DOI:10.19476/j.ysxb.1004.0609.2017.11.09

成形角度对激光选区熔化成形CoCrMoW合金的影响

余伟泳,肖志瑜,程玉婉,陈莹莹,高超峰,张卫文

(华南理工大学 国家金属近净成形工程技术研究中心,广州 510640)

摘 要:以自主制备的气雾化CoCrMoW合金球形微细粉末为原料,采用激光选区熔化(SLM)工艺成形出与加工平面成不同角度的试样,并研究其显微组织与物理力学性能。结果表明:成形试样主要由FCC的γ相和HCP的ε相组成。随着成形倾斜角度的增大,试样的相对密度呈现先减小后增大的趋势,倾斜角为90°时,试样密度最高,相对密度达到99.2%;表面粗糙度呈现先增加后减小的趋势,在0°时达到最小值7.84 μm,在15°时达到最大值19.85 μm;抗拉强度、伸长率及显微硬度大致呈现先增大后减小的趋势,抗拉强度和显微硬度在60°时达到最大值,分别为1174MPa和412.5HV,伸长率在45°时达到最大值12.9%。

关键词:CoCrMoW合金;激光选区熔化;成形角度;力学性能

文章编号:1004-0609(2017)-11-2251-09 中图分类号:TF125.2 文献标志码:A

钴铬合金具有较好的力学性能、优良的耐腐蚀性和生物相容性等优点,广泛应用于牙科修复、人工髋关节修复及膝关节修复等领域[1]。激光选区熔化(Selective laser melting,SLM)是一种运用分层制造逐层堆积理念的快速成形技术,利用金属粉末直接制备出近全致密且性能优异的金属零件[2-4]。已有学者对该技术在骨科、整形外科、牙桥牙冠等方面的应用进行了研究[5]。

影响SLM成形的因素超过130个,其中工艺参数、材料特性等对成形性能有着较大的影响[6]。国内外学者的研究主要集中在扫描速度、激光功率、加工层厚和间距等工艺参数上[7-10]。也有部分学者研究了成形倾斜角度对零件性能的影响:VANDENBROUCKE等[11]和STRANO等[12]分别研究了倾斜角度对SLM成形纯钛和316L不锈钢表面粗糙度的影响,结果表明,随着倾斜角度的增加,试样表面粗糙度呈先增大后减小的规律;WEN等[13]和王黎[14]利用SLM技术成形316L不锈钢,研究了在水平方向(X-Y平面)和垂直方向(Z轴方向)上不同摆放角度成形试样的力学性能差异,研究结果发现:沿垂直方向摆放试样的伸长率明显高于沿水平方向摆放的试样,这些研究说明倾斜角度是SLM成形过程中重要的影响因素。目前,尚无学者研究倾斜角从0°变化到90°过程中,CoCrMoW合金的物理及力学性能的变化规律,而不同成形倾斜角可能会对CoCrMoW合金的成形质量及显微组织产生影响,进而影响到成形零件的物理力学性能,值得深入研究。因此,本文作者利用激光选区熔化设备DiMetal-100探讨CoCrMoW合金SLM成形过程中倾斜角的变化对成形质量和性能的影响,以期对临床医疗CoCrMoW合金的成形加工提供重要的技术指导,具有重要的意义。

1 实验

1.1 实验材料

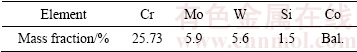

本实验采用气雾化制备的CoCrMoW合金粉末为原材料,其化学成分如表1所列,粉末形貌和粒度分布如图1所示。由图1可知,所使用的钴铬钼钨合金粉末球形度较高,粉末粒度较集中,平均粒径为28.7 μm。

表1 CoCr合金粉末化学成分

Table 1 Composition of CoCr alloy

图1 CoCrMoW合金粉末特性

Fig. 1 Property of CoCrMoW alloy powder

1.2 实验方法

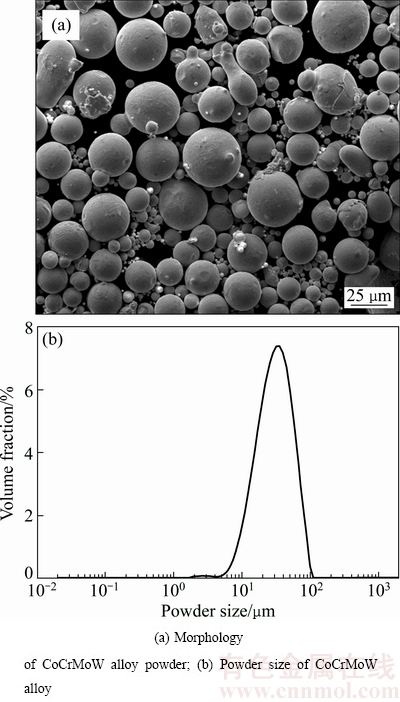

利用华南理工大学自主研发的Dimetal-100激光选区熔化设备进行成形。在三维建模软件中设计并绘制出需要加工的拉伸试样,导出STL格式文件后在Magics15.01中进行零件排布、添加支撑和切片处理。图2所示为试样尺寸及试样摆放角度示意图,7组试样的摆放方向分别与成形平面成0°、15°、30°、45°、60°、75°、90°。经正交试验优化后,选用的成形工艺参数为激光功率P=160 W,扫描速度v=400 mm/s,扫描间距h=0.08 mm,加工层厚t=0.025 mm,扫描策略为正交层错扫描方式。成形过程中采用316L不锈钢作为基板材料,氩气作为保护气体。

1.3 性能测试与分析

采用MASTERSIZER2000粒度分析仪对CoCrMoW合金粉末进行粒度分析。利用阿基米德排水法测量试样密度;利用TALYSURF CLI1000表面轮廓仪测量试样的表面粗糙度;利用XRD测试仪器D8 ADVANCE对SLM成形试样进行物相分析。将成形试样进行打磨抛光后,采用在盐酸中浸泡8 h[15]的方法进行腐蚀,用Leica金相显微镜观察其显微组织;采用DHV-1000Z型显微维氏硬度计测试试样的显微硬度。采用扫描电镜(NOVA NANOSEM 430)观察成形零件的表面形貌、显微组织及拉伸断口形貌。拉伸试验在CMT5105型100 kN万能试验机上进行。

图2 试样尺寸和摆放示意图

Fig. 2 Schematic diagram of specimen and specimen orientations in machine

2 结果及讨论

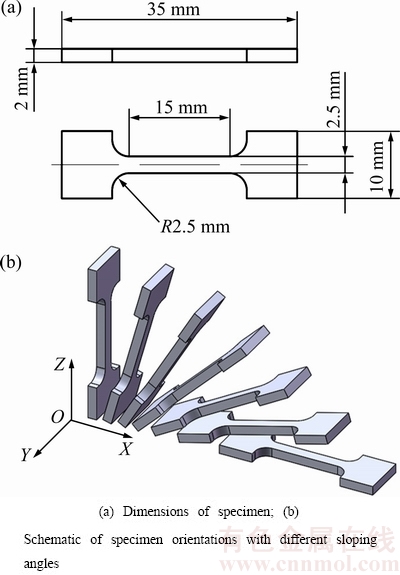

2.1 成形倾斜角对CoCrMoW合金相对密度的影响

成形角度对试样的相对密度的影响如图3所示,由图3可见:随着倾斜角的增大,成形试样相对密度呈现先减小后增大的趋势,其中,倾斜角为90°时试样密度最高,相对密度达到99.2%,倾斜角度为30°时密度最低,相对密度为98.4%。

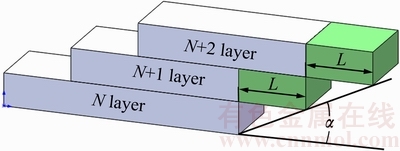

不同倾斜角成形试样密度存在差异主要受成形件相邻两层之间的悬垂长度L影响,其示意图如图4所示。成形过程中,倾斜角度在15°~75°之间的样品存在悬垂结构,长度为L的悬垂部分在成形时,激光直接作用在仅有少量片体支撑的粉末上,粉末熔化后会在毛细管力和重力的作用下沉陷到下方粉末中,造成试样密度降低。成形倾斜角度α越小,悬垂长度L越长,其落渣量越多,导致相对密度降低。但实验结果表明,15°试样的密度反而稍高于30°试样的,这可能是因为15°试样在加工时,由于其角度很低,需要添加的支撑数目比30°试样的多,较多的支撑减少了15°试样的落渣量,最终导致15°试样的密度反而稍高于30°试样的。

图3 倾斜角对试样相对密度的影响

Fig. 3 Effect of sloping angle on relative density of sample

图4 悬垂长度示意图

Fig. 4 Schematic diagram of overhang length

2.2 成形倾斜角对CoCrMoW合金表面粗糙度的影响

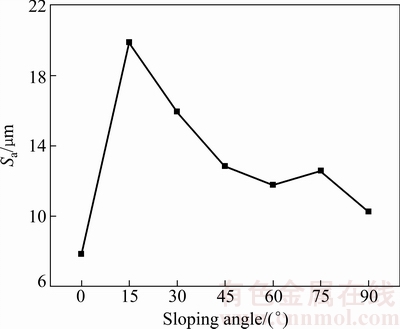

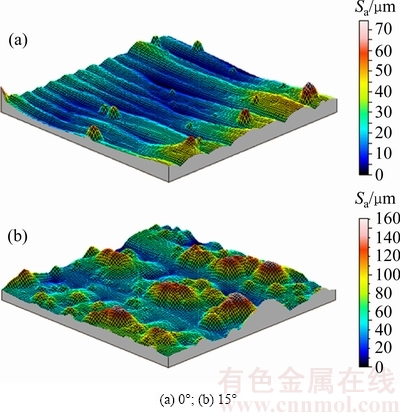

成形倾斜角对试样上表面粗糙度(表面轮廓算数平均偏差Sa)的影响如图5所示。随着倾斜角的增加,表面粗糙度大致呈现先增加后减小的趋势,在0°时为最小值7.84 μm,在15°时达到最大值19.85 μm,图6即为0°和15°的表面区域形貌示意图。

图5 倾斜角对试样表面粗糙度的影响

Fig. 5 Effect of sloping angle on Sa of sample surface

图6 试样表面区域形貌示意图

Fig. 6 Schematic diagrams of surface area morphologies of samples

图7 台阶现象及粉末粘附示意图

Fig. 7 Schematic diagram of stair phenomenon and powder adhesion

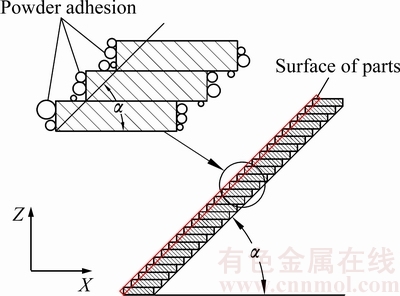

倾斜角在15°到90°间的试样表面质量较0°试样的差,主要是受成形过程中台阶现象以及表面颗粒粘附的影响。图7所示为台阶效应及粉末粘附的示意图,倾斜摆放的试样在成形过程中,相邻两层之间相对错开了一定距离,导致表面出现高低不平的现象。在层厚一定的前提下,倾斜角越小,相邻两层之间错开距离越大,台阶现象越明显,表面质量越差,这是15°~75°成形试样表面质量相对较差的主要原因。

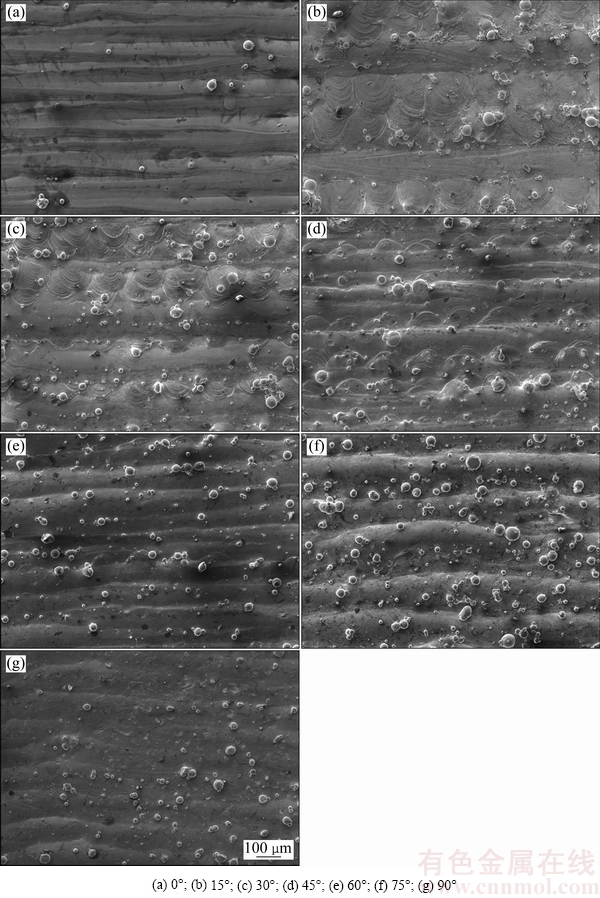

SLM试样表面质量还受到表面粘附颗粒的影响,图8所示为不同倾斜角CoCrMoW合金试样表面形貌SEM像,可以看到:成形零件表面熔道搭接较好,没有明显孔洞产生,同时,不同倾斜角度成形试样的表面都粘附有部分颗粒,且0°试样表面的粘附颗粒明显少于其他成形角度试样表面的。粘附颗粒主要分为粉末粘附及飞溅颗粒两种形式。粉末粘附是指在每一层成形图形的轮廓处,高温的熔池与周围非成形区域的粉末接触,熔池冷却凝固过程中粘连了部分粉末,形成粉末粘附,其示意图如图7所示,这种粘附现象在每一层的加工中都会发生,因此,15°~90°这6组成形试样的表面均粘附了较多颗粒。0°试样为水平摆放,其上表面在凝固过程中不与合金粉末接触,但也有少量颗粒粘附,这些颗粒为飞溅颗粒,其形成的原因是在SLM成形过程中,高能量的激光作用金属粉末上,使金属粉末和熔池产生粉末飞溅和液滴飞溅,这些飞溅有一部分会散落并最终粘连在成形试样表面。表面粘附颗粒较多是导致90°成形试样表面粗糙度大于0°试样的原因。

2.3 成形倾斜角对CoCrMoW合金相组成及显微组织的影响

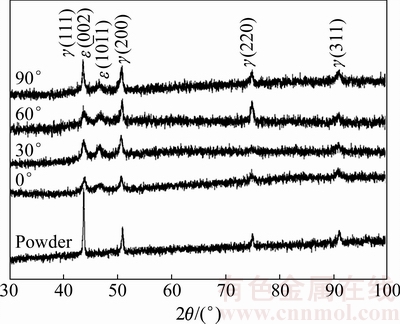

图9所示为CoCrMoW合金粉末和成形试样的XRD分析结果,可以看出,CoCrMoW合金粉末由FCC的γ相组成,而SLM成形的CoCrMoW合金由FCC结构的γ相和HCP结构的ε相组成。在SLM成形过程中,粉末在激光的作用下快速熔化形成熔池,激光移开后,熔池急速冷却形成γ相,同时抑制了凝固过程中ε相的形成。但SLM是一个逐层成形的过程,在每一层的成形过程中,激光以较高能量同时作用在粉末和实体上,使粉末熔化的同时也对粉末底部的实体进行加热和熔化,这个过程等同于对已成形区域中受加热而未重新熔化的区域进行了热处理,为ε相的形成提供了条件。从XRD分析结果还可以看出,不同角度所包含的两种相含量有所不同,但差距不明显。

图8 不同成形角度试样表面形貌的SEM像

Fig. 8 SEM images of surface morphologies of sample in various forming angles

图9 试样的XRD谱

Fig. 9 XRD pattern of samples

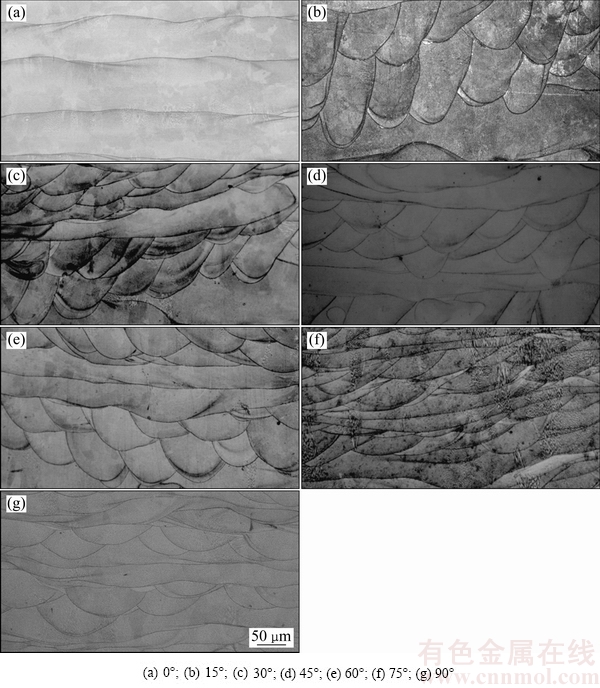

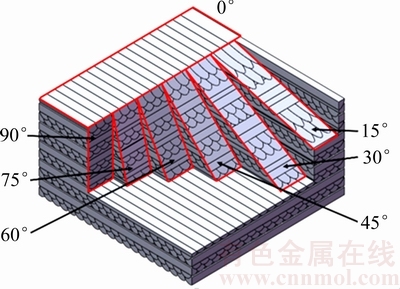

图10所示为光学显微镜下不同倾斜角度成形试样的上表面金相组织,可以看到:0°试样的熔道方向为水平方向,而15°到90°的试样出现两个方向上的熔道,且随着倾斜角度增加,熔道深度大致上呈递减趋势,熔接线数量呈增加趋势,这是由成形样品的摆放倾斜角不同引起的。不同角度的熔道边界大致可以看成将三维堆积的熔道剖切后露出的熔道之间的熔接线,其示意图如图11所示,可以看出,其熔道深度及熔接线数量随角度变化的变化规律与得到的金相组织一致。

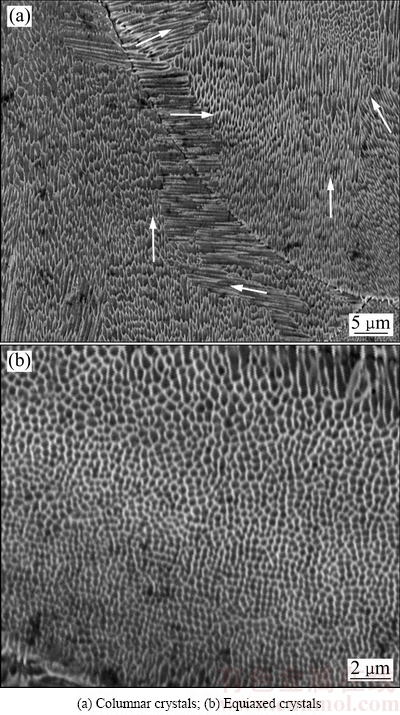

图12所示为成形零件在扫描电镜下的柱状晶和等轴晶两种不同组织,不同成形角度试样中都含有这两种组织。由图12(b)可以看出,其等轴晶组织晶粒细小均匀,晶粒尺寸在1 μm以下。在SLM成形过程中,高能量的激光束作用在粉末上并快速离开,使粉末在短时间内熔化并快速冷却,因而形成的晶粒细小。从图12(a)中还可以看出,晶体沿多个方向生长(图中箭头为晶粒生长方向),这是由于SLM成形过程中,激光的扫描路径受计算机系统控制形成移动的热源,同时激光扫描时也会使已成形的实体发生重熔,使传热过程产生复杂的变化,从而使晶体沿着多个方向散热,最终导致试样内部出现非平衡的微观结构。

图10 不同成形角度试样的显微组织

Fig. 10 Micrographs of specimens with various forming angles

图11 不同成形角度熔接线示意图

Fig. 11 Schematic diagram of molten pool boundaries in various forming angles

图12 CoCrMoW合金显微组织的SEM像

Fig. 12 SEM images of microstructures of CoCrMoW alloy

2.4 成形角度对CoCrMoW合金力学性能的影响

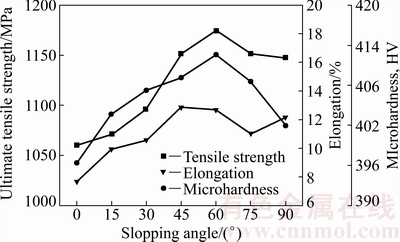

不同倾斜角对抗拉强度、显微硬度及伸长率的影响如图13所示。随倾斜角度增大,试样的抗拉强度及显微硬度大致呈现先增大后减小的趋势,并在60°时出现一个峰值,此时的抗拉强度达到1174 MPa,显微硬度达到412.5HV。试样的伸长率在45°时达到最高值12.9%。

图13 倾斜角对抗拉强度及显微维氏硬度的影响

Fig. 13 Effects of sloping angle on ultimate tensile strength, elongation and microhardness

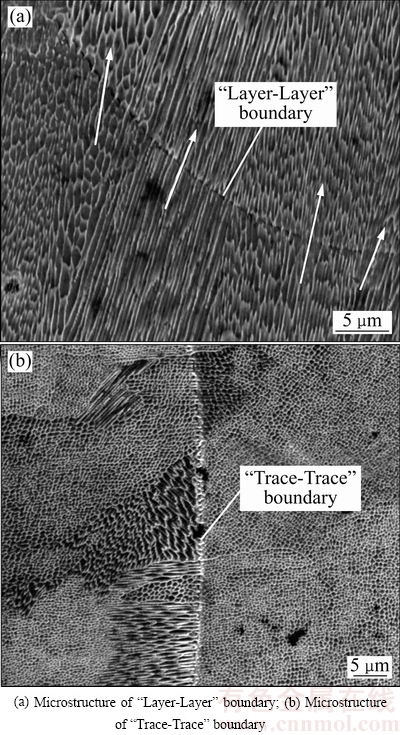

不同倾斜角度的试样力学性能出现不同,可能是由内部缺陷不同造成的。在SLM成形过程中,试样内部主要的缺陷为熔道搭接缺陷、残余应力以及微观孔洞。由不同成形角度的光学显微组织(见图10)可知:7组成形试样的熔道搭接情况不同,这可能是造成其力学性能不同的原因。SLM成形工艺中,熔道搭接主要包含两种形式,即沿X轴或Y轴方向上相邻熔道的搭接(即“道-道”搭接)和沿Z轴方向上的搭接(即“层-层”搭接)。“道-道”搭接与“层-层”搭接的搭接效果可以通过熔道附近的晶粒生长情况来判断,图14所示为“层-层”搭接与“道-道”搭接处的显微组织,可以看出,“层-层”搭接的熔道边界两边的晶粒取向基本一致(图中箭头方向为晶粒取向),熔道搭接效果较好,而“道-道”搭接的熔道边界两边的晶粒取向不一致,其搭接效果不如“层-层”搭接好。

图14 熔道搭接处的显微组织

Fig. 14 Microstructures of molten pool boundaries

“层-层”搭接与“道-道”搭接在熔池附近出现这种晶粒取向不同的现象,是由SLM特殊的成形工艺造成的。本实验中平行于X轴或Y轴方向上,同一层内熔道之间的搭接距离(即“道-道”搭接距离)为80 μm,而平行于Z轴的熔道搭接距离(即“层-层”搭接距离)为25 μm;在一定范围内,搭接距离越小,熔道之间的结合越好,因此层与层之间搭接比同一层内熔道间的搭接效果更好。同时,激光在加工完一层之后,需要经过铺粉才进行下一层的加工,已加工层有足够的时间冷却,在加工下一层时,“层-层”之间的温度差大于“道-道”之间的温度差,而晶粒沿着散热最快的方向生长,所以晶粒生长方向大都为垂直方向,使得“层-层”搭接的熔道边界两边的晶粒取向基本一致。熔道两侧晶粒取向一致,在拉伸时试样受力更均匀,拉伸性能更好。

在不同成形角度试样中,0°试样沿着拉伸方向的熔道搭接方式为“道-道”搭接,而90°试样则为“层-层”搭接,15°~75°试样的熔道搭接方式为两种搭接相结合,且角度越大,“层-层”搭接所占的比例越高,因此,倾斜角度越大,拉伸方向上的熔道搭接效果越好,试样的拉伸性能越好。但实验结果表明,75°和90°成形试样的性能反而下降,这可能是由试样内部的残余应力造成的。有研究发现:随着加工层数的增加,零件内部的残余应力也相应增加[16],本实验中,75°和90°试样的成形高度较高,加工层数较多,最终试样内部的残余应力也相应增加,这可能是75°和90°试样的拉伸性能有所下降的原因。60°试样的高度比75°和90°试样的低,且以“层-层”搭接为主,熔道搭接的效果和残余应力之间存在最优的组合状态,导致其抗拉强度最高。

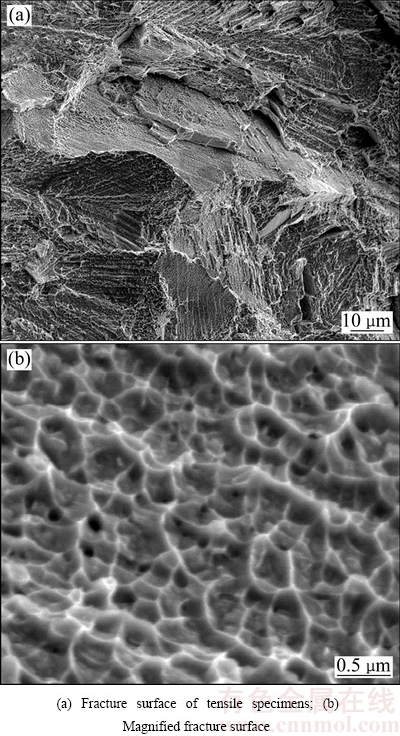

不同成形倾斜角的拉伸断口形貌基本一致,图15所示为试样的拉伸断口形貌,从图15(a)可以看出,其断面具有明显的解理小平面和撕裂棱,具有凹凸不平的层错台阶,解理面的放大图可以观察到断口含有大量细小韧窝,如图15(b)所示,表明材料具有一定的韧性,材料的断裂特性属于准解理断裂。

图15 拉伸试样拉伸断口的微观形貌

Fig. 15 Microphologies of fracture surfaces of tensile specimens

3 结论

1) 随着成形角度的增大,试样的相对密度呈现先减小后增大的趋势,倾斜角为90°时试样密度最高,相对密度达到99.2%;表面粗糙度呈先增加后减小的趋势,在0°时为最小值7.84 μm,在15°时达到最大值19.85 μm。

2) 经激光选区熔化成形的钴铬钼钨合金试样晶粒细小,其等轴晶的晶粒尺寸在1 μm以下;试样主要由FCC的γ相和HCP的ε相组成。

3) 随着成形角度的增大,试样的抗拉强度及显微硬度大致呈现先增大后减小的趋势,并在60°时达到最大值,抗拉强度和硬度分别达到1174 MPa和412.5HV,在45°时伸长率达到最大值12.9%,拉伸断口呈准解理断裂。

REFERENCES

[1] MUDDUGANGADHAR B C, AMARNATH G S, TRIPATHI S, DIKSHIT S, DIVYA M S. Biomaterials for dental implants: An overview[J]. International Journal of Oral Implantology & Clinical Research, 2011, 2(1): 13-24.

[2] MUMTAZ K A, ERASENTHIRAN P, HOPKINSON N. High density selective laser melting of Waspaloy [J]. Journal of Materials Processing Technology, 2008, 195(1/3): 77-87.

[J]. Journal of Materials Processing Technology, 2008, 195(1/3): 77-87.

[3] 苏海军, 尉凯晨, 郭 伟, 马菱薇, 于瑞龙, 张 冰, 张 军, 刘 林, 傅恒志. 激光快速成形技术新进展及其在高性能材料加工中的应用[J]. 中国有色金属学报, 2013, 23(6): 1567-1574.

SU Hai-jun, WEI Kai-chen, GUO Wei, MA Ling-wei, YU Rui-long, ZHANG Bing, ZHANG Jun, LIU Lin, FU Heng-zhi. New development of laser rapid forming and its application in high performance materials processing[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1567-1574.

[4] 程灵钰, 张 升, 魏青松, 史玉升. 激光选区熔化成形不锈钢与纳米羟基磷灰石复合材料的组织及力学性能[J]. 中国有色金属学报, 2014, 24(6): 1510-1517.

CHENG Ling-yu, ZHANG Sheng, WEI Qing-song, SHI Yu-sheng. Microstructure and mechanical properties of stainless steel and nano hydroxyapatite composites fabricated by selective laser melting[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(6): 1510-1517.

[5] NOORT R V. The future of dental devices is digital[J]. Dental Materials, 2012, 28(1): 3-12.

[6] MONROY K P, DELGADO J, SERENO L, CIURANA J, HENDRICHS N J. Effects of the Selective laser melting manufacturing process on the properties of CoCrMo single tracks[J]. Metals and Materials International, 2014, 20(5): 873-884.

[7] 王 黎, 魏青松, 贺文婷, 史玉升. 粉末特性与工艺参数对SLM成形的影响[J]. 华中科技大学学报(自然科学版), 2012, 40(6): 20-23.

WANG Li, WEI Qing-song, HE Wen-ting, SHI Yu-sheng. Influence of powder characteristic and process parameters on SLM formability[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2012, 40(6): 20-23.

[8] TAKAICHI A, SUYALATU, NAKAMOTO T, JOKO N, NOMURA N, TSUTSUMI Y, MIGITA S, DOI H, KUROSU S, CHIBA A. Microstructures and mechanical properties of Co-29Cr-6Mo alloy fabricated by selective laser melting process for dental applications[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2013, 21(3): 67-76.

[9] LI R D, SHI Y S, WANG Z G, WANG L, LIU J H, JIANG W. Densification behavior of gas and water atomized 316L stainless steel powder during selective laser melting[J]. Applied Surface Science, 2010, 256(13): 4350-4356.

[10] 王赟达, 杨永强, 宋长辉, 刘凤美, 麦淑珍. 基于响应面法优化激光选区熔化成型CoCrMo合金工艺及其电化学行为[J]. 中国有色金属学报, 2014, 24(10): 2497-2505.

WANG Yun-da, YANG Yong-qiang, SONG Chang-hui, LIU Feng-mei, MAI Shu-zhen. Process optimization and electrochemical behavior of CoCrMo alloy fabricated by selective laser melting based on response surface method[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(10): 2497-2505.

[11] VANDENBROUCKE B, KRUTH J P. Selective laser melting of biocompatible metals for rapid manufacturing of medical parts[J]. Rapid Prototyping Journal, 2006, 13(4): 196-203.

[12] STRANO G, HAO L, EVERSON R M, EVANS K E. Surface roughness analysis, modelling and prediction in selective laser melting[J]. Journal of Materials Processing Technology, 2013, 213(4): 589-597.

[13] WEN S F, LI S, WEI Q S, YAN C Z, ZHANG S, SHI Y S. Effect of molten pool boundaries on the mechanical properties of selective laser melting parts[J]. Journal of Materials Processing Technology, 2014, 214(11): 2660-2667.

[14] 王 黎. 选择性激光熔化成形金属零件性能研究[D]. 武汉: 华中科技大学, 2012.

WANG Li. Research on the performance in selective laser melting of metallic part[D]. Wuhan: Huazhong University of Science and Technology, 2012.

[15] HEDBERG Y S, QIAN B, SHEN Z, VIRTANEN S, WALLINDER I O. In vitro biocompatibility of CoCrMo dental alloys fabricated by selective laser melting[J]. Dental Materials, 2014, 30(5): 525-534.

[16] MERCELIS P, KRUTH J P. Residual stresses in selective laser sintering and selective laser melting[J]. Rapid Prototyping Journal, 2006, 12(5): 254-265.

Effect of sloping angle on forming of CoCrMoW alloy by selective laser melting

YU Wei-yong, XIAO Zhi-yu, CHENG Yu-wan, CHEN Ying-ying, GAO Chao-feng, ZHANG Wei-wen

(National Engineering Research Center of Near-Net-Shape Forming for Metallic Material, South China University of Technology, Guangzhou 510640, China)

Abstract: CoCrMoW alloy was formed by selective laser melting with different sloping angles using self-prepared spherical fine powder, its microstructure and mechanical properties were studied. The results indicate that microstructures of SLM samples are composed of γ phase in FCC structure and ε phase in HCP structure. With the increase of sloping angle, the alloy density decreases firstly and then increases gradually, and reaches at a maximum of 99.2% when the sloping angle is 90°. On the contrary, the surface roughness of the specimens increases initially and then decreases. A minimum roughness of 7.84 μm and a maximum roughness of 19.85 μm appear at 0° and 15°. Meanwhile, the ultimate tensile strength, elongation and microhardness arise initially, then drop afterward. The ultimate tensile strength and microhardness reach at a maximum of 1174 MPa and 412.5 HV, respectively, when the sloping angle is 60°. The elongation reaches at a maximum of 12.9% at an angle of 45°.

Key words: CoCrMoW alloy; selective laser melting; sloping angle; mechanical property

Foundation item: Project(51627805) supported by the National Natural Science Foundation for Scientific Instrument Development Project, China; Project(2015A030312003) supported by the Guangdong Natural Science Foundation for Research Team, China; Projects(2014B010129003, 2016B030302006) supported by Science and Technology Program of Guangdong Province, China; Project(201604016049) supported by Science and Technology Research Program of Guangzhou, China

Received date: 2016-10-12; Accepted date: 2017-04-26

Corresponding author: XIAO Zhi-yu; Tel: +86-13922266121; E-mail: zhyxiao@scut.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金重大仪器专项(51627805);广东省自然科学基金团队项目(2015A030312003);广东省科技攻关项目(2014B010129003,2016B030302006);广州市科技计划项目(201604016049)

收稿日期:2016-10-12;修订日期:2017-04-26

通信作者:肖志瑜,教授,博士;电话:13922266121;E-mail:zhyxiao@scut.edu.cn