文章编号:1004-0609(2015)12-3327-09

轴承用耐磨Al-Sn-Cu合金的显微组织与性能

章升程1,潘清林1, 2,李 波1,黄 星1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属先进结构材料与制造协同创新中心,长沙 410083)

摘 要:采用直接水冷铸造法制备Al-Sn-Cu合金,通过室温力学性能测试、摩擦磨损试验、金相显微分析(OM)、扫描电镜分析(SEM)、X射线衍射分析(XRD)、透射电镜分析(TEM)等手段对合金不同状态下的力学性能、摩擦磨损性能、显微组织结构及其演变规律进行研究。结果表明:经过(480 ℃, 19 h)均匀化处理,合金组织中呈连续网状分布的β(Sn)消失,变成球状和块状依附或者围绕在Al2Cu周围;挤压变形之后,β(Sn)和Al2Cu被拉长破碎并得到细化,组织得到改善。合金适宜的固溶-时效制度为(490 ℃, 1 h)固溶、水淬后(190 ℃, 4 h)时效,在此状态下,晶内出现弥散分布的Al2Cu析出相和纳米级尺寸的β(Sn),合金的抗拉强度、屈服强度、伸长率、摩擦因数和磨痕宽度分别为318 MPa、252 MPa、10.5%、0.1053和1446.49 μm,具有良好的力学性能和摩擦磨损性能。

关键词:Al-Sn-Cu合金;挤压;组织;力学性能;摩擦磨损性能;固溶;时效处理

中图分类号:TG146.2 文献标志码:A

Microstructure and properties of wear resistant Al-Sn-Cu bearing alloy

ZHANG Sheng-cheng1, PAN Qing-lin1,2, LI Bo1, HUANG Xing1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Nonferrous Metal Oriented Advanced Structural Materials and Manufacturing Cooperative Innovation Center,

Central South University, Changsha 410083, China)

Abstract: The Al-Sn-Cu alloy was prepared by direct water-cooling casting. The mechanical properties, wear properties, microstructure and evolvement rule of alloy were investigated by means of room temperature tensile test, wear test, OM, SEM, XRD and TEM. The results show that the continuous webbed β(Sn) disappears, and Al2Cu phases are attached or enveloped by globular and nubbly β(Sn) phases after homogenization treatment(480℃, 19 h). The β(Sn) and Al2Cu phases are elongated and broken after extrusion, which results in the fine microstructure of alloy. The suitable solution and aging treatment of alloy is solution treated at 490 ℃ for l h, water-quenched and then aged at 190 ℃ for 4 h. The ultimate tensile strength, yield strength, elongation, friction coefficient and wear width of alloy are 318 MPa, 252 MPa, 10.5%, 0.1053 and 1446.49 μm, respectively, after the suitable solution and aging treatment. At the same time, Al2Cu precipitated phases and nano-sized β(Sn) dispersively distribute in the crystal, which leads to the fine mechanical properties and wear properties of alloy.

Key words: Al-Sn-Cu alloy; extrusion; microstructure; mechanical property; wear property; solution; aging treatment

巴氏合金轴承材料嵌藏性、顺应性、耐腐蚀性良好,铜基轴承合金的承载能力和疲劳强度很高,两者过去一直都被认为是理想的轴承材料,得到了广泛的应用[1-3]。但随着现代机组向高速、重载和增压强化方向发展,对轴承材料的强度、导热性及安全可靠性提出了更高的要求[4]。铝基轴承合金较巴氏合金、铜基轴承合金具有更佳的综合性能,正逐渐取代后者,广泛地被应用于汽车工业、航天航空、机械制造等领域[5-6]。

铝铅合金和铝锡合金是应用最广的铝基轴承合 金[7-8],然而由于铅对环境的严重污染,无铅轴承合金已成为轴承材料发展的必然趋势[3]。因此,铝锡轴承合金成为国内外研究的重点。对于铝锡合金,前人已有一定的研究。袁鸽成等[9]发现在Al-Sn-Si合金的均匀态组织中,β(Sn)相以硅粒子为核心聚集球化形成了软相包围硬相的“岛状”相结构。这种软硬相结合的复合相组织是耐磨减磨合金的最佳相组态[10]。LIU等[11]在研究机械合金化制备纳米结构的Al-Sn合金时发现,均匀弥散分布的纳米β(Sn)相能显著提高合金的力学性能。LU等[12]发现在双尺度结构的Al-Sn合金中加入适量Mg有利于β(Sn)的均匀分布和强塑性的提高,从而获得良好的摩擦磨损性能。但是以上研究基本集中在Al-Sn-Si及Al-Sn-Mg等合金,关于Al-Sn-Cu合金的研究却鲜见报道。鉴于铝锡合金的耐磨性、抗擦伤性不足以及置换周期较短[13-14],本文作者开发出一种新型耐磨Al-Sn-Cu轴承合金,探讨了不同状态下合金显微组织结构的演变规律,并重点研究了不同时效制度对合金组织及力学、摩擦磨损性能的影响,为该Al-Sn-Cu合金更好的满足工业生产需求提供理论依据。

1 实验

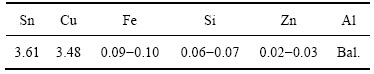

本实验中所用Al-Sn-Cu合金成分如表1所列。

表1 Al-Sn-Cu合金名义成分

Table 1 Nominal compositions of Al-Sn-Cu alloy (mass fraction, %)

采用直接水冷铸造法得到合金铸锭。获得均匀细小的相组织对提高铝锡合金机械及摩擦磨损性能是非常有利的,经过适宜的热处理,合金的相呈弥散分布,强硬度及耐磨性都得到很大提高[15-17]。因此,合金在(480 ℃, 19 h)的制度下进行均匀化处理,随后在25 MN挤压机上进行挤压成型,挤压温度为380 ℃,挤压比为20。在(490 ℃, 1 h)的制度下进行固溶处理,水淬后立即进行时效处理,时效制度为(190 ℃, 1 h)、(190 ℃, 2 h)、(190 ℃, 4 h)、(190 ℃, 6 h)、(190 ℃, 12 h)。

拉伸试验根据GB/T 228-2002《金属材料室温拉伸试验方法》在MTS-810型电液伺服材料试验机上进行,拉伸速率为2 mm/min。摩擦磨损试验在UMT-3摩擦磨损试验仪上进行,待磨试样(25 mm×25 mm×20 mm)与直径为9.5 mm、HRC为62的铬钢球对磨,试验在油润滑、室温条件下进行,试验载荷和转速分别为150 N和480 r/min,摩擦时间为30 min。在Leica DM ILM型金相显微镜上进行金相观察,腐蚀液为混合酸(2 mL HF+3 mL HCl+5 mL HNO3+250 mL H2O)。合金第二相及磨损表面形貌观察在FEI Quanta-200型扫描电镜下进行。在理学D/max 2500型18 kW转靶X射线衍射仪上,对样品进行物相分析。合金透射电镜组织观察在Tecnai G220S-TWIN型透射电镜上进行,透射样经机械减薄后双喷穿孔而成,双喷液为100 mL HNO3+300 mL CH3OH。

2 结果与讨论

2.1 不同状态合金显微组织观察与分析

2.1.1 合金XRD结果分析

图1所示为合金不同状态下的XRD谱,由图1可知,Al-Sn-Cu合金的组织组成物为:α(Al)、β(Sn)及Al2Cu化合物。由此可见,Sn元素在合金中未形成化合物,微量的Fe、Si元素也没有形成化合物。其中,α(Al)是铝基固溶体,β(Sn)为正方结构,晶格常数为a=0.5831 nm、b=c=0.3132 nm,Al2Cu以第二相及析出相的形式存在。在铸态及均匀态时,合金组织中存在β(Sn)相及Al2Cu第二相。在整个时效过程中,Al2Cu相得到充分析出。

图1 不同状态下的合金XRD谱

Fig. 1 XRD patterns of Al-Sn-Cu alloy after different treatments

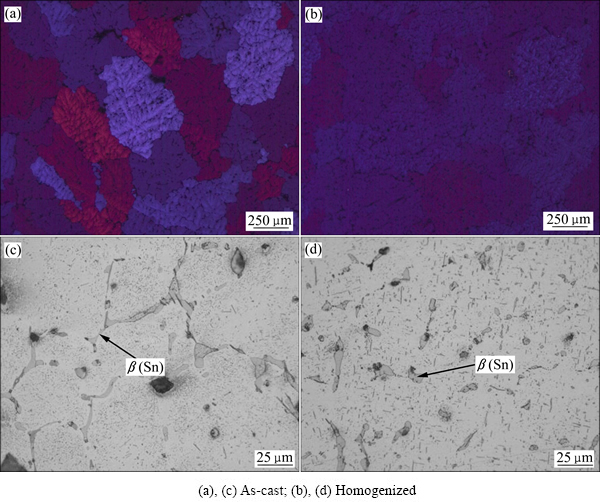

2.1.2 合金铸态、均匀态及挤压态组织观察与分析

图2所示为Al-Sn-Cu合金铸态和均匀态的金相组织。其中,图2(a)和(c)所示为铸态金相组织,图2(b)和(d)所示为均匀态金相组织。由图2可知,图2(a)中晶内存在着大量的树枝状晶,偏析较为严重,呈明显铸态组织特征。图2(b)中晶内的树枝状晶已基本消失,偏析程度也大大降低,均匀化处理后合金的组织得到了显著的改善。图2(c)中β(Sn)在晶界处呈连续网状分布,图2(d)中晶界处的β(Sn)则发生了聚集球化,这说明均匀化处理后β(Sn)相的连续网状已破裂,形成了球状和块状的β(Sn)。

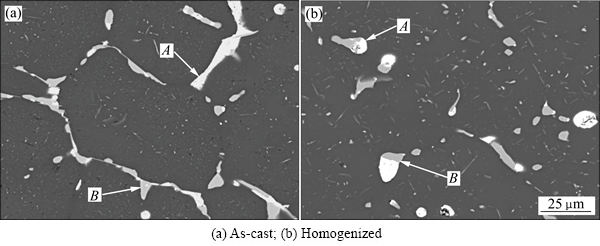

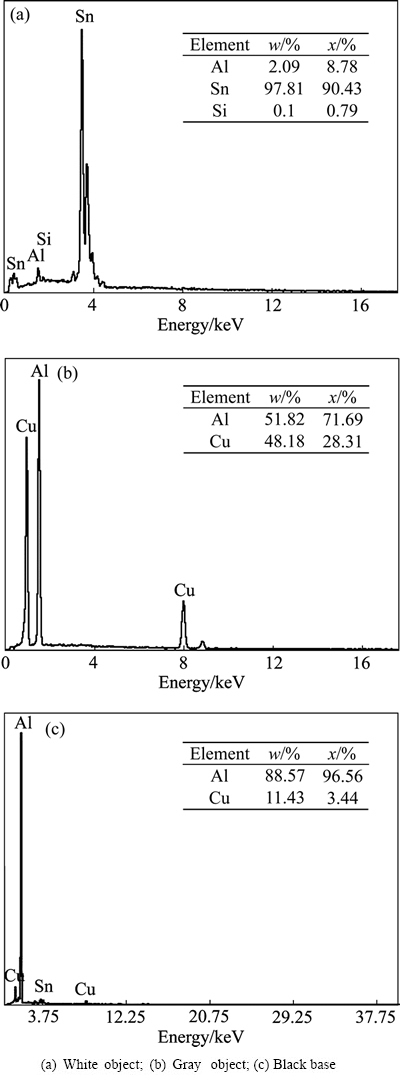

图3所示为合金铸态与均匀态的SEM像,从图3中可以更清楚地观察合金均匀化处理后的第二相形貌。其中,照片中的黑色基底为α(Al) (见图4(c)),弥散分布的针状灰色相为Al2Cu第二相。由图3可知,合金中主要分布有白色(A)和灰色(B)两种相,由EDS分析(见图4)可知,白色相主要成分是Sn,含有少量的Al,还有极少量的Si(可能扫到白色相附近的基底);而灰色相含有Al、Cu元素,为Al、Cu化合物。结合图1的XRD谱,白色相(A)为β(Sn),灰色相(B)为Al2Cu化合物。图3(a)中β(Sn)相和Al2Cu相呈明显连续网状分布于晶界处,而图3(b)中,连续网状的β(Sn)相和Al2Cu相已经消失,出现了块状和球状的β(Sn)相和Al2Cu相。这进一步说明,合金经均匀化处理后,连续网状的β(Sn)变成了球状和块状β(Sn),并且其依附或者围绕在Al2Cu周围。

图2 Al-Sn-Cu合金铸态和均匀态的金相显微组织

Fig. 2 Microstructures of Al-Sn-Cu alloy

图3 Al-Sn-Cu合金铸态和均匀态SEM像

Fig. 3 SEM images of Al-Sn-Cu alloy

图4 合金组织成分EDS分析结果

Fig. 4 Results of EDS analysis

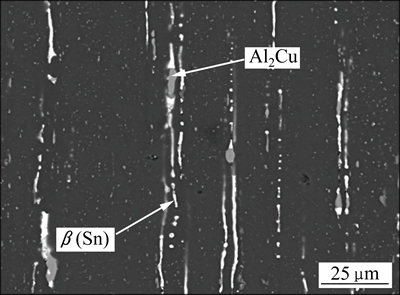

图5所示为Al-Sn-Cu合金经挤压后的SEM像。与图3(b)均匀态组织对比可知,经挤压变形之后,合金中的β(Sn)相被拉长成纤维状,并得到不同程度的破碎。β(Sn)相和Al2Cu化合物较均匀态时都发生了明显的细化,均匀地分布在基体之中,合金组织得到改善。

在均匀态、挤压态时,该合金组织中的许多β(Sn)都依附或者围绕着Al2Cu生长(见图3和5),这类似于Al-Sn-Si合金中β(Sn)包Si的“岛状”组织[9]。在铸锭凝固冷却时,Al2Cu和β(Sn)会优先在α(Al)晶界及位错等缺陷处形核长大,呈连续网状分布于晶界处。合金在(480 ℃, 1 h)制度下进行均匀化处理,晶界处的Al2Cu会逐渐溶解于基体,β(Sn)则发生熔融,熔融的β(Sn)相更有利于晶界的移动和自身的聚集球化,Al2Cu溶解和β(Sn)聚集球化过后,连续网状基本消失。在随后的冷却过程中,形成了球状和块状的Al2Cu相和β(Sn)相,但优先形核的细小Al2Cu粒子为熔融的β(Sn)重新形核提供了有利的非均匀形核核心,β(Sn)会依附或者围绕着Al2Cu生长。经挤压加工后,β(Sn)、Al2Cu以及β(Sn)依附或者围绕Al2Cu的组织都被拉长并且破碎,尺寸变得细小,合金组织得到改善。

图5 Al-Sn-Cu合金挤压态SEM像

Fig. 5 SEM image of Al-Sn-Cu alloy after extrusion

2.1.3 合金固溶时效态组织演变分析

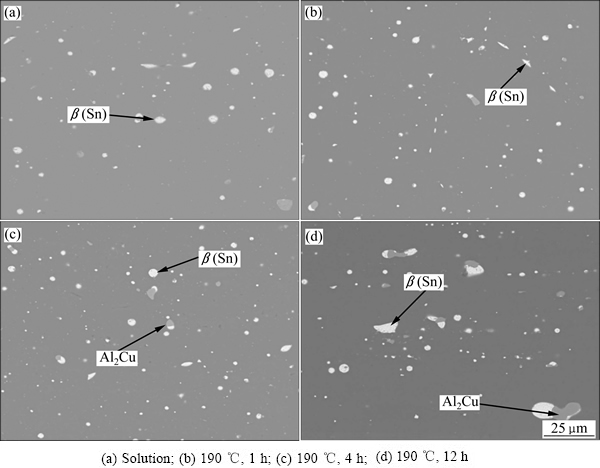

图6所示为Al-Sn-Cu合金经不同固溶-时效制度处理后的SEM像。由图1的XRD和图4的EDS分析可知,图6中的白色相为β(Sn),灰色相为Al2Cu。图6(a)所示为固溶态组织,由图可知,Al2Cu第二相绝大部分已经固溶到了基体,细小的β(Sn)相较为均匀地分布在基体中。图6(b)~(d)所示为190 ℃不同时效时间的组织,时效1 h时,Al2Cu相析出并不明显,此时β(Sn)相细小并呈均匀分布。时效4 h时,Al2Cu析出相大量生成,并均匀弥散地分布于基体,β(Sn)相的分布更加均匀。随着时效时间的延长,到12 h后,Al2Cu析出相已经长大,β(Sn)相也发生了粗化,尺寸有所增加。

图6 不同固溶时效状态下的合金SEM像

Fig. 6 SEM images of Al-Sn-Cu alloy after different solution and aging treatments

2.2 合金力学性能与TEM像

2.2.1 合金的力学性能

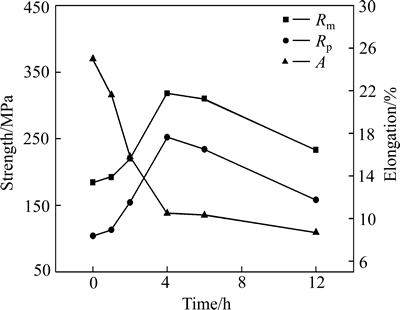

图7所示是190 ℃不同时效时间下的合金室温拉伸力学性能曲线。由图7可以看出,时效1 h时,合金抗拉强度、屈服强度很低,但伸长率非常高。随着时效时间的延长,抗拉强度、屈服强度升高,伸长率下降,在4 h时合金强度最高(318 MPa),达到峰值。随着时效时间的进一步延长,合金抗拉强度、屈服强度下降,伸长率有所降低。到12 h时,合金伸长率降到最低,抗拉强度、屈服强度也较低。

图7 不同时效状态的力学性能

Fig. 7 Tensile testing curves of Al-Sn-Cu alloy after different aging treatments

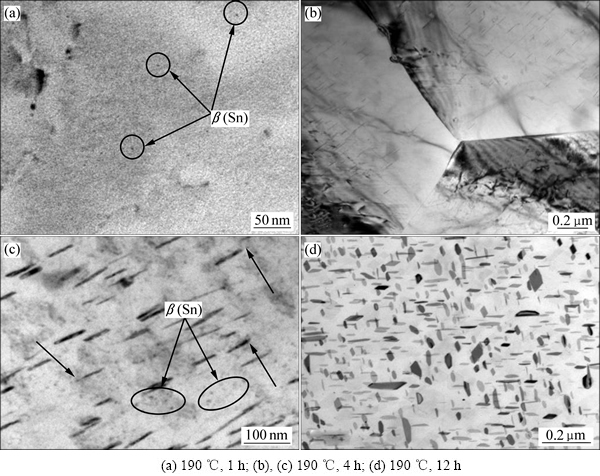

2.2.2 TEM像

合金不同时效状态的TEM观察结果如图8所示。图8(a)所示为合金时效1 h时的高倍TEM像,此时层片状的θ″与θ′相并未析出,但可以发现有许多细小弥散的黑色球状相分布在基体之中。HONMA等[18]和BOURGEOIS等[19]在Al-Cu-Sn合金中也发现了这种小黑点,证实该小黑点为β(Sn),并通过会聚电子衍 射(CBED)得出与基体的位相关系为(100)Sn//(111)α和[010]Sn//[112]α。结合XRD分析可知,该小黑点是刚形核的β(Sn)相,其尺寸非常细小,约为1~2 nm。图8(b)和(c)所示为合金时效4 h时的TEM像,大量层片状、针状的θ″与θ′相已经形成,弥散均匀地分布在基体中,长度大约为100 nm,厚度约为5 nm;球状的β(Sn)相开始有长大,尺寸约为2~5 nm。图8(d)所示为合金时效12 h的TEM像,由图8(d)可知,绝大部分的θ″与θ′相已经出现了长大粗化现象,形状变短变粗,长度方向变为50~100 nm,厚度方向则急剧粗化,达到30~50 nm。

图8 不同时效状态Al-Sn-Cu合金的TEM像

Fig. 8 TEM images of Al-Sn-Cu alloy after different aging treatments

θ″与θ′相是Al-Sn-Cu合金中非常有利的强化相。大量研究表明[19-23],在时效过程中,合金中的Sn可以促进θ″与θ′相的形核,并抑制其长大。有关其机理主要存在两种观点,第一种观点认为,在较高温度时效时,许多β(Sn)粒子会先于θ″与θ′相析出,细小的β(Sn)粒子为θ″与θ′相析出充当了非常有利的非均匀形核核心,大大提高θ″与θ′相的形核率,从而促进其形核。第二种观点认为,在较低温度时效时,θ″与θ′相在形成初期,Sn原子会聚集在其表面,不仅降低θ″与θ′相与母相的界面能,也会降低其相对于母相的界面能,θ″与θ′相的形核功变低,形核非常容易进行。在本实验中,时效1 h时,晶内析出许多β(Sn)粒子,但没有观察到θ″与θ′相(见图8(a)),说明β(Sn)粒子先于θ″和θ′相析出;时效4 h时,可以观察到部分细小的θ″与θ′相在β(Sn)粒子上析出(见图8(c)中黑色箭头所示),说明β(Sn)粒子可以作为θ″与θ′相的形核点。这与第一种机理观点不谋而合。

时效初期,晶内还未析出θ″和θ′相,合金强度较低。随着时效的继续,θ″和θ′相开始生成长大,其与母相产生共格应变,阻碍位错的运动,合金强度不断上升。在θ″和θ′相的析出过程中,先行析出的β(Sn)粒子促进了θ″和θ′相的形核,增加θ″和θ′相的形核率,加快了时效硬化速率,在较短时间(4 h)就达到了峰值。在峰时效时,θ″和θ′相非常细小且弥散均匀分布(见图8(b)和(c)),合金的强度得到很大的提高。时效后期,θ″和θ′相开始长大粗化,其数量减少,间距变大,位错与之的交互作用由切过变为绕过,合金强度下降。

2.3 摩擦磨损性能与磨损表面形貌

2.3.1 合金摩擦磨损性能

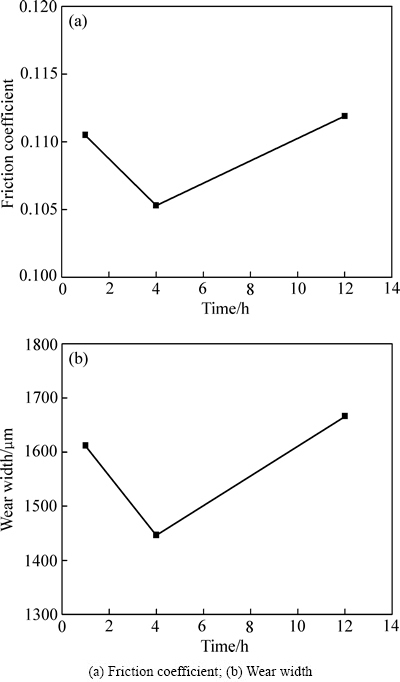

图9(a)所示为190 ℃不同时效时间的合金摩擦因数曲线。由图9(a)可知,随着时效时间的延长,合金的摩擦因数先减小后增加。在时效1 h时,合金强硬度较低,基体较软,摩擦因数较高(0.1105);时效4 h时,合金强硬度达到最高,摩擦因数降低为0.1053;时效12 h时,合金强硬度降低,并且由于其表面摩擦氧化层的破碎脱落,摩擦因数进一步升高,达到0.1119。图9(b)所示为磨痕宽度在190 ℃时随时效时间的变化曲线,由图9(b)可知,在时效4 h时,合金的磨痕宽度最低,为1446.49 μm。综合摩擦因数和磨痕宽度,合金在(190 ℃, 4 h)时效制度下,具有良好的摩擦磨损性能。

图9 不同时效状态下的Al-Sn-Cu合金摩擦磨损性能

Fig. 9 Wear properties of Al-Sn-Cu alloy after different aging treatments

2.3.2 磨损表面形貌

图10所示为190 ℃不同时效时间合金的磨损表面形貌。由图10(a)可以看出,合金在时效1 h时,其磨损表面存在粗大的犁沟和粘着痕迹,还可见粘着剥落坑,磨损严重。图10(b)所示为合金时效4 h的磨损表面形貌,由图10(b)可知,磨损表面只存在一定程度的犁沟,并无粘着痕迹和剥落坑,磨损表面质量较好。合金时效12 h的磨损表面形貌如图10(c)所示,可以看出,磨损表面产生了裂纹源,同时还存在一定程度的犁沟和粘着剥落现象,磨损加剧。综上所述,合金在时效4 h时的磨损表面形貌最好,这进一步表明,合金在(190 ℃, 4 h)时效制度下,具有良好的摩擦磨损性能。

合金的摩擦磨损特性与其组织、力学性能有着密切的关系。戴安伦等[24]发现高铝青铜合金经过固溶时效处理以后,硬质第二相均匀地分布在软相基体上,力学性能及摩擦磨损性能都得到相应提高。BRAVO等[25]在研究滑动轴承合金摩擦磨损性能时发现高强度和高硬度是获得良好摩擦磨损性能的重要条件。LU等[26]发现双尺度结构的Al-Sn合金的摩擦磨损性能要优于超细晶Al-Sn合金的,这是因为虽然超细晶Al-Sn合金强度非常高,但其塑韧性很差,而双尺度结构的Al-Sn合金却在保有高强度的同时,具有良好的塑韧性。这说明高强度和高塑性都是获得良好摩擦磨损性能必不可少的关键因素。时效1 h时,Al-Sn-Cu合金塑性虽然非常好,但其强度非常低,摩擦磨损性能不佳。时效12 h时,合金的强度和塑性都很低,摩擦因数和磨痕宽度较时效1 h时的都有所增加,摩擦磨损性能更差;时效4 h时,合金强度最高,塑性也较好(伸长率达10.5%),此时,其摩擦因数和磨痕宽度最低,磨损表面形貌也最好,具有最佳的摩擦磨损性能。

图10 不同时效状态下的合金磨损表面形貌

Fig. 10 Worn surface morphologies of alloy after different aging treatments

3 结论

1) Al-Sn-Cu合金的组织组成物为:α(Al)、β(Sn)及Al2Cu化合物。经过(480 ℃, 19 h)均匀化处理,连续网状的β(Sn)相消失,出现球状和块状β(Sn)相,其依附或者围绕在Al2Cu的周围。挤压变形之后,组织中的β(Sn)被拉长并破碎,β(Sn)和Al2Cu都得到细化,合金的组织得到改善。

2) 合金在(190 ℃, 4 h)时效时,晶内出现弥散分布的Al2Cu析出相和纳米级尺寸的β(Sn),合金的抗拉强度Rm、屈服强度Rp、伸长率A分别为318 MPa、252 MPa、10.5%,具有良好的力学性能。

3) 合金在(190 ℃, 4 h)时效时,其摩擦因数和磨痕宽度最低,分别为0.1053和1446.49 μm,磨损表面形貌最佳,具有良好的摩擦磨损性能。

REFERNCES

[1] 郭亚希, 谢敬佩, 王文焱, 王爱琴. 铸造方法对巴氏合金组织及性能的影响[J]. 河南科技大学学报(自然科学版), 2009, 30(4): 8-11.

GUO Ya-xi, XIE Jin-pei, WANG Wen-yan, WANG Ai-qin. Effects of casting method on microstructure and property of babbitt alloy[J]. Journal of Henan University of Science & Technology(Natural Science), 2009, 30(4): 8-11.

[2] 于 乐, 贾成厂. 机械合金化法强化Cu-10Sn合金[J]. 中国有色金属学报, 2013, 23(8): 2169-2175.

YU Le, JIA Cheng-chang. Strengthening of Cu10Sn alloy by mechanical alloying[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(8): 2169-2175.

[3] 尹延国, 林福东, 焦明华, 解 挺, 俞建卫, 田 明. 无铅含铋铜-钢双金属轴承材料的摩擦学特性[J]. 中国有色金属学报, 2011, 21(5): 1038-1044.

YIN Yan-guo, LIN Fu-dong, JIA Ming-hua, XIE Ting, YU Jian-wei, TIAN Ming. Tribological performance of lead-free Bi-contained copper-steel bimetal bearing materials[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(5): 1038-1044.

[4] 杨丽洁. 浅谈轴瓦材料的性能与使用[J]. 科技创新导报,2012, 4: 64.

YANG Li-jie. The introduction of the property and using of bearing shell material[J]. Science and Technology Innovation Herald, 2012, 4: 64.

[5] 朱 俊. 车用滑动轴承及常用的合金材料[J]. 汽车工程师, 2009, 1: 40-42.

ZHU Jun. Vehicle sliding bearing and alloy materials[J]. Auto Engineer, 2009, 1: 40-42.

[6] 陈玉明, 揭晓华, 吴 锋, 李黎明. 铝基滑动轴承合金材料的研究进展[J]. 材料研究与应用, 2007, 1(2): 95-98.

CHEN Yu-ming, JIE Xiao-hua, WU Feng, LI Li-ming. The research progress of aluminum base sliding bearing alloy materials[J]. Material Research and Application, 2007, 1(2): 95-98.

[7] 李溪滨, 刘如铁, 杨慧敏. 铝铅石墨固体自润滑复合材料的性能[J]. 中国有色金属学报, 2003, 13(2): 465-468.

LI Xi-bin, LIU Ru-tie, YANG Hui-min. Properties of solid self lubricating Al-Pb-graphite composites[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 465-468.

[8] 袁鸽成, 黎祚坚, 娄燕雄, 张新明. 硅含量对新型铝锡硅合金摩擦磨损性能的影响[J]. 中国有色金属学报, 1998, 8(1): 101-105.

YUAN Ge-cheng, LI Zuo-jian, LOU Yan-xiong, ZHANG Xin-ming. Influence of silicon content on friction and wear characteristics of new Al-Sn-Si alloys [J]. The Chinese Journal of Nonferrous Metals, 1998, 8(1): 101-105.

[9] 袁鸽成, 黎祚坚, 娄燕雄, 张新明. 新型铝锡硅合金结晶行为及显微组织[J]. 中国有色金属学报, 1997, 7(4): 110-114.

YUAN Ge-cheng, LI Zuo-jian, LOU Yan-xiong, ZHANG Xin-ming. Crystallization and microstructure of new Al-Sn-Si alloy [J]. The Chinese Journal of Nonferrous Metals, 1997, 7(4): 110-114.

[10] MESHI L, SAMUHA S, COHEN R S, LAIKHTMAN A. Dislocation structure and hardness of surface layers under friction of copper in different lubricant conditions[J]. Acta Materialia, 2011, 59: 342-348.

[11] LIU X, ZENG M Q, MA Y, ZHU M. Melting behavior and the correlation of Sn distribution on hardness in a nanostructured Al-Sn alloy[J]. Materials Science and Engineering A, 2009, 506: 1-7.

[12] LU Z C, GAO Y, ZENG M Q, ZHU M. Improving wear performance of dual-scale Al-Sn alloys: The role of Mg addition in enhancing Sn distribution and tribolayer stability[J]. Wear, 2014, 309: 216-225.

[13] 王士忠. 滑动轴承用铝合金: 中国, CN 101082094A[P]. 2007-12-05.

WANG Shi-zhong. The sliding bearing alloy: China, CN 101082094A[P]. 2007-12-05.

[14] 张崇才, 王 龙, 刘召杰. 新型铝基滑动轴承合金的性能与应用[J]. 机械工程材料, 2003, 27(7): 45-49.

ZHANG Chong-cai, WANG Long, LIU Zhao-jie. Properties and application of new aluminum base sliding bearing alloy[J]. Materials for Mechanical Engineering, 2003, 27(7): 45-49.

[15] KONG C J, BROWN P D, HORLOCK A. Influence of high velocity spraying conditions on the microstructure and properties of an Al-12wt%Sn-1wt%Cu alloys[J]. Materials Science Forum, 2002, 396: 1133-1138.

[16] LIU X, ZENG M Q, MA Y, ZHU M. Wear behavior of Al-Sn alloys with different distribution of Sn dispersoids manipulated by mechanical alloying and sintering[J]. Wear, 2008, 265: 1857-1863.

[17] 张崇才, 王 龙, 王守峰, 邓平璋. 时效工艺对新型铝基滑动轴承合金组织与性能的影响[J]. 金属热处理, 2005, 30(12): 31-35.

ZHANG Chong-cai, WANG Long, WANG Shou-feng, DENG Ping-zhang. Effect of aging treatment on microstructure and properties of a new aluminum matrix sliding bearing alloy[J]. Heat Treatment of Metals, 2005, 30(12): 31-35.

[18] HONMA T, SAXEY D W, RINGER S P. Effect of trace addition of Sn in Al-Cu alloy[J]. Material Science Forum, 2006, 519: 203-208.

[19] BOURGEOIS L, DWYER C, WEYLAND M, NIE J F, MUDDLE B C. The magic thicknesses of precipitates in Sn-microalloyed Al-Cu[J]. Acta Materialia, 2012, 60: 633-644.

[20] BANERJEE S J, ROBI P S, SRINIVASAN A, LAKAVATH P K. Effect of trace addition of Sn on microstructure and mechanical properties of Al-Cu-Mg alloys[J]. Materials and Design, 2010, 31: 4007-4015.

[21] HUTCHINSON C R, LOO P T, JBASTOW T, HILL A J, TEIXEIRA J C. Quantifying the strain-induced dissolution of precipitates in Al alloy microstructures using nuclear magnetic resonance[J]. Acta Materialia, 2009, 57: 5645-5653.

[22] TEIXEIRA J C, BOURGEOIS L, SINCLAIR C W, HUTCHINSON C R. The effect of shear-resistant, plate-shaped precipitates on the work hardening of Al alloys: Towards a prediction of the strength-elongation correlation[J]. Acta Materialia, 2009, 57: 6075-6089.

[23] 舒 军, 陈志国, 李世晨, 张纪帅, 任杰克. 微量Sn和In对Al-3.5%Cu合金时效行为及显微组织演变的影响[J]. 中国有色金属学报, 2012, 22(9): 2486-2491.

SHU Jun, CHEN Zhi-guo, LI Shi-chen, ZHANG Ji-shuai, REN Ke-jie. Effect of trace Sn(In) addition on ageing behaviour and microstructure evolution of Al-3.5%Cu alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2486-2491.

[24] 戴安伦, 严高闯, 朱治愿, 朱 凯, 陈 慧, 牛文明. 新型高铝青铜合金Cu-12Al-X在高温下的摩擦磨损行为[J]. 中国有色金属学报, 2013, 23(11): 3083-3090.

DAI An-lun, YAN Gao-chuang, ZHU Zhi-yuan, ZHU Kai, CHEN Hui, NIU Wen-ming. Wear-friction behavior of novel high aluminum bronzes alloy Cu-12Al-X in high temperature condition[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(11): 3083-3090.

[25] BRAVO A E, DURAN H A, JACOBO V H, ORTIZ A, SCHOUWENAARS R. Towards new formulations for journal bearing alloys[J]. Wear, 2013, 302: 1528-1535.

[26] LU Z C, ZENG M Q, GAO Y, ZHU M. Minimizing tribolayer damage by strength-ductility matching in dual-scale structured Al-Sn alloys: A mechanism for improving wear performance[J]. Wear, 2013, 304: 162-172.

(编辑 王 超)

基金项目:教育部2011计划资助项目(2013AH100055)

收稿日期:2015-02-09;修订日期:2015-05-21

通信作者:潘清林,教授,博士;电话:0731-88830933;E-mail: pql@csu.edu.cn