文章编号: 1004-0609(2005)01-0152-05

以硫酸镍为主盐的镁合金化学镀镍

李建中1, 邵忠财2, 田彦文1

(1.东北大学 材料与冶金学院, 沈阳 110004; 2. 沈阳理工大学 环境与化学工程学院, 沈阳 110168)

摘 要: 以硫酸镍为主盐, 采用正交实验确定了镁合金“无氟绿色环保”碱性化学镀镍镀液成分及操作条件。 选择适合镁合金化学镀的缓冲剂, 考察了镀液参数对化学镀的影响。 结果表明: 缓冲剂Na2CO3适合镁合金化学镀镍, 它不仅能提高化学镀镍速度, 而且可以调节镀层与基体间的结合力, 缓冲化学镀过程中pH值的变化; 碱性化学镀的pH值范围为8.5~11.5; 络合剂柠檬酸钠的最佳浓度为30g/L; 所得镀层均匀致密, 孔隙率少, 属于晶态特征明显的低磷镀层, 耐蚀性较好, 化学镀层与镁合金基体结合良好。

关键词: 镁合金; 化学镀; 缓冲剂; 耐蚀性; 结合力 中图分类号: TQ153.1

文献标识码: A

Electroless nickel plating on magnesium alloy in solution with NiSO4 as main salt

LI Jian-zhong1, SHAO Zhong-cai2, TIAN Yan-wen1

(1. School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China;

2. Faculty of Environmental and Chemical Engineering,

Shenyang Institute of Technology, Shenyang 110168, China)

Abstract: The electroless nickel-plating on magnesium alloy was studied, using NiSO4 as the main salt in the electroless plating alkaline solutions. The effects of the buffer agent and plating parameters on the properties and structures of the plating coatings on magnesium alloy were investigated in detail. The compositions of the non-fluoride and environmentally friendly plating bath were optimized through Latin orthogonal experiment. The buffer agent (Na2CO3) added to the plating bath was found to be useful in increasing the growth rate of the plating coating, adjusting the adhesion between the electroless plating coatings and the substrates, and maintaining the pH value within the range of 8.5-11.5, which is required for the successful electroless nickel-plating on magnesium alloy with NiSO4 as the main salt. Trisodium citrate dihydrate was found to be an essential component of the plating bath to plate magnesium alloy, with an optimum concentration of 30g/L. The obtained plating coatings are crystalline, having advantages such as low-phosphorus content, high density, low-porosity, good corrosion resistance and strengthened adhesion.

Key words: magnesium alloy; electroless plating; buffers; corrosion resistance; adhesion

镁合金具有密度小、 比强度高、 降噪减振、 可回收等特点, 且具有很好的铸造性能和切削加工性能, 已受到汽车、 航空航天、 电子、 通讯等行业的广泛关注。 近年来, 镁合金的用量在全球范围内的年增长率高达20%, 显示了极好的应用前景。 然而, 由于镁合金的化学活性较高, 耐蚀性和耐磨性差, 限制了其更广泛应用[1-5]。 在镁合金表面直接化学镀镍可以提高耐蚀性、 耐磨性等性能, 镀层均匀致密, 且操作简单, 还可以在形状复杂的工件上施镀, 大大促进了镁合金的应用。 镁合金化学镀镍方法有两种: 一种是传统的DOW氏浸锌法, 另一种是直接化学镀方法。 多年来, 二种化学镀液镍盐多以碱式碳酸镍或醋酸镍为主, 化学镀液成本高, 稳定性差, 且多含有氟化物, 污染环境, 不适于工业应用。 而镁合金在含有SO2-4或Cl-的镀液中腐蚀速度较快, 施镀较难, 所以, 以硫酸镍或氯化镍为镁合金化学镀液主盐的研究较少[5-11]。 Inoue等[12]研究表明, 镁合金在NaCl溶液中腐蚀速度主要取决于溶液的pH值, 在具有良好的缓冲性能的溶液中腐蚀速度明显下降。 本文作者以硫酸镍为成膜主盐, 选择适合镁合金化学镀的缓冲剂, 开发“无氟绿色环保”的镁合金化学镀液, 考察镀液参数对化学镀的影响。

1 实验

实验材料采用铸造镁合金, 化学成分(质量分数)为Mg 93.0%, Al 6.5%, 其他0.5%。 试样尺寸均为50mm×40mm×20mm。 镁合金化学镀镍工艺流程为: 预磨试样→碱性除油→酸性浸蚀→活化→直接化学镀镍(各步间水洗)。

酸性浸蚀溶液为CrO3 120g/L, HNO3 110mL/L; 活化溶液HF(70%) 220mL/L。 采用4因素3水平正交实验确定直接化学镀液组成为NiSO4 25g/L, NaH2PO2 30g/L, C6H5Na3O7 30g/L, Na2CO3 30 g/L, NH3·H2O为pH调节剂, 控制pH值为11, 温度(80±2)℃。

考察镁基体腐蚀情况时, 模拟无还原剂—NaH2PO2化学镀时的镀液组成, pH值为11(NH3·H2O调节)和温度(80±2)℃等操作条件。 采用pHS-25C数字式pH计监测其溶液pH值的变化。 附带能谱仪的SSX-550扫描电镜观察试样的表面形貌和成分分布, 以电子天平(精度0.1mg)研究化学镀层质量随时间的变化, 通过X射线衍射仪检测化学镀层的相结构。

2 结果与讨论

2.1 缓冲剂的选择和镁基体在模拟镀液中的腐蚀

不同缓冲剂条件下镁合金基体质量随浸泡时间的变化如图1所示。 由图可知, 在3种不同缓冲剂下, 镁合金的质量损失呈线性变化, 直线的斜率可以表征镁合金基体的腐蚀率, 即斜率越大, 腐蚀率越小。 分别以Na2CO3、 Na2B4O7、 CH3COONa为缓冲剂时, 镁基体腐蚀率相应为-0.015、 -0.022和-0.056。 可见, 在模拟镀液中, 缓冲剂Na2CO3缓蚀性能较好。 H2CO3电离常数为k1=4.4×10-7, k2=4.7×10-11 ; H2B4O7电离常数为k1=1×10-4, k2=1×10-9; CH3COOH 电离常数为k=1.75×10-5。 它们相应的盐电离出的酸根离子结合H+离子的能力取决于其电离常数, 即电离常数越小, 结合H+离子的能力越强。 二元酸根离子主要是二级电离常数起作用, 而H2CO3的二级电离常数k2=4.7×10-11明显小于其他二者。 因此, 无论从缓蚀性能, 还是其成本, 缓冲剂Na2CO3都比较适合镁合金化学镀。

图1 镁基体在不同缓冲剂条件下质量损失随时间的变化

Fig.1 Variation of mass loss of magnesium alloy with time under different buffers

不同pH值条件下, 以Na2CO3为缓冲剂和无缓冲剂时, 镁合金在模拟镀液中的腐蚀结果如图2所示。 由图可知, 相同pH值条件下, 镁基体在有缓冲剂的模拟镀液中腐蚀率远远小于无缓冲剂的模拟镀液中的腐蚀率。 同时, 无论有无缓冲剂, 都是pH值越高, 镁合金基体腐蚀率越小。 可见, 在含有 SO2-4的溶液中, 镁合金基体的腐蚀主要是由于H+离子引起的。

2.2 碱性化学镀的主要影响因素

缓冲剂Na2CO3对化学镀速、 镀层表观和镀层结合力的影响如表1所示。 由表1可知, 随着缓冲剂Na2CO3浓度的增加, 化学镀速随之增加, 镀层表观也明显好转, 而镀层与镁合金基体结合力却显著恶化。 化学镀层与基体的结合力根据锉刀实验来评价[13], 并给予其相应的等级分数。 但是, 如果镀液中没有缓冲剂, 镁合金基体不仅不能被施镀, 反而被镀液腐蚀。 这是由于化学镀初期镀液中镍离子与镁基体发生置换反应, 瞬间没有H+离子产生, 但有了催化中心的镍, 化学镀液迅速发生氧化还原反应, 沉积Ni-P。 同时, 伴随产生大量的H2气和H+离子[13, 14]。 大量H2气上溢, 携带H+离子也瞬间逃离镁合金基体。 若在镁合金基体周围没有缓冲剂电解出的CO2-3离子, H+离子将很快地扩散回到镁合金基体附近, 从而腐蚀基体, 同时沉积的少量Ni-P层也被腐蚀掉。 而当镀液中存在一定量的缓冲剂时, 电解出的CO2-3离子将很好地束缚H+离子, 进而Ni-P层顺利沉积。 当然, 缓冲剂浓度小时, 一些H+离子挣脱CO2-3离子的束缚, 也会腐蚀镁合金基体, 形成点腐蚀; 但缓冲剂浓度过大, H+离子很难逃脱CO2-3离子的束缚, 这样会降低镀层与基体的凹凸咬合, 影响其结合力。

图2 镁基体在不同条件下质量损失随时间的变化

Fig.2 Variation of mass loss of magnesium alloy with time under different conditions

表1 缓冲剂Na2CO3对化学镀速、镀层表观和镀层结合力的影响

Table 1 Effects of different concentrations of Na2CO3 in plating bath on rate, surface appearance and adhesion of coating

化学镀液的pH值对化学镀速和镀层形貌也有重要的影响。 镀液中的H+离子除了被缓冲剂电解出CO2-3离子束缚外, 一些H+离子也会与化学镀液中的OH-离子结合, 从而降低pH值。 当pH值低于8.5时, 化学镀速低, 化学镀层很容易出现点腐蚀或者镀层灰暗; 当pH值高于11.5时, 尽管化学镀速高, 但化学镀层与镁合金基体的结合力明显降低。 pH值低于8.5或高于11.5都不适合镁合金化学镀。 适量的缓冲剂可以有效地控制化学镀液的pH值变化, 提高化学镀液的使用周期。

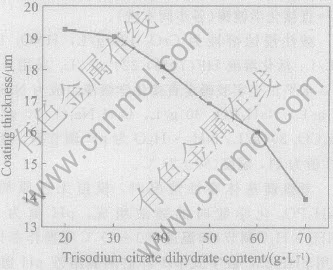

在相同条件下, 化学镀1h的镀层厚度与柠檬酸钠浓度的关系如图3所示。 由图可见, 随着柠檬酸钠浓度的降低, 化学镀速增快。 但是, 当柠檬酸钠的浓度小于20g/L, 化学镀液容易出现絮状沉淀。 这是由于大量的Ni2+离子没有被络合, 形成了镍的沉淀物。

图3 化学镀1h的镀层厚度与柠檬酸钠浓度的关系

Fig.3 Relationship between coating thickness for 1h electroless plating and trisodium citrate dihydrate content

2.3 镁合金碱性化学镀层的性能

图4所示为碱性化学镀层的X射线衍射谱。 由图可知, 衍射峰较尖锐, 镀层为单一Ni相, 晶态特征明显。 图5所示为化学镀层的表面形貌。 由图可见, 化学镀层表面均匀致密, 孔隙率稀少, 无明显的表面缺陷。 通过能谱分析可知, 其表面成分(质量分数)为Ni 94.61%, P 5.39%, 属于低磷化学镀层。 碱性化学镀层的横截面形貌如图6所示。 由图可见, 镀层与镁合金基体结合良好、 致密, 自表面到基体无孔洞或其他类型缺陷。

图4 碱性化学镀层的X射线衍射谱

Fig.4 XRD pattern of electroless plating coating

图5 碱性化学镀层的表面形貌

Fig.5 Surface morphology of electroless plating coating

图6 碱性化学镀层的横截面形貌

Fig.6 Cross section morphology of electroless plating coating

根据浓硝酸实验法评价碱性化学镀层的耐蚀性[14]。 碱性化学镀层的浓硝酸实验时间为216s, 由此可知, 碱性化学镀层的耐蚀性良好。

根据GB/T13913-92[15], 利用热震实验和锉刀实验评价镀层的结合力。 样品在(250±10)℃的高温炉内保温1h时, 取出后立即投入冷水中, 反复进行20次, 试样表面仍然完好, 无起皮和剥落现象。 利用锉刀沿45°锉去非主要表面, 露出基体金属与镀层的界面, 镀层不起皮, 说明采用此工艺所得碱性化学镀层的结合良好。

3 结论

1) 开发出“无氟绿色环保”的镁合金化学镀液。 缓冲剂Na2CO3适合作为硫酸镍为成膜主盐的镁合金化学镀镍。

2) 缓冲剂Na2CO3在化学镀过程中, 不仅可以提高化学镀速, 而且可以调节镀层与基体之间的结合力及缓冲化学镀过程pH值变化。

3) 确定了碱性化学镀的pH值取值范围为8.5~11.5; 得到了络合剂柠檬酸钠的最佳浓度为30g/L。 此条件下, 化学镀所得镀层均匀致密, 孔隙率小, 属于晶态特征明显的低磷镀层, 且耐蚀性好; 化学镀层与镁合金基体结合良好。

REFERENCES

[1]Mordike B L, Ebert T. Magnesium properties-application-potential[J]. Materials Science and Engineering A, 2001, A302: 37-45.

[2]曾荣昌, 柯伟, 徐永波. Mg合金的最新发展及应用前景[J]. 金属学报, 2001, 37(7): 673-681.

ZENG Rong-chang, KE Wei, XU Yong-bo. Recent development and application of magnesium alloys[J]. Acata Metallurgica Sinica, 2001, 37(7): 673-681.

[3]Ambat R, Zhou W. Electroless nickel-plating on AZ91D magnesium alloy: effect of substrate microstructure and plating parameters[J]. Surface and Coating Technology, 2004, 179: 124-134.

[4]HUO H W, LI Y, WANG F H. Corrosion of AZ91D magnesium alloy with a chemical conversion coating and electroless nickel layer[J]. Corrosion Science, 2004, 46: 1467-1477.

[5]Sharma A K, Suresh M R, Bhojraj H. Electroless nickel plating on magnesium alloy[J]. Metal Finishing, 1998(3): 10-18.

[6]XIANG Yang-hui, HU Wen-bin, LIU Xin-kuan. Initial deposition mechanism of electroless nickel plating on magnesium alloys[J]. Trans IMF, 2001, 79(1): 30-32.

[7]霍宏伟, 李瑛, 王福会. AZ91D镁合金化学镀镍[J]. 中国腐蚀与防护学报, 2002, 22(1): 14-17.

HUO Hong-wei, LI Ying, WANG Fu-hui. Electroless nickel plating on AZ91D magnesium alloy[J]. Journal of Chinese Society for Corrosion and Protection, 2002, 22(1): 14-17.

[8]Fairweather W A. Electroless nickel plating of magnesium[J]. Trans IMF, 1997, 75(3): 113-117.

[9]刘新宽, 向阳辉, 胡文彬. 镁合金化学镀镍研究状况[J]. 宇航材料工艺, 2001(4): 21-26.

LIU Xin-kuan, XIANG Yang-hui, HU Wen-bin. Review of electroless nickel coating on magnesium alloys[J]. Aerospace Materials & Technology, 2001(4): 21-26.

[10]Brown L. UK company leads the way in magnesium plating[J]. Finishing, 1994, 18(11): 22-25.

[11]刘新宽, 向阳辉, 胡文彬, 等. 镁合金化学镀镍溶液的老化[J]. 中国有色金属学报, 2003, 13(4): 1046-1050.

LIU Xin-kuan, XIANG Yang-hui, HU Wen-bin, et al. Ageing of electroless nickel bath of magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(4): 1046-1050.

[12]Inour H, Sugahara K, Yamamoto A. Corrosion rate of magnesium and its alloys in buffered chloride solutions[J]. Corrosion Science, 2002(44): 603-610.

[13]姜晓霞, 沈伟. 化学镀理论及实践[M]. 北京: 国防工业出版社, 2000. 26.

JIANG Xiao-xia, SHEN Wei. The Fundamentals and Practice of Electroless Plating[M]. Beijing: National Defense Industry Press, 2000. 26.

[14]刘新宽, 向阳辉, 胡文彬. 镁合金化学镀镍层的结合机理[J]. 中国腐蚀与防护学报, 2002, 22(4): 233-236.

LIU Xin-kuan, XIANG Yang-hui, HU Wen-bin. Adhesion mechanism of direct electroless nickel coating on magnesium alloys[J]. Journal of Chinese Society for Corrosion and Protection, 2002, 22(4): 233-236.

[15]GB/T13913-92. Autocatalytic Nickel-Phosphorus Coating-Specification and Test Methods[S].

基金项目: 辽宁省自然科学基金资助项目(002054)

收稿日期: 2004-07-10; 修订日期: 2004-10-15

作者简介: 李建中(1976-), 男, 博士研究生.

通讯作者: 田彦文, 教授; 电话: 024-83687731; 传真: 024-83687731; E-mail: mengsuo66@163.com

(编辑陈爱华)