文章编号:1004-0609(2014)11-2718-09

粗晶纯铝疲劳位错结构的热稳定性

郭巍巍1,齐成军1,颜 莹1,李小武1, 2

(1. 东北大学 理学院 材料物理与化学研究所,沈阳 110819;

2. 东北大学 材料各向异性与织构教育部重点实验室,沈阳 110819)

摘 要:在不同总应变幅下对高层错能粗晶纯铝进行疲劳实验直至达到近似相同的累积应变量,然后再在不同温度(200、330和450 ℃)进行退火处理。利用透射电子显微镜观察疲劳位错结构及其退火后微观结构的变化。结果表明:粗晶纯铝疲劳位错结构主要为胞结构,胞尺寸随着外加应变幅的升高逐渐减小,胞壁逐渐变得致密,胞内位错密度下降;粗晶纯铝疲劳处理后在3个温度下进行退火处理,所有样品的疲劳位错结构均发生明显的回复现象;只是在相对较低温度200 ℃退火时,低应变幅下形成的位错结构的回复机制主要为空位消失和异号位错相消,而中、高应变幅下位错结构的回复机制主要表现为多边形化回复机制。粗晶纯铝经不同总应变幅疲劳后的DSC曲线测量结果与TEM观察结果基本一致。

关键词:纯铝;疲劳位错结构;热稳定性;退火;回复

中图分类号:TG146

Thermal stability of fatigue dislocation structures in coarse-grained pure aluminum

GUO Wei-wei1, QI Cheng-jun1, YAN Ying1, LI Xiao-wu1, 2

(1. Institute of Materials Physics and Chemistry, College of Sciences, Northeastern University, Shenyang 110819, China;

2. Key Laboratory for Anisotropic and Texture of Materials, Ministry of Education, Northeastern University, Shenyang 110819, China)

Abstract: Coarse-grained pure Al with a high stacking fault energy was first fatigued at different total strain amplitudes (Dεt/2) up to almost the same accumulated strain, and then annealed at different temperatures (200, 330 and 450 ℃) for 30 min. The fatigue dislocation structures as well as the microstructural changes resulting from subsequent annealing treatments were detected by TEM. The results show that the dislocation structures of fatigued pure Al are mainly characterized by dislocation cells. With increasing Det/2, the average cell size decreases, the cell walls become more densified, and the density of dislocations in cells decreases. For the coarse-grained pure Al samples fatigued and then annealed at those three temperatures for 30 min, a clear recovery of fatigue dislocation structures occurs for all samples. The only difference exists in the recovery mechanism of the samples fatigued at different strain amplitudes and then annealed at a comparatively lower temperature of 200 ℃; for instance, the recovery process of dislocation structures induced by fatigue at lower strain amplitude is mainly determined by the disappearance of vacancies and the annihilation of dislocations of opposite sign, while the polygonization recovery dominates at higher strain amplitudes. The results of DSC measurements on the pure Al samples fatigued at different strain amplitudes are basically consistent with the results of TEM observations.

Key words: pure Al; fatigue dislocation structure; thermal stability; annealing; recovery

单晶、多晶纯铝作为典型的面心立方(FCC)金属晶体,其循环形变行为及微观位错结构得到了广泛的研究[1-7]。不同于铜晶体疲劳位错结构对外加应力幅或应变幅以及晶体取向具有强烈依赖性而呈现出明显不同特征(如脉络、驻留滑移带PSB楼梯、迷宫、位错胞和位错墙等)[8-9],铝的疲劳位错结构相对单一,主要由位错胞结构组成[6],这是由于铝晶体具有较高的层错能,使晶体中形成层错的难度增大,易于交滑移的发生,从而有助于多滑移系的开动和三维位错结构的形成[6]。一般认为,金属晶体在疲劳变形后形成的位错组态为低能位错结构[10-11],而与特定疲劳位错结构相关的能量问题是“位错理论”研究领域长期以来备受关注的课题,其中,对疲劳位错结构热稳定性的认识尚待深入。目前,关于FCC金属晶体疲劳位错结构退火后的热稳定性研究只在铜晶体方面有少量报道。例如,WANG[12]研究了平均晶粒尺寸约为80 mm的铜多晶体疲劳位错结构的热稳定性,他发现疲劳后的原始位错结构为墙结构和胞结构,在400 ℃退火30 min后仍可观察到清晰的PSB墙结构,基本保持了原始形态,位错墙之间的通道中出现了一些单个位错;当退火温度为620 ℃时,位错密度大幅下降,位错结构发生了明显的回复,但并没有发生再结晶现象。CHEN等[13]研究了[ ]单滑移取向铜单晶体的低周疲劳位错结构的热稳定性,观察到类似于再结晶行为的动力学现象,也没有再结晶现象的发生,只观察到了回复导致的位错网络结构。最近,郭巍巍等[14-15]系统研究了[

]单滑移取向铜单晶体的低周疲劳位错结构的热稳定性,观察到类似于再结晶行为的动力学现象,也没有再结晶现象的发生,只观察到了回复导致的位错网络结构。最近,郭巍巍等[14-15]系统研究了[ 18 41]单滑移取向以及[

18 41]单滑移取向以及[ ]共面双滑移取向铜单晶体在不同塑性应变幅下疲劳后位错结构的热稳定性。研究发现,当循环饱和后累积到较大的塑性应变量,所有疲劳后的样品在300 ℃退火后均发生了明显回复现象,而在500 ℃和800 ℃退火后则观察到严重的再结晶现象和退火孪晶。上述结果表明,疲劳位错结构的热稳定性不仅与外加应变幅和退火温度有关,而且与循环累积应变量密切相关。为了进一步揭示不同层错能FCC金属晶体材料疲劳位错结构及其热稳定性,本文作者选取具有高层错能(166 mJ/m2)的粗晶纯铝,研究其疲劳后的位错结构及其在不同温度退火后的变化。

]共面双滑移取向铜单晶体在不同塑性应变幅下疲劳后位错结构的热稳定性。研究发现,当循环饱和后累积到较大的塑性应变量,所有疲劳后的样品在300 ℃退火后均发生了明显回复现象,而在500 ℃和800 ℃退火后则观察到严重的再结晶现象和退火孪晶。上述结果表明,疲劳位错结构的热稳定性不仅与外加应变幅和退火温度有关,而且与循环累积应变量密切相关。为了进一步揭示不同层错能FCC金属晶体材料疲劳位错结构及其热稳定性,本文作者选取具有高层错能(166 mJ/m2)的粗晶纯铝,研究其疲劳后的位错结构及其在不同温度退火后的变化。

1 实验

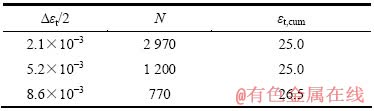

本实验中选取的粗晶纯铝的纯度为99.996%,对其进行形变量为60%的冷轧处理,然后进行再结晶退火,退火温度为350 ℃,保温时间为20 min,其轧面的金相组织(Optical microstructure, OM)如图1所示,可见晶粒尺寸在100~500 μm之间。疲劳试样由电火花线切割机加工而成,疲劳试样的总体尺寸为7 mm×7 mm×58 mm,标距区尺寸为7 mm×5 mm×10 mm。在进行疲劳实验之前,对粗晶纯铝样品进行电解抛光,消除试样表面的残余应变,以便进行接下来的疲劳实验和表面形貌观察。粗晶纯铝的对称拉-压疲劳实验于室温和空气环境中在型号为HUF-2020的CARE 20 kN电液伺服疲劳实验机上进行。实验采用总应变幅控制,控制信号为正弦波,频率0.5 Hz,选取低、中、高3个总应变幅,均循环到累积总应变量(et,cum=4NDεt/2)约为25时停止,具体实验参数如表1所列。

图1 粗晶纯铝轧面的OM像

Fig. 1 OM image of coarse-grained pure Al along rolling plane

表1 纯铝的疲劳试验条件和循环饱和数据

Table 1 Fatigue test conditions and cyclic saturation data of coarse-grained pure Al

循环变形试验后,利用扫描电子显微镜(SEM)观察纯铝样品表面变形及损伤形貌。然后利用电火花切割机沿垂直于加载轴方向在疲劳后试样标距区切出厚度约为0.5 mm的薄片若干,将这些样品平均分成4组,其中一组直接用于疲劳后微观位错结构的透射电子显微镜(TEM)观察,而另外3组则分别在200、330和450 ℃ 3个温度下进行真空等温退火,以观察疲劳位错结构在不同温度退火后的热稳定性。TEM样品经机械减薄到100 mm左右后用冲模获得直径3 mm的圆片,继续机械减薄到70 mm再进行电解双喷减薄,双喷液的成分如下:100 mL 硝酸和300 mL甲醇的混合溶液,电压为16 V,温度为-18 ℃。实验所用的透射电子显微镜为FEI公司的Tecnai G2 20型电镜。为了进一步考察疲劳后退火处理中样品的吸放热情况,对疲劳后样品进行了差式扫描量热仪(DSC)测试,通过DSC曲线来分析疲劳样品是否存在位错结构的临界转变温度。

2 结果与分析

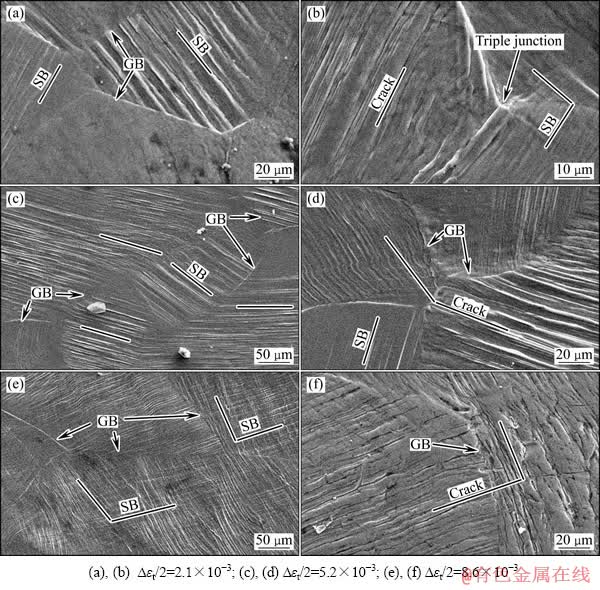

首先利用SEM对不同总应变幅下疲劳处理后粗晶纯铝的表面变形特征进行观察,其结果如图2所示。在低应变幅(Dεt/2=2.1×10-3)下,仅在部分取向晶粒内观察到滑移带(见图2(a)),由于滑移集中以及相邻晶粒之间的滑移带撞击使得晶界呈现凸起现象,部分塑性应变较大的晶粒内部甚至出现了沿滑带移轻微开裂的现象(见图2(b));随着总应变幅升高至中等应变幅(Dεt/2=5.2×10-3),绝大部分晶粒内可观察到位错滑移的开动,滑移带变得较为密集(见图2(c)),挤出侵入现象明显,毗邻晶粒内的滑移撞击更为严重,晶界凸起非常显著,在某些晶粒内部可明显观察到沿滑移带开裂的现象(见图2(d));经高应变幅(Dεt/2=8.6×10-3)疲劳后,表面损伤明显加剧,几乎所有晶粒内都出现密集的滑移带,而且在很多晶粒内可观察到双滑移现象(见图2(e))以及密集的沿滑移带开裂的现象(见图2(f))。尽管3个应变幅下的循环变形累积总应变量相近,但是由于总应变幅不同,每次循环所对应的塑性应变幅有所不同,随着总应变幅的增加,局部塑性形变越来越大,晶粒内开动的滑移就愈为密集,不同滑移系间的位错相互作用以及位错滑移与晶界之间的交互作用变得愈为强烈,导致滑移开裂现象更加显著。

图2 粗晶纯铝经不同总应变幅疲劳处理后表面损伤形貌的SEM像

Fig. 2 SEM images of surface deformation features of coarse-grained pure Al fatigued at different total strain amplitudes

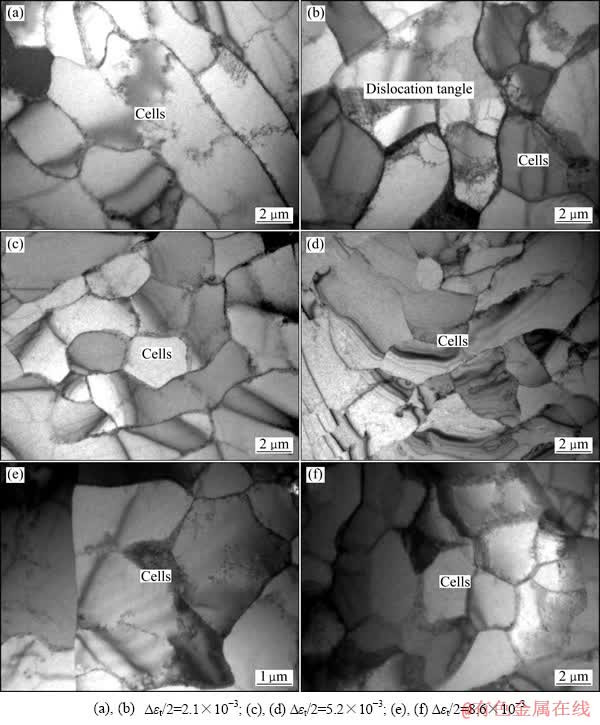

图3 经不同总应变幅疲劳处理后粗晶纯铝样品微观位错结构的TEM像

Fig. 3 TEM images of dislocation structures of coarse-grained pure Al specimens cycled at different total strain amplitudes

图3所示为粗晶纯铝经不同总应变幅疲劳后微观位错结构的TEM像。在低应变幅(Dεt/2=2.1×10-3)下疲劳处理后,纯铝的位错结构由大量的位错胞组成,平均胞尺寸在3~5 μm之间,一些胞内存在位错缠结,胞壁比较松散(见图3(a)和(b));中等应变幅(Dεt/2=5.2×10-3)下疲劳处理后位错结构仍以位错胞结构为主,但是此时胞内位错密度明显降低,胞壁变得致密,平均胞尺寸约在2~4 μm之间(见图3(c)和(d));当应变幅增加到Dεt/2=8.6×10-3,位错胞结构变得更加致密,平均胞尺寸继续减小至1~3 μm之间(见图3(e)和(f))。总之,经不同应变幅疲劳处理后纯铝疲劳位错结构均由位错胞结构组成,且随着应变幅的升高,位错胞结构的平均尺寸逐渐减小,胞壁逐渐变得致密,胞内位错密度逐渐下降。事实上,由于纯铝具有很高的层错能,其在循环变形过程中,在较低应力水平下就能开动交滑移,滑移位错之间发生相互作用后就会通过形成位错胞结构来屏蔽彼此之间的长程应力,随着导致新滑移位错产生所需流变应力的增加,位错胞尺寸会逐渐减小[16]。因此,随着应变幅的增加,循环流变应力增加,位错胞尺寸不断减小,胞壁变得致密以承担更高的塑性变形,这与高应变幅下严重的表面变形损伤(见图2(f))相对应。

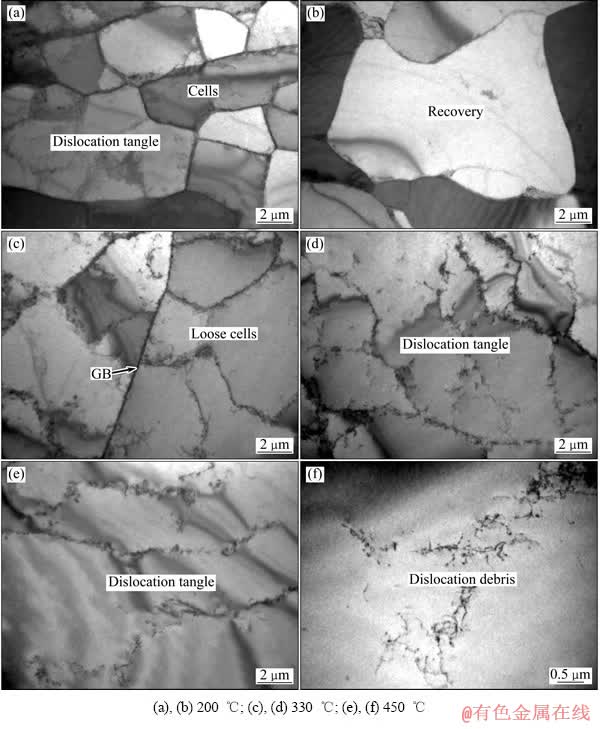

为了考察这种高层错能FCC金属材料疲劳位错结构的热稳定性,对粗晶纯铝疲劳处理后的样品分别在200、330和450 ℃下等温退火30 min,然后利用TEM 观察其在不同温度下退火后位错结构的变化,其结果如图4~6所示。

图4 Δεt/2=2.1×10-3时粗晶纯铝疲劳处理后在不同温度退火30 min微观结构的TEM像

Fig. 4 TEM images of dislocation structures of coarse-grained pure Al specimens cycled at Dεt/2=2.1×10-3 and then annealed at different temperatures for 30 min

图4所示为纯铝经低应变幅Dεt/2=2.1×10-3疲劳处理后分别在不同温度退火后的微观结构。低应变幅疲劳处理后纯铝的初始位错结构为松散的胞结构,胞内有松散的位错缠结(见图3(a)和(b))。200 ℃退火后发现位错结构发生了比较明显的回复,退火使得部分位错胞的胞壁变得疏松,位错胞因回复而合并成较大的胞结构,且胞内形成松散的位错结构(见图4(a)和(b));当退火温度为330 ℃时,由于温度升高,原子活性增大,在晶界附近可以观察到位错胞结构变得更加松散(见图4(c)),多数位错胞壁回复成松散的位错缠结(见图4(d));当退火温度达到450 ℃时,回复更加严重,位错胞壁由松散的位错缠结组成,变得隐约可见(见图4(e)),而且样品中整体位错密度大大下降,有些区域仅能观察到残留的位错碎片(见图4(f))。

粗晶纯铝经中等应变幅(Dεt/2=5.2×10-3)疲劳处理后再在不同温度下退火之后的微观结构如图5所示。当退火温度为200 ℃时,观察到了典型的多边形化回复现象(见图5(a))。中等应变幅循环变形之后位错分布不均匀,大多塞积在位错胞壁,退火时,螺位错的交滑移和刃位错的攀移引起位错的重新分布和部分消失以及位错胞壁的平直化,形成了较平直的亚晶界,此时由空间位错网络所分开的位错胞就转化为由更规则、更薄而较平直的亚晶界所分开的亚晶,亚晶粒内部还可以观察到正在回复消散的位错胞(见图5(b))。330 ℃退火后与低应变幅中等温度退火实验结果相似,在此温度下出现了异号位错对消,使得位错密度下降,胞壁变得松散(见图5(c))。并且出现了类似于低温退火时的亚晶界,这表明也有胞壁多边形化回复发生(见图5(d))。当退火温度进一步升高到450 ℃时,可以观察到胞壁位错缠结已经变得相当松散,位错密度下降明显,发生了很严重的回复现象(见图5(e)和(f)),这与低应变幅样品的高温退火结果基本一致。

图5 Δεt/2=5.2×10-3时粗晶纯铝疲劳后在不同温度退火30 min微观结构的TEM像

Fig. 5 TEM images of dislocation structures of coarse-grained pure Al specimens cycled at Dεt/2=5.2×10-3 and then annealed at different temperatures for 30 min

粗晶纯铝高应变幅(Dεt/2=8.6×10-3)下疲劳位错结构经不同温度退火后变化的规律(见图6)与中等应变幅(Dεt/2=5.2×10-3)下疲劳位错结构退火的热稳定性变化规律(见图5)非常类似。在低温200 ℃下退火后,可以观察到胞壁平直化,出现了多边形化回复现象,有类似亚晶存在,但并没有再结晶现象发生(见图6(a)和(b))。中等温度(330 ℃)退火后,纯铝样品中胞壁位错密度下降,变成了松散的胞结构或者松散的位错缠结(见图6(c)和(d))。而经高温450 ℃退火后,发生了比较严重的回复现象,胞壁变得完全散乱,可观察到凌乱的位错线(见图6(e)和(f))。

图6 Δεt/2=8.6×10-3时粗晶纯铝疲劳处理后在不同温度退火30 min微观结构的TEM像

Fig. 6 TEM images of dislocation structures of coarse-grained pure Al specimens cycled at Dεt/2=8.6×10-3 and then annealed at different temperatures for 30 min

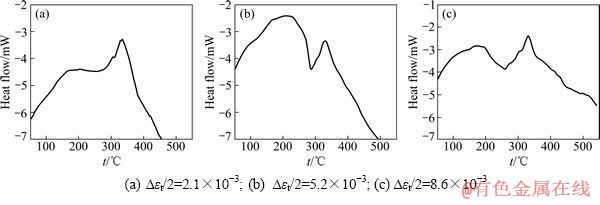

图7 粗晶纯铝经不同总应变幅循环变形后的DSC曲线

Fig. 7 Typical DSC plots for cyclically deformed pure Al specimens at different total strain amplitudes

为了探究疲劳后纯铝样品随退火温度升高的吸放热情况,对疲劳后的纯铝样品进行了DSC测试,其结果如图7所示。显然,所有样品在300~400 ℃之间均有一个明显的较宽的放热峰,在350 ℃左右出现峰值,这表明在这个温度范围内,所有疲劳试样均发生了储存能的大量释放,位错结构发生了明显的回复现象。对比于在330和450 ℃下退火后TEM的观察结果可以发现,在这两个温度下位错结构的确发生了非常明显的回复现象,特别是经450 ℃退火后,位错密度急剧下降,回复非常严重。值得注意的是,经中、高应变幅疲劳后的样品相比于低应变幅下疲劳的样品,在150~250 ℃之间出现了一个宽化峰,这表明在这个温度范围内中、高应变幅疲劳样品有一定热量释放,位错结构发生了明显的变化,与低应变幅下的疲劳样品的低温回复机制有所不同。实际上,TEM观察已表 明,中、高应变幅低温退火时的确出现多边形化回复现象,这正好对应于150~250 ℃宽化峰的出现。

3 讨论

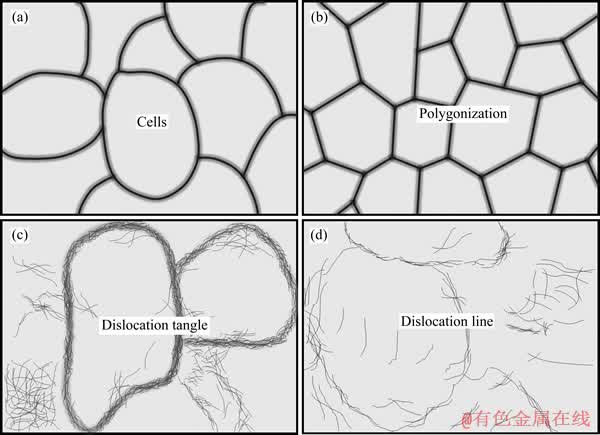

不同应变幅下疲劳处理后的粗晶纯铝样品在不同温度退火后,其位错结构的热稳定性呈现出一定的规律性和特殊性。所有样品的疲劳微观结构均发生了明显的退火回复现象,且随着退火温度的升高回复愈为严重。这表明高层错能材料在疲劳后形成的所谓的低能位错胞结构,其退火热稳定性也是有限的。图8所示为粗晶纯铝疲劳位错结构经退火处理后的回复特征示意图。纯铝疲劳后再在相对较低的温度200 ℃退火处理后,不同应变幅下疲劳样品表现出了不同的回复机制:1) 低应变幅疲劳样品观察到的是回复的位错胞结构(见图8(a)),在某些大位错胞之内,松散的位错已经完全湮灭消失,位错密度很低,其回复机制主要是空位的消失和异号位错的对消[18]。空位消失主要有以下两种方式:其一,由于退火时原子活性增大,位错与空位的运动加强,导致位错与空位结合而引起位错发生正攀移,空位消失;其二,空位之间集聚成空位片,然后崩塌转化为位错环,空位消失。2) 中、高应变幅疲劳样品观察到的是多边形化机制[18](见图8(b))。这是由于局部塑性变形较大(见图2(c)~(f)),在低温退火时原子活性相对较低的前提下,螺位错的交滑移和刃位错的攀移就能出现,引起位错的重新分布和部分消失以及位错胞壁的平直化,形成了具有高曲率较平直的亚晶界,此时由空间位错网络所分开的位错胞就转化为由更规则且平直的亚晶界所分开的亚晶。这种多边形化现象实际上可为再结晶形核提供核心,但在该条件下并未发生真正的再结晶现象,这是由于在中和高应变幅下,疲劳过程中动态回复的发生,以及高温退火升温过程中所发生的多边形化,都会释放一部分应变能,从而降低了再结晶的驱动力,因此,未观察到再结晶的发生。在中、高温度330和450 ℃退火处理后,所有应变幅下疲劳处理后的纯铝样品都表现出相同的回复特性。即在中等温度退火,由于温度升高,原子活性增大,位错胞结构因空位消失而演变成松散的位错缠结(见图8(c));在较高的温度退火处理时,发生显著的异号位错的对消,使得位错密度明显下降。同一滑移面上的异号位错在热激活作用下,相互吸引、会聚而消失,不在同一滑移面上的异号刃型位错则通过空位集聚消除半原子面或空位逃逸制造半原子面而消失,多数位错胞壁最终回复成为松散的位错缠结或位错线(见图8(d))。

图8 不同应变幅下疲劳后粗晶纯铝微观结构再经退火处理后发生回复的特征示意图

Fig. 8 Schematic diagram of microstructures in cyclically deformed pure Al at different total strain amplitudes (a) Low strain amplitude, 200 ℃; (b) Medium strain and high strain amplitudes, 200 ℃; (c) All strain amplitudes, 330 ℃; (d) All amplitudes, 450 ℃

4 结论

1) 粗晶纯铝经低、中、高应变幅疲劳处理后,位错结构均主要为胞结构。随着外加总应变幅的升高,位错胞尺寸逐渐减小,胞壁逐渐变致密,胞内位错密度逐渐下降。

2) 粗晶纯铝经低、中、高3个恒总应变幅循环变形,然后分别在200、330和450 ℃下等温退火30 min。所有样品在各温度均发生了明显的回复现象,但都没有观察到再结晶的发生。

3) 粗晶纯铝疲劳处理后再在相对较低的温度200℃退火处理后,低应变幅下疲劳处理后的样品的回复机制主要为空位的消失和异号位错的对消,而在中、高应变幅下疲劳处理后的样品由于局部塑性变形比较大,除了以上回复方式之外存在多边形化回复机制,这正好对应于DSC曲线中出现的150~250 ℃宽化峰。

REFERENCE

[1] VORREN O, RYUM N. Cyclic deformation of al-single crystals at low constant plastic strain amplitudes[J]. Acta Metallurgica, 1987, 35(4): 855-866.

[2] VORREN O, RYUM N. Cyclic deformation of al single crystals: effect of the crystallographic orientation[J]. Acta Metallurgica, 1988, 36(6): 1443-1453.

[3] VIDEM M, RYUM N. Cyclic deformation of [001] aluminium single crystals[J]. Mater Sci Eng A, 1996, 219(1/2): 1-10.

[4] VIDEM M, RYUM N. Cyclic deformation and fracture of pure aluminium polycrystals[J]. Mater Sci Eng A, 1996, 219(1/2): 11-20.

[5] 刘国东, 朱振刚, 王 静. 高纯铝单晶在拉压疲劳早期过程中的行为[J]. 金属学报, 1996, 32(5): 510-515.

LIU Guo-dong, ZHU Zhen-gang, WANG Jing. Behavior of Al single crystal during early stage of push-pull fatigue[J]. Acta Metall Sin, 1996, 32(5): 510-515.

[6] EL-MADHOUN Y, MOHAMED A, BASSIM M N. Cyclic stress-strain response and dislocation structures in polycrystalline aluminum[J]. Mater Sci Eng A, 2003, 359: 220-227.

[7] FUJII T, SAWATARI N, ONAKA S, KATO M. Cyclic deformation of pure aluminum single crystals with double-slip orientations[J]. Mater Sci Eng A, 2004, 387/389: 486-490.

[8] LI X W, HU Y M, WANG Z G. Investigation of dislocation structure in a cyclically deformed copper single crystal using electron channeling contrast technique in SEM[J]. Mater Sci Eng A, 1998, 248: 299-303.

[9] LI, X W, UMAKOSHI Y, GONG B, LI S X, WANG Z G. Dislocation structures in fatigued critical and conjugate double-slip-oriented copper single crystals[J]. Mater Sci Eng A, 2002, 333: 51-59.

[10] KUHLMAN-WILSDORF D, COMINS N R. Dislocation cell formation and work hardening in the unidirectional glide of f.c.c. metals I: Basic theoretical analysis of cell walls parallel to the primary glide plane in early stage II[J]. Mater Sci Eng, 1983, 60(1): 7-24.

[11] KUHLMAN-WILSDORF D. Deformation bands, the LEOS theory and their importance in texture development[J]. Phil Mag A, 1999, 79: 955-1008.

[12] WANG Z R. Experimental study of the thermal stability of dislocation structures produced through cyclic deformation in copper polycrystals[J]. Scripta Mater, 1998, 39(1): 493-500.

[13] CHEN S, GOTTSTEIN S. Recoery in low -cycle-fatigued copper single crystals[J]. Mater Sci Eng, 1989, 110(8): 9-11.

[14] 郭巍巍, 齐成军, 李小武. 一个共面双滑移取向铜单晶体疲劳位错结构的热稳定性研究[J]. 金属学报, 2013, 49(1): 107-114.

GUO Wei-wei, QI Cheng-jun, LI Xiao-wu. Investigations on thermal stability of fatigue dislocation structures in a double-slip-oriented Cu single crystal[J]. Acta Metall Sin, 2013, 49(1): 107-114.

[15] 郭巍巍, 任 焕, 齐成军, 李小武. 一个单滑移取向铜单晶体疲劳位错结构的热稳定性研究[J]. 物理学报, 2012, 61(15): 156201-1-156201-8.

GUO Wei-weu, REN Huan, QI Cheng-jun, LI Xiao-wu. Investigations on the thermal stability of fatigue dislocation structures in a single-slip-oriented Cu single crystals[J]. Acta Phys Sin, 2012, 61(15): 156201-1-156201-8.

[16] KUHLMANN-WILSDORF D. A critical test on theories of work-hardening for the case of drawn iron wire[J]. Metall Trans, 1970, 1(11): 3173-3179.

[17] CHICOIS J, FOUGERES R, GUICHON G, HAMEL A, VINCENT A. Mobilite des dislocations lors de la sollicitation cyclique de l'aluminium polycristallin[J]. Acta Metallurgica, 1986, 34: 2157-2170.

[18] 李 超. 金属学原理[M]. 哈尔滨工业大学出版社, 1966: 291-293.

LI Chao. Principles of Metallography[M]. Harbin: Harbin Institute of Technology Press, 1966: 291-293.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51071041,51271054,51231002);中央高校基本科研业务费(N110105001,N120505001);高等学校博士学科点专项科研基金资助项目(20110042110017)

收稿日期:2013-12-20;修订日期:2014-07-20

通信作者:李小武,教授,博士;电话:024-83678479;E-mail:xwli@mail.neu.edu.cn