Settlement characteristics of large-diameter shield excavation below existing subway in close vicinity

来源期刊:中南大学学报(英文版)2021年第3期

论文作者:房倩 杜建明 李建业 张顶立 曹利强

文章页码:882 - 897

Key words:adjacent excavation; shield method; operational parameters; settlement characteristics

Abstract: A case of Qinghuayuan tunnel excavation below the existing Beijing Subway Line 10 is presented. The new Qinghuayuan tunnel, part of the Beijing-Zhangjiakou High-speed Railway, was excavated by a shield machine with an outer diameter of 12.2 m. The existing subway was excavated by shallow tunnelling method. The project layout, geological conditions, reinforcement measures, operational parameters of shield machine and monitoring results of the project are introduced. During the Qinghuayuan tunnel excavation below the existing subway, total thrust, shield driving speed, cutterhead rotation speed and torque were manually controlled below the average values obtained from the previous monitoring of this project, which could effectively reduce the disturbance of the surrounding soil induced by shield excavation. The Gaussian fitting function can appropriately fit both the ground and the existing subway settlements. The trough width is influenced not only by the excavation overburden depth, but also by the forepoling reinforcement and tail void grouting measures.

Cite this article as: FANG Qian, DU Jian-ming, LI Jian-ye, ZHANG Ding-li, CAO Li-qiang. Settlement characteristics of large-diameter shield excavation below existing subway in close vicinity [J]. Journal of Central South University, 2021, 28(3): 882-897. DOI: https://doi.org/10.1007/s11771-021-4628-7.

J. Cent. South Univ. (2021) 28: 882-897

DOI: https://doi.org/10.1007/s11771-021-4628-7

FANG Qian(房倩)1, DU Jian-ming(杜建明)1, LI Jian-ye(李建业)1,ZHANG Ding-li(张顶立)1, CAO Li-qiang(曹利强)2

1. Key Laboratory for Urban Underground Engineering of Ministry of Education,Beijing Jiaotong University, Beijing 100044, China;

2. College of Civil and Transportation Engineering, Underground Polis Academy,Shenzhen University, Shenzhen 518060, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Abstract: A case of Qinghuayuan tunnel excavation below the existing Beijing Subway Line 10 is presented. The new Qinghuayuan tunnel, part of the Beijing-Zhangjiakou High-speed Railway, was excavated by a shield machine with an outer diameter of 12.2 m. The existing subway was excavated by shallow tunnelling method. The project layout, geological conditions, reinforcement measures, operational parameters of shield machine and monitoring results of the project are introduced. During the Qinghuayuan tunnel excavation below the existing subway, total thrust, shield driving speed, cutterhead rotation speed and torque were manually controlled below the average values obtained from the previous monitoring of this project, which could effectively reduce the disturbance of the surrounding soil induced by shield excavation. The Gaussian fitting function can appropriately fit both the ground and the existing subway settlements. The trough width is influenced not only by the excavation overburden depth, but also by the forepoling reinforcement and tail void grouting measures.

Key words: adjacent excavation; shield method; operational parameters; settlement characteristics

Cite this article as: FANG Qian, DU Jian-ming, LI Jian-ye, ZHANG Ding-li, CAO Li-qiang. Settlement characteristics of large-diameter shield excavation below existing subway in close vicinity [J]. Journal of Central South University, 2021, 28(3): 882-897. DOI: https://doi.org/10.1007/s11771-021-4628-7.

1 Introduction

With the development of underground railways in densely-built urban areas, the cases of new tunnels excavation below existing tunnels have been increasingly reported [1-10]. The new tunnels construction will inevitably result in secondary disturbance to the soil around the existing structures, which will aggravate the soil deformation [11-13]. If the protective measures of the soil are improper, it is challenging to ensure the safety of both the existing and new tunnels [4].

The shield method [6, 12, 14] and the shallow tunnelling method [15-17] are two typical ways of excavating new tunnels below existing tunnels. The related studies mainly focused on the mechanical responses of the existing tunnels and the reinforcement measures of the projects during the past decades. The mechanical behaviours of the existing tunnels have been investigated by using field observation [2, 4, 6, 7, 12], theoretical analysis [18-22], numerical simulation [23-26], and physical modelling [27, 28]. The reinforcement measures of related projects include grouting [6, 29], freezing [30, 31] and jacking [2, 7]. The monitoring data obtained by field observation can not only provide valuable references for subsequent projects, but also can be used to verify the results of numerical simulation and theoretical analysis [32-34]. Therefore, field observation has become a universally recognized research method. LI et al [1] presented the responses of a double-deck metro tunnel induced by twin shields tunnelling below. The excavation diameters of the two shields were 6.28 m. ZHANG et al [23] investigated the deformations of the existing subway tunnel caused by an above-traversing EPB shield and a down-traversing shield by numerical simulation and field observation. The excavation diameters of the shields were 6.43 m. YIN et al [25] studied the influences of excavation clearance of the new twin shield tunnels on the deformation behaviours of existing tunnels and ground surface using numerical simulation and field observation. The excavation diameters of the two shields were 6.3 m. CHEN et al [12] presented the deformation and stress characteristics of existing twin tunnels caused by twin shield tunnels under-crossing. The excavation diameters of the two shields were 6.28 m. JIN et al [29] reported the in-tunnel grouting measure for excavation twin shield tunnels beneath existing tunnels. The settlement and stress characteristics of existing tunnels were investigated based on the field monitoring data. The excavation diameters of the two shields were 6.28 m. LI et al [26] investigated the deformation characteristics of ground surface and existing tunnels caused by twin shield tunnels construction undercrossing with oblique angel. The excavation diameters of the two shields were 6.28 m. The existing studies concerned on the ground surface settlement, deformation and stress characteristics of existing tunnel, and reinforcement measures. Nevertheless, in the previous cases of urban tunnelling adjacent to existing infrastructures, the maximum excavation diameter of the new shield tunnel was 6.34 m.

This research presents a comprehensive case study of the new Qinghuayuan shield excavation below the existing subway Line 10 in Beijing. The external diameter of the new shield tunnel is 12.2 m, which is so far the largest shield machine used in Beijing. The reinforcement measures, the operational parameters of shield machine, and the settlement monitoring results of this project are systematically illustrated.

2 Project overview

2.1 New Qinghuayuan tunnel and existing Subway Line 10

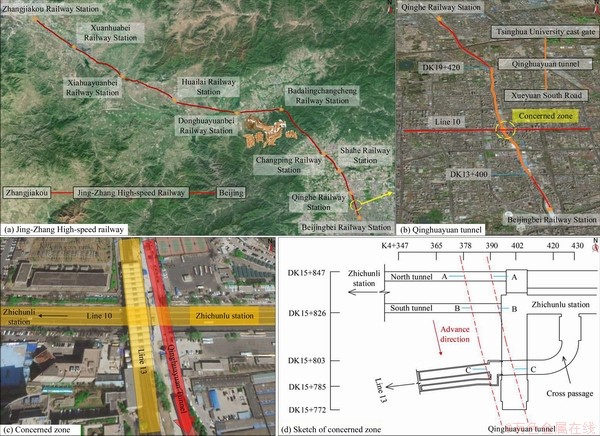

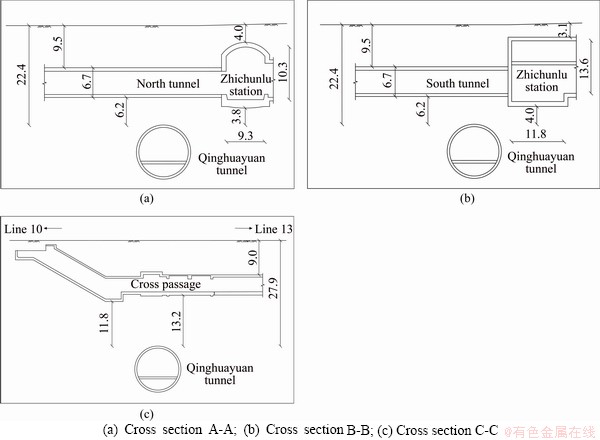

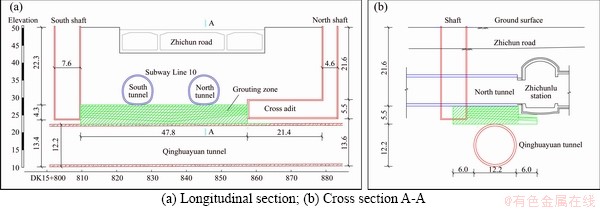

The Jing-Zhang High-speed Railway is one intercity railway connecting Beijing and Zhangjiakou (Figure 1(a)). It serves for the Beijing Winter Olympics in 2022. The new Qinghuayuan tunnel is part of the Jing-Zhang High-speed Railway. It is located in Haidian district, Beijing. It runs from the Xueyuan South Road to the east gate of Tsinghua University. It was excavated below the existing Zhichunlu station of Beijing Subway Line 10 (Figure 1(b)). The spatial relationship of the existing Zhichunlu station of Beijing Subway Line 10 and the Qinghuayuan tunnel is shown in Figure 1(c). The concerned zone of this research is shown in Figure 1(d). The cross sections of the Qinghuayuan tunnel at three typical chainages (DK15+844; DK15+829; DK15+799) are shown in Figure 2.

Beijing Subway Line 10 is a loop line. The twin subway tunnels, running east-west between Zhichunlu station and Zhichunli station of Line 10, were excavated by shallow tunnelling method. The cross section of each of the twin tunnels shapes is the horseshoe shape. The overburden depth of the twin tunnels is about 9.5 m. The excavation width and height of the twin tunnels are 6.5 m and 6.7 m, respectively. Shotcrete primary lining (C25, 30 cm thickness) and cast-in-place concrete secondary lining (C30, 50 cm thickness) are adopted as tunnel support. The twin tunnels, referred to as the “North tunnel” and the “South tunnel”, are horizontally parallel. The pillar width between the twin tunnels is 7.6 m. The north of the Zhichunlu station, of which the width and height are 9.25 m and 10.30 m, respectively (Figure 2(a)), was excavated by shallow tunnelling method. The concrete types of primary and secondary linings are C25 and C30, respectively. The thicknesses of the primary and secondary linings are 30 and 50 cm, respectively. The south of the Zhichunlu station, of which the width is 11.8 m and height is 13.6 m (Figure 2(b)), was excavated by open-cut method. The cross passage between Subway Line 10 and Line 13 is shown in Figure 2(c).

The Qinghuayuan tunnel involved building a double-track railway tunnel with a length of 6.02 km (from DK13+400 to DK19+420). The maximum slope of the Qinghuayuan tunnel is about 3% and the minimum radius of curvature is about 995 m. From DK15+826 to DK15+847, the Qinghuayuan tunnel was excavated under the existing Subway Line 10. The intersection angle and the vertical clearance between the Qinghuayuan tunnel and existing Subway Line 10 are 79° and 6.5 m, respectively. From DK15+772 to DK15+803, the Qinghuayuan tunnel was constructed under the existing cross passage linking Subway Line 10 and Line 13 at Zhichunlu station.

Figure 1 Views of Jing-Zhang High-speed Railway, Qinghuayuan tunnel, and Zhichunlu station

Figure 2 Cross sections of Qinghuayuan tunnel and Zhichunlu station (unit: m):

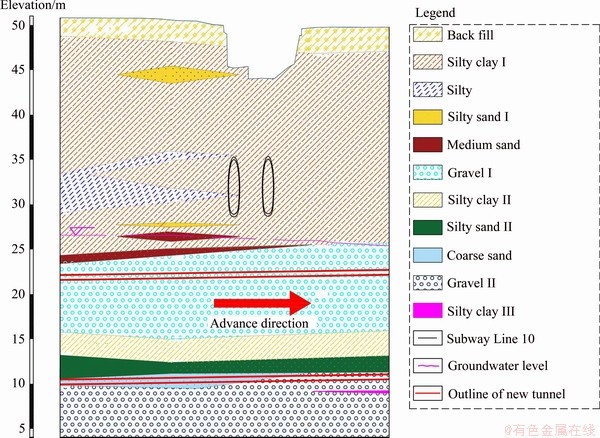

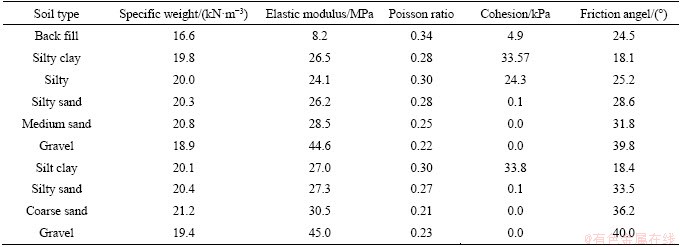

2.2 Geological conditions

The geological profile along the Qinghuayuan tunnel is shown in Figure 3. The existing twin subway tunnels of Line 10 are mainly located in silty clay. The Qinghuayuan tunnel is located in interbedded soils, composed of gravel, silty clay, silty sand, and coarse sand. The phreatic water level ranges from 1.38 m to 5.09 m below the surface. The typical values of the physical and mechanical parameters of the soil are shown in Table 1.

Figure 3 Geological profile along Qinghuayuan tunnel

Table 1 Physical and mechanical properties of soils

2.3 Multilayer forepoling reinforcement

To safeguard both the operation of the existing twin subway tunnels and the construction of the Qinghuayuan tunnel, the multilayer forepoling reinforcement measure was adopted. This measure was implemented from February 7th to February 15th, 2018. On March 9th and March 12th, the shield machine cutterhead was excavated below the north and south tunnels of Subway Line 10, respectively. On March 19th, the shield machine tail passed the cross passage of Zhichunlu station. The longitudinal section and cross section of the multilayer forepoling reinforcement measure are shown in Figure 4.

The south shaft was excavated on the south side of Zhichun Road. The grouting holes were horizontally drilled on the south shaft wall. The horizontal and vertical center-to-center spacings of the grouting holes were 0.36 m and 1.2 m, respectively. The north shaft was excavated on the north side of Zhichun Road, and then a cross adit was excavated horizontally from the shaft sheeting. The grouting holes were horizontally drilled on the face of the cross adit. The horizontal and vertical center-to-center spacings of the grouting holes were 0.46 m and 0.4 m, respectively. The diameter of a grouting hole was 50 mm and the diffusion radius of a grouting hole was supposed to 0.8 m. The grouting pressure was controlled under 0.4 MPa.

2.4 Operational parameters of shield machine

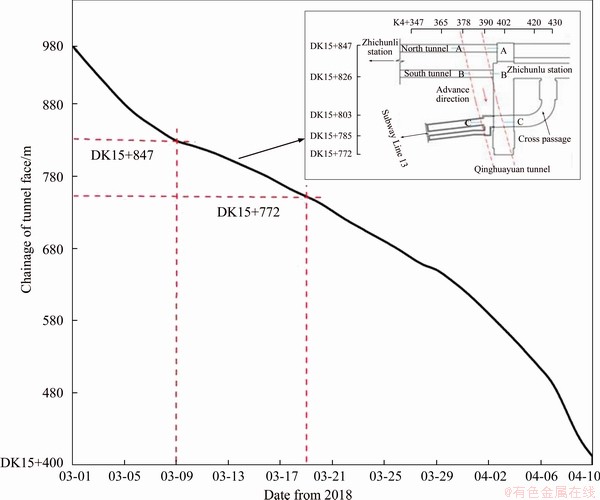

From March 9th to March 19th, 2018, the shield machine was excavated below the existing twin tunnels of Subway Line 10 and Zhichunlu station. The location of shield cutterhead with time is shown Figure 5.

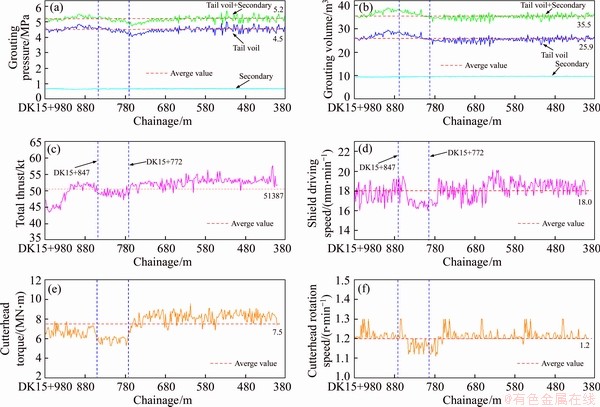

The operational parameters of the shield machine, such as grouting pressure, grouting volume, total thrust, shield driving speed, cutterhead torque, and cutterhead rotation speed are shown in Figure 6. The tail void grouting pressure is about 6.4 times the secondary grouting pressure. And the tail void grouting volume is about 2.7 times the secondary grouting volume. The fluctuations of the secondary grouting pressure and volume are negligible in comparison to those of the tail void grouting. During the excavation from DK15+847 to DK15+809, the grouting pressure and volume are higher than the average values obtained from DK15+980 to DK15+400, which can reduce the settlement of the existing structure of Subway Line 10 and Zhichunlu station. During the excavation from DK15+847 to DK15+722, the total thrust, shield driving speed, cutterhead torque and rotation speed were manually controlled below the average values obtained from DK15+980 to DK15+400 to reduce the disturbance of the surrounding soil induced by shield excavation.

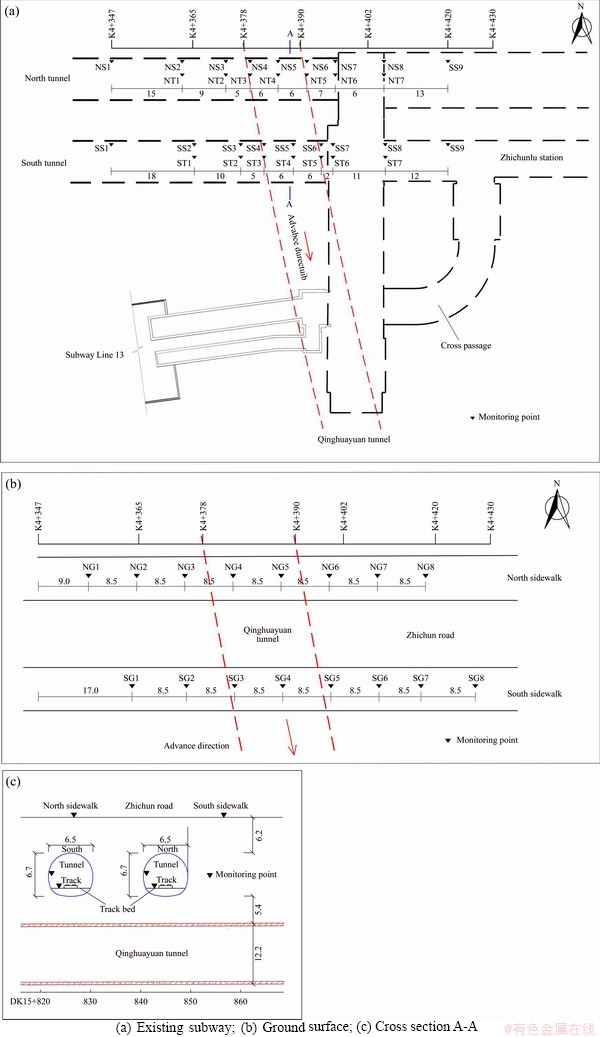

3 Layout of monitoring points

During the Qinghuayuan tunnel excavation, the settlement of the existing twin subway tunnels and the ground surface were continuously monitored. The layout of the monitoring points along the existing twin subway tunnels and the ground surface is shown in Figure 7. The first letter “N” or “S” of the monitoring point label indicates “north tunnel” or “south tunnel”. The second letter “T”, “S” or “G” indicates “track bed”, “tunnel structure” or “ground surface”.

The hydrostatic level system was adopted to monitor the settlement due to the Qinghuayuan tunnel excavation. At each monitoring point of the track bed and tunnel structure, a hydrostatic level cell was installed on the surface using expansion bolts. The signals observed from the hydrostatic level cells were sent back to the central monitoring system and recorded at 30 min intervals. The total station was adopted to monitor the settlement of the ground surface. The ground surface settlement monitoring points were installed in the soils below the road structure to record the soil surface settlement.

Figure 4 Sketch of multilayer forepoling reinforcement (unit: m):

Figure 5 Location of shield cutterhead with time (unit: m)

Figure 6 Operational parameters of shield machine

Figure 7 Layouts of monitoring points (unit: m):

To reduce the ambient interference and to improve the accuracy of the monitoring results, the monitoring data were collected during the non-service time of Subway Line 10 after midnight. The representative data were selected from the huge volume of collected data to represent the daily settlement magnitude of the existing twin subway tunnels and the ground surface. Note that the monitoring results may be affected by the shaft and cross adit excavation, therefore, to study the deformation induced by the shield excavation of the Qinghuayuan tunnel, the deformation readings after multilayer forepoling were used in this research.

4 Analysis of monitoring data

4.1 Typical stages of shield tunnelling

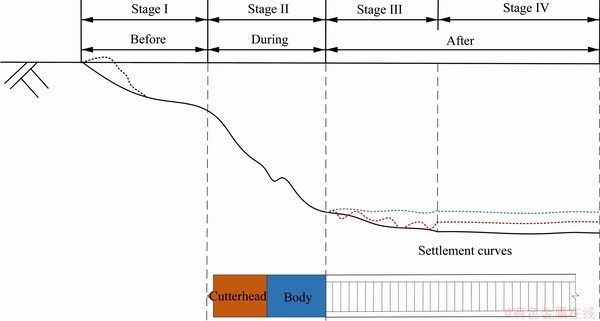

To facilitate the following illustration, the driving process of shield machine is divided into 4 stages (Figure 8).

Stage I: Before shield passing. When the shield cutterhead approaches the concerned cross section, the monitoring points settle (total thrust of shield machine lower than lateral earth pressure) or heave (total thrust of shield machine higher than lateral earth pressure).

Stage II: During shield passing. When the shield body passes the concerned cross section, the monitoring points settle due to volume loss caused by over-excavation, body tapering, and friction between TBM skin and surrounding soil.

Stage III: After shield passing. After the shield tail passes the concerned cross section, the monitoring points may settle, heave, or fluctuate, which is associated with the tail void grouting.

Stage IV: Stratum consolidation and deformation stabilization. When the shield advances far away from the cross section, the slurry is hardened. The stratum is consolidated. And the deformation is stable. Noted, the settlement may also increase slowly due to the soil creep deformation and the ovalization of segmental lining.

4.2 Characteristics of settlement curves

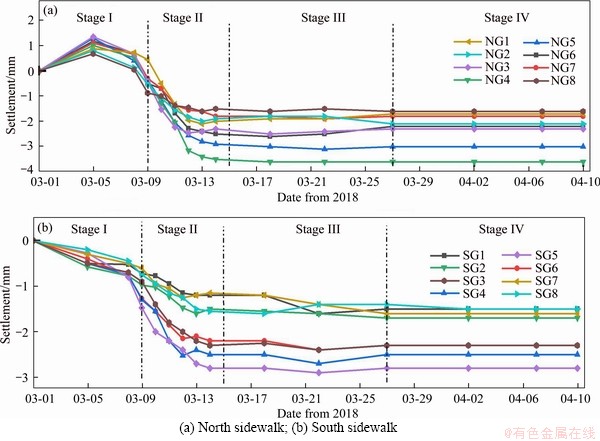

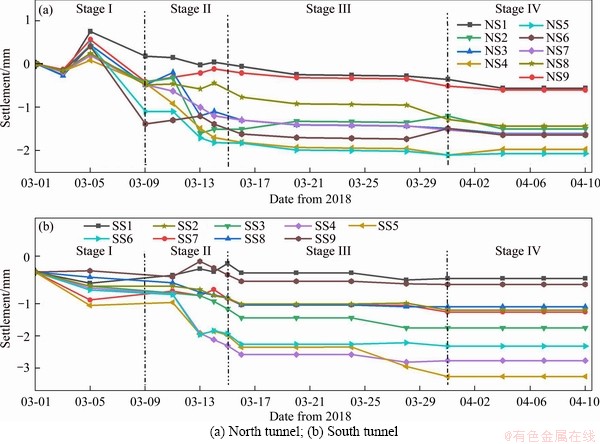

The ground surface settlement curves of the north and south sidewalks of the Zhichun Road due to the Qinghuayuan shield excavation are shown in Figure 9. The settlement curves of the north and south tracks, the north and south tunnels are shown in Figures 10 and 11, respectively. The shield machine approached the existing subway from the north side on March 9th and left from the south side on March 19th.

Stage I: When the shield cutterhead approached the north side of the existing subway,the total thrust of shield machine (up to 52.9 kt) was higher than the lateral earth pressure (50 kt), so the ground heaved first (from 0.68 to 1.30 mm). Then the ground settled (settlement value from 0.38 to 0.88 mm) due to the reduction of total thrust (low to 49.157 kt). The slurry of multilayer forepoling is not completely hardened, so the tracks (from 0.21 to 0.37 mm) and tunnels (from 0.13 to 0.26 mm) settled first. Then the tracks (from 0.18 to 0.32 mm) and tunnels (from 0.13 to 0.18 mm) heaved due to the increase of tail void grouting pressure (up to 4.62 MPa) and volume (up to 29.0 m3). The operational parameters of shield machine during excavation under the south side of the existing subway were adjusted referring to the monitoring data associated with the north side, the total thrust of shield was controlled between 49.157 kt and 50.918 kt, which was sometimes lower than the lateral earth pressure (50 kt). Therefore, the south ground settled (from 0.38 to 1.30 mm) without observed heave. The tail void grouting pressure was controlled between 4.52 and 4.56 MPa. The tail void grouting volume was controlled between 27.8 and 28.4 m3. Both the grouting pressure and grouting volume of the south tunnel were lower than those of the north tunnel. Therefore, the south tracks (from 0.08 to 0.15 mm) and tunnels (from 0.04 to 1.03 mm) settled without observed heave.

Figure 8 Surface settlement stages associated with shield excavation

Figure 9 Development of ground surface settlements with time:

Figure 10 Settlements of existing track beds:

Figure 11 Settlements of existing tunnels:

Stage II: The ground surface settlement was about 1.8 to 3.9 times the settlement of Stage I. The settlement of tracks was 3.2 to 4.3 times the settlement of Stage I. The maximum settlement of tunnels was 2.4 to 3.1 times the settlement of Stage I. The settlement values in Stage II were higher than those in Stage I due to ground loss produced by over-excavation, body tapering, and friction between shield skin and surrounding soil. The recorded settlement values of south ground were generally smaller than those of the north due to the total thrust of shield at the south ground was controlled between 48.023 kt and 50.918 kt, which was lower than that at the north (from 49.256 kt to 51.287 kt). The recorded settlement values of south tacks and tunnels were generally greater than those of the north due to the tail void grouting volume of shield at the south side of the existing subway was controlled between 34.3 and 34.8 m3, which was lower than that at the north (from 35.5 and 36.8 m3).

Stage III: When the shield tail left the south side of the existing subway, the ground surface continuously settled (settlement value from 0.1 to 0.2 mm) due to surrounding soil was disturbed by volume loss. The tracks fluctuate and the tunnel settle may be due to the tail void grouting and pressure were controlled unreasonably.

Stage IV: After the shield tail was far away from the south side of the existing subway, the slurry hardened and the stratum consolidated. The settlements of the ground and the existing subway were negligible, indicating that the ground and the existing subway settlement had reached a steady state.

4.3 Characteristics of settlement troughs

The transverse settlement curves of ground surface and existing subway can be fitted by inverted Gaussian distribution curve [35], that is

(1)

(1)

(2)

(2)

where S(x) is ground surface settlement value at x m away from tunnel axis; Smax,s is ground surface settlement at the axis of the tunnel; x is the horizontal distance from the tunnel axis; is is width parameter of ground surface settlement trough; R is tunnel radius; V is stratum loss rate. The value of is can be calculated by a simple method proposed by O’REILLY et al [36]:

(3)

(3)

where K is an empirically determined trough width parameter; h is tunnel axis depth.

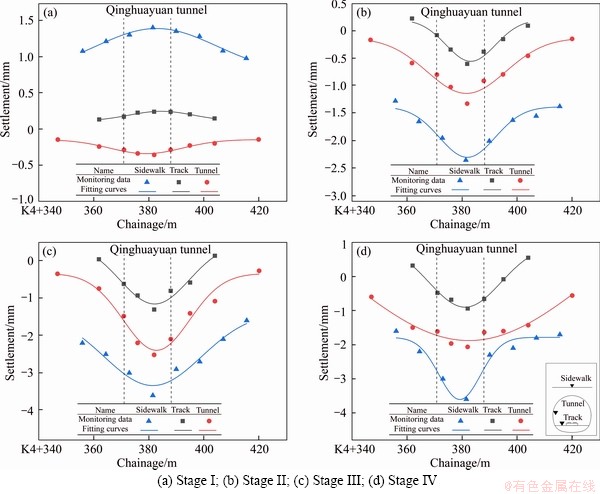

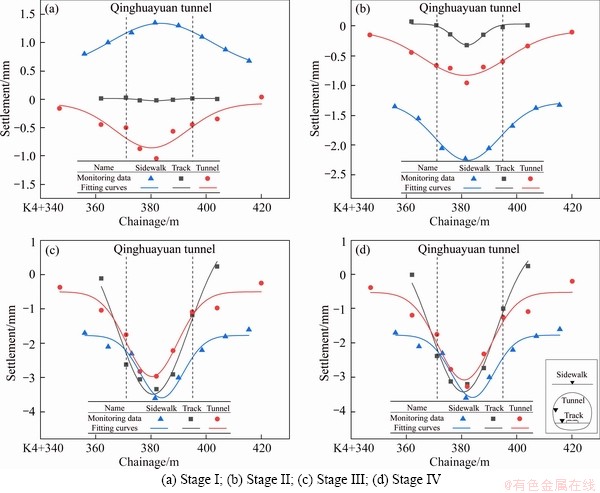

The settlement troughs of the ground, tracks, and tunnels of north and south are shown in Figures 12 and 13, respectively.

The deformation magnitudes of ground surface are greater than those of the tunnel and track due to the fact that the soil between the existing subway and the Qinghuayuan tunnel has been reinforced. The track is smaller than the tunnel. The settlement curves of surface display inverted “U” shape, and the settlement curves of tunnel and track display “U” shape in stage I, which can be in line with the Gaussian distribution function. The settlement curves of surface, tunnel and track in stages II, III and IV display “U” shape, which can be well fitted by the Gaussian distribution function

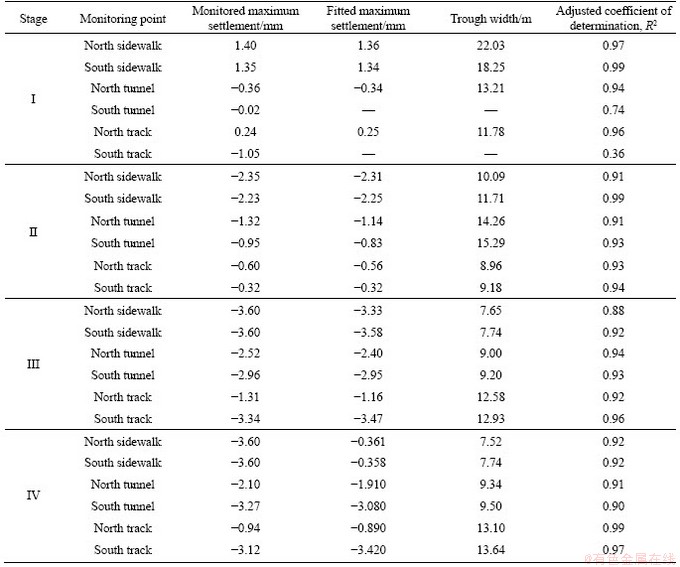

The settlement parameters of the ground surface, existing tunnels, and tracks obtained by monitoring and fitting are is presented in Table 2.

Figure 12 Settlement troughs at north:

Fig 13 Settlement troughs at south:

The adjusted coefficient of determination (Adj. R-Square) indicates how well the monitoring points data match the fitting curve. The better the fit is, the closer the adjusted R2 will be to the value of 1. The adjusted R2 above 0.85 indicate the monitoring settlement profile in line with the Gaussian distribution curve.

The adjusted R2 of the ground uplift is greater than 0.95, indicating that the Gaussian fitting curve can not only predict the ground surface settlement but can also fit the monitoring data of the ground surface heave. According to the Gaussian fitting curve, the settlement trough width varies (from 7.52 to 22.03 m) greatly because the rigidities of soil, tracks and tunnels are different. In addition, before the shield cutterhead approached the existing subway, the soil between the existing subway and the Qinghuayuan tunnel had been reinforced by the multilayer forepoling reinforcement measure.

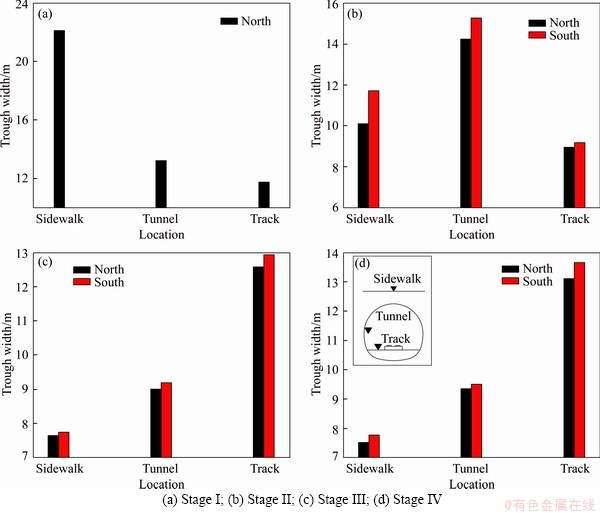

The settlement troughs of different locations at north and south are shown in Figure 14. In stage I, the trough width decreases with the increase of overburden depth, which is in accordance with our commonsense. In the other stages, due to the complicated behaviours of the multilayer forepoling reinforcement and the tail void grouting, the trough width no longer decreases with the increase of overburden depth. In addition, this may be related to the fact that we do not have enough monitoring points on ground surface.

5 Conclusions

This paper presents a case of the Qinghuayuan tunnel excavation below the existing Beijing Subway Line 10. The monitoring data associated with the operational parameters of shield machine are systematically illustrated. The maximum settlement of the existing subway was successfully controlled in 3.6 mm. This study can provide valuable references for future similar projects, and the key findings of this study are summarized as follows:

Table 2 Settlement parameters of ground surface, existing tunnels, and tracks

1) The surface and subsurface settlement were greatly influenced by the operational parameters of shield machine, such as the total thrust, the shield driving speed, the cutterhead rotation speed and the torque. After the operational parameters were manually controlled below the average values of this project, the disturbance of the surrounding soil induced by shield excavation could be effectively reduced.

2) The tail void grouting volume was about 2.7 times the secondary grouting volume. The fluctuations of the secondary grouting pressure and volume were negligible in comparison to those of the tail void grouting. Therefore, the settlement produced by shield excavation was dominantly influenced by tail void grouting in comparison to secondary grouting.

3) The Gaussian fitting function can not only predict the ground surface settlement, but can also fit the monitoring data of the ground surface heave. Due to the forepoling reinforcement and tail void grouting measures, the characteristics of settlement trough at different depths behave differently from excavation in green field without reinforcement measures.

Contributors

The overarching research goals were developed by FANG Qian. ZHANG Ding-li and CAO Li-qiang performed the field monitoring. The initial draft of the manuscript was written by DU Jian-ming and LI Jian-ye. All authors replied to reviewers’ comments and revised the final version.

Conflict of interest

FANG Qian, DU Jian-ming, LI Jian-ye, ZHANG Ding-li, and CAO Li-qiang declare that they have no conflict of interest.

Figure 14 Settlements of different locations:

References

[1] LI Xing-gao, YUAN Da-jun. Response of a double-decked metro tunnel to shield driving of twin closely under-crossing tunnels [J]. Tunnelling and Underground Space Technology, 2012, 28: 18-30. DOI: 10.1016/j.tust.2011.08.005.

[2] LI Xing-gao, ZHANG Cheng-ping, YUAN Da-jun. An in-tunnel jacking above tunnel protection methodology for excavating a tunnel under a tunnel in service [J]. Tunnelling and Underground Space Technology, 2013, 34: 22-37. DOI: 10.1016/j.tust.2012.10.004.

[3] LI Qian-qian, ZHANG Ding-li, FANG Qian, LI Dong. Study of deformation characteristics of tunnels traversing adjacently under shield tunnels by shallow tunnelling method [J]. Chinese Journal of Rock Mechanics & Engineering, 2014, 33(S2): 3911-3918. DOI: 10.13722/j.cnki.jrme.2014. s2.065. (in Chinese)

[4] WANG Shi-min WANG Xian-ming, CHEN Bing, FU Yan-bin, JIAN Yun-qi, LU Xi-xi. Critical state analysis of instability of shield tunnel segment lining [J]. Tunnelling and Underground Space Technology, 2020, 96: 103180. DOI: 10.1016/j.tust.2019.103180.

[5] ZHANG Qiong-fang, XIA Tang-dai, DING Zhi, HUANG Xiao-bin, LIN Cun-gang. Effect of nearby undercrossing tunneling on the deformation of existing metro tunnel and construction control [J]. Rock and Soil Mechanics, 2016, 37(12): 3561-3568. DOI: 10.16285/j.rsm.2016.12.027. (in Chinese)

[6] XIE Xiong-yao, WANG Qiang, QI Yong, LI Jun, YU Xing-guo. Settlement control of slurry shield tunneling crossing adjacent buildings in mixed ground of round gravel and mudstone [J]. Chinese Journal of Geotechnical Engineering, 2017, 39(9): 1951-1959. DOI: 10.11779/ CJGE201709006. (in Chinese)

[7] ZHANG Cheng-ping, ZHANG Xu, FANG Qian. Behaviors of existing twin subway tunnels due to new subway station excavation below in close vicinity [J]. Tunnelling and Underground Space Technology, 2018, 81: 121-128. DOI: 10.1016/j.tust.2018.07.020.

[8] BAI Hai-wei, WANG Jian-chen, LIU Yun-liang, ZHANG Ding-li. Safety control and mechanical response of existing underground structures induced by excavation of new tunnels under construction [J]. Chinese Journal of Geotechnical Engineering, 2019, 41(5): 874-884. DOI: 10.11779/CJGE 201905010. (in Chinese)

[9] LAI Hong-peng, ZHENG Hai-wei, CHEN Rui, KANG Zuo, LIU Yang. Settlement behaviors of existing tunnel caused by obliquely under-crossing shield tunneling in close proximity with small intersection angle [J]. Tunnelling and Underground Space Technology, 2020, 97: 103258. DOI: 10.1016/j.tust.2019.103258.

[10] LI Shao-hua, LI Peng-fei, ZHANG Ming-ju. Analysis of additional stress for a curved shield tunnel [J]. Tunnelling and Underground Space Technology, 2021, 107: 103675. DOI: 10.1016/j.tust.2020.103675.

[11] NG C W W, BOONYARAK T, MASIN D. Three- dimensional centrifuge and numerical modeling of the interaction between perpendicularly crossing tunnels [J]. Canadian Geotechnical Journal, 2013, 50(9): 935-946. DOI: 10.1139/cgj-2012-0445.

[12] CHEN Ren-peng, LIN Xing-tao, KANG Xin, ZHONG Zhi-quan, LIU Yuan, ZHANG Pin, WU Huai-na. Deformation and stress characteristics of existing twin tunnels induced by close-distance EPBS under-crossing [J]. Tunnelling and Underground Space Technology, 2018, 82: 468-481. DOI: 10.1016/j.tust.2018.08.059.

[13] LIU Tong, XIE Yuan, FENG Zhi-hua, LUO Yan-bin, WANG Ke, XU Wei. Better understanding the failure modes of tunnels excavated in the boulder-cobble mixed strata by distinct element method [J]. Engineering Failure Analysis, 2020, 116:104712. DOI: 10.1016/j.engfailanal.2020.104712.

[14] COOPER M L, CHAPMAN D N, ROGERS C D F, CHAN A H C. Movements in the Piccadilly line tunnels due to the Heathrow express construction [J]. Geotechnique, 2002, 52(4): 243-257. DOI: 10.1680/geot.52.4.24341019.

[15] FANG Qian, ZHANG Ding-Li, WONG L N Y. Shallow tunnelling method (STM) for subway station construction in soft ground [J]. Tunnelling and Underground Space Technology, 2012, 29: 10-30. DOI: 10.1016/j.tust.2011.12. 007.

[16] FANG Qian, ZHANG Ding-li, LI Qian-qian, WONG L N Y. Effects of twin tunnels construction beneath existing shield-driven twin tunnels [J]. Tunnelling and Underground Space Technology, 2015, 45: 128-137. DOI: 10.1016/j.tust. 2014.10.001.

[17] FANG Qian, TAI Qi-min, ZHANG Ding-li, WONG L N Y. Ground surface settlements due to construction of closely-spaced twin tunnels with different geometric arrangements [J]. Tunnelling and Underground Space Technology, 2016, 51: 144-151. DOI: 10.1016/j.tust.2015. 10.031.

[18] LIU Xiang, FANG Qian, ZHANG Ding-li. Mechanical responses of existing tunnel due to new tunnelling below without clearance [J]. Tunnelling and Underground Space Technology, 2018, 80: 44-52. DOI: 10.1016/j.tust.2018. 06.001.

[19] LIU Xiang, FANG Qian, ZHANG Ding-li, WANG Zhong-ju. Behaviour of existing tunnel due to new tunnel construction below [J]. Computers & Geotechnics, 2019, 110: 71-81. DOI: 10.1016/j.compgeo.2019.02.013.

[20] ZHANG Dong-mei, HUANG Zhong-kai, LI Zi-li, ZONG Xiang, ZHANG Dong-ming. Analytical solution for the response of an existing tunnel to a new tunnel excavation underneath [J]. Computers & Geotechnics, 2019, 108: 197-211. DOI: 10.1016/j.compgeo.2018.12.026.

[21] ZHOU Zhong, CEHN Yun, LIU Zhuang-zhuang, MIAO Lin-wu. Theoretical prediction model for deformations caused by construction of new tunnels undercrossing existing tunnels based on the equivalent layered method [J]. Computers & Geotechnics, 2020, 123: 103565. DOI: 10.1016/j.compgeo.2020.103565.

[22] LIU Bo, YU Zhi-wei, HAN Yan-hui, WANG Zhi-liu, ZHANG Rong-hui, WANG Shi-jie. Analytical solution for the response of an existing tunnel induced by above-crossing shield tunnel [J]. Computers & Geotechnics, 2020, 124: 103624. DOI: 10.1016/ j.compgeo.2020.103624.

[23] ZHANG Zhi-guo, HUANG Mao-song. Geotechnical influence on existing subway tunnels induced by multiline tunneling in Shanghai soft soil [J]. Computers & Geotechnics, 2014, 56: 121-132. DOI: 10.1016/j.compgeo. 2013.11.008.

[24] NG C W W, FONG K Y, LIU Han-long. The effects of existing horseshoe-shaped tunnel sizes on circular crossing tunnel interactions: Three-dimensional numerical analyses [J]. Tunnelling and Underground Space Technology, 2018, 77: 68-79. DOI: 10.1016/j.tust.2018.03.025.

[25] YIN Ming-lun, JIANG Hua, JIANG Yu-sheng, SUN Zheng-yang, WU Quan-li. Effect of the excavation clearance of an under-crossing shield tunnel on existing shield tunnels [J]. Tunnelling and Underground Space Technology, 2018, 78: 245-258. DOI: 10.1016/j.tust.2018.04.034.

[26] LI Xing-tao, CHEN Ren-peng, WU Huai-na, CHENG Hong-zhan. Deformation behaviors of existing tunnels caused by shield tunneling undercrossing with oblique angle [J]. Tunnelling and Underground Space Technology, 2019, 89: 78-90. DOI: doi.org/10.1016/j.tust.2019.03.021.

[27] JIANG Biao, CHEN Liang, YANG Jun-sheng, WANG Shu-ying, NG C W W. Effects of twin-tunnel excavation on an existing horseshoe-shaped tunnel considering the influence of a settlement joint [J]. Canadian Geotechnical Journal, 2017, 54(9): 1346-1355. DOI: 10.1139/cgj-2015- 0389.

[28] JIN Da-long, YUAN Da-jun, WEI Jia-xin, LI Xing-gao, LU Ping. Centrifugal model test of group tunneling with small spacing beneath existing tunnels [J]. Chinese Journal of Geotechnical Engineering, 2018, 40(8): 1507-1514. DOI: 10.11779/CJGE201808017. (in Chinese)

[29] JIN Da-long, YUAN Da-jun, LI Xing-gao, ZHENG Hao-tian. An in-tunnel grouting protection method for excavating twin tunnels beneath an existing tunnel [J]. Tunnelling and Underground Space Technology, 2018, 71: 27-35. DOI: 10.1016/j.tust.2017.08.002.

[30] RUSSO G P, CORBO A D, CAVUOTO F P, AUTUORI S L. Artificial ground freezing to excavate a tunnel in sandy soil. Measurements and back analysis [J]. Tunnelling and Underground Space Technology, 2015, 50: 226-238. DOI: 10.1016/j.tust.2015.07.008.

[31] CAI Hai-bing, LIU Zheng, LI Sheng, ZHENG Teng-long. Improved analytical prediction of ground frost heave during tunnel construction using artificial ground freezing technique [J]. Tunnelling and Underground Space Technology, 2019, 92: 103050. DOI: 10.1016/j.tust.2019.103050 .

[32] ZHENG He-bin, LI Peng-fei, MA Guo-wei. Stability analysis of the middle soil pillar for asymmetric parallel tunnels by using model testing and numerical simulations [J]. Tunnelling and Underground Space Technology, 2021, 108: 103686. DOI: 10.1016/j.tust.2020.103686.

[33] HE Si-yue, LAI Jin-xing, ZHONG YU-jian, WANG Ke, XU Wei, WANG Li-xin, LIU Tong, ZHANG Cheng-ping. Damage behaviors, prediction methods and prevention methods of rockburst in 13 deep traffic tunnels in China [J]. Engineering Failure Analysis, 2021, 121: 105178. DOI: 10.1016/j.engfailanal.2020.105178.

[34] HAN Xuan, LI Ning, STANDING J R. An adaptability study of Gaussian equation applied to predicting ground settlements induced by tunneling in China [J]. Rock and Soil Mechanics, 2007, 28(1): 23-30. DOI: 10.16285/j.rsm. 2007.01.005. (in Chinese)

[35] PECK R B. Deep excavations and tunneling in soft ground [C]// Pro 7th Int Conf SMFE. Mexico City, 1969: 225-290.

[36] O’REILLY M P, NEW B M. Settlements above tunnels in the United Kingdom—Their magnitude and prediction [C]// Proc Tunnelling 82. London: Institution of Mining and Metallurgy, 1982: 173-181.

(Edited by YANG Hua)

中文导读

大直径盾构隧道紧邻下穿既有地铁施工诱发地层沉降特征分析

摘要:研究依托京张高铁清华园隧道下穿既有北京地铁10号工程,既有地铁车站采用浅埋暗挖法施工,新建清华园隧道采用盾构法施工。论文详细介绍了工程地质条件、工程空间位置关系、地层加固措施以及盾构机掘进参数,建立了下穿既有线工程中,地层、既有结构变形与盾构掘进参数的关系。结果表明:在新建隧道下穿掘进过程中,盾构机的相关操作参数(盾构机的推进速度以及总推力,刀盘的旋转速度以及扭矩)被控制在平均值之下来减小盾构开挖对周围地层的扰动,高斯方程可以较好地拟合地层和既有线沉降,地层沉降槽宽度受隧道埋深、地层加固措施以及盾构机尾部注浆的综合影响。

关键词:近接开挖;盾构法;盾构掘进参数;沉降特征

Foundation item: Project(U1934210) supported by the Key Project of High-speed Rail Joint Fund of National Natural Science Foundation of China; Project(8202037) supported by the Natural Science Foundation of Beijing, China

Received date: 2020-07-25; Accepted date: 2021-01-07

Corresponding author: FANG Qian, PhD, Professor; Tel: +86-10-51688115; E-mail: qfang@bjtu.edu.cn; ORCID: https://orcid.org/ 0000-0002-8148-9228