kJ/mol (6)

由式(3)~(6)可知:直接消耗固体炭的还原反应及布多尔反应均伴随着强烈的吸热效应。可见:在还原过程中,伴随着生物质炭的消耗势必吸收大量热量,由此可导致球团间接触点温度降低,这在一定程度上减弱了球团间的黏结程度。

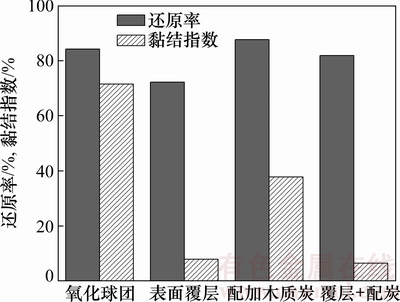

2.5 配加生物质炭与表面覆层对黏结抑制比较

根据文献[15-16],在球团表面喷涂质量分数为0.3%的CaO覆层可取得较好的黏结抑制效果,但同时带来2个方面的问题:1) 球团还原速率减小;2) 球团铁品位降低(以喷涂的覆层剂残留在球团中计,可导致还原产品铁品位降低0.19%)。因此,采用铁精矿球团中配加一定量的生物质炭的方式加以取代,并在n(C)/n(Fe)为0.3、粒度为10 mm的条件下达到最优效果。从还原后球团的还原率与黏结指数2个方面对2种抑制方法进行比较,结果如图8所示。

图6 还原后球团黏结界面的微观结构

Fig. 6 SEM images of sticking interface between reduced pellets

图7 配加生物质炭时还原过程中料层的变化行为

Fig. 7 Burden change behavior during reduction process with charcoal addition

比较球团表面覆层和配加生物质炭2种黏结抑制方式,它们各有特点。从图8可见:采用球团表面覆层可降低黏结指数60%以上,但明显减慢了还原速率;而在氧化球团中配加生物质炭时,其还原速率有所加快,但黏结指数仅降低33.7%,对黏结的抑制效果不如在球团表面覆层的抑制效果明显。因此,结合两者优点,采取表面覆层与配加生物质炭复合作用的方式,所得球团的还原率为81.88%,接近于氧化球团还原时的84.24%,而黏结指数仅为6.5%,较氧化球团还原时降低了65%。这表明采用复合作用的黏结抑制措施可克服表面覆层时还原速度慢的缺点,同时避免了单纯配加生物质炭时对黏结抑制较弱的不良效果,是一种理想的黏结抑制方法。

图8 不同抑制措施对球团还原度及黏结指数的影响

Fig. 8 Effect of prevention measures on reduction degree and sticking index of pellets

3 结论

1) 配加生物质炭能有效抑制还原过程中球团间的黏结现象,并一定程度上促进了球团的还原过程,适宜的生物质炭粒度为10 mm,C与Fe的物质的量比n(C)/n(Fe)为0.3。

2) 生物质炭在还原过程中起到了还原剂、物理阻隔、松动料层和吸热剂等多重作用,因此,对球团黏结有较好的抑制效果。

3) 采用球团表面覆层与配加生物质炭复合作用的方式,克服了表面覆层时还原速度慢的缺点,同时避免了单纯配加生物质炭时对黏结抑制较弱的不良效果,是一种理想的黏结抑制方法。

参考文献:

[1] 范晓慧, 邱冠周, 姜涛, 等. 我国直接还原铁生产的现状与发展前景[J]. 炼铁, 2002, 21(3): 53-56.

FAN Xiaohui, QIU Guanzhou, JIANG Tao, et al. Present status and development prospect of iron ore direct reduction[J]. Ironmaking, 2002, 21(3): 53-56.

[2] 黄柱成, 易凌云, 彭虎, 等. 焙烧温度对氧化球团性质及其气基直接还原过程的影响[J]. 中南大学学报(自然科学版), 2012, 43(8): 2889-2895.

HUANG Zhucheng, YI Lingyun, PENG Hu, et al. Effects of roast temperature on the properties of oxide pellets and its gas-based direct reduction[J]. Journal of Central South University (Science and Technology), 2012, 43(8): 2889-2895.

[3] Midrex Technologies Inc.2012 world direct reduction statistics[EB/OL]. [2013-06-18]. http://www.Midrex.com.

[4] KOMATINA M, GUDENAU H W. The sticking problem during direct reduction[J]. Metalurgija: Journal of Metallurgy, 2004, 30(2): 309-328.

[5] GRANSDEN J F, SHEASBY J S. The sticking of iron ore during reduction by hydrogen in a fluidized bed[J]. Canadian Metallurgical Quarterly, 1974, 13(4): 649-657.

[6] ZHANG Ben, GONG Xuzhong, WANG Zhi, et al. Relation between sticking and metallic iron precipitation on the surface of Fe2O3 particles reduced by CO in the fluidized bed[J]. ISIJ International, 2011, 51(9): 1403-1409.

[7] ZHANG Ben, WANG Zhi, GONG Xuzhong, et al. A comparative study of influence of fluidized conditions on sticking time during reduction of Fe2O3 particles with CO[J]. Powder Technology, 2012, 225: 1-6.

[8] 方觉. 流化床铁矿石还原的粘结失流机理[J]. 钢铁, 1991, 26(5): 11-15.

FANG Jue. Sticking problem in fluidized bed iron ore reduction[J]. Iron and Steel, 1991, 26(5): 11-15.

[9] YI Lingyun, HUANG Zhucheng, JIANG Tao. Sticking of iron ore pellets during reduction with hydrogen and carbon monoxide mixtures: Behavior and mechanism[J]. Powder Technology, 2013, 235: 1001-1007.

[10] HIGGINS D R, GRAY N B, DAVIDSON M R. Simulating particle agglomeration in the flash smelting reaction shaft[J]. Minerals Engineering, 2009, 22(14): 1251-1265.

[11] 钟怡玮, 公旭中, 王志, 等. Fe表面纳微结构对Fe2O3流态化还原过程黏结失流的影响[J]. 北京科技大学学报, 2011, 33(4): 406-412.

ZHONG Yiwei, GONG Xuzhong, WANG Zhi, et al. Effect of iron surfaces with nano/micro structures on the sticking of Fe2O3 in fluidized bed reduction[J]. Journal of University of Science and Technology Beijing, 2011, 33(4): 406-412.

[12] WONG P L M, KIM M J, KIM H S, et al. Sticking behavior in direct reduction of iron ore[J]. Ironmaking & Steelmaking, 1999, 26(1): 53-57.

[13] HAYASHl S, SAWAl S, IGUCH Y. Influence of coating oxide and sulfur pressure on sticking during fluidized bed reduction of iron ores[J]. ISIJ International, 1993, 33(10): 1078-1087.

[14] BASDAG A, AROL A I. Coating of iron oxide pellets for direct reduction[J]. Scandinavian Journal of Metallurgy, 2002, 31: 229-233.

[15] YI Lingyun, HUANG Zhucheng, LI Tiehui, et al. Sticking of iron ore pellets in direct reduction with hydrogen and carbon monoxide: Behavior and prevention[J]. Journal of Central South University, 2014, 21(2): 506-510.

[16] 易凌云. 铁矿球团CO-H2混合气体气基直接还原基础研究[D]. 长沙: 中南大学资源加工与生物工程学院, 2013: 94-102.

YI Lingyun. Fundamental research on gas-based direct reduction of iron ore pellets with carbon monoxide and hydrogen mixtures[D]. Changsha: Central South University. School of Minerals Processing and Bioengineering, 2013: 94-102.

[17] 范晓慧, 季志云, 甘敏, 等. 生物质燃料应用于铁矿烧结的研究[J]. 中南大学学报(自然科学版), 2013, 44(5): 1747-1753.

FAN Xiaohui, JI Zhiyun, GAN Min, et al. Application of biomass fuel in iron ore sintering[J]. Journal of Central South University (Science and Technology), 2013, 44(5): 1747-1753.

[18] MOHAMMAD Z, MARIA M P, TREVOR A T F. Biomass for iron ore sintering[J]. Minerals Engineering, 2010, 23(14): 1139-1145.

[19] STREZOV V. Iron ore reduction using sawdust: Experimental analysis and kinetic modeling[J]. Renewable Energy, 2006, 31(12): 1892-1905.

(编辑 陈灿华)

收稿日期:2016-12-12;修回日期:2017-03-15

基金项目(Foundation item):国家自然科学基金资助项目(51504230)(Project(51504230) supported by the National Natural Science Foundation of China)

通信作者:黄柱成,博士,教授,博士生导师,从事钢铁冶金、综合利用等研究;E-mail: zchuangcsu@126.com