从低品位红土镍矿中高效回收镍铁

梁威,王晖,符剑刚,何章兴

(中南大学 化学化工学院 有色金属资源化学教育部重点实验室,湖南 长沙,410083)

摘要:以低品位红土镍矿(w(Ni)=1.52%,w(Fe)=14.08%)为原料,采用“一步还原焙烧-磁选”工艺制取镍铁合金。考察反应温度、反应时间、还原煤量和复合添加剂对红土镍矿焙烧效果的影响。研究结果表明:在还原煤为20%、复合添加剂为12%、焙烧温度为1 200 ℃、通N2保护条件下焙烧180 min,原矿中的大部分氧化镍和少量氧化铁得到选择性还原;焙砂水淬急冷后常规磁选,得到Ni质量分数为10.74%,Fe与Ni的质量分数之比为4.5,Ni回收率为86.23%的镍铁精矿,达到从红土镍矿中高效回收镍铁的目的。

关键字:红土镍矿;选择性还原焙烧;复合添加剂;磁选;镍铁

中图分类号:TF815;TF803.12 文献标志码:A 文章编号:1672-7207(2011)08-2173-05

High recovery of ferro-nickel from low grade nickel laterite ore

LIANG Wei, WANG Hui, FU Jian-gang, HE Zhang-xing

(Key Laboratory of Resources Chemistry of Nonferrous Metals, Ministry of Education,

School of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China)

Abstract: The process of one-step reduction roasting and magnetic separation was adopted to prepare ferro-nickel alloy from low-grade nickel laterite ore (w(Ni)=1.52%, w(Fe)=14.08%). The roasting factors including roasting temperature, time, reducing coal amount and compound additive were investigated. The results indicate that under the conditions of adding 20% reducing coal, 12% compound additive, roasting temperature and roasting in a N2 protected atmosphere 180 min at 1 200 ℃, most of nickel and a spot of iron are selectively reduced. Then conventional magnetic separation is carried out after water quenching of the roasted ore. The content of Ni and the ratio of Fe/Ni are 10.74% and 4.5 in ferro-nickel concentrate prepared by this method, respectively. And the recovery rate of Ni is 86.23%, which indicates that a high recovery of ferro-nickel from nickel laterite ore is achieved indeed.

Key words: nickel laterite ore; selective reduction roasting; compound additive; magnetic separation; ferro-nickel

镍作为一种重要的有色金属,广泛应用于冶金、化工、石油、建筑、机械制造、仪器仪表、电池、电镀、航天等领域,是经济和社会发展不可缺少的金属资源[1-2]。世界镍的资源储量约1.6亿t,其中,30%~40%为硫化镍矿,60%~70%为红土镍矿。由于硫化矿提取工艺成熟,60%镍产量来源于硫化镍矿,但世界可供开发的硫化矿资源有限,而红土镍矿资源丰富,采矿成本低,因此,开发红土镍矿具有重要的现实意义[3]。红土镍矿是含镍蛇纹岩在热带或亚热带地区经过大规模长期风化淋滤变质而成的,是由铁、铝、硅等含水氧化物组成的疏松的黏土状硅酸盐氧化型矿物[1-4]。红土镍矿床的上部为褐铁型红土矿,适合于湿法工艺处理[5-6];下部为镁质硅酸镍矿,适合用火法工艺处理。而处于中间过渡的矿石同时适于两种工艺。实验所用原料属于中间过渡段矿石,目前国内外选矿厂处理此类矿石主要采用电炉炼冰镍法[7]和高压酸浸法[8],日本大江山冶炼厂曾采用火-湿法相结合工艺来处理红土镍矿[9]。近几年,有学者研究硫酸盐焙烧[10]和离析焙烧[11-12]等提取工艺,并取得一定进展。在此,本文作者以低品位红土镍矿为原料,采用“选择性还原焙烧–磁选”工艺富集镍铁,考察红土镍矿冶炼镍铁合金的工艺条件,研究“一步焙烧”法选择性回收镍铁的可能性。

1 原料与实验流程

1.1 原料及试剂

实验所用原矿取自印度尼西亚某红土镍矿。主要矿物为石英,其次为蛇纹石、蒙脱石和滑石等,镍主要赋存于蛇纹石矿物中。原料化学分析结果(质量分 数)见表1。

表1 红土镍矿化学成分分析

Table 1 Chemical analysis of nickel laterite ore %

实验所用试剂均为分析纯,煤为工业品。

1.2 镍铁还原机理

由于原矿中的镍主要赋存于蛇纹石中,利用传统选矿工艺无法实现镍的富集,本实验以固定碳为还原剂的熔融还原法进行镍铁的精炼。还原焙烧主要是将镍、铁等有价金属的氧化物还原成高磁性的金属相,之后通过磁选分离的方法将磁性物与脉石等杂质成分分离,达到富集镍铁的目的。其中可能发生的化学反应[13-14]主要有:

C+CO2=2CO (1)

NiSiO3=NiO+SiO2 (2)

NiO+C=Ni+CO (3)

NiO+CO=Ni+CO2 (4)

Fe2O3+3CO=2Fe+3CO2 (5)

Fe+NiO=Ni+FeO (6)

在矿样的焙烧过程中,固体碳和CO2发生反应,吸收大量热能,生成CO,进行碳的气化反应(布多尔反应),产生的CO参与镍矿石的间接还原,从总的结果看消耗的不是CO,而是碳,这就是目前所公认的固体碳还原氧化物的两步还原机理。固体碳还原反应实际上可以视为间接还原反应和布多尔反应的组合,其同样适于本实验中红土镍矿的还原。

1.3 实验流程

称取定量烘干细磨的红土镍矿(粒径为0.3 mm)、适量煤粉以及添加剂,充分混匀,装于已预热的100 mL刚玉坩埚中,在设定的温度和时间下通N2保护还原焙烧后,水淬急冷;焙砂粉碎后加水调浆,在设定磁感应强度(0.35 T)下磁选分离。磁性产品经真空干燥后,对镍和铁含量进行测定。实验流程见图1。

图1 红土镍矿还原焙烧工艺流程

Fig.1 Flow sheet of reduction roasting of nickel laterite ore

实验用还原焙烧设备为智能控温箱式纤维电炉;磨矿设备采用MZ-100型密封式制样粉碎机;磁选设备采用SSL-型磁选管(内径为50 mm)。

2 结果与讨论

2.1 还原焙烧条件对镍品位和回收率的影响

2.1.1 还原煤用量的影响

还原剂加入量直接影响还原焙烧的气氛。还原剂不够,镍、铁不能充分还原;还原剂过量,会导致大量铁被还原成金属态,达不到选择性还原的目的,影响精矿的镍品位。将原矿在焙烧温度为1 200 ℃和复合添加剂含量为12%、不同还原煤加入量下N2保护焙烧180 min,常规磁选后所得磁选产品的镍品位ηp及回收率ηh如图2所示。

从图2可知:还原剂用量(质量分数,下同)从10%增加至20%时,精矿中镍的品位和回收率都随之提高;继续增大煤粉加入量,镍的品位和回收率都有所下降。合适的煤粉加入量应控制在20%左右。

2.1.2 焙烧温度的影响

在固定矿样与煤粉(20%)及复合添加剂(12%)直接混匀条件下,通N2保护在不同温度下焙烧180 min,水淬急冷后常规磁选,磁性产品结果如图3所示。

图2 还原剂用量对镍回收率与品位的影响

Fig.2 Effect of reductant mass fractions on grade and recovery of Ni

图3 焙烧温度对镍回收率与品位的影响

Fig.3 Effect of roasting temperature on grade and recovery of Ni

由图3可知:还原焙烧温度对镍铁精矿镍的品位及回收率有显著的影响,实验的最佳还原焙烧温度为1 200 ℃。在此条件下,精矿镍品位为10.74%,镍回收率为86.23%。

2.1.3 焙烧时间的影响

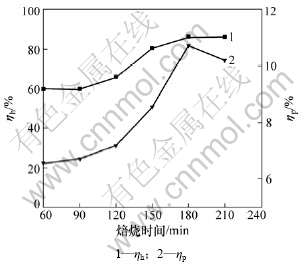

焙烧时间从宏观上反映反应的速度,时间越长表明反应速度越慢,时间越短表明反应速度越快。在焙烧温度1 200 ℃、矿样与煤粉(20%)及复合添加剂(12%)直接混匀条件下,在不同时间下通N2保护焙烧,水淬急冷后常规磁选,结果如图4所示。

图4 焙烧时间对镍回收率与品位的影响

Fig.4 Effect of roasting time on grade and recovery of Ni

由图4可知:当还原焙烧时间从60 min逐渐增加至180 min时,红土镍矿还原焙烧团块的镍品位和回收率都逐渐增高;但还原焙烧时间继续增加至210 min时,随着还原焙烧温度的升高,焙砂的镍品位和回收率的增幅趋于平缓。这可能是由于延长还原时间会消耗更多的还原剂,用同等质量的还原剂在还原焙烧后期不能保证足够强的还原气氛,导致部分焙砂可能被再次氧化。因此,本研究的还原焙烧时间取180 min。

2.1.4 复合添加剂用量的影响

(1) 碳酸钙用量的影响。在焙烧过程中,适当加入CaO可以提高焙砂的碱度,同时焙烧时还可能发生以下反应:CaO+NiSiO3=CaO·SiO2+NiO,从而提高NiO的活度,使之易于被还原进入金属镍相。因此,在固定其他条件不变的情况下,通过改变碳酸钙的加入量来考察CaO对焙烧效果的影响,其结果见表2。

由表2可知:碳酸钙的加入使精矿的镍品位有明显提高,但当碳酸钙加入量为从2%增加8%时,精矿镍品位变化趋于平缓。且碳酸钙的加入并未解决精矿镍回收率低的问题。

(2) 复合添加剂用量的影响。添加剂的加入对整个焙烧过程有很大的影响,但只加碳酸钙能提高精矿的镍品位,回收率变化不大。文献[11]报道了离析焙烧红土镍矿提取镍的方法,经实验证明不适用于此红土矿。因此,实验尝试选择几种复合添加剂混合使用实验,其中复合添加剂T的效果较好,结果如图5所示。

由图5可见:复合添加剂T加入量从0提高到12%时,精矿中的镍回收率和品位都有明显提高,其中镍回收率达到了86.23%,品位提高到10.74%;当添加剂用量继续增加到16%时,精矿中的镍回收率提高为87.46%,品位却下降到10.45%。所以本实验以12%的添加剂为宜,在此条件下,镍的回收率和品位分别为86.23%和10.74%。

表2 碳酸钙用量对镍回收率与品位的影响

Table 2 Effect of calcium carbonate mass fractions on grade and recovery of Ni

图5 添加剂用量对镍回收率与品位的影响

Fig.5 Effect of compound additive mass fractions on grade and recovery of Ni

2.2 焙砂分析

红土镍矿在最佳条件下焙烧后,破碎、制样,进行X线衍射分析(XRD)和扫描电镜(SEM)分析,结果如图6和图7所示。从图6分析发现:焙砂的主要成分为石英、硅酸钙镁等;其中的镍主要以金属镍为主,其次为硅酸镍;铁主要以金属铁和硅酸铁存在。图7(a)所示为红土镍矿在900 ℃下焙烧后的SEM图像,可以看出部分颗粒之间发生轻度的烧结现象;但焙砂常规磁选后,精矿镍品位和回收率均很低。图7(b)所示为红土镍矿在1 200 ℃下焙烧180 min后的SEM图像,可以看出大部分颗粒发生熔融,原矿在此焙烧温度下发生了严重烧结,在焙烧过程中可能有液相生成。在此温度下,精矿中的镍品位和回收率有很大提高,说明在高温下硅酸镍可以很容易被分解还原。对焙砂中的镍、铁进行了物相分析,结果如表3和表4所示。

由表3可知:原矿中的大部分镍已经被还原(81.46%),只有小部分的硅酸镍未被还原,微量的氧化镍存在可能是金属镍暴露在空气中被部分氧化的结果。由表4可知:只有部分铁被还原出来(36.33%),铁相中还有1/3的菱铁矿以及25%的硅酸矿。富集之后Fe/Ni为4.5,表明焙烧过程达到选择性还原的目的。

图6 焙砂的XRD图谱

Fig.6 XRD pattern of roasted ores

图7 不同温度下焙砂的扫描电镜照片

Fig.7 SEM images of roasted ores at different temperatures

表3 镍物相分析

Table 3 Phase analysis of Ni

表4 铁物相分析

Table 4 Phase analysis of Fe

3 结论

(1) 低品位红土镍矿通过“一步还原焙烧–磁选”分离,可以得到镍铁精矿。在焙烧温度为1 200 ℃、还原煤粉为20%、复合添加剂为12%、通N2保护焙烧180 min条件下,制备出含Ni 10.74%的镍铁精矿,Ni回收率为86.23%。

(2) 在焙烧过程中,发生烧结对提高镍精矿的品位和回收率有利;原矿中的大部分镍和少量铁得到了有效还原;磁选精矿Fe与Ni的质量分数比为4.5,表明焙烧达到了选择性还原的目的。

参考文献:

[1] 彭容秋. 镍冶金[M]. 长沙: 中南大学出版社, 2005: 2-4, 165-166.

PENG Rong-qiu. Metallurgy of nickel[M]. Changsha: Central South University Press, 2005: 2-4, 165-166.

[2] Kotzé I J. Pilot plant production of ferronickel from nickel oxide ore sand dusts in a DC arc furnace[J]. Minerals Engineering, 2002, 15(11): 1017-1022.

[3] 赵昌明, 翟玉春, 刘岩, 等. 红土镍矿在NaOH亚熔盐体系中的预脱硅[J]. 中国有色金属学报, 2009, 19(5): 949-954.

ZHAO Chang-ming, ZHAI Yu-chun, LIU Yan, et al. Pre-desilication of laterite in NaOH sub-molten salt system[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(5): 949-954.

[4] 李建华, 程威, 肖志海. 红土镍矿处理工艺综述[J]. 湿法冶金, 2004, 23(4): 191-194.

LI Jian-hua, CHENG Wei, XIAO Zhi-hai. Review on process technologies of nickel laterite ore[J]. Hydrometallurgy of China, 2004, 23(4): 191-194.

[5] McDonald R G, Whittington B I. Atmospheric acid leaching of nickel laterites review Part I. Sulphuric acid technologies[J]. Hydrometallurgy, 2008, 91(1/2/3/4): 35-55.

[6] Stamboliadis E, Alevizos G, Za?ratos J. Leaching residue of nickeliferous laterites as a source of iron concentrate[J]. Minerals Engineering, 2004, 17(2): 245-252.

[7] 张友平, 周渝生, 李肇毅, 等. 红土镍矿资源特点和火法冶金工艺分析[J]. 铁合金, 2007(6): 18-21.

ZHANG You-ping, ZHOU Yu-sheng, LI Zhao-yi, et al. Characteristics of laterite resource and analysis on its pyrometallurgy process[J]. Ferro-Alloys, 2007(6): 18-21.

[8] Purwanto H, Shimada T, Takahashi R, et al. Recovery of nickel from selectively reduced laterite ore by sulphuric acid leaching[J]. ISIJ International, 2003, 43(2): 181-186

[9] 石清侠, 邱国兴, 王秀美. 红土镍矿直接还原富集镍工艺研究[J]. 黄金, 2009, 30(11): 46-49.

SHI Qing-xia, QIU Guo-xing, WANG Xiu-mei. Study on direct reduction and enrichment of nickel from laterite-nickel ore[J]. Gold, 2009, 30(11): 46-49.

[10] Swamy Y V, Kar B B, Mohanty J K. Physico-chemical characterization and sulphatization roasting of low-grade nickeliferous laterites[J]. Hydrometallurgy, 2003, 69(1/3): 89-98.

[11] 张军, 张宗华. 铁镁质硅酸镍矿的离析选别实验研究[J]. 矿业工程, 2007, 5(6): 36-38.

ZHANG Jun, ZHANG Zong-hua. The research of mineral processing on Fe-Mg garnierite[J]. Mining Engineering, 2007, 5(6): 36-38.

[12] 陈晓鸣, 张宗华. 元江硅酸镍矿开发新技术半工业试验研究[J]. 有色金属: 选矿部分, 2007(3): 25-28.

CHEN Xiao-ming, ZHANG Zong-hua. Research on semi-industral trial of new technology to develop the nickel silicate in Yuanjiang[J]. Nonferrous Metals: Mineral Processing Section, 2007(3): 25-28.

[13] 阮书锋, 江培海, 王成彦, 等. 低品位红土镍矿选择性还原焙烧实验研究[J]. 矿冶, 2007, 16(2): 31-35.

RUAN Shu-feng, JIANG Pei-hai, WANG Cheng-yan, et al. Experimental study on low-grade nickeliferous laterite ore with selective reduction roasting technology[J]. Ming & Metallurgy, 2007, 16(2): 31-35.

[14] 刘岩, 翟玉春, 张纪谦, 等. 从镍精矿中提取镍铁合金的还原工艺[J]. 过程工程学报, 2005, 5(6): 626-630.

LIU Yan, ZHAI Chun-yu, ZHANG Ji-qian, et al. Reduction technology of preparation of ferronickel power from nickel concentrate[J]. The Chinese Journal of Process Engineering, 2005, 5(6): 626-630.

(编辑 杨幼平)

收稿日期:2010-08-22;修回日期:2010-11-18

基金项目:国家自然科学基金资助项目(50704036)

通信作者:王晖(1968-),男,安徽太湖人,博士,副教授,从事资源回收及矿物加工等领域研究;电话:0731-88836309;E-mail:huiwang1968@163.com