DOI:10.19476/j.ysxb.1004.0609.2019.10.01

固相合成法制备Al2O3亚微米颗粒增强AZ31复合材料及强化机理

胡茂良,魏帅虎,吉泽升,许红雨,王 晔

(哈尔滨理工大学 材料科学与工程学院,哈尔滨 150040)

摘 要:采用固相合成方法制备Al2O3亚微米颗粒增强AZ31镁基复合材料,利用OM、SEM、TEM对Al2O3/AZ31镁基复合材料进行组织观察,利用维氏硬度仪、电子万能拉伸试验机对Al2O3/AZ31镁基复合材料进行力学性能测试。结果表明:经过固相合成后,Al2O3亚微米颗粒均匀的分布在AZ31基体中,通过对基体位错运动的钉扎作用,使该区域的位错密度增加,促进动态再结晶形核,复合材料的晶粒被显著细化。Al2O3/AZ31复合材料的力学性能随着Al2O3亚微米颗粒含量的增加而提高,当Al2O3颗粒含量为2%时,复合材料的力学性能达到最大值,其硬度、抗拉强度、屈服强度和伸长率分别为83HV、302 MPa、203 MPa和8.15%。

关键词:固相合成;AZ31镁基复合材料;力学性能;强化机理;显微组织

文章编号:1004-0609(2019)-10-2217-08 中图分类号:TG146.2 文献标志码:A

镁及镁合金是目前工业领域最轻的结构工程材料之一,具有密度低、比强度和比刚度高,电磁屏蔽性能好等特点,被广泛的应用在航空航天、汽车、数码3C等领域[1-3]。然而,由于镁合金属于密排六方结构,室温下的滑移面较少,导致其力学性能差,在一定程度上限制了镁及镁合金的发展[4]。陶瓷颗粒具有硬度大、弹性模量高等特点,常被用来作为增强相。通过添加陶瓷颗粒制备镁基复合材料,能够提高镁合金的力学性能,扩大镁合金的应用领域。

对于颗粒增强镁基复合材料,颗粒尺寸对复合材料的组织和力学性能影响较大[5]。微米级的颗粒增强相,能够通过阻碍晶界运动,起到细化晶粒的作用,提高了复合材料的屈服强度和抗拉强度,但其塑性较低[6]。相比于微米级颗粒,亚微米级的颗粒增强相,能够通过钉扎位错,起到细化晶粒的作用,在有效提高复合材料的力学性能的同时,提高了复合材料的塑性[7]。PARAMSOTHY等[8]利用DMD技术将50 nm的Al2O3颗粒加入到AZ31和ZK60镁合金中,成功制备出纳米级Al2O3颗粒增强的镁基复合材料。加入Al2O3颗粒后,镁基体的晶粒显著细化,力学性能得到显著提高,其硬度由64HV提升到83HV,抗拉强度由263 MPa升高到317 MPa。盛绍顶等[9]利用快速凝固结合粉末冶金法制备了Al2O3颗粒增强AZ91镁基复合材料,Al2O3颗粒在镁基体中均匀分布,复合材料的性能得到较大提高。PRASAD等[10]利用粉末冶金法制备了Al2O3/Mg复合材料,研究了高温下复合材料的应力应变,在高应力下,复合材料的变形行为与基体的变形行为相似,当加载应力较低时,其复合材料的变形行为与基体的变形行为不同。HABIBNEJAD- KORAYEM等[11]采用熔铸法制备了Al2O3/AZ31镁基复合材料,当Al2O3颗粒含量为2%时复合材料的力学性能达到最佳值。范艳艳等[12]将30 nm的Al2O3颗粒作为增强相加入到AZ91D中,利用搅拌铸造法制备了Al2O3/AZ91D镁基复合材料,由于Al2O3颗粒的存在,致使镁基体的晶粒显著细化,从而使复合材料的性能得到提高。

近年来,多数研究学者采用传统的熔铸法、粉末冶金法和快速凝固法来制备Al2O3/Mg镁基复合材料,然而传统的方法存在制备工艺复杂、原料烧损、成本高等问题。固相合成法是将镁屑与增强颗粒经过机械混合后,在一定压力下冷压成坯,然后加热到一定温度,热挤成形,并最终得到复合材料。该方法制备工艺简单、成本低廉、能够有效的避免了原料的烧损等问题。武淑艳等[13]利用固相合成法将回收的AZ31屑料制备成合金,并分析了屑料对AZ31镁合金的组织与力学性能的影响。文丽华等[14]利用固相合成法制备了Mg-Nd-Zn-Zr镁合金,并研究了时效对该合金的组织与性能的影响。然而,很少有研究学者利用固相合成法制备镁基复合材料,因此,本研究采用固相合成法制备尺寸为500 nm的Al2O3颗粒增强AZ31镁基复合材料,并研究不同含量Al2O3颗粒对复合材料的组织与力学性能的影响。

1 实验

1.1 试验材料

本试验选用东北轻合金有限公司生产的AZ31镁合金作为镁基体,其具体化学成分如表1所列,Al2O3颗粒增强相选用河南洛阳兄弟耐火材料有限公司生产的Al2O3陶瓷颗粒,其平均粒径大小为500 nm。

表1 AZ31镁合金化学成分

Table 1 Chemical composition of AZ31 magnesium alloy (mass fraction, %)

1.2 试验方法

AZ31镁锭进行切屑加工,切屑加工成长3.50~ 5.45 mm,宽1.40~2.85 mm,厚度为0.15~0.55 mm的长条状碎屑,然后将AZ31镁屑料与500 nm的Al2O3颗粒放入行星式球磨机中,在氩气氛围下球磨3 h,球磨机的转速设定为150 r/min。将球磨后的混合料装入冷压模具中,在室温下,压力为650 MPa,保压15 s后,制成直径为40 mm,高为40 mm的圆柱坯料。最后将得到的坯料放入热挤压模具中,其中,在热挤压之前需要在模具外层涂抹石墨,以减小与套筒之间的摩擦力,然后加热到400 ℃,保温20 min后,在压力为600 MPa,挤压速度为2 mm/s,挤压比为25:1的条件下热挤出直径为8 mm的棒材,得到Al2O3颗粒增强的镁基复合材料。

1.3 分析测试

利用OLYMPUS-GX71-6230A型号的金相显微镜和FEI-SIRION型号的扫描电镜对Al2O3/AZ31复合材料进行显微组织观察和分析,其中测试试样须经过机械抛光和腐蚀。采用万能电子拉伸实验机和维氏显微硬度仪对复合材料进行力学性能测试和硬度测试。其中拉伸测试和硬度测试时,每组实验测试3个点,取平均值以保证数据的准确性。利用Image-Pro Plus 软件分析测量Al2O3/AZ31复合材料的晶粒大小分布情况。

2 实验结果

2.1 微观组织分析

图1 Al2O3/AZ31复合材料的微观组织形貌

Fig. 1 Optical microstructures of Al2O3/AZ31 composites paralleling to extrusion direction

图1所示为不同含量的Al2O3亚微米颗粒增强 AZ31镁基复合材料的微观组织形貌。如图1(a)所示,当未添加Al2O3颗粒时,AZ31镁基体的晶粒大部分为粗大变形的,存在少量的再结晶小晶粒。如图1(b)所示,当添加0.5%的亚微米级Al2O3颗粒时,复合材料的晶粒被细化,且在大的变形晶粒周围开始出现“项链状”再结晶小晶粒。由于亚微米级的Al2O3颗粒存在,对基体中的位错运动起到钉扎作用[15],促使该区域的位错密度增大,形成高密度位错区,该区域促进了动态再结晶形核,并最终使复合材料的晶粒被细化。如图1(c)所示,随着Al2O3颗粒含量的增加,复合材料的晶粒尺寸逐渐降低,其再结晶小晶粒逐渐增多。当Al2O3颗粒含量为2%时,动态再结晶充分发生,粗大晶粒被细化,复合材料的晶粒尺寸显著减小,如图1(d)所示。由于Al2O3颗粒含量的增加,其在镁基体中的分布更加均匀,导致其钉扎效果更加显著,使复合材料的晶粒被显著细化。

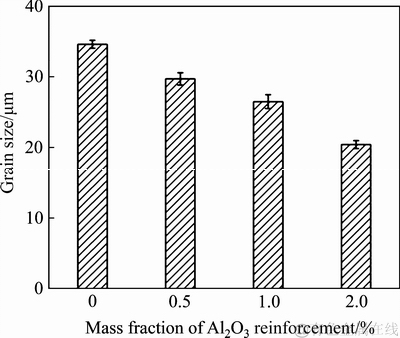

图2所示为不同含量的Al2O3/AZ31复合材料的平均晶粒尺寸。如图2所示,当未添加Al2O3颗粒时,AZ31镁基体的晶粒大小为34.56 μm。当添加Al2O3颗粒后,复合材料的晶粒被显著细化。当Al2O3颗粒含量为0.5%和1%时,复合材料的晶粒大小为29.67 μm和26.45 μm,相比于AZ31镁基体,其晶粒尺寸分别下降了14.14%和23.46%。当Al2O3颗粒含量为2%时,复合材料的晶粒达到最小20.38 μm,相比于AZ31镁基体,其晶粒尺寸下降了41.03%。一方面由于亚微米Al2O3颗粒的存在,对复合材料中的位错运动起到钉扎作用,且伴随着Al2O3颗粒含量的增加,其钉扎作用逐渐增强,对位错运动的阻碍增大,并最终提高了该区域的位错密度,高密度位错区能够有效地促进再结晶形核,从而使复合材料的晶粒被显著细化;另一方面,由于Al2O3颗粒含量的增加,其在基体中的分布逐渐均匀,从而起到了弥散强化的作用。

图2 Al2O3/AZ31复合材料的平均晶粒尺寸

Fig. 2 Statistical grain size distributions of Al2O3/AZ31 composites

图3所示为2%含量的Al2O3/AZ31复合材料的SEM像。如图3(a)所示,固相合成后,亚微米级的Al2O3颗粒均匀的分布在AZ31镁基体中。Al2O3颗粒与AZ31镁基体的界面结合是完好的,没有微裂纹和微孔产生。在Al2O3颗粒周围,存在动态再结晶的晶粒,如图3(b)所示。图3(c)所示为图3(b)中点C的能谱分析,白色颗粒为添加的Al2O3颗粒增强相。图3(d)所示为图3(a)中直线A的线扫描分析,其结果进一步证明了图中白色颗粒为Al2O3颗粒。由于镁合金滑移系少,层错能低,晶界扩散速率高,位错易塞积,在热挤压过程中容易产生高密度位错区,且在热挤压过程中,达到了镁合金的再结晶温度区间,促使了复合材料发生再结晶。同时,在热挤压过程中,由于亚微米级的Al2O3颗粒存在,使复合材料发生晶格畸变,造成该区域的应力集中,复合材料释放应力形成位错,Al2O3颗粒对位错运动起到钉扎作用,促使该区域的位错密度不断累积,最终形成高密度位错区,该区域促进了动态再结晶的形核并发生再结晶现象。

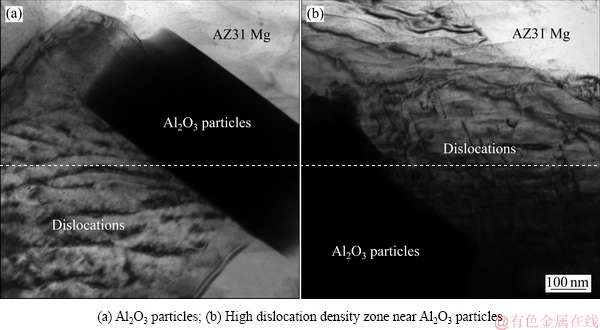

图4所示为含 2%Al2O3的Al2O3/AZ31复合材料的TEM像。复合材料经过固相合成后,在Al2O3颗粒周围,形成了高密度的位错区域。该区域形成的主要原因:一方面,在固相合成过程中,由于亚微米级的Al2O3颗粒的存在,对复合材料中位错的运动起到钉扎作用,使该区域的位错密度逐渐累积并形成高密度位错区;另一方面,由于Al2O3颗粒与AZ31镁基体在力学和热力学上的不匹配,导致在Al2O3颗粒与AZ31镁基体的界面结合处会产生热错配残余应力,该应力的存在促进了位错的形成,且伴随着热挤压过程,其应力不断增加,并最终在Al2O3颗粒周围形成高密度位错区[16]。该区域被誉为再结晶形核的理想场所,能够有效地促进动态在结晶的形核,使复合材料的晶粒被显著细化。

2.2 力学性能分析

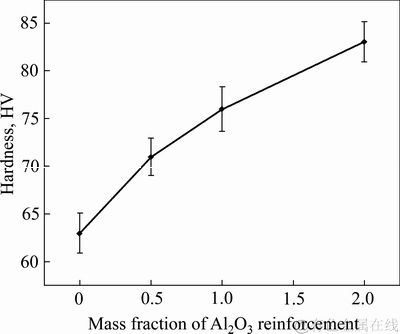

图5所示为不同含量的Al2O3/AZ31复合材料的维氏硬度。随着Al2O3颗粒含量的增加,复合材料的硬度显著提高。当Al2O3颗粒含量为2%时,复合材料的硬度达到最大值83HV,相比于未添加Al2O3颗粒时,复合材料的硬度提高了31.74%。复合材料硬度增加的主要原因:Al2O3颗粒在AZ31镁基体中的均匀分布,起到了弥散强化的作用。此外,由于Al2O3颗粒的存在,对复合材料中的位错运动起到了钉扎作用,从而使复合材料的晶粒被显著细化,起到了细晶强化的作用,且Al2O3颗粒属于陶瓷颗粒,其具有较高的强度和硬度,在复合材料承受较大的载荷时,能够有效地承担较大的载荷,起到载荷转移的作用[17]。

图3 Al2O3/AZ31复合材料的SEM像和能谱分析结果

Fig. 3 SEM micrographs and EDS analysis results of Al2O3/AZ31 composites by solid-phase synthesis

图4 Al2O3/AZ31复合材料的TEM像

Fig. 4 TEM images of Al2O3/AZ31 composites

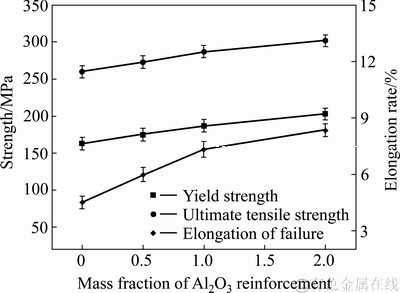

图6所示为不同含量的Al2O3/AZ31复合材料的屈服强度、抗拉强度、伸长率。如图6所示,随着Al2O3颗粒含量的增加,其复合材料的屈服强度、抗拉强度、伸长率逐渐提高。当未添加Al2O3颗粒时,AZ31镁基体的抗拉强度、屈服强度和伸长率分别为260 MPa、163 MPa和4.5%;当Al2O3颗粒含量为2%时,复合材料的抗拉强度、屈服强度和伸长率分别达到最大值302 MPa、203 MPa和8.15%,相比于AZ31镁基体,分别提高了16.15%、24.54%和81.11%。由此可知,随着亚微米Al2O3颗粒的加入,复合材料的抗拉强度和屈服强度提高的同时,其伸长率得到较大提高。

图5 Al2O3/AZ31复合材料的维氏硬度

Fig. 5 Vickers hardness of Al2O3/AZ31 composites

图6 Al2O3/AZ31复合材料的强度及伸长率

Fig. 6 Strength and elongation rate of Al2O3/AZ31composites

3 分析与讨论

由于亚微米级Al2O3颗粒的存在,从而使Al2O3/ AZ31复合材料的力学性能得到显著提高。首先要归因于载荷转化。由于Al2O3颗粒具有高的硬度和弹性模量,在复合材料承受较大的应力时,能够有效地分担载荷,从而提高复合材料的屈服强度。载荷转化对复合材料屈服强度的影响可以通过式(1)计算[18]:

(1)

(1)

式中: 表示AZ31镁合金的屈服强度为163 MPa;

表示AZ31镁合金的屈服强度为163 MPa; 表示含量为2%的Al2O3颗粒的体积分数为0.54%,因此,通过式(1)计算可知,通过载荷转化复合材料的屈服强度提高0.44 MPa。

表示含量为2%的Al2O3颗粒的体积分数为0.54%,因此,通过式(1)计算可知,通过载荷转化复合材料的屈服强度提高0.44 MPa。

在热挤压过程中,由于Al2O3颗粒与AZ31镁基体在力学和热力学上的不匹配( ),在界面处会产生热错配残余应力,导致在Al2O3颗粒周围可以形成高密度位错区,从而提高了复合材料的屈服强度。

),在界面处会产生热错配残余应力,导致在Al2O3颗粒周围可以形成高密度位错区,从而提高了复合材料的屈服强度。 对复合材料屈服强度的提高可以通过式(2)计算[19-20]:

对复合材料屈服强度的提高可以通过式(2)计算[19-20]:

(2)

(2)

式中: 表示AZ31镁合金与Al2O3颗粒之间热膨胀系数之差为25.26×10-5 ℃-1;

表示AZ31镁合金与Al2O3颗粒之间热膨胀系数之差为25.26×10-5 ℃-1; 表示热加压温度与室温的差值为375 ℃;b表示镁的晶格常数为0.321 nm;G表示为AZ31镁合金的剪切模量16.6 GPa;

表示热加压温度与室温的差值为375 ℃;b表示镁的晶格常数为0.321 nm;G表示为AZ31镁合金的剪切模量16.6 GPa; 设为常数1;D和Vp分别表示Al2O3颗粒的平均直径和所占的体积分数分别为500 nm和0.54%。因此,通过式(2)计算可知,通过位错强化机制使复合材料的屈服强度提高20.37 MPa

设为常数1;D和Vp分别表示Al2O3颗粒的平均直径和所占的体积分数分别为500 nm和0.54%。因此,通过式(2)计算可知,通过位错强化机制使复合材料的屈服强度提高20.37 MPa

固相合成过程中,由于Al2O3颗粒的存在,使Al2O3/AZ31复合材料的晶粒得到显著细化,从而起到了细晶强化的作用,使复合材料的屈服强度得到有效提高。细晶强化对复合材料屈服强度的提高可以通过Hall-Patch式(3)计算[21]:

(3)

(3)

式中: 和

和 分别表示复合材料和AZ31镁基体的平均晶粒大小分别为20.38 μm和34.56 μm;K表示Hall-Patch系数为0.13 MPa·m1/2。

分别表示复合材料和AZ31镁基体的平均晶粒大小分别为20.38 μm和34.56 μm;K表示Hall-Patch系数为0.13 MPa·m1/2。

通过式(3)计算可知,通过细晶强化使复合材料的屈服强度提高了6.76 MPa。对于亚微米级颗粒可以增强金属基复合材料,存在Orowan强化机制( ),能够有效地提高复合材料的屈服强度。Orowan强化机制对复合材料屈服强度的提高可以通过公式Orowan- Ashby(4)计算[22-23]:

),能够有效地提高复合材料的屈服强度。Orowan强化机制对复合材料屈服强度的提高可以通过公式Orowan- Ashby(4)计算[22-23]:

(4)

(4)

因此,通过式(4)计算可得,利用Orowan强化机制可以使复合材料的屈服强度提高9.26 MPa。颗粒增强金属基复合材料的理论屈服强度可以通过式(5)计算[24]:

(5)

(5)

式中: 表示复合材料的理论屈服强度;A和B分别表示

表示复合材料的理论屈服强度;A和B分别表示 和

和 强化;0.5Vp表示载荷转化作用。

强化;0.5Vp表示载荷转化作用。

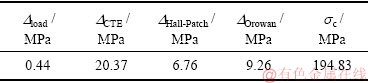

表2所列为通过 、

、 、

、 和

和 强化的计算值和复合材料的理论屈服强度。由表2可知,复合材料的理论屈服强度和实验值存在一定的差值,其差值为8.17 MPa,造成差值的原因可能为由于亚微米级的Al2O3颗粒的存在,对复合材料的晶粒起到一定的影响,从而使实验值高于理论计算值。由此可知,对于亚微米级Al2O3颗粒增强AZ31镁基复合材料,通过

强化的计算值和复合材料的理论屈服强度。由表2可知,复合材料的理论屈服强度和实验值存在一定的差值,其差值为8.17 MPa,造成差值的原因可能为由于亚微米级的Al2O3颗粒的存在,对复合材料的晶粒起到一定的影响,从而使实验值高于理论计算值。由此可知,对于亚微米级Al2O3颗粒增强AZ31镁基复合材料,通过 、

、 、

、 和

和 强化机理,能够有效地提高复合材料的屈服强度。

强化机理,能够有效地提高复合材料的屈服强度。

表2 Al2O3/AZ31复合材料屈服强度的理论计算值

Table 2 Calculated value of Al2O3/AZ31 composites yield strength

4 结论

1) 固相合成法可以制备Al2O3亚微米颗粒增强AZ31镁基复合材料,且Al2O3颗粒均匀地分散在AZ31镁基体中,复合材料晶粒被显著细化。

2) Al2O3/AZ31复合材料的力学性能随着Al2O3颗粒含量的增加而提高。当Al2O3颗粒含量为2%时,复合材料的性能达到最大值,其硬度、抗拉强度、屈服强度和伸长率分别为83HV、302 MPa、203 MPa和8.15%。

3) 由于Al2O3颗粒的存在,对位错运动起到了钉扎效果,促进了动态再结晶形核,从而使复合材料晶粒被细化。通过 、

、 、

、 和

和 强化机理,复合材料的屈服强度得到显著提高。

强化机理,复合材料的屈服强度得到显著提高。

REFERENCES

[1] 盛绍顶, 陈 鼎, 陈振华, 陈 刚, 严红革. 快速凝固/粉末冶金AZ91/SiCp镁基复合材料的相组成及界面[J]. 中国有色金属学报, 2008, 18(7): 1185-1190.

SHENG Shao-ding, CHEN Ding, CHEN Zhen-hua, CHEN Gang, YAN Hong-ge. Phase composition and interface of rapidly solidified/powder metallurgy AZ91/SiCp Mg-based composite material[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(7): 1185-1190.

[2] 胡 志, 闫 洪, 聂 俏, 凌李石保. 超声法制备纳米SiC颗粒增强AZ61镁基复合材料的显微组织[J]. 中国有色金属学报, 2009, 19(5): 841-846.

HU Zhi, YAN Hong, NIE Qiao, LING Li-shi-bao. Microstructure of SiC nanoparticles reinforced AZ61 magnesium composites fabricated by ultrasonic method[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(5): 841-846.

[3] 吴国华, 肖 寒, 周慧子, 王瑞雪, 程 明, 张士宏. 挤压态AZ31镁合金温热拉伸性能的各向异性[J]. 中国有色金属学报, 2017, 27(1): 57-63.

WU Guo-hua, XIAO Han, ZHOU Hui-zi, WANG Rui-xue, CHENG Ming, ZHANG Shi-hong. Anisotropy of warm- temperature tensile properties of extruded AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(1): 57-63.

[4] 李结木, 邓坤坤. 热处理对颗粒增强镁基复合材料组织与性能的影响[J]. 材料热处理报, 2012, 33(9): 29-32.

LI Jie-mu, DENG Kun-kun. Effect of heat treatment on microstructure and mechanical properties of particle reinforced magnesium matrix composite[J]. Transactions of Materials and Heat Treatment, 2012, 33(9): 29-32.

[5] 王艳彬, 陈嫚丽, 赵志翔. Al2O3微粒的尺度律对镁微观组织和拉伸性能的影响[J]. 精密成形工程, 2011, 3(2): 15-19, 30.

WANG Yan-bin, CHEN Man-li, ZHAO Zhi-xiang. Effects on magnesium microstructure and mechanical propertiesof the scaling laws of Al2O3 micro-particles[J]. Journal of Netshape Forming Engineering, 2011, 3(2): 15-19, 30.

[6] PARK B G, CROSKY A G, HELLIER A K. Fracture toughness of microsphere Al2O3-Al particulate metal matrix composites[J]. Composites Part B, 2008, 39(7/8): 1270-1279.

[7] OZSOY I, LI G, CHOI H, ZHAO H J. Shape effects on nanoparticle engulfment for metal matrix nano composites[J]. Journal of Crystal Growth, 2015, 422: 62-68.

[8] PARAMSOTHY M, CHAN J, KWOK R, GUPTA M. Al2O3 nanoparticle addition to commercial magnesium alloys: Multiple beneficial effects[J]. Nanomaterials, 2012, 2(2): 147-162.

[9] 盛绍顶, 严红革, 陈振华. 快速凝固结合粉末冶金法制备Al2O3颗粒增强AZ91镁基复合材料的组织与力学性能[J]. 机械工程材料, 2010, 34(10): 40-42, 54.

SHEN Shao-ding, YAN Hong-ge, CHEN Zhen-hua. Microstructure and mechanical properties of Al2O3p/AZ91 Mg-based composites prepared by RS/PM process[J]. Materials for Mechanical Engineering, 2010, 34(10): 40-42, 54.

[10] PRASAD Y V R K, RAO K P, GUPTA M. Hot workability and deformation mechanisms in Mg/nano-Al2O3 composites[J]. Composites Science & Technology, 2009, 69(7/8): 1070-1076.

[11] HABIBNEJAD-KORAYEM M, MAHMUDI R, POOLE W J. Work hardening behavior of Mg-based nano-composites strengthened by Al2O3 nano-particles[J]. Materials Science & Engineering A, 2013, 567(4): 89-94.

[12] 范艳艳, 李秋书, 李亚斐. Al2O3颗粒增强AZ91D镁基复合材料的研究[J]. 中国铸造装备与技术, 2011, 2011(1): 16-19.

FAN Yan-yan, LI Qiu-shu, LI Ya-fei. A study on AZ91D Mg matrix compound materials enforced by Al2O3 particles[J]. China Foundry Machinery & Technology, 2011, 2011(1): 16-19.

[13] WU Shu-yan, JI Ze-sheng, RONG Shou-fan, HU Mao-liang. Microstructure and mechanical properties of AZ31B magnesium alloy prepared by solid-state recycling process from chips[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(5): 783-788.

[14] 文丽华, 吉泽升, 许红雨, 王宝芹, 宁慧燕, 翁江翔, 胡茂良. 固相再生Mg-Nd-Zn-Zr镁合金的时效强化[J]. 中国有色金属学报, 2016, 26(7): 1408-1413.

WEN Li-hua, JI Ze-sheng, XU Hong-yu, WANG Bao-qin, NING Hui-yan, WENG Jiang-xiang, HU Mao-liang. Aging strengthening of Mg-Nd-Zn-Zr magnesium alloy prepared by solid recycling process[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(7): 1408-1413.

[15] DENG K K, WU K, WU Y W, NIE K B, ZHENG M Y. Effect of submicron size SiC particulates on microstructure and mechanical properties of AZ91 magnesium matrix composites[J]. Journal of Alloys & Compounds, 2010, 504(2): 542-547.

[16] DENG K K, WANG X J, WANG C J, SHI J Y, HU X S, WU K. Effects of bimodal size SiC particles on the microstructure evolution and fracture mechanism of AZ91 matrix at room temperature[J]. Materials Science & Engineering A, 2012, 553(38): 74-79.

[17] SUN X F, WANG C J, DENG K K, KANG J W, BAI Y, NIE K B, SHANG S J. Aging behavior of AZ91 matrix influenced by 5 μm SiCp: Investigation on the microstructure and mechanical properties[J]. Journal of Alloys & Compounds, 2017, 727(5): 1263-1272.

[18] RAMAKRISHNAN N. An analytical study on strengthening of particulate reinforced metal matrix composites[J]. Acta Materialia, 1996, 44(1): 69-77.

[19] GUO X, SHECHTMAN D. Extruded high-strength solid materials based on magnesium with zinc, yttrium, and cerium additives[J]. Glass Physics and Chemistry, 2005, 31(1): 44-52

[20] HASSAN S F, GUPTA M. Effect of type of primary processing on the microstructure, CTE and mechanical properties of magnesium/alumina nanocomposites[J]. Composite Structures, 2006, 72(1): 19-26.

[21] HANSEN N. The effect of grain size and strain on the tensile flow stress of aluminium at room temperature[J]. Acta Materialia, 1977, 25(8): 863-869.

[22] HAN B Q, DUNAND D C. Microstructure and mechanical properties of magnesium containing high volume fractions of yttria dispersoids[J]. Materials Science & Engineering A, 2000, 277(1/2): 297-304

[23] NGUYEN Q B, GUPTA M. Enhancing compressive response of AZ31B magnesium alloy using alumina nano particulates[J]. Composites Science & Technology, 2008, 68(10/11): 2185-2192.

[24] ZHANG Z, CHEN D L. Contribution of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites[J]. Materials Science & Engineering A, 2008, 483(1): 148-152.

Fabrication of submicron size Al2O3/AZ31 composite prepared by solid-phase synthesis and its strengthening mechanism

HU Mao-liang, WEI Shuai-hu, JI Ze-sheng, XU Hong-yu, WANG Ye

(School of Materials Science and Engineering, Harbin University of Science and Technology, Harbin 150040, China)

Abstract: The solid-phase synthesis was used to prepare the submicron size Al2O3/AZ31 composite. Its microstructure and mechanical properties were characterized by optical microscopy, scanning electron microscopy, transmission electron microscopy, Vickers hardness tester and electron universal strength tester. The results show that the submicron size Al2O3 particles are uniformly distributed in AZ31 magnesium matrix after solid-phase synthesis. Al2O3 particles increase the dislocation density by pinning the dislocation motion of the matrix, promoting the dynamic recrystallization nucleation, resulting in refined grains of the composites. Meanwhile, the mechanical properties of the composites increase with the increase of the content of submicron size Al2O3 particles. When the content of Al2O3 particles is 2%, the mechanical properties of the composite reach the maximum. The hardness, tensile strength, yield strength and elongation are 83HV, 302 MPa, 203 MPa and 8.15%, respectively.

Key words: solid-phase synthesis; AZ31 magnesium composites; mechanical property; strengthening mechanism; microstructures

Foundation item: Project(51404082) supported by the National Natural Science Foundation of China; Project(201510) supported by the Science Funds for the Young Innovative Talents of HUST, China

Received date: 2018-08-30; Accepted date: 2018-11-22

Corresponding author: HU Mao-liang; Tel: +86-13936585119; E-mail: humaoliang@hrbust.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51404082);哈尔滨理工大学青年拔尖创新人才培养计划(201510)

收稿日期:2018-08-30;修订日期:2018-11-22

通信作者:胡茂良,教授,博士;电话:13936585119;E-mail:humaoliang@hrbust.edu.cn