文章编号:1004-0609(2015)-01-0058-05

热处理对高压凝固Ti-48Al合金组织演变的影响

朱冬冬1, 2,董 多1, 2,倪成员1,周兆忠1,张德丰1,魏尊杰2

(1. 衢州学院 机械工程学院,衢州 324000;

2. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001)

摘 要:采用六面顶压机制备2和4 GPa下高压凝固试样,并在真空封装后进行1100 ℃保温12 h空冷的高温热处理实验,研究经高压凝固后Ti-48Al合金组织的演变规律以及高压凝固后热处理对Ti-48Al合金组织变化的影响。结果表明:经高压凝固后,随着凝固压力的增加,枝晶间γ相数量减少;当压力到达4 GPa时,片层组织的体积分数约为99.31%。经热处理后,常压凝固试样变化不大,而高压凝固试样中均形成魏氏组织,采用1100 ℃炉冷热处理和EBSD技术进行分析,确定了高压下魏氏体组织的形成机制。

关键词:钛铝金属间化合物;高压凝固;热处理;魏氏体

中图分类号:TG 146.2;TG292 文献标志码:A

Effect of heat treatment on microstructure evolution of Ti-48Al alloy solidified under high pressure

ZHU Dong-dong1, 2, DONG Duo1, 2, NI Cheng-yuan1, ZHOU Zhao-zhong1, ZHANG De-feng1, WEI Zun-jie2

(1. School of Mechanical Engineering, Quzhou University, Quzhou 324000, China)

(2. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China)

Abstract: High pressure solidification samples were prepared at 2 and 4 GPa on a HTDS-032F type cubic hydraulic pressure machine. Then, the samples were heat-treated at 1120 ℃ for 12 h. The effect of high pressure on the microstructure evolution of Ti-48Al alloy solidified under high pressure and heat treatment on the microstructure evolution of Ti-48Al alloy solidified under different pressures were investigated. The results indicate that, when solidified under high pressure, the γ-segregate phase decreases with increasing the pressure. When the pressure reaches 4 GPa, the volume fraction of lamellar structure is about 99.31%. After heat treatment, the microstructure solidified under normal pressure is not changed, but Widmanst tten lamellar microstructure forms in high pressure solidified samples by NAKA mechanism, which is confirmed by heat treatment and EBSD analysis.

tten lamellar microstructure forms in high pressure solidified samples by NAKA mechanism, which is confirmed by heat treatment and EBSD analysis.

Key words: TiAl intermetallic; high pressure solidification; heat treatment; Widmanst tten

tten

凝固过程对合金凝固后的组织形貌、相组成及其大小和分布起着决定性的作用,进而决定铸件的各种性能[1]。合金在常压下凝固时[2-3],熔体温度的作用较大,此时压力对凝固动力学和热力学参数产生的影响可以忽略不计[4],随着高压技术的发展,当压力能够达到GPa级时,使得在高压下研究金属和合金的性质以及制备新材料等成为现实[5]。研究指出一般的物质在经历1 GPa的高压过程中,平均出现5种不同的相变,因此,采用高压技术合成具有特殊功能的新材料是当前国内外高压研究领域的一个主要方向[6],当金属或合金在高压下凝固时,会产生许多不同于常压下凝固时的新现象[7],获得不同于常压作用的金属凝固组织。因此,开展高压作用下金属凝固过程的研究成为当前金属凝固领域的一个新的研究方向,是凝固领域前沿研究方向之一。

TiAl合金作为一种新型高温结构材料,因其具有较低的密度、较高的弹性模量、优良的高温强度以及良好的高温抗氧化性能而引起广泛的关注[8-9]。TiAl合金的力学性能与其组织密切相关[10-12],合金相变的机理研究对于建立合金的组织与力学性能之间的关系具有十分重要的意义[13-14]。目前,关于热处理对高压下凝固钛铝金属间化合物组织变化规律的研究尚未见报道,因此,研究热处理对高压凝固钛铝金属间化合物组织的影响,对于探索高压凝固规律有重要意义,并为改善合金性能提供理论基础。

1 实验

用海绵钛(0级)和高纯铝(99.99%)在中频感应炉中熔制Ti-48Al母合金,将母合金浇入石墨模具得到150 mm×100 mm×16 mm的板状试样。利用线切割加工成圆柱试样,再用5%HF(体积分数)清洗,打磨表面氧化物,制成d 20 mm×9 mm的圆柱试样,用于高压凝固。高压实验在HTDS-032F型六面顶压机上进行。试样用绝缘圈包裹,用叶腊石做密封兼传压材料,将压力升高到指定压力(2和4 GPa)后,开始加热至合金熔化,保温保压5 min后,停止加热,待试样冷却到室温,卸压,取出试样进行测试分析。

采用线切割从不同压力下凝固的母合金锭上切取5 mm×5 mm×3 mm的试样,用金相砂纸将试样打磨后清洗,以去除表面油渍和氧化皮。将试样进行真空封装后,待热处理炉升到指定温度,放入封装好的试样,进行热处理试验。

合金显微组织观察采用Zeiss MC82 DX光学显微镜;EBSD分析在Hitachi S×570扫描电子显微镜上进行,EBSD试样经双喷电解抛光技术制备而成,电解抛光液配方为:34%(体积分数)正丁醇、6%(体积分数)高氯酸、60%(体积分数)甲醇。

2 结果与讨论

2.1 不同压力下的凝固组织

图1所示为Ti-48Al合金经不同压力下凝固后的显微组织。常压下,枝晶间γ相体积分数较多,几乎连成一体;随着凝固压力的增加,枝晶间γ相数量减少,2 GPa时,枝晶间γ相晶团尺寸变小且数量较少,片层组织基本连成一体;当压力到达4 GPa时,枝晶间只有极少量γ相存在,且组织中有明显的三角晶界存在,如图1(c)和(d)所示,经计算4GPa时片层组织的体积分数约为99.31%。MCCULLOUGH等[15]的研究表明,Ti-48Al合金在实际凝固过程中包晶反应L+α→γ较难发生,枝晶间γ相均是从Al元素含量达55.1%的液相中直接析出,在高压凝固过程中,压力增加引起扩散系数呈指数级减小,从而导致了Al元素很难从液相经α相扩散至γ相中,进而导致在高压凝固条件下能达到55.1%的液相体积分数减少,即最终凝固的枝晶间γ相减少,α相体积分数增加,α相经过凝固最终转化为片层组织,故随着压力的增加,片层组织逐渐增多,枝晶间γ相逐渐减少,压力到达4 GPa时,已接近全片层组织。

图1 不同压力下凝固Ti-48Al合金的光学显微组织

Fig. 1 Optical microstructures of Ti-48Al alloy solidified under different pressures

2.2 热处理对合金组织的影响

图2所示为3种不同压力下凝固的Ti-48Al合金经1100 ℃保温12 h后空冷所获得的组织照片。图2显示经热处理后,常压下组织并无明显变化,仍是由片层组织及枝晶间γ相组成。而当凝固压力为2 GPa和4 GPa时,凝固后试样的组织较热处理前的发生明显变化,生成大量魏氏组织,而魏氏组织在常压条件下只有加热到α单相区保温且以较大的冷速冷却时才能出现。

图2 不同压力下凝固Ti-48Al合金热处理空冷的显微组织

Fig. 2 Microstructures of Ti-48Al alloy solidified under different pressures after heat treatment

为研究热处理后魏氏体的形成机理,必须要了解魏氏体的形成机制,关于其形成机制目前主要有两种,YAMABE的机制是指在初始冷却的时候形成了孪晶[16],在随后的冷却过程中,α相基体转变成片层组织,而孪晶则转变成为魏氏组织。研究表明在冷却的过程中α相会形成3种不同种类的孪晶,导致形成的魏氏体与原片层组织有夹角分别为34.54°、64.58°和95°。

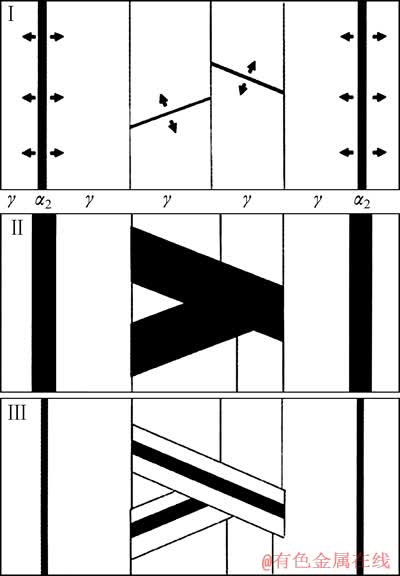

NAKA等[17]的机制认为,在加热过程中α2首先无序化成α相,随着保温时间的增加,已存在的α相相体积分数增加。 同时在之前的γ片层的(111)面上会有新的α形核并长大,在随后的冷却过程中,新生成的板条会转化成片层即形成了魏氏组织,如图3所示。通过此机制形成的魏氏组织,魏氏体和原层片之间的夹角间的夹角为38.9°、56.3°和70.5°。

为研究魏氏体的形成机制,本实验中设计了1100 ℃保温12 h后再炉冷的实验,魏氏组织若是按YAMABE的机制形成的话,则冷却速度的改变将会导致初始冷却的时候不再形成孪晶,从而炉冷组织无魏氏组织生成。

图3 NAKA机制的魏氏组织形成机制[14]

Fig. 3 Widmanstatten lamellar variants formed within lamellar colony by NAKA mechanism[14]

图4所示为合金经热处理后炉冷条件下的显微组织照片。由图4可以看出,其组织与空冷组织类似,常压试样的组织与热处理前相比,仍无明显变化。高压试样经热处理后也是由大量魏氏组织生成。

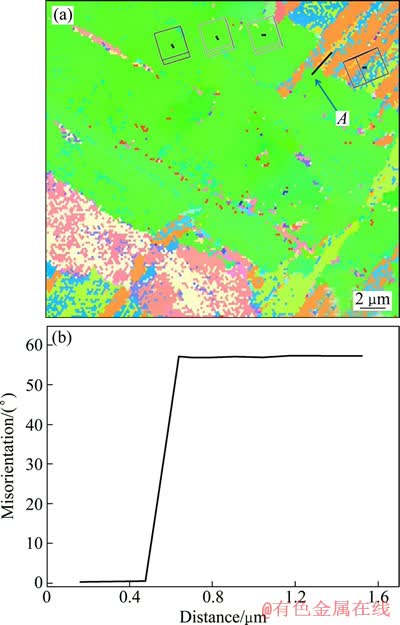

通过之前的分析可以看出,从魏氏组织与原始片层组织之间的夹角关系也能辨别魏氏组织是的形成机制,EBSD技术能较好地分析两种组织之间的取向差,故本实验中采用EBSD技术对魏氏组织与原始片层组织的空间位向进行分析,如图5(a)所示,并在图中A点所示位置分析魏氏组织与片层组织的取向差,如图5(b)所示,经计算得魏氏组织与原始片层组织之间的夹角约为57.1°,最接近于56.3°,进一步证明在本实验条件下所获得的魏氏组织是按NAKA机制形成的。

图4 不同压力下凝固Ti-48Al合金热处理炉冷的显微组织

Fig. 4 Microstructures of Ti-48Al alloy solidified under different pressures after heat treatment

图5 4 GPa凝固Ti-48Al合金热处理空冷的EBSD像和A点魏氏组织与片层组织的取向差

Fig. 5 EBSD image (a) of Ti-48Al alloy solidified under 4GPa after heat treatment and misorientation (b) between Widmanstatten lath and lamellar in zone A

综上所述,对于常压凝固的试样,在热处理时只有在α单相区保温并以较大的冷速冷却时才会出现魏氏组织,而经过高压凝固后,在1100 ℃热处理后空冷炉冷时,组织中均出现较多的魏氏组织。这主要是由于高压凝固所获得的凝固组织片层组织体积分数增加,结合作者之前的研究结果[18],高压使得Ti-48Al合金片层间距变细,因而片层组织中γ相和α2相的长径比均增加,片层组织一经热处理更易发生瑞利分解失稳,有利于α2相向α相转变,在之前的γ片层的(111)面上新形核的α相最终转变为魏氏组织,因而高压后的试样在热处理后,γ片层的(111)面上会较容易有新的α形核并长大,故在1100 ℃时,α相就能迅速增长,从而在随后的冷却过程中转化为大量的魏氏组织。

3 结论

1) Ti-48Al合金经高压凝固后,随着凝固压力的增加,枝晶间γ相体积分数减小,当压力达到4 GPa时,枝晶间只有极少量γ相存在,且有明显的三角晶界存在。

2) 高压凝固试样经1100 ℃、12 h热处理后分别在炉冷和空冷条件下均形成魏氏组织,并通过理论分析及实验验证了魏氏组织的形成机制,而常压凝固Ti-48Al合金试样,在该条件下热处理组织变化不大。

REFERENCES

[1] 胡汉起. 金属凝固原理[M].北京: 机械工业出版社, 2000: 46.

HU Han-qi. Solidification theory of metal[M]. Beijing: China Mechine Press, 2000: 46.

[2] WANG Yan, LIU Yong, YANG Guang-yu, LI Hui-zhong, TANG Bei. Microstructure of cast γ-TiAl based alloy solidified from β phase region[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(1): 215-222.

[3] 张红伟, NAKAJIMA Keiji, 王恩刚, 赫冀成. Al-Si 合金宏观偏析、凝固组织演变的元胞自动机-控制容积法耦合模拟[J]. 中国有色金属学报, 2012, 22: 1883-1896.

ZHANG Hong-wei, NAKAJIMA Keiji, WANG En-gang, HE Ji-cheng. Simulation of macrosegregation and solidification microstructure evolution for Al-Si alloy by coupled cellular automaton-finite volume model[J]. The Chinese Journal of Nonferrous Metals, 2012, 22: 1883-1896.

[4] 彭 鹏, 李新中, 苏彦庆, 刘冬梅, 郭景杰, 傅恒志. 定向凝固Sn-36%Ni包晶合金凝固组织特征长度的表征[J]. 中国有色金属学报, 2013, 23(10): 2446-2453.

PENG Peng, LI Xin-zhong, SU Yan-qin, LIU Dong-mei, GUO Jing-jie, FU Hen-zhi. Characterization of microstructural length scales in directionally solidified Sn-36%Ni peritectic alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(10): 2446-2453.

[5] 严青松, 王 芳, 芦 刚, 熊博文, 卢百平, 徐 帅. 凝固压力对真空差压铸造ZL114A合金中Si分布的影响[J]. 特种铸造及有色合金, 2013, 33: 989-992.

YAN Qing-song, WANG Fang, LU Gang, XIONG Bo-wen, LU Bai-ping, XU Shuai. Effect of solidification pressure on Si distribution in vacuum counter-pressure casting ZL114A Al alloy[J]. Special Casting & Nonferrous Alloys, 2013, 33: 989-992.

[6] 苏 磊. 超高压条件下室温离子液体结构和性质的研究进展[J]. 高压物理学报,2014, 23(1): 1-10.

SU Lei. Progress of investigations on the condensed structures and properties of room temperature ionic liquid under high pressure[J]. 2014, 23(1): 1-10.

[7] SCHILLING J S. The use of high pressure in basic and materials science[J]. Journal of Physics and Chemistry of Solids, 1998. 59(4): 553-568.

[8] 王宏伟, 朱冬冬, 邹鹑鸣, 魏尊杰. 快速凝固Ti-48Al合金的组织及纳米硬度[J]. 中国有色金属学报, 2011, 21(S1): s328-s332.

WANG Hong-wei, ZHU Dong-dong, ZOU Chun-min, WEI Zun-jie. Microstructure and nanohardness of Ti-48%Al alloy prepared by rapid solidification under different cooling rates[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(S1): s328-s332.

[9] YANG Jie-ren, CHEN Rui-run, DING Hong-shen. Heat transfer and macrostructure formation of Nb containing TiAl alloy directionally solidified by square cold crucible[J]. Intermetallics, 2013, 42: 184-191.

[10] QU H P, LI P, ZHANG S Q. The effects of heat treatment on the microstructure and mechanical property of laser melting deposition γ-TiAl intermetallic alloys[J]. Materials & Design, 2010, 31(4): 2201-2210.

[11] 张 敏, 张 莉, 宋学全, 张柯禹. 热处理对含Hf钛铝基合金显微组织的影响[J].金属热处理, 2012, 37: 49-52.

ZHANG Min, ZHANG Li, SONG Xue-quan, ZHANG Ke-yu. Effect of heat treatment on microstructure of Ti-Al based alloy containing hafnium[J]. Heat Treatment of Metals, 2012, 37: 49-52.

[12] 肖代红. 冷却速率对粗晶铸造TiAl 合金显微组织的影响[J]. 中国材料研究进展, 2008, 28(9): 666-668.

XIAO Dai-hong. Effects of cool ing rate on microstructure of TiAl alloy[J]. Special Casting & Nonferrous Alloys, 2008, 28(9): 666-668.

[13] 李臻熙, 曹春晓. TiAl基合金的α→γ相变研究进展稀有金属材料与工程[J]. 2000, 29(2): 73-77.

LI Zhen-xi, CAO Chun-xiao. Advances in the research of α→γ phase transformation in TiAl-based Alloy[J]. Rare Metal Materials and Engineering, 2000, 29(2): 73-77.

[14] SCHWAIGHOFER E, CLEMENS H, MAYER S. Microstructural design and mechanical properties of a cast and heat-treated intermetallic multi-phase γ-TiAl based alloy[J]. Intermetallics, 2014, 44(1): 128-140.

[15] MCCULLOUGH C, VALENCIA J J, LEVI C G. MEHRABIAN R. Phase equilibria and solidification in Ti-Al alloys[J]. Acta Metallurgica, 1988, 37: 1321-1336.

[16] HU D, HUANG A J, AND WU X. TEM characterisation of Widmanstatten microstructures in TiAl-based alloys[J]. Intermetallics, 2005, 13(2): 211-216.

[17] DEY S R, HAZOTTE A, NAKA S. Development of Widmanstatten laths in a near-[gamma] TiAl alloy[J]. Acta Materialia, 2005, 53(14): 3783-3794.

[18] WANG Hong-wei, ZHU Dong-dong, ZOU Chun-ming, WEI Zun-jie. Evolution of the microstructure and nanohardness of Ti-48at.%Al alloy solidified under high pressure[J]. Materials & Design, 2012, 34: 488-493.

(编辑 龙怀中)

基金项目:衢州学院校科研启动基金资助项目(BSYJ201407);浙江省教育厅科研项目(Y201431713)

收稿日期:2014-05-30;修订日期:2014-09-15

通信作者:董 多,讲师;电话:0570-8026634;E-mail:dongduohit@163.com