文章编号:1004-0609(2014)02-0395-08

固溶原子及析出相对强变形Al-4Cu合金晶粒细化效果的影响

赵凤晓1,许晓嫦1, 2,张 奇1,徐浩浩1,刘海全1,曾慧颖1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:通过透射电镜观察和XRD检测分析,对比纯Al试样,研究了多向压缩变形(MAC)过程中固溶原子及析出相对Al-4Cu合金晶粒细化效果的影响。结果表明:室温下,经过相同变形道次后,固溶原子的存在导致Al-4Cu合金所形成的亚晶粒形貌不规则,晶内位错密度较高,呈长约200 nm、宽约100 nm的类竹节状,纯Al中亚晶粒内部位错密度低,呈直径约600 nm的等轴状;Al-4Cu合金在室温下的析出相回溶过程抑制细小晶粒的形成,有利于亚晶内部位错密度的降低,50 ℃下的析出相回溶及再析出过程有利于细小晶粒的形成。

关键词:Al-4Cu合金;强变形;析出相回溶;晶粒尺寸;亚晶

中图分类号:TG37 文献标志码:A

Effect of solute atom and precipitated phase on grain refinement of Al-4Cu alloy by severe plastic deformation

ZHAO Feng-xiao1, XU Xiao-chang1, 2, ZHANG Qi1, XU Hao-hao1, LIU Hai-quan1, ZENG Hui-ying1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: The size and morphology of pure Al and Al-4Cu alloy processed by multi-axial compression (MAC) deformation were characterized by transmission electron microscopy and X-ray diffractometry to investigate the effect of solute atom and precipitated phase on grain refinement of Al-4Cu alloy by severe plastic deformation. The results show that the existence of solute atom in Al-4Cu alloy is associated with the irregular morphology of subgrain and higher dislocation density than that of pure Al. However, the former in bamboo-like shape exhibits smaller grain size with a length of about 200 nm and a width of about 100 nm than the latter in equiaxed shape with a diameter of about 600 nm. Also, at room temperature grain refinement is suppressed by the re-dissolution of severely deformed precipitated phase, which is helpful to the decrease of dislocation density, and at 50 ℃ the re-dissolution and re-precipitation of precipitate phase contributes to the grain refinement.

Key words: Al-4Cu alloy; severe plastic deformation; precipitated phase re-dissolution; grain size; subgrain

在塑性理论中,金属材料的晶粒尺寸对其塑性变形行为没有影响[1],但是Hall-Petch公式表明,随着晶粒尺寸的减小,合金强度会明显增高,这一点已经被很多实验证实,同时晶粒细化对金属的其他性能有很大影响,可提高材料的综合力学性能[2-3]。晶粒细化已成为提高材料综合性能的有效手段,是当今新型高性能材料的发展趋势。通过强塑性变形细化显微结构,是生产超细晶金属结构材料的有效方法。目前主要的强塑性变形方法有等径角挤压(ECAP)[4-7]、扭转变形(HPT)[8]、累积轧制(ARB)[9]和多向压缩变形(MAC)[10]等。在众多强变形方法中,MAC技术由于工艺简单、成本低、在现有工业装备下即可制备大块致密材料等优点,因此,有望直接应用于工业化生产[11]。

国际上有关强塑性变形的文献报道较多,KUNDU等[12]利用MAC加工铜,证实了MAC细化晶粒的可行性。在强变形的研究中,人们还发现一个重要的微观组织现象,即强应变引起析出相回溶现象[6, 13]。MURAYAMA等[6]在Al-4Cu二元合金的等径挤压变形中观察到呈针状的θ′过渡相在室温下数道次等径挤压过程中逐步分解成短链状颗粒直至回溶入基体。许晓嫦等[13-15]采用MAC技术重点研究了第二相粒子的回溶机制及其在随后继续变形过程中的再析出行为。目前,国内外对这一现象的机理研究较多,而关于固溶原子及析出相在强变形过程中对合金晶粒细化效果的影响研究报道较少。之前的研究主要集中在具有相同基体的合金在不同加工工艺下的组织与晶粒细化,而对不同基体在相同加工工艺下的组织与晶粒细化研究并未涉及。因此,本文作者采用透射电镜观察以及XRD检测分析,以纯Al作为基体,Cu原子作为固溶原子,探讨纯Al与不同热处理工艺下的Al-4Cu合金在强变形过程中固溶原子Cu及析出相θ″对合金晶粒细化效果的影响,使强变形合金晶粒细化的相关研究更加全面和完善。

1 实验

1.1 试样制备

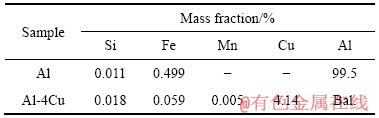

实验以工业纯Al(99.5%,质量分数)和电解纯Cu(99.5%,质量分数)为原料,在石墨坩埚中熔炼,铁模铸造。试样化学成分如表1所列。对比试样纯Al为工业纯(99.5%)。铸锭经过485 ℃、24 h均匀化处理后加工成10 mm×10 mm×15 mm的长方体,随后进行如表2所示的热处理。

表1 纯Al和Al-4Cu合金试样的化学成分

Table 1 Chemical compositions of Al and Al-4Cu alloy

表2 纯Al及Al-4Cu合金的热处理工艺

Table 2 Heat-treatment processes of Al and Al-4Cu alloy

1.2 实验方法

在自行设计的MAC模具上进行多向压缩变形。模具采用Cr12模具钢制备,其示意图如图1所示。

图1 多向压缩模具示意图

Fig. 1 Schematic diagram of MAC die

采用型号为WE60、最大负荷为60 t的液压式万能材料试验机,按应变轴X→Y→Z→X进行换方向压缩,以MoS2作为润滑剂。每道次的等效应变(ε)约为0.4,变形速率为5~10 mm/s。试样分别在室温和50 ℃下进行15道次(ε=6)多向压缩变形,用菲利普TECNAI- G2透射电子显微镜和日本理学D/max-2550/PC型X射线衍射仪分别观察晶粒尺寸和析出相的演变。透射电子显微镜观察试样在MAC变形后垂直于压缩方向取样,试样先机械减薄到0.1 mm,随后在MTP-1电解双喷仪上进行减薄,电解温度为-25 ℃。电解液为30%HNO3+70%CH3OH(体积分数)。

2 结果与讨论

2.1 固溶原子对合金晶粒细化的影响

图2所示为Al-4Cu合金固溶态试样和纯Al在室温加工15道次后的TEM像。

图2 室温下经MAC变形15道次后不同试样的TEM像

Fig. 2 TEM images of different samples after MAC deformation by 15 passes at room temperature

从图2可以清楚地看到固溶态试样在室温下变形15道次(ε=6)后出现明显的层片状结构,层片宽度为100~200 nm,如图2(a)箭头所示。纯Al经15道次变形后观察不到层片结构,也很少观察到明显拉长的变形晶粒,大部分晶粒以近等轴的亚晶粒形式存在,亚晶粒的结构发展较为完善,已观察不到明显的位错网结构,晶界较薄而清晰(见图2(b))。

图3所示为Al-4Cu合金固溶态试样与纯Al在室温加工15道次后的高倍TEM像。

从图3可以清楚地看到固溶态试样在室温下变形15道次(ε=6)后,层片结构呈类竹节状,长约200 nm,宽约100 nm,大量位错在其内部聚集形成位错缠结,部分晶粒内部位错缠结不明显(见图3(a))。纯Al经15道次变形后晶粒基本以等轴的亚晶粒为主,晶粒尺寸在600 nm左右,亚晶粒内部的位错密度低,位错缠结主要集中在胞壁处(见图3(b))。

图3 室温下经MAC变形15道次后不同试样的高倍TEM像

Fig. 3 TEM images of different samples after MAC deformation by 15 passes under higher magnification at room temperature

以上实验结果表明:室温下,经相同变形道次后,纯Al中已观察不到变形组织,转变为尺寸在600 nm左右、形貌较为完善的近等轴亚晶粒;Al-4Cu合金固溶态试样中仍存在明显的高密度位错变形组织,亚晶粒多为长宽比较大的类竹节状。

在材料的强变形过程中,材料的基体本质特征影响最终的晶粒细化效果,其基体本质特征包括材料的层错能和晶格结构等[5, 16]。固溶原子的加入对材料的层错能、晶格结构有较大的影响。纯Al层错能约为0.2 J/m2,属于高层错能金属。Al中添加Cu原子后可以降低材料的层错能[17]。Cu原子融入Al晶格中产生非对称性晶格畸变,与位错发生弹性交互作用,同样会对强变形过程产生影响。

在强变形下,纯Al的层错能高,极易发生螺型位错的交滑移和韧性位错的攀移,部分位错沿特定的滑移面排列成位错墙,形成宽度为1 μm的层片结 构[18-20]。随着变形的继续,这些高能量的位错在应力作用下运动并反应,导致同一滑移面上的异号位错相消,位错密度下降,位错沿垂直于滑移面方向排列成具有一定取向差的位错墙,切割层片结构最终形成尺寸为600 nm左右的亚晶粒。相对于高层错能的纯Al,固溶原子的加入导致Al-4Cu合金的层错能降低,在强变形过程中大部分位错分解为层错,这些层错不能产生交滑移,使得位错运动限制在一定的滑移面上,导致位错在滑移面上排列,形成如图2(a)所示宽度为100~200 nm的层片结构。在部分晶粒内部,不同滑移系的开动切割胞结构和层片结构,使其演化为类竹节状的亚晶粒。Cu原子融入Al晶格中产生非对称性晶格畸变,与位错发生弹性交互作用,使基体的抗变形力提高[21],导致位错间反应缓慢,很难通过交滑移和攀移而湮灭,使得亚晶粒内部的位错密度较高。同时,造成Al-4Cu合金中的位错运动能力相对较弱,具有较低的回复率,这延缓了微观结构的形成[17]。所以,在相同的变形量下,出现Al-4Cu合金和纯Al两种不同的组织状态。由此可以推论:在相同变形量下,固溶原子延缓了Al-4Cu合金均匀微观结构的形成,造成纯Al的晶粒形貌和内部结构的完善性优于Al-4Cu合金的,但晶粒尺寸比Al-4Cu合金的粗大。

2.2 析出相回溶和回溶后再析出对Al-4Cu合金晶粒细化的影响

采用本研究中热处理制度获取含θ″相的Al-4Cu合金,与具有相同基体特征的Al-4Cu固溶态试样进行对比,分析析出相回溶以及回溶后再析出两个过程对晶粒细化的影响。

2.2.1 析出相回溶对晶粒细化的影响

图4(a)所示为在本研究中所采用的热处理工艺下获得的含θ″相试样的TEM像。θ″相均匀地分布在基体中。如箭头所示,θ″相的长度约为50 nm、宽度约为2 nm。由于与基体完全共格,因而在θ″短片的周围显出模糊的影像。

图4(b)和(c)所示为含θ″相试样在室温下经MAC强变形15道次(ε=6)后的TEM像。由图4(b)和(c)可以观察到明显的层片结构,一个层片结构内部出现多个位错胞结构,亚晶粒的形貌极不规则,出现近等轴状亚晶粒。析出相在强变形过程中发生了回溶,重新形成过饱和固溶体,几乎看不到析出相的存在。亚晶粒呈现类竹节状,晶粒的长度约为400 nm,宽度约为150 nm。与固溶态试样(见图2(a)、3(a)和3(b))相比,含θ″相试样在变形后的晶粒尺寸大于固溶态试样在变形后的晶粒尺寸,同时,其亚晶粒内部的位错密度明显低于固溶态试样亚晶粒内部的位错密度。

图4 含θ″相Al-4Cu合金室温MAC变形后的TEM像

Fig. 4 TEM images of specimens containing θ″ phase after MAC passes at ambient temperature

图5所示为含θ″相试样变形前与室温变形15道次(ε=6)后的XRD谱。由图5可以看出,含θ″相试样室温变形15道次(ε=6)后θ″相衍射峰消失,说明析出相已经完全回溶,与图4(b)相符。

图5 含θ″相试样在室温下经不同MAC变形后的XRD谱

Fig. 5 XRD patterns of specimens containing θ″ phase after different MAC passes at room temperature

实验结果表明:在室温及相同变形量下,含θ″相试样的晶粒细化效果不及固溶态试样的晶粒细化效果。与固溶态试样相比,两试样内部亚晶粒均以类竹节状的形貌存在,固溶态试样亚晶粒尺寸更小,含θ″相试样内亚晶粒的长度约为400 nm,宽度约为150 nm;固溶态试样内亚晶粒的长度约为200 nm、宽度约为100 nm,但位错密度明显高于含θ″相试样的。

在强变形过程中,由于析出相处易于出现应力集中,形变将首先在析出物上产生,所以析出相粒子相对于基体颗粒提前破碎、变细小[22-23]。破碎、细小的析出相与基体的接触面积增大,使界面上的基体浓度提高,这样基体和析出相之间出现能量级浓度梯度,在能量级浓度梯度的驱使下发生析出相的回溶[24]。在强变形过程中,部分位错会在析出相处堆积,随变形量的增加,析出相出现回溶,原析出相处堆积的位错发生对消,导致位错密度降低[25]。从能量角度来看,对于单相固溶态试样,在低温强塑性变形过程中,外加变形能同时作用于加工硬化与晶粒细化两个过程,而对于含θ″相的试样,外加的变形能同时作用于加工硬化、析出相回溶和晶粒细化3个过程,所以,用于晶粒细化的变形能小于固溶态试样中用于晶粒细化的变形能,晶粒细化的程度随之相对较小[23],造成室温下含θ″相试样中亚晶粒尺寸大于固溶态试样中亚晶粒尺寸,同时亚晶粒内部位错密度明显低于固溶态试样的。由此可以推论,室温下的析出相回溶过程抑制了细小晶粒的形成,有利于亚晶粒内部位错密度的降低。

2.2.2 析出相回溶后再析出对晶粒细化的影响

图6所示为含θ″相试样与固溶态试样在50 ℃下经MAC变形后的TEM像。从图6可观察到,含θ″相试样经MAC变形1道次(ε=0.4)后(见图6(a)),θ″析出相周围聚集着大量的位错,如箭头所示,不再有未变形态(见图4(a))时的有序分布。当MAC变形6道次(ε=2.4)后(见图6(b)),可以看到层片结构,层片结构内部存在类竹节状亚晶粒,θ″相消失。经MAC变形15道次(ε=6)后,观察到层片结构,且层片结构的宽度小于200 nm(见图6(c))。高倍TEM像显示,在含θ″相试样中部分区域可以观察到类竹节状亚晶粒分解成小尺寸近等轴亚晶粒,但绝大部分亚晶粒仍以类竹节状存在,长度和宽度均在100 nm左右;在亚晶界处观察到少量颗粒状析出相,较为弥散地分布在亚晶界处(见图6(d))。说明含θ″相试样在MAC变形6~15道次之间发生了析出相再析出过程。固溶态试样于50 ℃经15道次变形后形成层片结构(见图6(e)),高倍TEM像显示类竹节状亚晶粒长度约为200 nm,宽度约为100 nm,晶界处未发现析出相存在(见图6(f))。

图7所示为含θ″相试样在50 ℃下经不同MAC道次变形后的XRD谱。如图7(a)所示,含θ″相试样经MAC变形1道次(ε=0.4)后依然存在θ″析出相,这与图6(a)所观察到的结果相符。在经MAC变形6道次(ε= 2.4)后,XRD谱显示不存在θ″相衍射峰,图6(b)的TEM像中观察不到析出相,这表明含θ″相试样在50 ℃下经MAC变形6道次(ε=2.4)后θ″相完全发生回溶。经MAC变形15道次(ε=6)后,XRD谱中出现新的θ相衍射峰,同样在图6(d)中观察到晶界处存在颗粒状析出相,这表明含θ″相试样在50 ℃下经MAC变形15道次(ε=6)后出现新的θ相。

实验结果表明:50 ℃下含θ″相试样经MAC变形6道次(ε=2.4)后θ″相完全回溶,经MAC变形15道次(ε=6)出现新的θ相。经MAC变形15道次(ε=6)后,含θ″相试样的晶粒长度和宽度均在100 nm左右,固溶态试样中亚晶粒的长度约为200 nm,宽度约为100 nm。与固溶态试样相比,在析出相回溶并再析出过程有利于细小晶粒的形成,亚晶粒尺寸小于Al-4Cu合金固溶态试样与室温下析出相回溶后形成的亚晶粒尺寸。

图6 含θ″相Al-4Cu合金与固溶态Al-4Cu合金试样在50 ℃经不同MAC变形后的TEM像

Fig. 6 TEM images of Al-4Cu specimens containing θ″ phase ((a)-(d)) and solid solution ((e), (f)) at 50 ℃

在50 ℃的变形温度下,形变能迫使析出相破碎,使表面能提高,50 ℃下原子扩散速度加快,造成析出相回溶所需的临界能量降低,在较低的变形量下析出相出现回溶。θ″相回溶后,基体重新出现过饱和度,晶格严重畸变,处于高能状态,与固溶态试样相比,在原θ″相处Cu原子发生严重偏聚,阻碍位错缠结的运动,位错胞向外扩展困难。同时,强塑性变形在基体中产生大量的层片结构和胞状结构等晶格缺陷,基体中重新出现的过饱和度驱使非共格的θ相在这些缺陷处重新形核析出[23],θ相的析出进一步钉扎层片结构和胞状结构处的位错。对于固溶态试样,在热处理过程中,Cu原子以较为均匀的方式融入基体晶格中,偏聚现象较弱,对位错缠结的阻碍作用没有强变形过程中形成的过饱和固溶态严重,位错胞向外扩展的阻力相对较小,导致最终形成的亚晶粒尺寸大于含θ″相试样的。同时,Cu原子的偏聚浓度达不到形核的浓度,所以,固溶态试样在相同加工工艺下没有析出相析出。由此可以推断:50 ℃下强变形后析出相回溶及再析出过程产生非共格θ相,位错难以切过,有利于晶粒的细化。

图7 含θ″相试样在50 ℃下经不同MAC变形后的XRD谱

Fig. 7 XRD patterns of specimens containing θ″ phase after different MAC passes at 50 ℃

3 结论

1) 在经过相同变形道次后,固溶原子所引起的层错能及晶格结构上的差异使纯Al与Al-4Cu合金的微观结构存在较大差异,较低的层错能与严重的晶格畸变延缓了Al-4Cu合金均匀微观结构的形成。纯Al在变形后的晶粒形貌、内部结构完善性优于Al-4Cu合金的,但晶粒尺寸比Al-4Cu合金的粗大。

2) 室温下析出相的回溶过程抑制了细小晶粒的形成,有利于亚晶内部位错密度的降低。与Al-4Cu合金固溶态试样相比,经相同变形量后含θ″相试样的亚晶粒同样呈类竹节状,长度约为400 nm,宽度约为150 nm,尺寸明显大于固溶态试样的。

3) 50 ℃下的析出相回溶及再析出过程有利于细小晶粒的形成,含θ″相Al-4Cu试样的亚晶粒尺寸小于Al-4Cu合金固溶态试样与室温下析出相回溶后形成的亚晶粒尺寸。

REFERENCES

[1] KAWASAKI M, AHN B, LANGDON T G. Effect of strain reversals on the processing of high-purity aluminum by high-pressure torsion[J]. Journal of Materials Science, 2010, 45(17): 4583-4593.

[2] TANG G C H, HOFFMAN M, YAN J L. Fatigue crack growth in ultrafine grained aluminiun alloy[J]. Materials Science Forum, 2011,34(7): 210-213.

[3] SEMENOVA I P, SALIMGAREEVA G K, LATYSH V V, ZAKARIA Q M, LAPOVOK R, LOWE T, VALIEV R Z. Enhanced fatigue strength of commercially pure Ti processed by severe plastic deformation[J]. Materials Science and Engineering A, 2009, 503(1): 92-95.

[4] ZHANG Jing, ZHANG Ke-shi, WU Hwai-Chung, YU Mei-hua. Experimental and numerical investigation on pure aluminum by ECAP[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(7): 1303-1311.

[5] CHENG Xu, ZENJI H, TERENCE G. Microstructural evolution in an aluminium solid solution alloy processed by ECAP[J]. Materials Science and Engineering A, 2011, 34(3): 528-537.

[6] MURAYAMA M, HONO K, HORITA Z. Microstructural evolution in an Al-1.7 at% Cu alloy deformed by equal-channel angular pressing[J]. Materials Transactions—JIM, 1999, 40(9): 938-941.

[7] HOSEINI M, MERATIAN M, TOROGHINEJAD M R, SZPUNAR J A. The role of grain orientation in microstructure evolution of pure aluminum processed by equal channel angular pressing[J]. Materials Characterization, 2010, 61(12): 1371-1378.

[8] TOTH L S, ARZAGHI M, FUNDENBERGER J J, BEAUSIR B, BOUAZIZ O, MASSION R A. Severe plastic deformation of metals by high-pressure tube twisting[J]. Scripta Materialia, 2009, 60(3): 175-177.

[9] 康志新, 彭勇辉, 赖晓明, 李元元, 赵海东, 张卫文. 剧塑性变形制备超细晶/纳米晶结构金属材料的研究现状和应用展望[J]. 中国有色金属学报, 2010, 20(4): 587-596.

KANG Zhi-xin, PENG Yong-hui, LAI Xiao-ming, LI Yuan-yuan, ZHAO Hai-dong, ZHANG Wei-wen. Research status and application prospect of ultrafine grained and/or nano-crystalline metallic materials processed by severe plastic deformation[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(4): 587-596.

[10] 党 朋, 许晓嫦, 刘志义, 于文斌, 宁爱林, 曾苏民. Al-4Cu合金θ′析出相在等径角挤压中的回溶机理[J]. 金属热处理, 2007, 32(8): 28-31.

DANG Peng, XU Xiao-chang, LIU Zhi-yi, YU Wen-bin, NING Ai-lin, ZENG Su-min. Dissolution mechanisms of θ′ precipitates in Al-4Cu alloy deformed by equal-channel angular pressing[J]. Heat Treatment of Metals, 2007, 32(8): 28-31.

[11] 胡 楠, 许晓嫦, 张孜昭, 屈 啸. 强变形诱导析出相回溶对Al-4Cu合金力学性能的影响[J]. 中国有色金属学报, 2010, 20(10): 1922-1931.

HU Nan, XU Xiao-chang, ZHANG Zi-zhao, QU Xiao. Effect of re-dissolution of severely deformed precipitated phase on mechanical properties of Al-4Cu alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(10): 1922-1931.

[12] KUNDU A, KAPOOR R, TEWARI R, CHAKRAVARTTY J K. Severe plastic deformation of copper using multiple compression in a channel die[J]. Scripta Materialia, 2008, 58(3): 235-238.

[13] 许晓嫦, 刘志义, 党 朋, 于文斌, 宁爱林, 曾苏民. 室温强塑性变形中铝合金时效析出相的演变[J]. 金属热处理, 2006, 31(8): 56-59.

XU Xiao-chang, LIU Zhi-yi, DANG Peng, YU Wen-bin, NING Ai-lin, ZENG Su-min. Evolution of aged precipitates of aluminum alloy under severe plastic deformation at room temperature[J]. Heat Treatment of Metals, 2006, 31(8): 56-59.

[14] 张孜昭, 许晓嫦, 刘志义, 夏卿坤, 曾苏民. 强变形诱导形成的Al-4Cu合金过饱和固溶体在继续变形时的再析出行为[J]. 中国有色金属学报, 2009, 19(11): 1962-1968.

ZHANG Zi-zhao, XU Xiao-chang, LIU Zhi-yi, XIA Qin-kun, ZENG Su-min. Effect of dissolution of precipitated phases on thermal stability of Al-4Cu alloy after severe plastic deformation[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(11): 1962-1968.

[15] 张孜昭, 许晓嫦, 胡 楠, 屈 啸, 陈振湘. 强变形诱导析出相回溶后的Al-4Cu合金再时效行为[J]. 中南大学学报: 自然科学版, 2010, 41(5): 1782-1790.

ZHANG Zi-zhao, XU Xiao-chang, HU Nan, QU Xiao, CHEN Zhen-xiang. Re-ageing behavior of Al-4Cu alloy after re-dissolution of precipitated phases caused by severe plastic deformation[J]. Journal of Central South University: Science and Technology, 2010, 41(5): 1782-1790.

[16] 汪建敏, 周孔亢, 陆 晋, 许晓静, 姜银方. 层错能在剧烈剪切变形时对晶粒细化的影响[J]. 机械工程学报, 2008, 44(11): 126-131.

WANG Jian-min, ZHOU Kong-kang, LU Jin, XU Xiao-jing, JIANG Yin-fang. Influence of stacking fault energy on grain-refining during severe shear deforming[J]. Chinese Journal of Mechanical Engineering, 2008, 44(11): 126-131.

[17] 吴世丁, 安祥海, 韩卫忠, 屈 伸, 张哲峰. 等通道转角挤压过程中FCC金属的微观结构演化与力学性能[J]. 金属学报, 2010, 46(3): 257-276.

WU Shi-ding, AN Xiang-hai, HAN Wei-zhong, QU Shen, ZHANG Zhe-feng. Microstructure evolution and mechanical properties of FCC metallic materials subject to equal channel angular pressing[J]. Acta Metallurgica Sinica, 2010, 46(3): 257-276.

[18] 林均品, 安希庸, 雷廷权. 铝合金的动态再结晶[J]. 金属科学与工艺, 1988, 7(2): 107-113.

LIN Jun-pin, AN Xi-yong, LEI Ting-quan. Dynamic recrystallization in aluminium alloys[J]. Metal Science and Technology, 1988, 7(2): 107-113.

[19] 郑立静, 陈昌麒, 周铁涛, 刘培英, 曾梅光. ECAP细晶机制及对纯铝显微组织和力学性能的影响[J]. 稀有金属材料与工程, 2004, 33(12): 1325-1328.

ZHENG Li-jing, CHEN Chang-qi, ZHOU Tie-tao, LIU Pei-ying, ZENG Mei-guang. Grain-refining mechanism of ECAP and its effect on microstructures and mechanical properties of pure Al[J]. Rare Metal Materials and Engineering, 2004, 33(12): 1325-1328.

[20] JIANG J, DING Y, ZUO F, SHAN A. Mechanical properties and microstructures of ultrafine-grained pure aluminum by asymmetric rolling[J]. Scripta Materialia, 2009, 60(10): 905-908.

[21] WEI W, ZHANG W, WEI K X, ZHONG Y, CHENG G, HU J. Finite element analysis of deformation behavior in continuous ECAP process[J]. Materials Science and Engineering A, 2009, 516(1): 111-118.

[22] 党 朋, 许晓嫦, 刘志义, 于文斌, 宁爱林, 曾苏民. 铝合金等径角挤压和多向压缩变形中析出相的回溶研究[J]. 材料热处理学报, 2007, 28(5): 82-85.

DANG Peng, XU Xiao-chang, LIU Zhi-yi, YU Wen-bin, NING Han-lin, ZENG Su-min. Dissolution mechanisms of θ′ precipitates in Al-4Cu alloy deformed by equal-channel angular pressing[J]. Transactions of Materials and Heat Treatment, 2007, 28(5): 82-85.

[23] 许晓嫦. 强变形诱导铝合金析出相低温回溶现象及应用基础研究[D]. 长沙: 中南大学, 2008: 86-157.

XU Xiao-chang. Basic investigation on the phenomenon of severe plastic deformation induced re-dissolution of precipitated phases at low temperature and its application[D]. Changsha: Central South University, 2008: 86-157.

[24] 许晓嫦, 刘志义, 张 坤, 郑青春, 叶呈武. 强变形诱导析出相回归后的再时效行为[J]. 中国有色金属学报, 2004, 14(5): 759-765.

XU Xiao-chang, LIU Zhi-yi, ZHANG Kun, ZHENG Qing-chun, YE Cheng-wu. Re-ageing behavior of retrogressive precipitated phase caused by severe plastic deformation[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(5): 759-765.

[25] FIGUEIREDO R B, LANGDON T G. Grain refinement and mechanical behavior of a magnesium alloy processed by ECAP[J]. Journal of Materials Science, 2010, 45(17): 4827-4836.

(编辑 陈卫萍)

基金项目:国家重点基础研究发展计划资助项目(2012CB619506-2)

收稿日期:2013-02-27;修订日期:2013-06-21

通信作者:许晓嫦,教授,博士;电话:13787797327;E-mail: xxc12@126.com