J. Cent. South Univ. Technol. (2011) 18: 238-243

DOI: 10.1007/s11771-011-0685-7

Evaluation of protective quality of prestressed concrete containment buildings of nuclear power plants

ZHENG Yan-guo(郑砚国)1, 2, LI Hui-qiang(李惠强)1

1. School of Civil Engineering and Mechanics,

Huazhong University of Science and Technology, Wuhan 430074, China;

2. CNNC Hunan Taohuajiang Nuclear Power Co. Ltd., Yiyang 413000, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2011

Abstract: The permeability and sorptivity properties of the two prestressed concrete containment buildings (PCCBs) of a nuclear power plant in South China, which had been under operation for 5 years, were measured by using the autoclam permeability system. The air permeability, sorptivity and water permeability indexes of No.1 PCCB are smaller than or equal to 0.11 ln(102 Pa)/min, 0.98×10-7 m3/min1/2 and 1.93×10-7 m3/min1/2, respectively, and the air permeability, sorptivity and water permeability indexes of No.2 PCCB are smaller than or equal to 0.17 ln(102 Pa)/min, 1.6×10-7 m3/min1/2 and 4.43×10-7 m3/min1/2, respectively. Based on the criteria for evaluating the protective quality of concrete structures in terms of their permeability and sorptivity properties, proposed by the research organization of the autoclam permeability system, the protective quality of No.1 PCCB is still in very good grade and that of No.2 PCCB is not in very good grade but in good grade, and the in-service inspection of the protective quality of No.2 PCCB should be strengthened in the future.

Key words: nuclear power plant; prestressed concrete containment building; permeability properties; sorptivity properties

1 Introduction

The prestressed concrete containment buildings (PCCBs) of nuclear power plants are special concrete structures which are designed to separate the reactors and other systems and equipment important to safety from the outside environment. They are the final barriers to prevent radioactive materials from spreading. After a nuclear power plant is put into operation, both the external events such as severe weather conditions and internal events such as loss-of-coolant accidents will make its PCCBs age. With the ageing, the protective quality of the PCCBs will degrade. In order to ensure the required leak-tightness and structural integrity of the PCCBs, their age-related degradation has to be effectively evaluated and controlled [1-2].

During the past 25 years, the International Atomic Energy Agency (IAEA), the United States Nuclear Regulatory Commission (US NRC), China and other countries have conducted a lot of studies on the ageing of the PCCBs. They stipulate that the in-service inspection of the ageing of the PCCBs should be started after they have been under operation for 5 years [3-7]. However, when a nuclear power plant is in operation, the destructive test method cannot be used for in-service inspection of its PCCBs. As a result, the in-service inspection and evaluation of the PCCBs have long been the research focus.

Therefore, for the two PCCBs at a nuclear power plant in South China which had been under operation for 5 years, the in-service inspection and evaluation of their protective quality have to be conducted. In the present study, the permeability and sorptivity properties of the two PCCBs were measured by using the autoclam permeability system and the evaluation of their protective quality was made by using the criteria for evaluating protective quality of concrete structures in terms of their permeability and sorptivity properties proposed by the research organization of the autoclam permeability system.

2 Test program

2.1 Autoclam permeability system

Autoclam permeability system was developed by researchers at Queen’s University of Belfast, Northern Ireland, UK. It is a new kind of instrument for measuring the air permeability, water permeability and sorptivity of concrete structures on site or in laboratory [8-10]. The autoclam permeability system consists of the autoclam body and the electronic controller, as shown in Fig.1.

Fig.1 Autoclam permeability system

In order to carry out an air permeability test, the pressure within the autoclam body is adjusted to slightly above 5×104 Pa and the decay of the pressure is monitored every minute for 15 min or until the pressure diminishes to zero. A line of natural logarithm of pressure against time is obtained by regression and the slope of the regressed line between the 5th minute and the 15th minute is used as an air permeability index.

The sorptivity test is carried out at the same test point as the air permeability test but at least 1 h later. Water is admitted into the test zone through a priming pump and the air escapes through the bleed tube. When the test chamber is completely filled with water, the priming pump automatically switches off and the pump pressure is adjusted to make the pressure in the test zone reach 2 kPa above atmospheric pressure. At this pressure, water is absorbed into the capillary pores via

capillary effect rather than the pressure-induced flow. As water is absorbed by capillary effect, the pressure inside tends to decrease, and in order to keep it constant, the pump and the control system are used. The variation in volume of water delivered is measured and recorded every minute for 15 min and the quantity of water absorbed during the test is recorded. A line of the quantity of water absorbed against the square root of time elapsed is obtained by regression and the slope of this line is used as a sorptivity index.

The water permeability test is conducted at different test points from the sorptivity test by using the same test procedure as that for sorptivity test. In this case, after priming the system, the pressure inside is adjusted to 5×104 Pa. Again a line of the quantity of water flowing into concrete against the square root of time elapsed is obtained by regression and the slope of this line between the 5th minute and 15th minute is used as a water permeability index.

2.2 Test arrangement

The nuclear power plant in South China, named DY-2 nuclear power plant, has two PCCBs. It was built in 1997 and put into operation in 2003. In accordance with the regulations by IAEA, from 2008, the ageing state of its two PCCBs had to be inspected and their protective quality had to be evaluated.

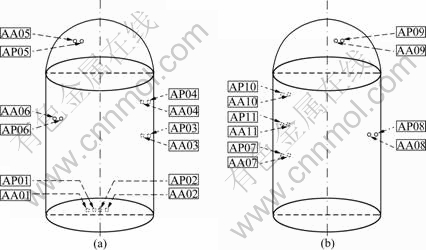

The permeability and sorptivity properties of the PCCBs are the most important indexes which reflect their protection function and performance. In order to measure the permeability and sorptivity properties with the autoclam permeability system, test points were selected for the two PCCBs and are shown in Fig.2. The installation of the autoclam permeability system for a test point is shown in Fig.3.

Fig.2 Test point arrangements for two PCCBs: (a) No.1; (b) No.2

Fig.3 Installation of autoclam permeability system for test point

3 Criteria for evaluating protective quality of PCCBs

Concrete permeability and sorptivity properties reflect the structure of the internal pores and the volume of voids within concrete. For hardened concrete as a solid material, its strength, corrosion resistance and durability are related to the structure of the internal pores and the volume of voids. So, the relationships can be established between the protective quality (strength, corrosion resistance and durability) of concrete and its permeability and sorptivity properties through testing, and the protective quality of concrete can be evaluated

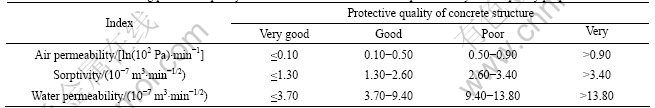

based on its permeability and sorptivity properties [10-13]. Table 1 gives the criteria for evaluating the protective quality of concrete structure based on its permeability and sorptivity properties, which was proposed by the research organization of the autoclam permeability system, and the testing practices have shown that Table 1 is applicable [14-17]. In this work, the criteria in Table 1 are used for evaluating the protective quality of the PCCBs.

4 Results and discussion

4.1 Air permeability

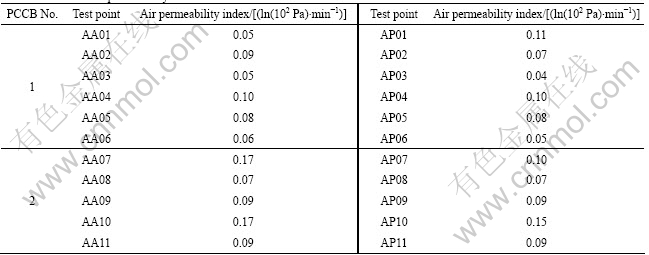

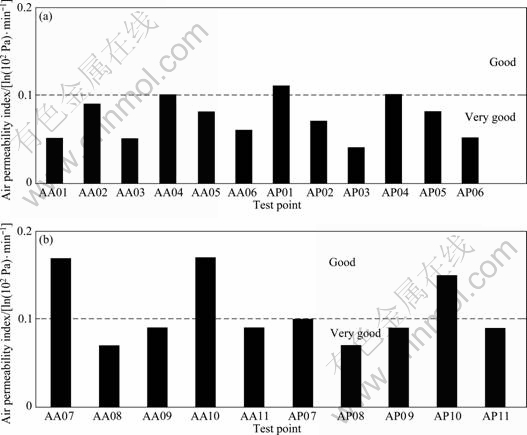

The measured air permeability indexes of the two PCCBs are listed in Table 2. Based on the criteria in terms of air permeability for evaluating the protective quality of concrete structures in Table 1, the measured air permeability indexes and the corresponding protective qualities for all the effective test points on the two PCCBs are illustrated in Fig.4.

The average values of the air permeability indexes of No.1 and No.2 PCCBs are found to be 0.07 ln(102 Pa)/min and 0.11 ln(102 Pa)/min from Table 2, respectively. For No.1 PCCB, only the air permeability index for test point AP01 is slightly larger than the threshold of 0.1 ln(102 Pa)/min. But for No.2 PCCB, the air permeability indexes for test points AA07, AA10 and AP10 are larger than the threshold of 0.1 ln(102 Pa)/min and smaller than the threshold of 0.5 ln(102 Pa)/min.

Table 1 Criteria for evaluating protective quality of concrete structures based on its permeability and sorptivity properties

Table 2 Measured air permeability indexes of PCCBs

Fig.4 Measured air permeability indexes and corresponding protective qualities of two PCCBs: (a) No.1; (B) No.2

Table 1 indicates that the air permeability index value for concrete structures having good protective quality ranges from 0.10 to 0.50 ln(102 Pa)/min. Therefore, the protective quality of No.1 and No.2 PCCBs can be evaluated as “Very good” and “Good”, respectively, in terms of the air permeability, and more attention should be paid to the in-service inspection of the protective quality of No.2 PCCB.

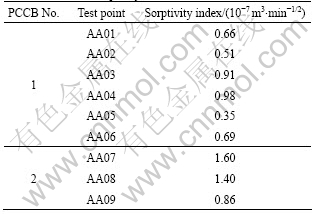

4.2 Sorptivity

The measured sorptivity indexes of the two PCCBs are listed in Table 3. Based on the criteria in terms of sorptivity for evaluating the protective quality of concrete structures in Table 1, the sorptivity indexes and the corresponding protective qualities for all the effective test points on the two PCCBs are illustrated in Fig.5.

For No.1 and No.2 PCCBs, their average values of the sorptivity indexes are found to be 0.84×10-7 and 1.80×10-7 m3/min1/2 from Table 3, respectively. For No.1 PCCB, the sorptivity indexes for all the effective test points are smaller than the threshold of 1.3×10-7 m3/min1/2. But for No.2 PCCB, the sorptivity indexes for test points AA07 and AA08 are larger than threshold of 1.3×10-7 m3/min1/2 and smaller than the threshold of 2.6×10-7 m3/min1/2. From Table 1, the sorptivity index value for concrete structures having good protective

Table 3 Measured sorptivity indexes of PCCBs

quality ranges (1.30-2.60)×10-7 m3/min1/2. As a result, the protective quality of No.1 and No.2 PCCBs can be evaluated as “Very good” and “Good”, respectively, in terms of the sorptivity, and the in-service inspection of the protective quality of No.2 PCCB should be the focus.

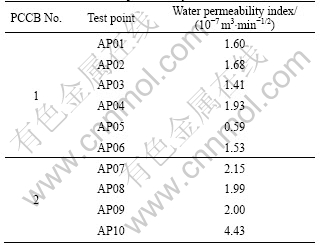

4.3 Water permeability

The measured water permeability indexes of the two PCCBs are listed in Table 4. Based on the criteria in terms of water permeability for evaluating the protective quality of concrete structures in Table 1, the measured water permeability indexes and the corresponding

Fig.5 Measured sorptivity indexes and corresponding protective qualities of two PCCBs: (a) No.1; (b) No.2

Table 4 Measured water permeability indexes of PCCBs

protective qualities for all the effective test points on the two PCCBs are illustrated in Fig.6.

It can be found from Table 4 that the average values of the water permeability indexes of No.1 and No.2 PCCBs are 1.46×10-7 and 2.64×10-7 m3/min1/2, respectively. For No.1 PCCB, the water permeability indexes for all the effective test points are much smaller than the threshold of 3.7×10-7 m3/min1/2. But for No.2 PCCB, the water permeability index for test point AP10 is relatively larger than the threshold of 3.7×10-7 m3/min1/2 and smaller than the threshold of 9.40×10-7 m3/min1/2. Table 1 shows that the water permeability index

Fig.6 Measured water permeability indexes and corresponding protective quality of two PCCBs: (a) No.1; (b) No.2

value for concrete structures having good protective quality ranges (3.70-9.40)×10-7 m3/min1/2. Consequently, the protective quality of No. 1 and No.2 PCCBs can be evaluated as “Very good” and “Good”, respectively, in terms of the water permeability, and the in-service inspection of the protective quality of No.2 PCCB should be strengthened.

5 Conclusions

1) The autoclam permeability system is used for measuring, on site, the air permeability, sorptivity and water permeability of the two PCCBs at a nuclear power plant in South China which has been under operation for 5 years. The practices show that the system is stable in its performance and easy to use and can be used for measuring the air permeability, sorptivity and water permeability of PCCBs.

2) The measured air permeability, sorptivity and water permeability indexes indicate that the protective qualities of No.1 and No.2 PCCBs are in very good and good grades, respectively, based on the criteria for evaluating the protective quality of concrete structures proposed by the research organization of the autoclam permeability system, and that more efforts should be put on the in-service inspection of No.2 PCCB at the plant in the future.

References

[1] International Atomic Energy Agency. Methodology for the management of ageing of nuclear power plant components important to safety [R]. Vienna: International Atomic Energy Agency, 1992.

[2] ZHENG Yan-guo, LI Hui-qiang. Ageing factors of prestressed concrete containment vessel in nuclear power plant [J]. Journal of Huazhong University of Science and Technology: Urban Science Edition, 2009, 26(4): 57-61. (in Chinese)

[3] YANG Lin, WANG Yong-huan, LIN Song-tao. Assessment and management of ageing of concrete containment building for nuclear power plants [J]. Industrial Construction, 2009, 39(Supplement): 1094-1106. (in Chinese)

[4] WANG Su-sheng. Ageing analysis and ageing detecting of concrete containment building for nuclear power plant [J]. Industrial Construction, 2009, 39(Supplement): 1085-1089. (in Chinese)

[5] US Nuclear Regulatory Commission Office of Nuclear Reactor Regulation. Generic aging lessons learned (GALL) report-summary [R]. Washington DC: Nuclear Regulatory Commission, 2001.

[6] US Nuclear Regulatory Commission Office of Nuclear Reactor Regulation. Generic aging lessons learned (GALL) report-tabulation of results [R]. Washington DC: Nuclear Regulatory Commission, 2001.

[7] International Atomic Energy Agency. Assessment and management of ageing of major nuclear power plant components important to safety: Concrete containment buildings (IAEA-TECDOC-1025) [S]. Vienna: International Atomic Energy Agency, 1998.

[8] BASHEER P A M, LONG A E, MONTGOMERY F R. The autoclam—A new test for permeability [J]. Concrete, 1994: 27-29.

[9] BASHEER P A M, MONTGOMERY F R, LONG A E. “CLAM” tests for measuring in-situ permeation properties of concrete [J]. Nondestr Test Eval, 1995, 12: 53-73.

[10] Structural Materials Research Group. Autoclam permeability system operating manual [R]. Northern Ireland: Department of Civil Engineering, Queen’s University, Belfast, U.K., 1994.

[11] LIU Jun, XING Feng, DONG Bi-qin. Research on relationship between pore structure and permeability [J]. Concrete, 2007(12): 35-41. (in Chinese)

[12] LIU Yun-hua. Study on the relationship between concrete permeability and deterioration [J]. Journal of Railway Science and Engineering, 2006, 3(1): 80-82. (in Chinese)

[13] JIN Wei-liang, ZHAO Yu-xi. State-of-the-art on durability of concrete structures [J]. Journal of Zhejiang University: Engineering Science, 2002, 36(4): 371-380. (in Chinese)

[14] HAO Ting-yu, HUI Yun-ling, MEI Ming-hu, SU Bo. Non-destructive testing of concrete durability in structures [J]. Journal of Southeast University: Natural Science Edition, 2006, 36(Suppl.II): 49-54.

[15] SONG Qi-ming, PENG Gai-fei, HAO Ting-yu. Surface permeability test of concrete [J]. Fujian Building Materials, 2006(4): 20-22. (in Chinese)

[16] BASHEER P A M, BASHEER L, NANUKUTTAN S. Role of in-situ measurement of transport properties of concrete on the assessment of its durability [C]// ACI/VCA International Symposium on Recent Advances in Concrete Technology and Sustainability Issues. Hanoi, Vietnam, 2009: 1-8.

[17] ELAHI A, BASHEER P A M, NANUKUTTAN S V, KHAN Q U Z. Mechanical and durability properties of high performance concretes containing supplementary cementitious materials [J]. Construction and Building Materials, 2010, 24(2): 292-299.

(Edited by YANG Bing)

Foundation item: Project(20050487017) supported by the Specialized Research Fund for the Doctoral Program of Higher Education of China; Project (2009567) supported by China National Nuclear Corporation

Received date: 2010-07-01; Accepted date: 2010-12-03

Corresponding author: LI Hui-qiang, Professor, PhD; Tel: +86-13511100163; E-mail: greensxg@126.com