文章编号:1004-0609(2014)03-0765-08

机械活化Ti47Ni47Al6粉末的烧结性能

刘子利,刘伯路,刘希琴,王立红

(南京航空航天大学 材料科学与技术学院,南京 210016)

摘 要:采用机械活化和粉末冶金方法制备Ti47Ni47Al6合金,通过光学显微镜、配备能谱分析的扫描电镜、X射线衍射仪、维氏硬度及抗弯强度测试手段研究机械活化对烧结合金显微组织和性能的影响。结果表明:随着球磨的进行,粉体中Ti和Ni的晶格常数增大,球磨20 h的Ti47Ni47Al6粉末形成了Ti-Ni-Al三元复合粉,但无新相形成。与球磨1 h粉末烧结制备的合金相比,球磨20 h的机械活化粉末烧结合金中Ti2Ni(Al)和Ni3Ti(Al)强化相数量、致密度、硬度及抗弯强度均增加。

关键词:Ti47Ni47Al6粉末;机械活化;烧结

中图分类号:TF124 文献标志码:A

Sintering properties of mechanically activated Ti47Ni47Al6 powders

LIU Zi-li, LIU Bo-lu, LIU Xi-qin, WANG Li-hong

(College of Materials Science and Technology, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China)

Abstract: Ti47Ni47Al6 alloys were prepared by the mechanical activation and powder metallurgy methods, and the effects of mechanical activation on the microstructure and mechanical properties of the sintered alloys were investigated by optical microscope, scanning electron microscope equipped with an energy dispersive X-ray spectrometer, X ray diffractometer, microhardness and bending strength tests. The results indicate that the lattice constants of Ti and Ni of the powders increase with the increase of ball-milling time, and the powders ball-milled for 20 h form the Ti-Ni-Al ternary powder with no formation of new phase. Compared with the sintered alloy prepared by the powders milled for 1 h, the number of Ti2Ni(Al) and Ni3Ti(Al) strengthening phases, the relative density, the microhardness and the flexural strength all increase for the sintered alloy prepared by the mechanical activated powder milled for 20 h.

Key words: Ti47Ni47Al6 powder; mechanical activation; sintering

作为一种新型金属间化合物结构材料,TiNiAl合金具有较高的比强度和良好的抗氧化性,有望在航空航天领域作为新型金属间化合物结构材料替代镍基超合金得到应用[1-5]。在近等摩尔比TiNi合金中加入适量Al替代Ti后,合金的室温及高温强度大幅度提高,室温压缩屈服强度可达2300 MPa(超过了Rene95镍基高温合金的),1000 ℃左右的屈服强度和中温区间使用的高温合金相当[1]。添加al替代等摩尔比TiNi合金中的Ni,合金的室温和高温力学性同样能得到大幅提高[3-5]。

目前,TiNiAl合金一般采用熔炼铸造制备,设备要求及熔化温度高(超过2000 ℃),因此制备成本较高;Al含量较高时易产生偏析,在很大程度上影响组织和性能的稳定性;同时TiNiAl金属间化合物硬度较高,机械加工比较困难。粉末冶金作为一种近净成形加工技术能大大减少后续的机械加工,在较低的烧结温度下制备出晶粒细小且组织均匀的材料[6-7]。Al含量对空心阴极等离子烧结Ti、Ni等摩尔比TiNiAl合金组织和力学性能影响的研究结果表明,Ti47Ni47Al6 具有最佳的室温力学性能[8]。

活化烧结是指采用物理或化学的手段使烧结温度降低、烧结时间缩短及烧结体性能提高的一种粉末冶金方法。机械活化是粉末高能球磨中形成包括粉末变形、冷焊合、断裂、复合化等现象的复杂过程,经过高能球磨后粉末的比表面及内部的空位、位错、层错等缺陷增加,从而使粉末的活性增强[9-10]。本文作者对Ti47Ni47Al6粉末进行机械活化,并以普通混合粉末和机械活化粉末为原料通过粉末冶金方法制备Ti47Ni47Al6合金,研究机械活化对烧结试样显微组织和室温力学性能的影响。

1 实验

采用Ti粉(纯度>99%,45 μm)、Ni粉(纯度>99.9%,3~7 μm)和Al粉(纯度>99%,48 μm),按Ti47Ni47Al6成分比例配料,加入约2%的硬脂酸(质量分数)作为过程控制剂。球磨前抽真空并充入高纯氩气,如此重复4次。球磨参数如下:球料比10:1,球磨转速200 r/min。球磨1、5、10和20 h后分别取少量粉末进行XRD测试和SEM观察。

取球磨1和20 h的Ti47Ni47Al6粉末进行压制,压制方式为普通双向压制成形,模具尺寸为6 mm×12 mm×30 mm,压制压力为700 MPa。烧结设备为氩气保护KBF16Q箱式烧结炉,升温步骤如下:室温加热至600 ℃的升温速率为5 ℃/min,600~900 ℃的升温速率为2 ℃/min,900 ℃保温3 h后随炉冷却。

烧结试样在HXS-1000A型显微维氏硬度计上进行硬度测试,设定载荷为100 N,加载时间为20 s,每个试样测定5次,取平均值。抗弯性能测试采用CSS-2202型电子万能试验机,跨距为14.8 mm,压头加载速率为0.1 mm/s。采用BrukerD8Advance X射线衍射仪(Cu靶,Kα谱线)进行物相分析。采用未腐蚀试样观察其孔隙形貌;使用14%HNO3+4%HF+蒸馏水腐蚀后,采用附带X射线能谱分析仪的FEI Quanta 200扫描电镜观察试样显微组织形貌。

2 结果与讨论

2.1 球磨粉末的XRD谱

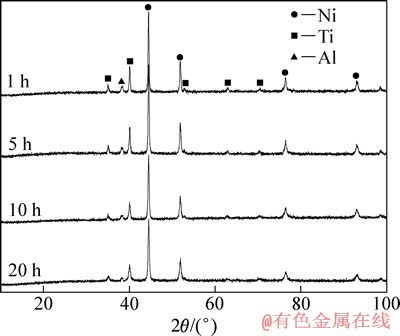

图1所示为转速为200 r/min不同球磨时间下Ti47Ni47Al6粉末的XRD谱。由图1可知,在球磨1 h样品的XRD谱中,衍射峰分别与Ti、Ni和Al尖锐的晶态衍射峰相对应。在随后的球磨过程中,样品的XRD谱发生了明显变化,Ti、Ni和Al的尖锐衍射峰逐渐宽化,峰强减弱。衍射峰的宽化是由于球磨过程中粉末发生了晶格畸变和晶粒细化,而峰强的变化表明Ti、Ni和Al三元素间发生了互扩散。此外,随着球磨的进行,Ti和Ni衍射峰往低角度方向移动,而Al衍射峰的移动不明显,这说明存在传统意义上的固溶,即Ni、Al原子和Ti、Al原子分别溶入Ti原子和Ni原子晶格中,导致二者点阵常数发生变化。球磨20 h后,XRD谱中仍为Ti、Ni单质衍射峰,并无新相的形成,Al的衍射峰几乎消失,大部分Al已经固溶于Ti、Ni中。

图1 不同球磨时间Ti47Ni47Al6粉末的XRD谱

Fig. 1 XRD patterns of Ti47Ni47Al6 powders milled for different times

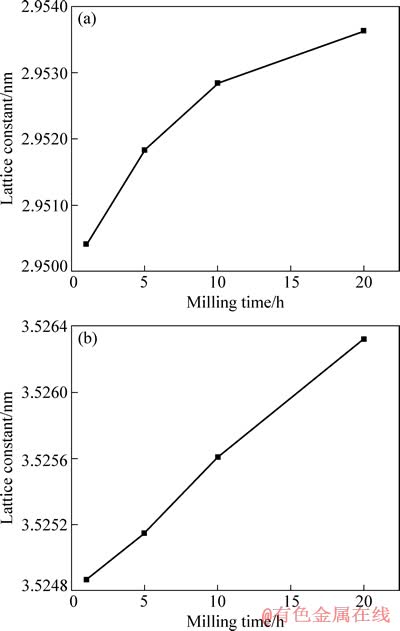

Ti和Ni晶格常数和球磨时间的关系如图2所示。由图2可知,随着球磨时间的延长,Ti和Ni的晶格常数增大。球磨1 h后Ti和Ni的晶格常数分别为2.95041和3.52487 nm,球磨20 h后增大至2.95363和3.52632 nm,分别增大了0.109%和0.041%。可见,Ti的晶格畸变程度大于Ni的晶格畸变程度,即Ni和Al向Ti中扩散的速率较大,这和Ti原子半径较大有关(rTi=0.200 nm,rAl=0.182 nm,rNi=0.162 nm),从而有利于Ni和Al向Ti中扩散[11]。

Ti47Ni47Al6粉末点阵应变与球磨时间关系如图3所示。由图3可知,点阵应变随球磨时间的延长而增大。点阵应变由以下的两个部分组成:粉末因受球磨介质的机械碰撞而产生的塑性变形;Ti、Ni和Al原子之间的相互扩散,溶入了对方的晶格点阵而产生的晶格畸变。点阵应变(3)可表示为

(1)

(1)

式中:ηp和ηl分别为粉末的塑性变形以及晶格畸变对点阵应变值的贡献[12]。随着球磨时间的延长,点阵应变增加,这是由于在球磨过程中粉末发生塑性变形,同时原子之间发生相互扩散而使晶格畸变程度增大。

图2 Ti和Ni晶格常数与球磨时间的关系

Fig. 2 Relationships between lattice constant of Ti (a) and Ni (b) and milling time

图3 Ti47Ni47Al6粉末点阵应变与球磨时间的关系

Fig. 3 Relationship between lattice strain of Ti47Ni47Al6 powders and milling time

2.2 球磨粉末颗粒的形貌

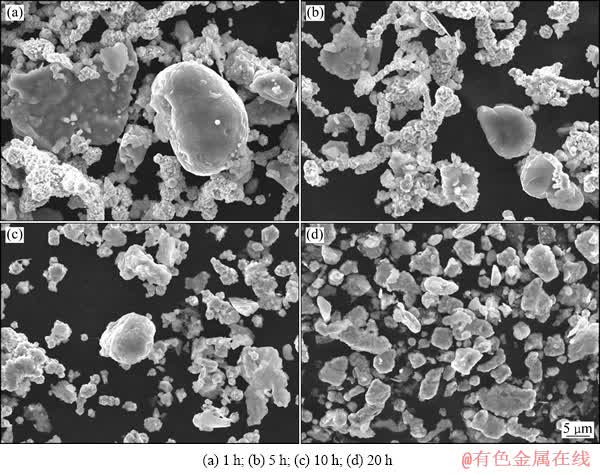

在200 r/min转速及不同球磨时间下Ti47Ni47Al6粉末的SEM像如图4所示;球磨20 h后粉末的SEM像及能谱分析如图5所示。由图4可知,经高能机械活化后,粉末颗粒尺寸与形貌发生了明显的变化。

图4 不同球磨时间Ti47Ni47Al6粉末的SEM像

Fig. 4 SEM images of Ti47Ni47Al6 powders milled for different times

图5 球磨20 h后Ti47Ni47Al6 粉末的SEM像及EDS能谱分析

Fig. 5 SEM images and EDS spectra of Ti47Ni47Al6 powders milled for 20 h

结合图4可知,球磨1 h的混合粉末中颗粒尺寸细小、呈团聚状态的为Ni颗粒,呈椭球状、边缘较为规则的为Al颗粒,呈块状、棱角分明的为Ti颗粒。球磨5 h后,Ti、Al颗粒尺寸显著减小,大多数Ni颗粒仍呈团聚状态,且开始附着于Ti、Al颗粒表面。球磨10 h后,颗粒尺寸变化不大,部分Ni团聚更加明显。球磨20 h后,颗粒的平均尺寸比球磨1 h的颗粒显著减小。结合图5可知,Ni、Al和Ti、Al原子分别扩散至Ti颗粒和Ni颗粒中。这说明Ti、Ni和Al粉末在高速磨球的碾压轧制和冷墩作用下,相互焊合在一起,形成了Ti-Ni-Al三元复合粉。

2.3 机械活化对烧结Ti47Ni47Al6合金显微组织的影响

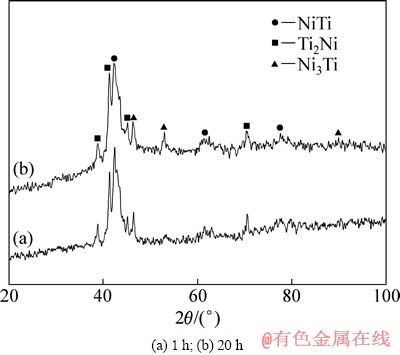

球磨1和20 h的Ti47Ni47Al6粉末在900 ℃烧结3 h后合金的XRD谱如图6所示。由图6可知,合金XRD谱上并未出现明显的Ti、Ni和Al单质衍射峰,表明烧结后试样均发生了完全合金化。球磨1 h Ti47Ni47Al6烧结后的相组成为基体相NiTi、强化相Ti2Ni及Ni3Ti;球磨20 h后,Ti2Ni和Ni3Ti衍射峰的峰强增加,表明其数量增加。在球磨1和20 h后的Ti47Ni47Al6烧结试样中均没有发现明显Al的合金相二相,Al主要固溶于基体相及强化相中。

图6 不同球磨时间Ti47Ni47Al6粉末烧结合金的XRD谱

Fig. 6 XRD patterns of alloys prepared by sintering of Ti47Ni47Al6 powders milled for different times

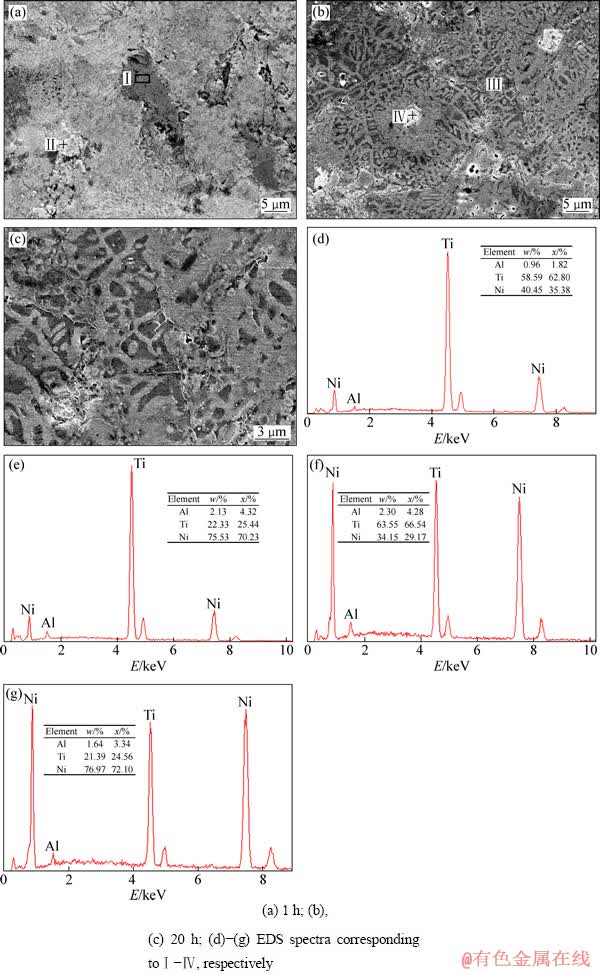

图7 不同球磨时间Ti47Ni47Al6粉末烧结合金的SEM像及EDS能谱

Fig. 7 SEM images and EDS spectra of alloys prepared by sintering of Ti47Ni47Al6 powders milled for different times

球磨1和20 h的Ti47Ni47Al6粉末在900 ℃烧结3 h后合金的SEM像及EDS能谱如图7所示。由图7并结合XRD谱(见图6)可知,球磨1 h的Ti47Ni47Al6烧结合金显微组织中深灰色相为Ti2Ni(Al),亮白色相为Ni3Ti(Al),而灰色相为NiTi(Al) 基体,Ti2Ni(Al)和Ni3Ti(Al) 强化相均呈块状分布。球磨20 h后的烧结试样中,Ti2Ni(Al)相尺寸变小,数量增多,弥散分布在NiTi(Al)相基体上;Ni3Ti(Al)仍呈块状分布,数量增多。

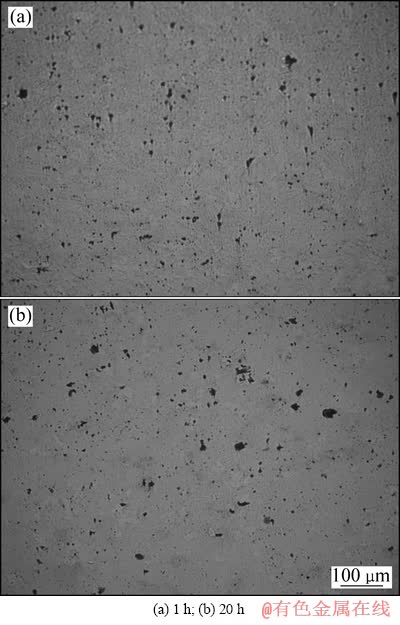

球磨1和20 h的Ti47Ni47Al6粉末在900 ℃烧结3 h后合金的孔隙形貌如图8所示。由图8可知,球磨1 h烧结试样显微组织中的孔隙多为小孔隙,近球形,也存在一些大孔隙;球磨20 h的烧结试样中大孔隙数量减少,尺寸减小,孔隙率降低。

图8 不同球磨时间下Ti47Ni47Al6粉末烧结合金的孔隙形貌

Fig. 8 Pore morphologies of alloys prepared by sintering of Ti47Ni47Al6 powders milled for different times

在600~900 ℃温度范围内,Ti-Ni反应相形成的吉布斯自由能的关系为ΔGf((Ti2Ni)>ΔGf(NiTi)>ΔGf(Ni3Ti)[13] ,因此,在Ti和Ni颗粒接触处首先形成Ni3Ti,随后通过Ni和Ti原子的互扩散,Ni3Ti长大并形成Ti2Ni和NiTi相。对于添加Al的Ti47Ni47Al6合金,TiAl3和NiAl3反应自由能在Ni-Al和Ti-Al体系中最低而优先生成,其中Ni与Al之间的反应自由能低于Ti与Al之间的反应自由能[14-16]。由Ti-Ni、 Ti-Al及Ni-Al二元相图可知,在Ni-Al共晶温度640 ℃以下烧结时,Ti、Ni和Al之间为固态扩散反应,在Al与Ni、Al与Ti颗粒接触处首先分别形成NiAl3和TiAl3。加热温度高于共晶温度时会发生共晶反应Al+Al3Ni L而产生液相。加热速率较低增加了Ni-Al及Ti-Al之间的扩散时间,从而促进了Al的固态扩散转变,因此,通过共晶反应产生的液相数量减少,可避免因共晶熔化而引起的热爆反应,有助于烧结致密度的提高[17]。此外,由烧结动力学原理可知,Al+Al3Ni共晶液相的出现加快了Ni与Ti间互扩散形成金属间化合物相的反应速度。在烧结温度超过Al熔点后,与Ti颗粒接触处剩余的Al熔化,然后与Ti颗粒外层的TiAl3发生包晶反应而加速Al向Ti颗粒内的扩散。由于Al在Ti颗粒外部的含量较高,此后附近Ni颗粒中的Ni原子向该Ti颗粒中心的扩散形成Ni-Ti金属间化合物相的过程将受阻,因此,更多Ti2Ni(Al)相出现在Ti47Ni47Al6烧结合金中。由于烧结过程中元素扩散不充分所导致的合金元素不均匀性,同时Ti-Ni合金相的形成过程受元素扩散控制,因此,在Ti47Ni47Al6烧结合金的组织为基体相TiNi和强化相Ti2Ni和Ni3Ti,Ti颗粒处易形成Ti2Ni(Al)相,而Ni颗粒处则易形成Ni3Ti(Al)。球磨20 h后Ti、Al颗粒尺寸显著减小,且形成了片层状Ti-Ni-Al三元复合粉,因此,Ti2Ni(Al)尺寸细小,数量增多。由于球磨后Ni颗粒呈块状分布,尺寸增大,增加了Ni原子的扩散距离,因此,块状Ni3Ti(Al)数量增多。

L而产生液相。加热速率较低增加了Ni-Al及Ti-Al之间的扩散时间,从而促进了Al的固态扩散转变,因此,通过共晶反应产生的液相数量减少,可避免因共晶熔化而引起的热爆反应,有助于烧结致密度的提高[17]。此外,由烧结动力学原理可知,Al+Al3Ni共晶液相的出现加快了Ni与Ti间互扩散形成金属间化合物相的反应速度。在烧结温度超过Al熔点后,与Ti颗粒接触处剩余的Al熔化,然后与Ti颗粒外层的TiAl3发生包晶反应而加速Al向Ti颗粒内的扩散。由于Al在Ti颗粒外部的含量较高,此后附近Ni颗粒中的Ni原子向该Ti颗粒中心的扩散形成Ni-Ti金属间化合物相的过程将受阻,因此,更多Ti2Ni(Al)相出现在Ti47Ni47Al6烧结合金中。由于烧结过程中元素扩散不充分所导致的合金元素不均匀性,同时Ti-Ni合金相的形成过程受元素扩散控制,因此,在Ti47Ni47Al6烧结合金的组织为基体相TiNi和强化相Ti2Ni和Ni3Ti,Ti颗粒处易形成Ti2Ni(Al)相,而Ni颗粒处则易形成Ni3Ti(Al)。球磨20 h后Ti、Al颗粒尺寸显著减小,且形成了片层状Ti-Ni-Al三元复合粉,因此,Ti2Ni(Al)尺寸细小,数量增多。由于球磨后Ni颗粒呈块状分布,尺寸增大,增加了Ni原子的扩散距离,因此,块状Ni3Ti(Al)数量增多。

球磨1 h和Ti47Ni47Al6粉末在900 ℃烧结3 h后,合金显微组织中较小的孔隙是由Ti和Ni原子之间的偏扩散形成的Kirkendall孔隙,较大的孔隙大多为原始孔隙和由原始Al颗粒处形成的孔隙经聚集长大后的孔隙。原始Al颗粒处形成孔隙有两方面的原因[18-20]:一是与Al和Ni、Ti之间的偏扩散有关,在固态阶段即Al熔点以下,由于扩散速率和溶解度差异,Al作为主要扩散组元向Ni和Ti进行扩散,产生Kirdendall效应,因此,在Al原始位置形成孔隙,偏扩散的差异随温度升高而升高;二是当烧结温度高于Al的熔点时,未扩散入周围Ni或Ti颗粒内的剩余熔化,熔化的Al迅速与周围的Ni或Ti反应而很快消耗完毕,从而在该处产生孔隙。这些孔隙在随后的烧结过程中随着晶粒长大和晶界迁移而聚集、长大、贯通,形成孔径不同的孔隙。

球磨20 h后,大孔隙数量减少,尺寸减小,孔隙率降低,可见机械活化对烧结致密化过程有明显的促进作用。这主要是由于[9, 12]:1) 机械活化有助于粉末细化,大大增加了粉末的总表面积和总表面能。由表面扩散动力学机制可知,其表面扩散容易进行,同时球磨20 h后所剩余的Al颗粒较少且尺寸细小,因此Al颗粒处产生的孔隙尺寸减小;2) 机械活化后粉末产生了一定的晶格畸变,粉体储存了一定的畸变能,由烧结热力学理论可知,过剩自由能的减小是烧结的原动力;3) 球磨过程中形成的局部温升能加速扩散和空位的形成。所有这些都有利于扩散和溶解-析出等机理的物质传输过程,从而加速烧结的进行,促进合金致密度的提高。

2.4 机械活化对Ti47Ni47Al6 粉末烧结合金性能的影响

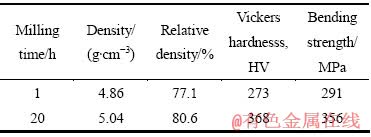

球磨1和20 h的Ti47Ni47Al6粉末在900 ℃烧结3 h后,合金的密度、致密度、显微硬度及抗弯强度如表1所列(Ti47Ni47Al6合金的理论密度约为6.3 g/cm3)。由表1可知,球磨1 h烧结试样的密度和致密度分别为4.86 g/cm3和77.1%,球磨20 h烧结试样的密度和致密度分别增加至5.04 g/cm3和80.6%。

球磨1 h烧结试样的硬度和抗弯强度分别为273HV和291 MPa,球磨20 h烧结试样硬度和抗弯强度分别增加至368HV和356 MPa,后者的两项指示比前者的分别提高了34.8%和22.3%。

球磨20 h Ti47Ni47Al6粉末颗粒的平均尺寸显著减小,颗粒尺寸不但影响烧结体的密度,而且影响其性能。在相同压坯密度条件下,粉末的分散程度越高,烧结后所获得的性能越好。这是因为粉末越细,比表面越大,而颗粒比表面的增大对促进烧结过程起着非常重要的作用[9]。同时,球磨20 h烧结试样中强化相Ti2Ni和Ni3Ti的数量增加,使合金的硬度和抗弯强度得到提高。

表1 不同球磨时间Ti47Ni47Al6粉末烧结合金的密度、显微硬度及抗弯强度

Table 1 Density, microhardness and bending strength of alloys prepared by sintering of Ti47Ni47Al6 powders milled for different times

3 结论

1) 随着球磨的进行,Ti、Ni的晶格常数及Ti47Ni47Al粉末的点阵应变增加。球磨20 h的Ti47Ni47Al6粉末形成了Ti-Ni-Al三元复合粉,但无新相的形成。

2) 球磨1 h 的Ti47Ni47Al6粉末烧结合金的显微组织主要由NiTi(Al) 基体相、Ti2Ni(Al)、Ni3Ti(Al) 强化相及孔隙组成。球磨20 h的烧结合金中Ti2Ni(Al)、Ni3Ti(Al)强化相数量增多,致密度提高至80.6%。

3) 球磨1 h 的Ti47Ni47Al6粉末烧结合金的维氏硬度及抗弯强度分别为273HV和291 MPa。球磨20 h后经机械活化的烧结合金的维氏硬度及抗弯强度显著增大,分别增加至369HV和356 MPa。

REFERENCES

[1] KOIZUMI Y, RO Y, NAKAZAWA S, HARADA H. NiTi-base intermetallic alloys strengthened by Al substitution[J]. Materials Science and Engineering A, 1997, 223(1/2): 36-41.

[2] WARREN P, MURAKAMI Y, KOIZUMI Y, HARADA H. Phase separation in NiTi-Ni2TiAl alloy system[J]. Materials Science and Engineering A, 1997, 223(1/2): 17-20.

[3] MENG L J, LI Y, ZHAO X Q, XU J, XU H B. The mechanical properties of intermetallic Ni50-xTi50Alx alloys(x=6, 7, 8, 9)[J]. Intermetallics, 2007, 15(5/6): 814-818.

[4] 徐惠彬, 孟令杰, 李 岩, 赵新青, 宫声凯. 一种钛镍铝高温合金材料及其制备方法: 中国, ZL200510053911.1[P]. 2007-06-13.

XU Hui-bin, MENG Ling-jie, LI Yan, ZHAO Xin-qing, GONG Sheng-kai. High temperature titanium nickel aluminium alloy materials and its preparation: China, ZL200510053911.1[P]. 2007-06-13.

[5] XU H B, MENG L J, XU J, LI Y, ZHAO X Q. Mechanical properties and oxidation characteristics of TiNiAl(Nb) intermetallics[J]. Intermetallics, 2007, 15(5/6): 778-782.

[6] 国为民, 宋璞生, 吴剑涛, 张凤戈, 杨 成, 张义文, 陈生大. 粉末高温合金的研制与展望[J]. 粉末冶金工业, 1999, 9(2): 9-16.

GUO Wei-min, SONG Pu-sheng, WU Jian-tao, ZHANG Feng-ge, YANG Cheng, ZHANG Yi-wen, CHEN Sheng-da. Development and prospect of powder metallurgy superalloys[J]. Powder Metallurgy Industry, 1999, 9(2): 9-16.

[7] XIAO D H, YUAN T C, OU X Q, HE Y H. Microstructure and mechanical properties of powder metallurgy Ti-Al-Mo-V-Ag alloy[J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 1269-1276.

[8] 刘伯路, 刘子利, 刘希琴, 王怀涛, 王文静. Al含量对空心阴极等离子烧结Ti/Ni等原子比TiNiAl合金组织和力学性能的影响[J]. 航空学报, 2013, 34(3): 711-718.

LIU Bo-lu, LIU Zi-li, LIU Xi-qin, WANG Huai-tao, WANG Wen-jing. Effect of Al content on microstructure and mechanical properties of hollow cathode plasma sintering TiNiAl alloys with equal Ti/Ni atom ratio[J]. Acta Aeronautica et Astronautica Sinica, 2013, 34(3): 711-718.

[9] 贾成厂, 刘小扬, 解子章, 赵 军. 用机械活化粉末制备钨合金[J]. 清华大学学报: 自然科学版, 1999, 39(6): 35-38.

JIA Cheng-chang, LIU Xiao-yang, XIE Zi-zhang, ZHAO Jun. Preparing tungsten alloys with mechanically activated powder[J]. Journal of Tsinghua University: Science and Technology, 1999, 39(6): 35-38.

[10] KHAYATI G R, JANHORBAN K, SHARIAT M H. Isothermal kinetics of mechanochemically and thermally synthesized Ag from Ag2O[J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 935-942.

[11] 诸葛兰剑, 李亚东, 金宗明, 孙建平. Ni-Ti-Cu粉末的机械合金化[J]. 材料科学与工艺, 1997, 5(2): 6-8.

ZHUGE Lan-jian, LI Ya-dong, JIN Zhong-ming, SUN Jian-ping. Mechanical alloying of Ni-Ti-Cu Powders[J]. Material Science and Technology, 1997, 5(2): 6-8.

[12] 游和清. 镍基三元金属间化合物合金的制备与表征[D]. 兰州: 兰州理工大学, 2007: 35-45.

YOU He-qing. The preparation and characterization of the nickel-based ternary intermetallic alloys[D]. Lanzhou: Lanzhou University of Technology, 2007: 35-45.

[13] 陈秀娟, 张 林, 夏天东, 赵文军. 热爆反应生成 NiTi的热力学与动力学分析[J]. 热加工工艺, 2007, 36(2): 10-12, 51.

CHEN Xiu-juan, ZHANG Lin, XIA Tian-dong, ZHAO Wen-jun. Thermodynamics and kinetics analysis of NiTi by combustion synthesis[J]. Hot Working Technology, 2007, 36(2): 10-12, 51.

[14] 王衍行, 林均品, 贺跃辉, 王艳丽, 陈国良. 元素粉末Ti与Al反应机理的研究进展[J]. 材料导报, 2007, 21(1): 83-85.

WANG Yan-hang, LIN Jun-pin, HE Yue-hui, WANG Yan-li, CHEN Guo-liang. Progress in reactive mechanism of Ti with Al elemental powders[J]. Materials Review, 2007, 21(1): 83-85.

[15] 王华彬, 韩杰才, 张幸红, 杜善义. Ni-Al粉连续加热过程中的反应机理[J]. 金属学报, 1998, 34(9): 992-998.

WANG Hua-bin, HAN Jie-cai, ZHANG Xin-hong, DU Shan-yi. Reaction mechanism of continually heating Ni and Al particles[J]. Acta Metallrugica Sinica, 1998, 34(9): 992-998.

[16] BRAIN I. 纯物质热化学数据手册[M]. 程乃良, 牛四通, 徐桂英, 译. 北京: 科学出版社, 2003: 42-71.

BRAIN I. Thermochemical data of pure substances[M]. CHENG Nai-liang, NIU Si-tong, XU Gui-ying, transl. Beijing: Science Press, 2003: 42-71.

[17] LIU B L, LIU Z L, LIU X Q, WANG W J, WANG L H. Effect of sintering temperature on the microstructure and mechanical properties of Ti50Ni50 and Ti47Ni47Al6 intermetallic alloys[J]. Journal of Alloys and Compounds, 2013, 578: 373-379.

[18] DONG H X, HE Y H, JIANG Y, WU L, ZOU J, XU N P, HUANG B Y, LIU C T. Effect of Al content on porous Ni-Al alloys[J]. Materials Science and Engineering A, 2011, 528: 4849-4855.

[19] LEE T K, MOSUNOV E I, HWANG S K. Consolidation of a gamma TiAl-Mn-Mo alloy by elemental powder metallurgy[J]. Materials Science and Engineering A, 1997, 239/240: 540-545.

[20] WANG G, DAHMS M, LEITNER G, SCHULTRICH S. Titanium aluminides from cold-extruded elemental powders with Al-contents of 25%-75% Al[J]. Journal of Materials Science, 1994, 29: 1847-1853.

(编辑 陈卫萍)

收稿日期:2013-04-11;修订日期:2013-10-25

通信作者:刘子利,教授,博士;电话:025-52112626;E-mail:zililiu@sohu.com