文章编号:1004-0609(2012)04-1229-06

Li4Ti5O12/TiN复合材料的制备及电化学性能

卢 海1,李艳红1,高宏权1, 2,张治安1,赖延清1,李 劼1,刘业翔1

(1. 中南大学 冶金科学与工程学院,长沙 410083;

2. 中国铝业股份有限公司郑州研究院,郑州 450041)

摘 要:以尿素为氮源,采用高温热处理方法在Li4Ti5O12表面自生长一层纳米尺寸厚度的TiN导电包覆膜。利用DSC-TG、Raman、TEM、FT-IR、XRD及恒流充放电等测试手段,研究热处理工艺对材料结构、形貌及电化学性能的影响。结果表明:使用适中的尿素原料含量可以获得均匀连续、厚度适中的TiN导电膜,较高的热处理温度有利于促进TiN的生成,而较短的热处理时间可以保持材料物相的纯净和较高结晶度。在尿素含量10%(质量分数)、热处理温度800 ℃、热处理时间20 min的工艺条件下,所制备的复合材料的容量和倍率性能最优,0.2C和3C初始放电比容量分别达到162.4和130.2 mA·h/g。

关键词:Li4Ti5O12;TiN;导电膜;复合材料;锂离子电池

中图分类号:TM912 文献标志码:A

Preparation and electrochemical performance of Li4Ti5O12/TiN composites

LU Hai1, LI Yan-hong1, GAO Hong-quan1, 2, ZHANG Zhi-an1, LAI Yan-qing1, LI Jie1, LIU Ye-xiang1

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. Zhengzhou Research Institute of CHALCO, Zhengzhou 450041, China)

Abstract: Conductive TiN self-growing film was prepared on the surface of Li4Ti5O12 particles through heat treatment with urea as nitrogen source. The crystalline structure, morphology and electrochemical properties were studied by DSC-TG, Raman, TEM, FT-IR, XRD and charge/discharge test. The results show that using appropriate urea content uniform and continuous TiN conductive film with proper thickness can be obtained. High temperature of heat treatment can promote the growth of TiN. Short time of heat treatment can keep high purity and crystallinity of material. The best process for synthesizing Li4Ti5O12/TiN composite is urea mass fraction of 10%, heat treatment temperature of 800 ℃ and heat treatment time of 20 min. Under this condition, the initial discharge specific capacity of the material at 0.2C and 3C are 162.4 and 130.2 mA·h/g, respectively.

Key words: Li4Ti5O12; TiN; conductive film; composite material; Li-ion battery

钛酸锂(Li4Ti5O12)作为锂离子电池下一代新型负极材料,具有嵌锂电位高、安全性好、零应变和循环寿命长等优点,受到国内外广泛研究和关注。然而,导电性差、倍率性能欠佳是限制钛酸锂大规模应用的主要缺陷。通过掺杂手段可以改变材料的电子结构、提高材料导电性,此类研究包括各种阳离子(如V5+、Fe3+、Mn4+、Ni2+、Cr3+和Mg2+等)[1-2]或阴离子掺杂(如Br-等)[3]。通过表面修饰或包覆导电体的方法亦可以 改善材料的导电性能,如采用C、Cu和Ag等包覆Li4Ti5O12[4-6]。

氮化钛(TiN)是一款具有良好导电性、导热性和热稳定性的材料。SNYDER等[7]利用TiCl4与NH3通过原子层沉积法(ALD)在Li4Ti5O12表面沉积一层TiN,使Li4Ti5O12的电化学性能得到明显提高。Samsung公司[8]通过热氨气反应在Li4Ti5O12表面自生长一层TiN薄膜,该复合材料显示出优异的倍率特性。但上述方法存在工艺复杂、成本较高和环境不友好等缺点,不易获得大规模生产。

本文作者以尿素为氮源,采用高温热处理方法在Li4Ti5O12表面自生长一层TiN导电膜。通过对制备工艺进行系统研究和优化,实现了TiN对Li4Ti5O12表面的良好修饰,同时提升了材料的电化学性能,为包覆修饰Li4Ti5O12提供了一条简单有效且更易实现的合成途径。

1 实验

1.1 材料制备

将尿素原料(成都金山化工试剂厂生产,纯度≥99.0 %)与Li4Ti5O12粉末原料(深圳市天骄科技开发有限公司生产,纯度≥99.0 %)在乙醇分散介质中球磨混合均匀,制得浆料于70 ℃烘干后放入刚玉坩埚中,然后在N2气氛下以5 ℃/min的升温速率进行热处理,随炉冷却后得到Li4Ti5O12/TiN复合材料。通过控制不同尿素含量、热处理温度和热处理时间分别制备不同材料样品。

1.2 材料分析表征

使用SDT-Q600型热分析仪(美国PerkinElmer公司生产)对复合材料进行DSC—TG热分析,温度范围为室温~900 ℃,升温速率为10 ℃/min;使用InVia拉曼光谱仪(英国Renishaw公司生产)进行Raman光谱分析,激光源为He-Ne,激光波长为32.8 nm,功率约为2.2 mW,曝光时间为20 s,所获数据分辨率为1 cm-1;使用TC-400型氮氧分析仪(美国LECO公司生产)检测复合材料的氮含量;使用PhilipsCM12透射电子显微镜(荷兰公司生产)进行微观形貌分析;使用NEXUS670傅立叶红外光谱仪(美国PE公司生产)进行FT-IR分析,KBr压片,波数范围为400~4 000 cm-1;使用Minflex型X射线衍射仪(日本Rigaku公司生产)进行XRD分析,Cu Kα,40 kV,100 mA,2θ为10°~85°。

1.3 电化学性能测试

以NMP为溶剂,将活性物质、乙炔黑和PVDF按质量比8:1:1混合均匀后涂在铜箔上,120 ℃下真空干燥24 h,然后冲压成电极片。在充满氩气的手套箱中,将工作电极、Celgard 2400多孔聚乙烯隔膜、金属锂片电极,组装成CR2025型扣式电池。电解液为1 mol/L LiPF6/EC+DMC+EMC,其中:DMC、EMC、EC的质量比为 1:1:1。

使用LAND电池测试仪(武汉金诺公司生产)对组装的扣式电池进行充放电性能测试,电压范围为0.8~ 2.5 V。

2 结果与讨论

2.1 热处理过程原料的质量损失特征

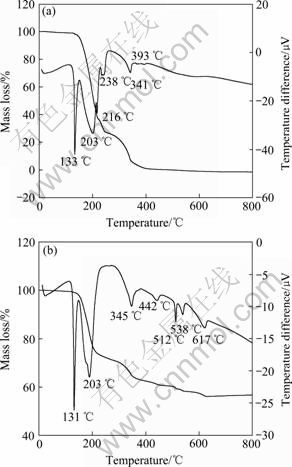

图1(a)和(b)所示分别为纯尿素原料和尿素/ Li4Ti5O12复合原料的DSC—TG曲线。由图1可以看出,尿素在400 ℃以内出现较多吸热峰,对应其多次的热分解过程[9],而400 ℃之后无明显吸热峰,且质量损失率趋于稳定,在99 %左右,说明尿素在400 ℃之前已几乎全部消耗掉。复合原料在400 ℃以内出现的吸热峰与尿素原料的基本一致,但在400 ℃以上出现4个明显吸热峰,分别为442、512、538和617 ℃。初步估计在这几个吸热过程中,尿素分解的中间体与Li4Ti5O12发生反应,最终生成了导电TiN。

图1 原料的DSC—TG曲线

Fig. 1 DSC—TG curves of reaction material: (a) Urea; (b) Urea/Li4Ti5O12

目前,以尿素为氮源制备氮化物的研究[10-12]主要存在以下两种反应观点,一种是尿素分解生成NH3后与反应物一步反应生成氮化物;另一种观点是多步骤反应机制,主要是反应物与尿素中间体结合后,逐步分解最后生成氮化物。从上述热重分析的过程来看,400 ℃后的4个吸热峰与多步反应过程更吻合。

2.2 尿素含量对Li4Ti5O12/TiN性能的影响

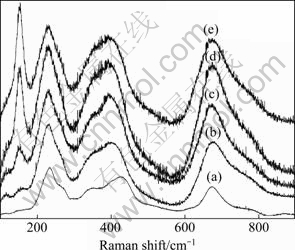

图2所示为不同尿素含量下合成的Li4Ti5O12/TiN复合材料Raman谱。Li4Ti5O12原料可观察到5个振动特征峰,分别位于233、270、360、429和680 cm-1,这些由尖晶石结构(A1g+Eg+3F2u)的特征Raman模式引起的特征峰与ALDON等[13]的报道相一致。

复合材料的Raman谱中存在明显的4个振动峰,在230和400 cm-1处的峰是由声子引起的,在665 cm-1处的拉曼峰是由光子引起的。值得注意的是,与Li4Ti5O12原料相比,复合材料在低频散射区153 cm-1出现了一个新的特征峰,该峰是由TiN的一阶横声子模式引起的,这说明复合材料中含有TiN,且随着尿素含量的增加,153 cm-1处的特征峰逐渐增强,说明材料中生成的TiN含量应该在逐渐增加。这亦可以通过表1所示的复合材料含氮分析结果得到佐证。

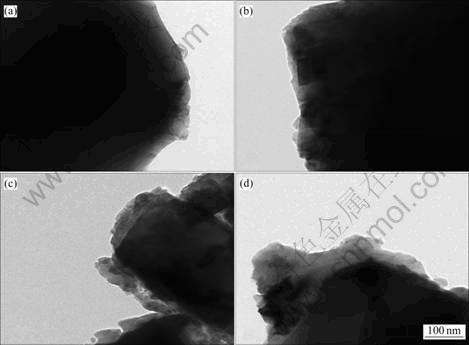

图3所示为不同尿素含量下合成的Li4Ti5O12/TiN复合材料的TEM像。由图3可以看到,尿素含量为5%时合成的材料表面包覆了一些不连续的、纳米尺寸厚度的薄膜物质,这层物质即是自生长的TiN导电膜;当尿素含量达到10%时,生成的TiN导电膜变得均匀、连续,基本完全包覆在Li4Ti5O12表面;而尿素含量继续提高到15%和20%时,TiN导电膜开始增厚,且膜层厚度变得不均匀,表面凸凹不平,这可能不利于充放电过程中锂离子的嵌入和脱出。TiN生长在Li4Ti5O12表面是由于尿素在热处理期间的分解产物与Li4Ti5O12颗粒表面接触,优先与表面的Li4Ti5O12发生反应,因此,形成了TiN的自生长包覆层。

图2 不同尿素含量合成的Li4Ti5O12/TiN复合材料Raman光谱

Fig. 2 Raman spectra of Li4Ti5O12/TiN synthesized at different urea contents: (a) Pristine Li4Ti5O12; (b) 5%; (c) 10%; (d) 15%; (e) 20%

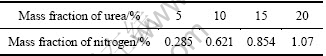

表1 不同尿素含量合成的Li4Ti5O12/TiN复合材料中含氮量

Table 1 Nitrogen content of Li4Ti5O12/TiN synthesized at different urea contents

图3 不同尿素含量合成的Li4Ti5O12/TiN复合材料的TEM像

Fig. 3 TEM images of Li4Ti5O12/TiN synthesized at different urea contents: (a) 5%; (b) 10%; (c) 15%; (d) 20%

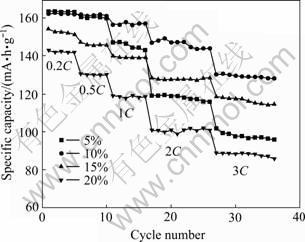

图4所示为不同尿素含量下合成的Li4Ti5O12/TiN复合材料倍率循环性能曲线。由图4可以看到,随着尿素含量的增加,合成的复合材料0.2C放电比容量逐渐下降,尿素含量为5%、10%、15%和20%时分别达到163.6、162.4、154.4和143.2 mA·h/g。这是由于尿素含量的增加提高了反应生成的TiN含量,相同电极质量下Li4Ti5O12活性物质的含量降低,因此,一定程度上影响到复合材料比容量的发挥。

然而,随着充放电倍率的增加,不同尿素含量下合成的复合材料的倍率性能差别越来越明显。在3C倍率下,尿素含量为5%、10%、15%和20%时材料初始放电比容量分别为101.9、130.2、118.5和89 mA·h/g。当尿素含量为5%时,尽管0.2C时的比容量最大,但是由于表面不连续的包覆膜影响了其倍率性能的提高,因此,高倍率下放电比容量下降较快;当尿素含量达到15%及以上时,由于表面生成的TiN层过厚,而且包覆层不均匀,不仅初始0.2C倍率放电比容量较低,而且高倍率放电比容量下降也较快;而尿素含量为10%时合成的复合材料倍率性能最好。可见,在Li4Ti5O12表面包覆一层连续均一、厚度适中的TiN导电膜,是获得优良电化学性能的关键。

图4 不同尿素含量合成的Li4Ti5O12/TiN复合材料的倍率循环性能

Fig. 4 Rate and cycling performance of Li4Ti5O12/TiN synthesized at different urea contents

2.3 热处理温度对Li4Ti5O12/TiN性能的影响

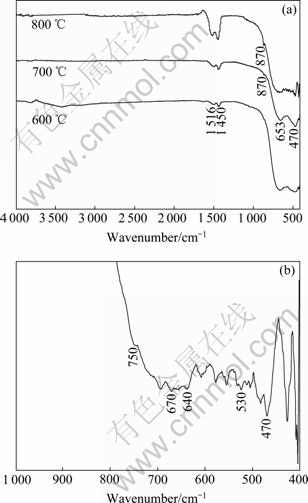

图5(a)所示为不同热处理温度下合成的Li4Ti5O12/TiN复合材料的FT-IR谱。其中,在653和470 cm-1处的两个峰分别为八面体[TiO6]的对称和不对称伸缩振动特征峰[14-15]。在1 450和1 516 cm-1处的两个峰对应于炭酸根的特征振动峰,这是CO2在TiO2表面反应的结果[16],特别800 ℃时,这两个峰的强度增强,说明材料中炭酸根的数量增加。

另外,在800 ℃低波数放大的FT-IR谱(见图5(b))中可以明显看到在750、670和530 cm-1出现了3个特征峰,与文献[17]报道的TiN的特征振动峰基本一致;而在热处理温度为600和700 ℃时,材料的TiN特征峰很不明显。这说明800 ℃热处理温度下更有利于TiN的生成。

图5 合成的Li4Ti5O12/TiN复合材料的FT-IR谱

Fig. 5 FT-IR spectra of Li4Ti5O12/TiN synthesized: (a) Different treatment temperatures; (b) Partial enlargement of FT-IR spectra at heat treatment temperature of 800 ℃

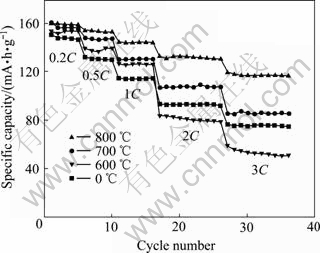

图6所示为不同热处理温度下合成的Li4Ti5O12/TiN复合材料的倍率循环性能曲线。由图6可以看出,随着热处理温度的增加,材料0.2C放电比容量略有增加,600、700和800 ℃热处理温度下分别达到153.8、156.3和159.7 mA·h/g,相比Li4Ti5O12原料(160 mA·h/g),放电比容量略有减小。

然而,随着充放电倍率的增加,不同热处理温度下合成材料的倍率性能差别越来越明显。在3C倍率下,600、700和800 ℃时合成材料的初始放电比容量分别为51.1、85.5和116.6 mA·h/g。相比Li4Ti5O12原料(3C比容量75 mA·h/g),600 ℃时复合材料容量下降较快,700 ℃时复合材料容量大于Li4Ti5O12原料的,而800 ℃时复合材料倍率性能达到最优。由于Li4Ti5O12电极表面经TiN层修饰,在材料颗粒间形成了导电网络,因此提高了材料的电子导电性,改善了材料的倍率性能。

图6 不同热处理温度合成的Li4Ti5O12/TiN复合材料的倍率循环性能

Fig. 6 Rate and cycling performance of Li4Ti5O12/TiN synthesized at different heat treatment temperatures

2.4 热处理时间对Li4Ti5O12/TiN性能的影响

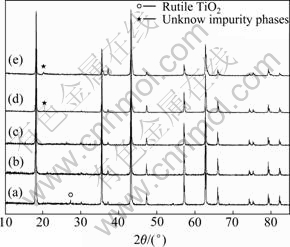

图7所示为不同热处理时间下合成的Li4Ti5O12/TiN复合材料的XRD谱。由图7可以看出,不同热处理时间合成的复合材料均呈标准的尖晶石型Li4Ti5O12晶体结构,且均为面心立方,空间群为 Fd3m,说明随着热处理时间的延长,Li4Ti5O12材料晶体结构并不会改变。然而,长时间热处理会导致材料衍射峰强度逐渐变小,说明结晶度逐渐下降。

Li4Ti5O12原料的晶体结构中检测到痕量金红石型TiO2的杂质峰,但随着热处理时间的延长,杂质相逐渐消失,这可能是由于材料表面经修饰后产生的Li2CO3[18]与TiO2反应消耗了TiO2的缘故。另外,热处理30 min以上的材料结构中还检测到少量其他未知杂质。因此,热处理时间少于30 min时,获得的材料物相较纯净,峰形较尖锐,结晶度较高。

图7 不同热处理时间合成的Li4Ti5O12/TiN复合材料的XRD谱

Fig. 7 XRD patterns of Li4Ti5O12/TiN synthesized at different heat treatment times: (a) Pristine Li4Ti5O12; (b) Heat treatment for 10 min; (c) Heat treatment for 20 min; (d) Heat treatment for 30 min; (e) Heat treatment for 40 min

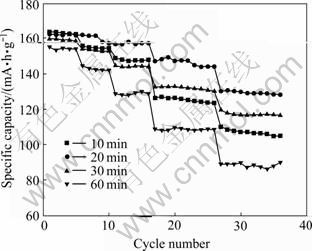

图8所示为不同热处理时间合成的Li4Ti5O12/TiN复合材料的倍率循环性能曲线。由图8可以看出,随着热处理时间的延长,材料0.2C放电比容量逐渐下降,热处理10、20、30和60 min时分别达到163.3、162.4、159.7和155 mA·h/g。

然而,随着充放电倍率的增加,不同热处理时间下合成材料的倍率性能差别越来越明显。在3C倍率下,热处理10、20、30和60 min时材料初始放电比容量分别为110.1、130.2、119.3和90 mA·h/g。60 min热处理材料的倍率性能最差。这可能一方面是由于杂质的影响,另一方面是由于晶体结构畸变较大,因此,材料电化学性能变差。可见,热处理时间不宜过长,控制在20 min左右为宜。

图8 不同热处理时间合成的Li4Ti5O12/TiN复合材料的倍率循环性能

Fig. 8 Rate and cycling performance of Li4Ti5O12/TiN synthesized at different heat treatment times

3 结论

1) 以尿素为氮源,通过高温热处理的方法,在Li4Ti5O12表面自生长一层纳米厚度的TiN导电包覆膜,制备了Li4Ti5O12/TiN复合电极材料。

2) 提高尿素原料含量可以提高复合材料中的TiN含量,但过多TiN会导致导电膜层增厚且厚度均一性差,从而影响材料的倍率容量。尿素含量为10%时合成的复合材料性能最好,0.2C及3C放电比容量分别达到了162.4和130.2 mA·h/g。

3) 较高的热处理温度有利于促进TiN的生成和材料倍率性能的提高,其中800 ℃时合成的复合材料性能最好,远优于未经热处理的纯Li4Ti5O12原料和其他热处理温度下合成的复合材料的性能。

4) 较短的热处理时间可以保持材料物相的纯净和较高结晶度,有利于改善材料电化学性能,控制热处理时间在20 min左右为宜。

REFERENCES

[1] KUBIAK P, GARCIA A, WOMES M, ALDON L, FOURCADE J O, LIPPENS P E, JUMAS J C. Phase transition in the spinel Li4Ti5O12 induced by lithium insertion: Influence of the substitutions Ti/V, Ti/Mn, Ti/Fe[J]. Journal of Power Sources, 2003, 119/121(1): 626-630.

[2] MUKAI K, ARIYOSHI K, OHZUKU T. Comparative study of Li[CrTi]O4, Li[Li1/3Ti5/3]O4 and Li1/2Fe1/2[Li1/2Fe1/2Ti]O4 in non-aqueous lithium cells[J]. Journal of Power Sources, 2005, 146(1/2): 213-216.

[3] QI Y L, HUANG Y D, JIA D Z, BAO S J, GUO Z P. Preparation and characterization of novel spinel Li4Ti5O12-xBrx anode materials[J]. Electrochimica Acta, 2009, 54(21): 4772-4776.

[4] HUANG S H, WEN Z Y, ZHANG J C, YANG X L. Improving the electrochemical performance of Li4Ti5O12/Ag composite by an electroless deposition method[J]. Electrochimica Acta, 2007, 52(11): 3704-3708.

[5] 蒋志军, 刘开宇, 陈云扬, 苏 耿, 赵立姣. Li4Ti5O12/(Cu+C)复合材料的制备及电化学性能[J]. 无机化学学报, 2011, 27(2): 239-244.

JIANG Zhi-jun, LIU Kai-yu, CHEN Yun-yang, SU Geng, ZHAO Li-jiao. Synthesis and electrochemical performance of Li4Ti5O12/(Cu+C) composite electrode material[J]. Chinese Journal of Inorganic Chemistry, 2011,27(2): 239-244.

[6] YANG L X, GAO L J. Li4Ti5O12/C composite electrode material synthesized involving conductive carbon precursor for Li-ion battery[J]. Journal of Alloys and Compounds, 2009, 485(1/2): 93-97.

[7] SNYDER M Q, TREBUKHOVA S A, RAVDEL B, WHEELER M C, DICARLO J, TRIPP C P, DESISTO W J. Synthesis and characterization of atomic layer deposited titanium nitride thin films on lithium titanate spinel powder as a lithium-ion battery anode[J]. Journal of Power Sources, 2007, 165(1): 379-385.

[8] PARK K S, BENAYAD A, KANG D J, DOO S G. Nitridation-driven conductive Li4Ti5O12 for lithium ion batteries[J]. Journal of the American Chemical Society, 2008, 130(45): 14930-14931.

[9] STAWOMIR P. Stages of the synthesis of indium nitride with the use of urea[J]. Thermochimica Acta, 1995, 256(2): 375-380.

[10] GOMATHI A, HARIKA M R, RAO C N R. Urea route to coat inorganic nanowires, carbon fibers and nanotubes by boron nitride[J]. Materials Science and Engineering A, 2008, 476(1/2): 29-33.

[11] ZHAO H Z, LEI M, CHEN X L, TANG W H. Facile route to metal nitrides through melamine and metal oxides[J]. Journal of Materials Chemistry, 2006, 16(45): 4407-4412.

[12] GOMATHI A. Ternary metal nitrides by the urea route[J]. Materials Research Bulletin, 2007, 42(5): 870-874.

[13] ALDON L, KUBIAK P, WOMES M, JUMAS J C, OLIVIER-FOURCADE J, TIRADO J L, CORREDOR J I, VICENTE C P. Chemical and electrochemical Li-insertion into the Li4Ti5O12 spinel[J]. Chemistry of Materials, 2004, 16(26): 5721-5725.

[14] RAJA M W, MAHANTY S, KUNDU M, BASU R N. Synthesis of nanocrystalline Li4Ti5O12 by a novel aqueous combustion technique[J]. Journal of Alloys and Compounds, 2009, 468(1/2): 258-262

[15] YU H Y, ZHANG X F, JALBOUT A F, YAN X D, PAN X M, XIE H M, WANG R S. High-rate characteristics of novel anode Li4Ti5O12/polyacene materials for Li-ion secondary batteries[J]. Electrochimica Acta, 2008, 53(12): 4200-4204.

[16] SNYDER M Q, DESISTO W J, TRIPP C P. An infrared study of the surface chemistry of lithium titanate spinel(Li4Ti5O12)[J]. Applied Surface Science, 2007, 253(24): 9336-9341.

[17] SNYDER M Q, MCCOOL B A, DICARLO J, TRIPP C P, DESISTO W J. An infrared study of the surface chemistry of titanium nitride atomic layer deposition on silica from TiCl4 and NH3[J]. Thin Solid Films, 2006, 514(1/2): 97-102.

[18] JAMNIK J, MAIER J. Generalised equivalent circuits for mass and charge transport: Chemical capacitance and its implications[J]. Physical Chemistry Chemical Physics, 2001, 3(9): 1668-1678.

(编辑 龙怀中)

基金项目:“十一五”国家科技支撑计划资助项目(2007BAE12B01)

收稿日期:2010-05-25;修订日期:2011-09-25

通信作者:张治安,副教授,博士;电话:0731-88830649;E-mail: zza75@163.com